Viking Gas Range Parts Diagram Overview

The efficient operation of any kitchen device relies on a well-organized system of interconnected elements. Recognizing the placement and purpose of these components is essential for both proper maintenance and potential repairs. In this section, we’ll explore how the various elements work together to ensure the device functions smoothly.

For those seeking to maintain or repair their kitchen equipment, it’s helpful to have a clear view of the internal structure. By examining how each piece fits and works within the overall system, users can more easily identify and address potential issues, ensuring the appliance continues to perform at its best.

Whether you’re conducting routine upkeep or tackling a specific problem, understanding the intricate layout of your appliance is the key to success. With the right approach, maintaining kitchen tools becomes a straightforward and manageable task.

Understanding Your Viking Gas Range Components

The various elements that make up your cooking appliance play a crucial role in its overall functionality. Each component has a specific purpose, working together to ensure efficient operation and heat control. Understanding how these elements interact can help you maintain the unit and identify potential issues before they become serious problems.

Key Sections of the Cooking Unit

The cooking appliance is divided into several distinct areas, each responsible for different tasks. From the heating mechanisms to the control systems, every part contributes to the smooth performance of the unit.

Main Functional Components

Below is an overview of the primary components that are essential to the operation of your appliance:

| Component | Description |

|---|---|

| Heating Elements | Responsible for generating and distributing heat for cooking. |

| Control Panel | Allows for adjustment of temperature and cooking settings. |

| Ignition System | Initiates the combustion process to start the heating elements. |

| Safety Valves | Ensures secure operation by controlling the fuel supply. |

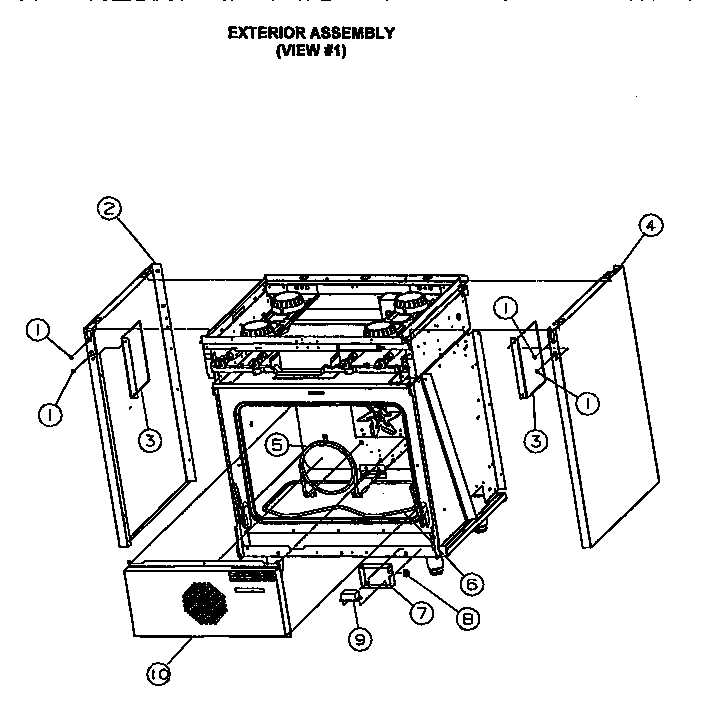

Main Parts of a Viking Gas Range

The key components of this cooking appliance are designed to ensure optimal performance and reliability. Each element works together to provide precise control over cooking temperatures, enhance safety, and offer ease of use. Understanding these features is essential for maintaining the equipment in good working condition and making the most out of its capabilities.

One of the primary elements is the surface where pots and pans rest during cooking. Below it, you will find the burners, which are responsible for distributing heat evenly. These heat sources come in various sizes to accommodate different cookware and cooking techniques.

Another critical section includes the controls, which allow users to adjust settings for temperature and other functionalities. In addition, the oven compartment, located below the surface, serves as a central space for baking and roasting. Finally, the ventilation system ensures that excess heat and fumes are properly managed during use, contributing to a safer and more comfortable cooking experience.

Identifying Key Functional Elements

Understanding the essential components of a cooking appliance helps ensure efficient use and maintenance. Each part plays a crucial role in the overall functionality, contributing to both performance and safety.

- Control Mechanisms: These elements regulate temperature and manage various settings to ensure precise cooking.

- Heat Sources: Integral to providing the required energy for cooking, these components generate and distribute heat evenly.

- Surface Structure: This area is designed for durability and effective heat transfer, making it critical for optimal operation.

- Safety Features: Built-in mechanisms that prevent overheating and other potential hazards, ensuring safe usage.

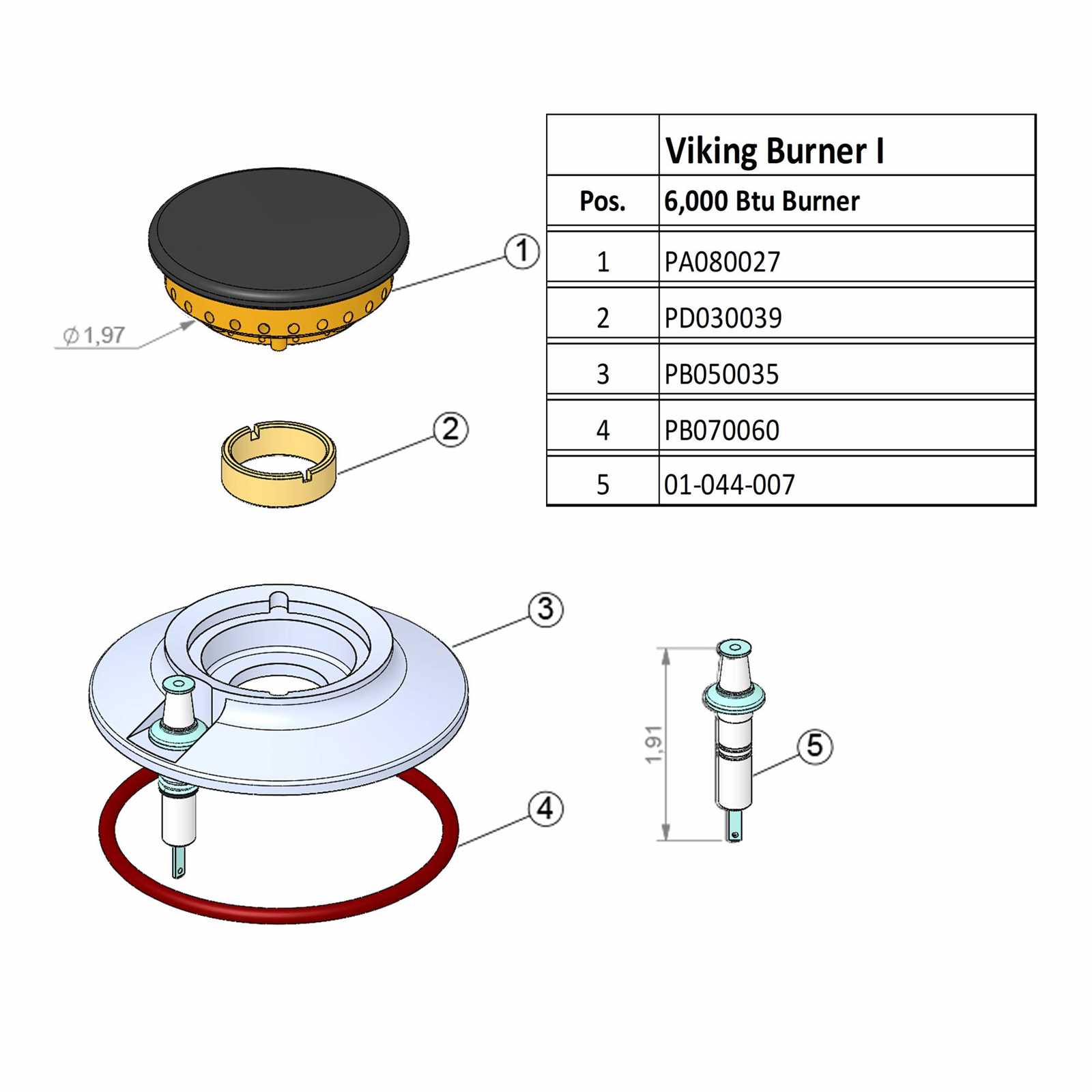

Exploring Burner Assembly Layout

The burner assembly is a critical component in cooking equipment, designed to ensure an even distribution of heat for efficient meal preparation. Understanding the structure and configuration of the burner elements helps in maintenance and optimization of cooking performance.

Main Components of the Burner Assembly

The burner unit typically consists of several interconnected parts that work together to control the flow and spread of heat. Key elements include the burners themselves, which are responsible for generating the heat, and the distribution channels that guide it to the cooking surface. Regular inspection and cleaning of these parts can enhance performance.

Optimizing Heat Distribution

To achieve consistent heat, the layout of the burner assembly must be balanced and free from blockages. Ensuring that all channels are clear and that the burners are aligned correctly is essential for effective cooking. Maintenance should focus on removing any debris that could obstruct heat flow, leading to improved efficiency.

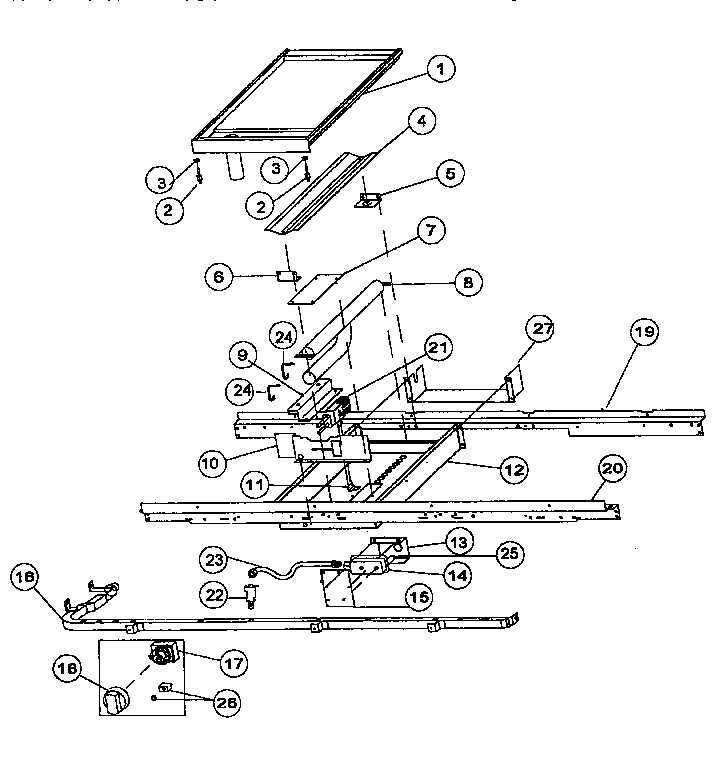

Gas Range Control Panel Overview

The control panel is the central interface that allows you to manage various functions of your cooking appliance. It offers a range of buttons, knobs, and displays that provide direct access to key settings and operations. Understanding how to use it effectively can simplify the cooking process and help ensure precision in temperature and timing.

Key Functions of the Control Panel

One of the primary features of the control panel is temperature control, which allows you to adjust the heat according to the dish being prepared. Another important function includes setting cooking modes, which can range from standard baking to broiling. In addition, the panel often features timers and alarms to assist with monitoring the cooking duration, making it easier to achieve consistent results.

Special Features for Enhanced Convenience

Many modern panels also include advanced settings like pre-programmed cooking modes, child safety locks, and digital displays for enhanced clarity. These features are designed to provide a more user-friendly experience and improve overall functionality.

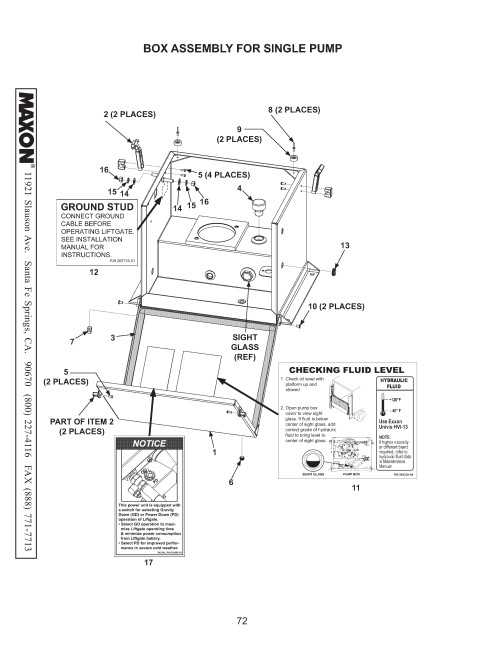

Diagram of the Oven Ignition System

The ignition system of an oven plays a crucial role in ensuring the safe and efficient operation of the appliance. Understanding the components involved can help users troubleshoot issues and perform maintenance tasks more effectively. This section provides an overview of the essential elements within the ignition mechanism.

Key Components

- Igniter: Responsible for generating the heat needed to ignite the fuel.

- Control Module: Manages the ignition sequence and monitors system performance.

- Thermocouple: A safety device that detects the presence of flame and prevents gas flow if not ignited.

- Wires: Connect the igniter and control module, facilitating electrical signals.

Ignition Process

- The control module sends a signal to the igniter.

- The igniter heats up and produces a spark.

- Once the flame is detected by the thermocouple, the gas supply is activated.

- Continuous monitoring ensures safe operation throughout cooking.

Understanding Gas Flow and Valves

The effective movement of fuel within a cooking appliance is essential for optimal performance. Proper management of the flow ensures that heat is distributed evenly, allowing for efficient cooking. Valves play a crucial role in regulating this flow, enabling precise control over temperature and cooking methods.

Components of Fuel Management

Several elements contribute to the management of fuel in a cooking system. Understanding these components can enhance the safety and efficiency of the appliance. The following table summarizes the key parts involved in this process:

| Component | Function |

|---|---|

| Control Valve | Regulates the flow of fuel based on user input. |

| Regulator | Maintains consistent pressure within the system. |

| Ignition System | Initiates combustion of the fuel for cooking. |

| Burner | Disperses fuel to create a controlled flame. |

Importance of Maintenance

Regular inspection and maintenance of the fuel management components are vital for safe operation. Ensuring that valves are functioning correctly and that there are no blockages can prevent hazardous situations. Proper upkeep not only enhances safety but also improves cooking efficiency, making it an essential practice for users.

Cleaning and Maintenance Tips for Parts

Maintaining the functionality and appearance of kitchen appliances is essential for their longevity and performance. Regular cleaning and upkeep not only enhance the aesthetic appeal but also ensure that each component operates efficiently. Here are some effective strategies to help you achieve optimal care for your equipment.

Routine Cleaning Practices

Establishing a regular cleaning schedule is crucial for preventing buildup and maintaining hygiene. Use a soft cloth or sponge along with mild detergents to wipe down surfaces after each use. Pay special attention to areas that accumulate grease and residue, as these can affect performance over time.

Deep Cleaning Techniques

For a thorough cleaning, consider disassembling removable components and soaking them in warm, soapy water. After soaking, scrub with a non-abrasive brush to eliminate stubborn stains. Rinse and dry each piece completely before reassembling. This method not only cleans but also allows for inspection of parts for wear and tear, helping you address any issues promptly.

Replacing Worn or Damaged Components

When components of your appliance become worn or damaged, timely replacement is crucial to ensure optimal functionality and safety. Identifying these parts early on can prevent further issues and enhance the longevity of your unit. Regular inspections and maintenance are key practices in recognizing when replacements are necessary.

Here are some common indicators that suggest components may need replacement:

| Indicator | Description |

|---|---|

| Unusual Noises | Strange sounds during operation can indicate wear and tear in moving parts. |

| Reduced Efficiency | If your appliance takes longer to complete tasks, it may signify failing components. |

| Visible Damage | Cracks, dents, or other visible damages are clear signs that replacement is necessary. |

| Frequent Breakdowns | Regular malfunctions suggest underlying issues with specific components that may need replacing. |

Addressing these issues promptly can save time and money in the long run. Always consult the manufacturer’s guidelines or a professional technician when selecting replacement components to ensure compatibility and quality.

Troubleshooting Common Range Issues

When faced with cooking appliance challenges, it’s essential to identify the symptoms to determine the underlying problem. Common malfunctions can disrupt meal preparation, but many issues can be resolved with basic troubleshooting techniques.

One frequent concern is the failure of heating elements to operate effectively. If food is taking longer to cook than expected, check the settings and ensure the components are functioning correctly. Sometimes, the problem can stem from a malfunctioning thermostat or incorrect temperature calibration.

Another issue may arise when control knobs are unresponsive or difficult to turn. This can often be attributed to dirt or grease buildup, which may impede their movement. Cleaning the knobs and surrounding areas can restore functionality.

In cases where there are unusual noises or odors, it’s crucial to investigate immediately. Loose components or blockages can cause these disturbances and may require tightening or clearing debris to ensure safe operation.

Lastly, if the appliance does not ignite, it may indicate a problem with the ignition system. Verifying the power supply and inspecting ignition components can help pinpoint the issue and facilitate repairs.

Maximizing Efficiency with Proper Setup

Achieving optimal performance in culinary environments requires a thoughtful arrangement of equipment and tools. This process involves ensuring that all elements are configured correctly to enhance functionality and streamline operations. By prioritizing organization and accessibility, one can significantly improve overall productivity in the kitchen.

Strategic Layout for Enhanced Workflow

Implementing a well-planned layout can drastically influence the efficiency of food preparation. Positioning essential items within easy reach minimizes movement and reduces time spent searching for tools. Consider the flow of tasks and arrange appliances to complement each other, allowing for a seamless transition from one step to the next.

Regular Maintenance for Optimal Functionality

Consistent upkeep of equipment is vital for sustaining high performance levels. Regular cleaning and inspections not only prolong the lifespan of tools but also prevent potential issues that could disrupt operations. Establish a routine maintenance schedule to ensure everything operates smoothly and efficiently, contributing to a more productive kitchen environment.