Comprehensive Guide to Flywheel Parts Diagram

The intricate world of rotational dynamics encompasses various components working in harmony to ensure smooth operation. A comprehensive grasp of these elements is essential for anyone involved in mechanical engineering or automotive design. Each piece plays a critical role in maintaining stability and efficiency, contributing to the overall performance of the system.

In this section, we will explore the different elements that contribute to the functionality of rotational systems. By breaking down the assembly into its fundamental components, we can uncover how they interact and influence each other. This examination provides valuable insights for both enthusiasts and professionals seeking to enhance their understanding of mechanical systems.

Through this exploration, you will gain a clearer perspective on the mechanics at play. Recognizing the relationships between each segment will empower you to appreciate their significance in maintaining balance and energy transfer. Join us as we delve into this fascinating topic, uncovering the ultimate mechanics behind these vital assemblies.

Understanding Flywheel Components

This section explores the essential elements that contribute to the functionality of a rotational energy storage device. By examining each component, we can gain insights into how they work together to enhance performance and efficiency in various mechanical systems.

Key Elements of the Mechanism

Every mechanism consists of distinct components that play a crucial role in its operation. These elements are designed to optimize energy transfer and reduce losses, ensuring smooth and reliable performance. Understanding these components can help in diagnosing issues and improving overall system effectiveness.

Component Overview

| Component Name | Function |

|---|---|

| Mass Element | Stores kinetic energy and stabilizes rotational motion. |

| Mounting Hub | Secures the mass element to the shaft, enabling rotation. |

| Peripheral Weights | Adjusts inertia and impacts the system’s responsiveness. |

| Coupling Mechanism | Facilitates connection with other components for energy transfer. |

| Damping Material | Reduces vibrations and enhances stability during operation. |

By understanding these crucial components, one can appreciate the complexities involved in energy storage systems and their role in enhancing mechanical efficiency.

Basic Functions of a Flywheel

These rotating components play a crucial role in storing and stabilizing energy within various mechanical systems. By maintaining momentum, they ensure smooth operation and reduce fluctuations in performance, contributing to overall efficiency.

Energy Storage

One of the primary functions is to capture kinetic energy generated during operation. This stored energy can be released when needed, allowing for more consistent power delivery and minimizing energy loss.

Stability and Balance

Additionally, these devices help in balancing forces within machinery. By counteracting vibrations and irregularities, they enhance the longevity and reliability of the entire system.

Types of Flywheels in Engineering

In the realm of mechanical systems, various rotating devices play a critical role in energy storage and stability. These components are designed to optimize performance by balancing forces and maintaining rotational speed, each serving distinct purposes in different applications.

Mechanical Variants

Among the numerous designs, mechanical versions are widely utilized in automotive and industrial settings. They effectively smooth out fluctuations in energy delivery, enhancing efficiency. Their construction often involves materials that provide durability while minimizing weight, ensuring optimal functionality.

Electrical Variants

On the other hand, electrical variants are integral in energy management systems. These are typically employed in applications like renewable energy storage, where they convert kinetic energy into electrical energy. This conversion allows for improved energy distribution and reliability in power systems.

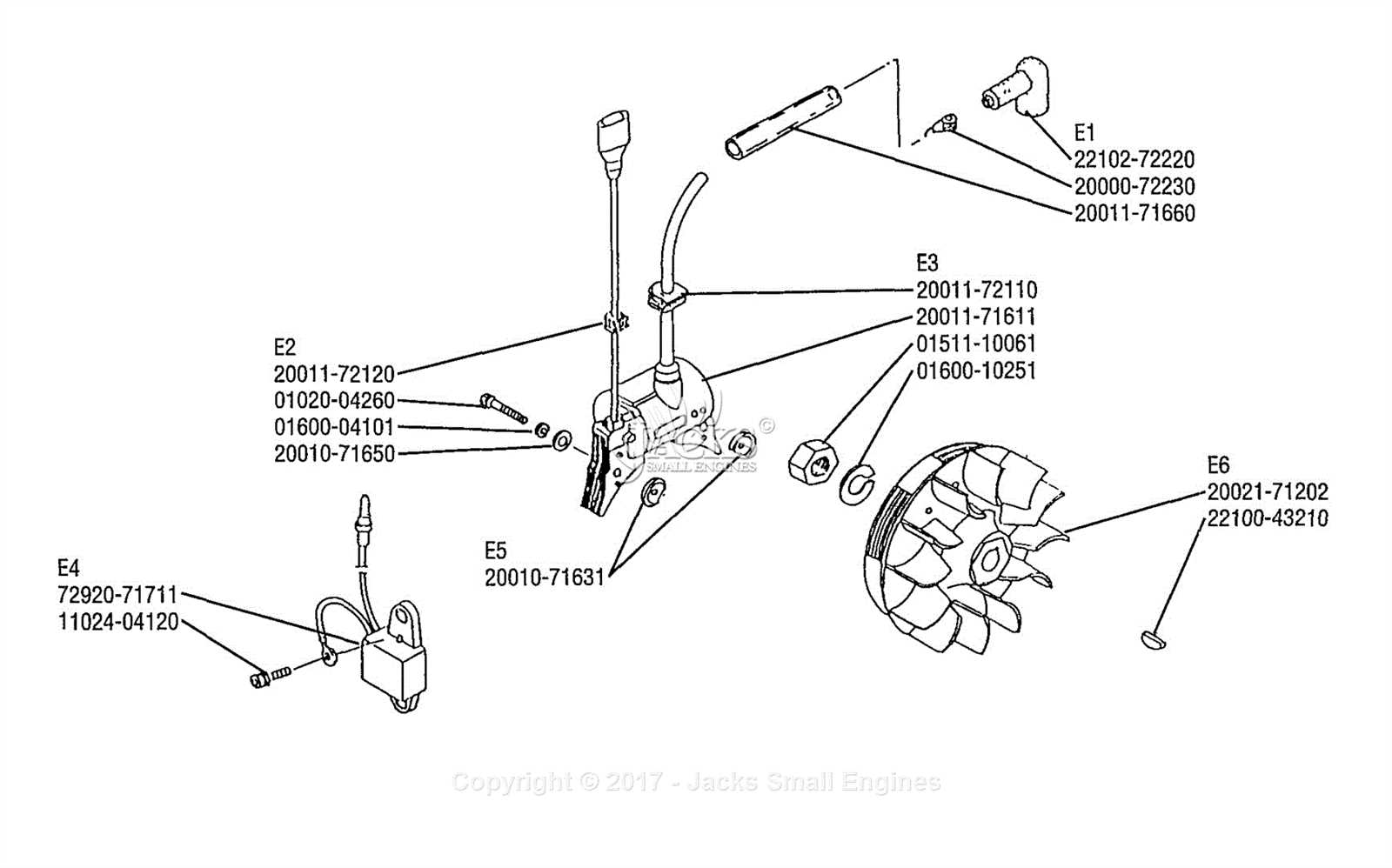

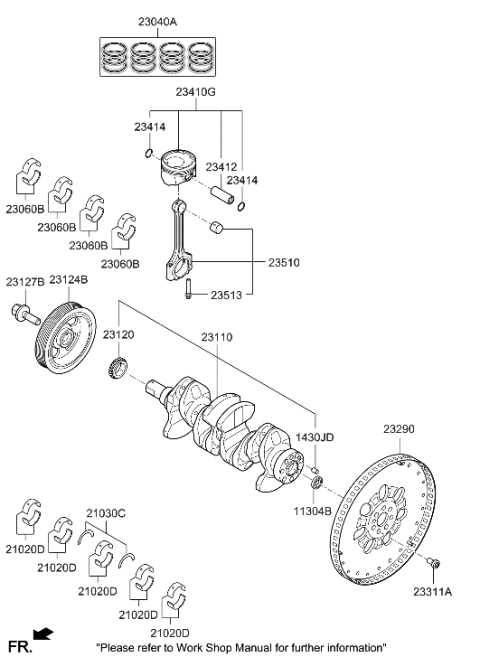

Diagrammatic Representation of Flywheel Parts

This section explores the visual depiction of a rotating mass assembly, focusing on the essential components that contribute to its functionality. Understanding these elements enhances comprehension of the system’s efficiency and mechanical advantages.

Key Elements

Each component plays a crucial role in energy storage and transfer. The primary structure typically features a circular design, enabling smooth motion while mitigating vibrations. Various attachments facilitate interaction with other mechanical systems, ensuring optimal performance.

Visual Insights

Illustrative representations provide a clearer understanding of spatial relationships and operational dynamics. Through these visuals, one can delve into the intricacies of the assembly, ultimately enhancing the knowledge of its engineering principles.

Materials Used in Flywheel Construction

The choice of materials for rotational energy storage devices is crucial for their performance and longevity. Various substances contribute to the efficiency, weight, and durability of these systems, impacting overall functionality.

| Material | Properties | Applications |

|---|---|---|

| Steel | High strength, ductility, cost-effective | Industrial applications, heavy machinery |

| Aluminum | Lightweight, good strength-to-weight ratio | Automotive, aerospace |

| Composite materials | High tensile strength, lightweight, corrosion-resistant | High-performance systems, racing |

| Cast iron | Durability, excellent vibration damping | Heavy-duty applications |

Selecting the appropriate material is essential for achieving optimal efficiency and performance in energy storage systems, allowing for effective energy management in various industries.

Applications of Flywheels in Machinery

Energy storage and stabilization are crucial in various mechanical systems. Devices designed for this purpose enhance performance by managing energy fluctuations, thereby improving efficiency and reliability in multiple applications.

Industrial Uses

- Power generation systems to smooth out output.

- Manufacturing equipment to maintain consistent operational speeds.

- Heavy machinery for load leveling during operations.

Automotive Applications

- Regenerative braking systems to recover energy.

- Engine performance enhancement by balancing power delivery.

- Hybrid vehicles for efficient energy management.

Maintenance Tips for Flywheel Systems

Regular upkeep is essential for ensuring optimal performance and longevity of rotational energy storage mechanisms. Implementing effective maintenance practices can prevent failures and enhance efficiency.

- Conduct routine inspections to check for wear and tear.

- Ensure proper alignment of all components to avoid undue stress.

- Regularly lubricate moving parts to minimize friction and heat generation.

Additionally, maintaining a clean environment around the system is crucial:

- Remove dust and debris that can interfere with functionality.

- Inspect seals and gaskets for any signs of leakage.

- Monitor operating temperatures to detect potential overheating issues.

Documenting maintenance activities helps in identifying patterns and potential problems:

- Keep a log of inspections and repairs.

- Note any unusual sounds or vibrations during operation.

- Review maintenance records regularly to adjust practices as needed.

By following these tips, operators can ensure the ultimate efficiency and reliability of their energy storage systems.

Flywheel Design Considerations and Challenges

The creation of energy storage components involves a series of critical decisions that can significantly impact performance and efficiency. Designers must balance various factors, including material selection, weight distribution, and rotational speed, to achieve optimal functionality.

| Consideration | Challenge |

|---|---|

| Material Selection | Finding a lightweight yet durable option that can withstand high rotational forces. |

| Weight Distribution | Ensuring even distribution to prevent vibrations that can lead to system failure. |

| Rotational Speed | Achieving high speeds while maintaining structural integrity and safety. |

| Energy Density | Maximizing energy storage without compromising size and weight. |

| Cost Efficiency | Balancing performance enhancements with budget constraints. |

These factors are interconnected and require a thorough analysis to navigate potential complications and ensure the ultimate effectiveness of the energy storage mechanism.

Impact of Flywheel Weight on Performance

The mass of a rotational energy storage component significantly influences overall system efficiency and responsiveness. Heavier units tend to store more energy, which can be beneficial in maintaining consistent power output. However, the trade-off often lies in the inertia they create, affecting acceleration and deceleration rates.

Benefits of Increased Mass

A greater weight in these components allows for improved energy retention during operation. This can lead to smoother power delivery and enhanced stability during varying loads. Additionally, a heavier unit can help in damping vibrations, resulting in reduced wear on associated mechanisms.

Drawbacks of Increased Mass

On the flip side, increased mass can impede quick response times. The additional inertia requires more force to initiate movement, which can slow down acceleration. This aspect may be particularly detrimental in applications requiring rapid changes in speed or direction.

| Weight Category | Performance Effect | Applications |

|---|---|---|

| Lightweight | Faster acceleration, lower energy storage | Racing, agility-focused machinery |

| Medium | Balanced performance, moderate energy retention | General automotive, industrial equipment |

| Heavy | Improved energy storage, slower response | Heavy machinery, power generation |

Flywheel Energy Storage Mechanisms

This section explores the innovative systems designed to store kinetic energy efficiently, harnessing rotational motion to provide power on demand. These mechanisms utilize the principles of inertia and angular momentum, enabling energy to be captured and released effectively.

Principles of Operation

The core principle involves converting electrical energy into kinetic energy, which is then maintained through continuous rotation. When energy is required, this stored kinetic energy can be transformed back into electrical energy, offering a rapid response to fluctuations in power demand.

Advantages and Applications

Benefits of these energy storage systems include high efficiency, longevity, and minimal environmental impact. They are particularly useful in applications such as grid stabilization, renewable energy integration, and electric vehicles, showcasing their versatility in modern energy solutions.

Comparing Flywheels with Other Energy Systems

The effectiveness of energy storage solutions can vary significantly based on their design and application. This section explores the comparative advantages and disadvantages of rotational energy storage mechanisms against alternative systems. By understanding these differences, one can better appreciate the contexts in which each system excels.

Advantages of Rotational Energy Systems

- High Efficiency: These mechanisms often exhibit superior energy conversion rates, minimizing losses during charging and discharging.

- Longevity: With fewer moving parts subject to wear, these systems typically have longer operational lifespans compared to chemical alternatives.

- Rapid Response: They can quickly deliver energy, making them suitable for applications requiring immediate power.

Limitations Compared to Other Technologies

- Energy Density: They generally store less energy per unit mass than chemical batteries, which can limit their use in certain applications.

- Physical Size: Their design can necessitate larger physical footprints, posing challenges for integration in space-constrained environments.

- Cost: Initial investment can be higher, affecting the overall economics of energy storage solutions.

In conclusion, while rotational energy storage systems offer unique benefits, they also come with specific challenges. Understanding these dynamics helps in selecting the most appropriate energy storage solution for a given application.

Future Trends in Flywheel Technology

The evolution of rotational energy storage systems is set to transform various industries. As demand for efficient and sustainable energy solutions grows, innovations are emerging that promise enhanced performance and reliability. These advancements aim to optimize energy density and reduce costs, making them more accessible for widespread use.

One significant trend is the integration of advanced materials, which can increase efficiency and lifespan. Lightweight composites and high-strength alloys are being developed to minimize energy loss during operation. Additionally, the incorporation of smart technologies allows for real-time monitoring and adaptive control, enhancing system responsiveness and reliability.

Another area of focus is the synergy with renewable energy sources. As societies shift towards greener options, the combination of these systems with solar and wind technologies can lead to a more stable energy supply. This hybrid approach offers the ultimate solution for energy storage, allowing for smoother integration into existing infrastructures.

Lastly, the growing interest in electrification of transportation is driving innovations in these systems for automotive and aerospace applications. This shift is expected to lead to breakthroughs in weight reduction and energy recovery, positioning them as critical components in the future of sustainable mobility.