Comprehensive Guide to Volvo Penta DP Outdrive Parts Diagram

The functionality of marine propulsion systems is crucial for optimal performance on the water. These complex mechanisms convert engine power into thrust, allowing vessels to navigate with precision and efficiency. A thorough understanding of their components can greatly enhance maintenance and repair efforts.

By exploring the intricate layout of these assemblies, enthusiasts and technicians alike can gain insights into their operational dynamics. Knowledge of individual elements not only aids in troubleshooting but also empowers users to make informed decisions during upgrades or replacements.

In this article, we will delve into the essential components of these drive systems, providing a clear visual representation that serves as an ultimate guide for both novice and experienced boaters. Understanding the relationships between different elements is key to achieving optimal vessel performance and longevity.

Understanding Volvo Penta DP Outdrive

This section delves into the intricacies of a crucial marine propulsion system, highlighting its components and functionality. A thorough comprehension of this mechanism is essential for anyone involved in boating or maritime activities, as it plays a significant role in performance and maneuverability on the water.

Key Components

The system consists of several integral elements, each contributing to its overall effectiveness. The drive unit, for instance, houses the gearing necessary for transforming engine power into thrust. Additionally, the propeller serves as the final component that converts rotational energy into forward motion, making it vital for navigation.

Maintenance and Troubleshooting

Overview of Outdrive Components

This section explores the essential elements of marine propulsion systems, focusing on their functionality and interaction. Understanding these components is crucial for effective maintenance and performance optimization of vessels.

| Component | Description |

|---|---|

| Gear Housing | Encloses the gear mechanism and provides protection against water ingress. |

| Propeller | Converts rotational energy into thrust, propelling the vessel through water. |

| Trim Tab | Helps to stabilize the boat and improve handling by adjusting the angle of the drive. |

| Shift Mechanism | Facilitates the engagement of forward, neutral, and reverse gears. |

| Oil Seal | Prevents lubricant leaks and protects internal components from contaminants. |

Importance of Proper Maintenance

Regular upkeep of marine propulsion systems is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to serious issues that not only affect the efficiency of the vessel but also pose safety risks. Proper care helps in identifying potential problems early, thereby reducing the risk of costly repairs.

Benefits of Routine Care

- Enhanced Performance: Regular checks and servicing keep systems running smoothly and efficiently.

- Increased Lifespan: Timely maintenance can extend the operational life of critical components.

- Safety Assurance: Well-maintained systems contribute to safer navigation and reduce the risk of accidents.

- Cost Efficiency: Preventative care minimizes the likelihood of unexpected breakdowns, saving money in the long run.

Key Maintenance Practices

- Regularly inspect and clean all mechanical components.

- Monitor fluid levels and replace filters as needed.

- Check for signs of wear and tear on moving parts.

- Ensure that electrical systems are functioning properly.

By adhering to a consistent maintenance schedule, vessel owners can ensure their equipment remains in peak condition, ultimately leading to a more enjoyable and reliable boating experience.

Common Issues with Outdrives

Understanding the frequent challenges faced by marine propulsion systems is crucial for maintaining optimal performance. Various factors can lead to inefficiencies and failures, often requiring timely intervention to avoid costly repairs.

Frequent Problems

- Seal Leaks: Deteriorating seals can result in fluid loss, affecting performance.

- Corrosion: Exposure to saltwater can lead to rust and deterioration of metal components.

- Gear Misalignment: Improper alignment can cause unusual noises and premature wear.

- Overheating: Insufficient cooling can lead to overheating, damaging internal parts.

Maintenance Tips

- Regular Inspections: Check seals, fluids, and components regularly.

- Corrosion Protection: Apply anti-corrosive coatings to vulnerable areas.

- Proper Alignment: Ensure alignment is accurate during installation and maintenance.

- Cooling System Checks: Regularly inspect the cooling system for efficiency.

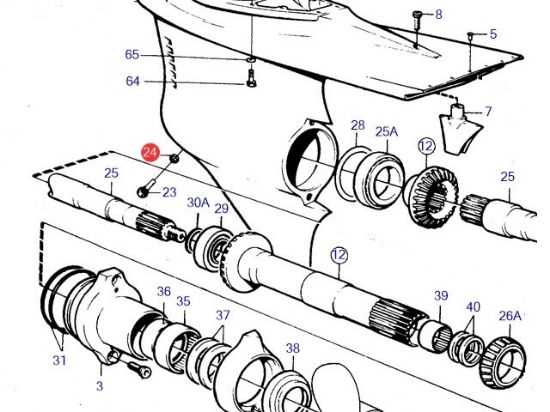

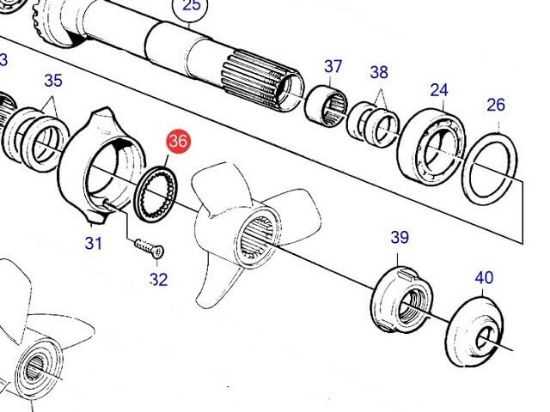

How to Identify Parts on Diagram

Understanding a technical illustration can significantly enhance your ability to troubleshoot and maintain your equipment. Recognizing the various components and their functions is essential for effective repairs and modifications. This section will guide you through the process of identifying the elements presented in a schematic representation.

Start by familiarizing yourself with the overall layout of the illustration. Each section usually represents a specific area of the assembly. Pay attention to the labels and numbers associated with each component, as they often correspond to a reference list or a key that provides additional information.

| Component | Description | Function |

|---|---|---|

| Housing | The outer shell that encases the internal components. | Protects and supports the internal mechanism. |

| Shaft | A cylindrical rod that transfers motion. | Transmits power from the engine to the propeller. |

| Seal | A device used to prevent leakage. | Maintains fluid integrity within the assembly. |

| Gear | A rotating part with teeth. | Facilitates speed and torque adjustments. |

| Mounting Bracket | A support that holds components in place. | Ensures stability and alignment of parts. |

By cross-referencing the labels on the illustration with the accompanying list, you can better understand the purpose of each part. Additionally, take note of any symbols or color codes used, as they may indicate specific functions or characteristics. With practice, interpreting these visual aids will become a more intuitive process, allowing for efficient diagnostics and repairs.

Tools Needed for Repairs

When it comes to maintaining and repairing marine propulsion systems, having the right tools is essential for ensuring efficiency and effectiveness. Proper equipment not only facilitates the repair process but also helps prevent potential damage during maintenance tasks.

Below is a list of essential tools that are commonly required:

- Socket Set: Various sizes to accommodate different fasteners.

- Wrenches: Both adjustable and fixed to handle a range of nuts and bolts.

- Screwdrivers: Flathead and Phillips types in different sizes for various applications.

- Pliers: Needle-nose and standard for gripping and manipulation.

- Torque Wrench: To ensure components are tightened to manufacturer specifications.

- Marine Grease: For lubrication of moving parts to reduce wear and tear.

- Sealant: Essential for preventing leaks in connections.

- Multimeter: For electrical diagnostics and troubleshooting.

- Cleaning Supplies: Brushes, cloths, and solvents to maintain cleanliness.

Additionally, some tasks may require specialized tools such as:

- Propeller Puller: For safe removal of propellers without damage.

- Alignment Tool: Ensures proper alignment during reassembly.

- Engine Hoist: For lifting and maneuvering heavy components.

Investing in quality tools will enhance the repair experience and contribute to the longevity of the system.

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring your marine propulsion system. By following a systematic method, you can ensure effective repairs while minimizing the risk of further issues. Each step is designed to guide you through the intricacies of the task, making the process more manageable and efficient.

Preparation and Inspection

Begin by gathering all necessary tools and materials. Thoroughly inspect the unit for any visible damage or wear. Document any findings, as this will help you identify parts that need replacement or repair during the process.

Disassembly and Replacement

Carefully disassemble the components, taking note of their arrangement. Replace any worn or damaged items with quality replacements. After securing all new parts, reassemble the unit meticulously, ensuring that everything fits correctly and functions as intended.

Upgrading Your Outdrive Components

Enhancing the performance of your marine propulsion system can significantly improve your vessel’s efficiency and longevity. By selecting superior components, you not only boost functionality but also ensure a smoother experience on the water. The key is to focus on quality and compatibility, ensuring that each element works in harmony with the rest.

Consider the following aspects when upgrading: materials, compatibility, and technology advancements. Choosing high-quality materials can lead to better durability and resistance to harsh conditions. Furthermore, always verify that new components fit seamlessly with existing systems to avoid any operational issues. Embracing modern technology may also provide enhancements in performance, fuel efficiency, and reliability.

Choosing Quality Replacement Parts

When maintaining marine equipment, selecting high-quality components is crucial for ensuring longevity and performance. The right choices can significantly enhance reliability and minimize the risk of breakdowns, providing peace of mind during navigation.

Understanding Quality Indicators

Look for manufacturers that offer robust warranties and adhere to strict quality control standards. Durability and performance should be your guiding principles, ensuring that the components can withstand harsh marine environments.

Researching Reputable Suppliers

Always opt for established vendors with positive customer feedback. Genuine components or reputable aftermarket alternatives typically guarantee compatibility and performance, making them wise investments for your marine endeavors.

Safety Tips During Maintenance

Ensuring safety while performing upkeep on marine equipment is crucial for both personal well-being and the longevity of the vessel. Adhering to specific precautions can significantly reduce the risk of accidents and injuries during these essential tasks.

Always wear appropriate protective gear, including gloves and safety glasses, to shield yourself from potential hazards. Before starting, disconnect the power source to avoid accidental activation of machinery. Keep your workspace tidy and free of obstacles to prevent trips and falls.

Use tools correctly and ensure they are in good condition. Familiarize yourself with the equipment’s manual to understand the proper procedures and maintenance schedules. If you’re unsure about any task, consult a professional to avoid costly mistakes.

Lastly, ensure that you have a first-aid kit accessible and know basic emergency procedures. Being prepared can make a significant difference in handling unexpected situations effectively.

Volvo Penta Warranty Information

This section provides essential insights into the guarantee offerings for marine equipment, ensuring users understand their rights and coverage. It encompasses the duration of the warranty, what is included, and the necessary steps for claims, allowing boat owners to navigate any potential issues with confidence.

| Coverage | Duration | Claim Process |

|---|---|---|

| Manufacturing defects | 2 years from purchase | Contact authorized dealer |

| Specific components | 5 years for certain parts | Provide proof of purchase |

| Wear and tear exclusions | N/A | Follow maintenance guidelines |

Understanding the warranty details is crucial for maintaining equipment efficiency and ensuring peace of mind during usage.

Frequently Asked Questions

This section aims to address common inquiries regarding the maintenance and components of marine propulsion systems. Whether you are a novice or an experienced user, finding the right information can enhance your understanding and ensure optimal performance.

Common Queries

- What are the essential components of a marine propulsion system?

- How do I identify specific issues with my unit?

- Where can I find reliable replacement components?

- What maintenance practices should I follow?

Troubleshooting Tips

- Check for leaks and signs of wear.

- Inspect the fluid levels regularly.

- Listen for unusual noises during operation.

- Consult the user manual for detailed guidance.

Resources for Further Learning

This section aims to guide enthusiasts and professionals toward valuable materials that deepen understanding and enhance skills related to marine propulsion systems. A variety of resources are available, covering theoretical concepts, practical applications, and troubleshooting techniques.

Books and Manuals

- Marine Engine Repair and Maintenance by John Doe

- The Comprehensive Guide to Marine Systems by Jane Smith

- Technical Manuals from Manufacturers

Online Courses and Tutorials

- Platform A: Marine Engineering Fundamentals

- Platform B: Advanced Propulsion Techniques

- YouTube Channels focusing on Marine Mechanics

Utilizing these resources will ultimately enhance your expertise and practical knowledge in the field.