Comprehensive Guide to John Deere 2950 Parts Diagram

The intricate workings of agricultural machinery rely heavily on a well-structured assembly of components. For operators and technicians, having access to detailed schematics can significantly enhance maintenance and repair efficiency. Such layouts not only help in identifying individual elements but also in understanding their interconnections within the larger system.

In the realm of heavy equipment, the organization of parts plays a crucial role in ensuring optimal performance. A comprehensive visual representation allows users to pinpoint specific sections, facilitating quicker troubleshooting and more effective management of resources. By familiarizing oneself with these layouts, one can streamline processes and reduce downtime.

This guide aims to provide insights into the various elements and their configurations, assisting users in navigating the complexities of machinery maintenance. Whether you’re a seasoned professional or a newcomer to the field, understanding these arrangements is essential for successful operation and care of your equipment.

Understanding John Deere 2950 Components

This section aims to explore the various elements that make up a specific agricultural machine. Each component plays a crucial role in ensuring the overall functionality and efficiency of the equipment, contributing to its performance in the field.

Key Elements of the Machinery

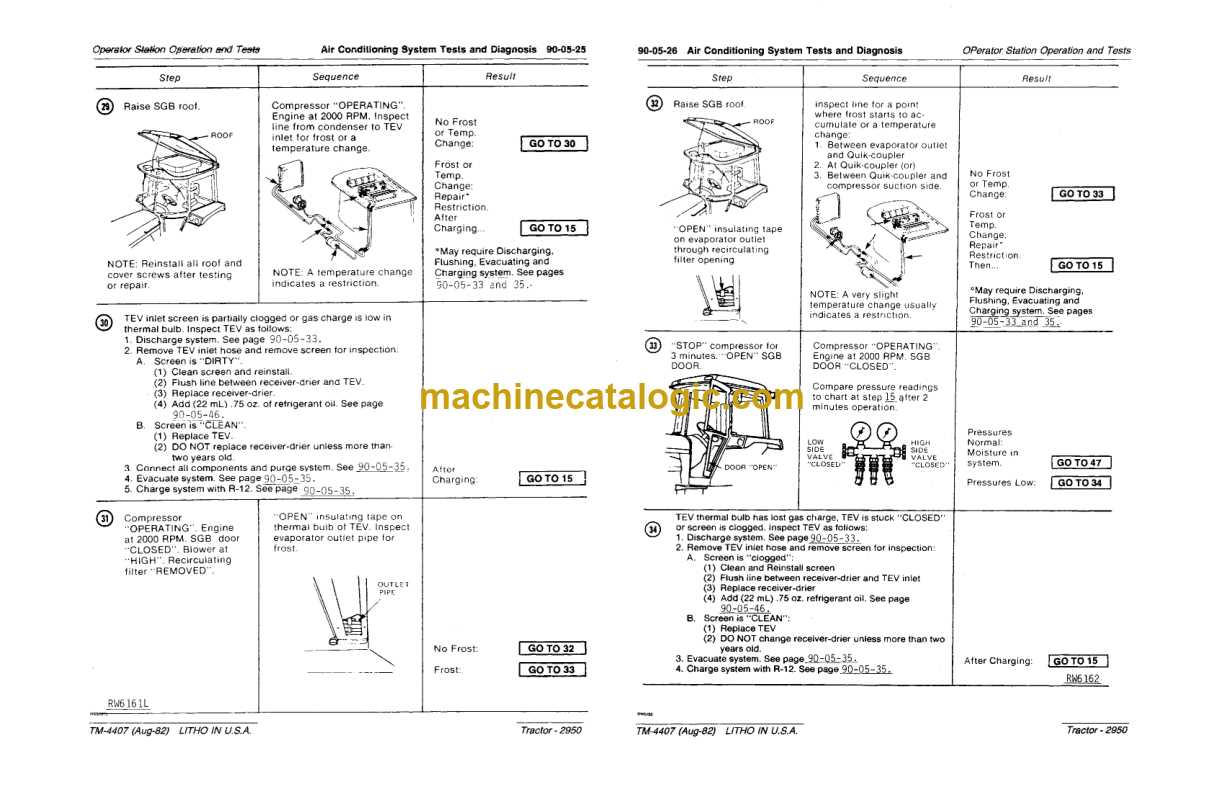

The primary components include the engine, transmission, and hydraulic systems. These elements work in harmony to provide the necessary power and control required for various farming tasks.

Maintenance and Optimization

Importance of Parts Diagrams

Visual representations of component layouts serve as essential tools for understanding machinery and equipment. They provide clarity on the intricate relationships between various elements, aiding in the identification and organization of individual pieces. This visual guidance is crucial for maintenance and repair, ensuring that technicians can efficiently address issues and perform replacements as needed.

Having access to detailed illustrations can significantly reduce downtime and enhance productivity. By offering a clear overview of assembly and disassembly processes, these representations allow users to work with confidence, minimizing the risk of errors during repairs. Furthermore, they can serve as valuable educational resources for those learning about machinery operation and upkeep.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids simplify complex information, making it easier to comprehend. |

| Efficiency | Quick reference for identifying components, reducing repair time. |

| Training Aid | Useful for educating new technicians on machinery layout and function. |

| Error Reduction | Minimizes mistakes by providing a clear guide for assembly and disassembly. |

Common Issues with 2950 Parts

When working with agricultural machinery, certain components may present frequent challenges that can affect overall performance and reliability. Understanding these common pitfalls can help in maintaining optimal functionality.

- Wear and Tear: Components often experience deterioration over time, leading to reduced efficiency.

- Hydraulic Leaks: Hydraulic systems are prone to leaks, which can cause significant operational issues.

- Electrical Failures: Wiring and connectors may corrode, resulting in intermittent power loss.

Addressing these issues promptly is essential for maintaining productivity and extending the lifespan of the equipment.

Where to Find OEM Parts

Locating original equipment manufacturer components can significantly enhance the performance and longevity of your machinery. Whether you are in need of replacement items or upgrades, sourcing these specific parts ensures compatibility and reliability. Here are some avenues to explore:

- Official Dealerships: Many manufacturers operate authorized dealerships that stock a comprehensive range of original components. Visiting these outlets often guarantees the authenticity of the items.

- Online Retailers: Numerous e-commerce platforms specialize in OEM components. Ensure you are purchasing from reputable sellers who provide detailed descriptions and part numbers.

- Manufacturer’s Website: Check the official website of the brand for a dedicated section on spare parts. Often, these sites provide diagrams and direct links to order parts online.

- Local Repair Shops: Many local service providers have access to genuine parts and can assist with sourcing them. Establishing a relationship with a trusted mechanic may also yield valuable recommendations.

- Parts Catalogs: Some companies publish physical or digital catalogs that list their components. These resources can be helpful in identifying the correct part numbers needed for your specific machine.

lessCopy code

By utilizing these resources, you can ensure that your equipment remains in peak condition with quality original parts that fit perfectly and function optimally.

Maintenance Tips for John Deere Tractors

Regular upkeep is essential for ensuring the longevity and optimal performance of your agricultural machinery. By adhering to a consistent maintenance schedule, you can prevent costly repairs and enhance the efficiency of your equipment. Here are some vital suggestions to keep your tractor running smoothly.

- Fluid Checks: Regularly inspect and change engine oil, hydraulic fluid, and coolant to maintain proper functioning.

- Filter Replacements: Replace air, fuel, and hydraulic filters as recommended to ensure clean operation and prevent contaminants from causing damage.

- Tire Maintenance: Check tire pressure and tread regularly to ensure optimal traction and stability during operation.

Additionally, periodic inspections can help identify potential issues before they escalate.

- Examine belts and hoses for wear and tear.

- Inspect battery terminals for corrosion.

- Check for leaks in hydraulic systems.

Proper storage also plays a significant role in maintaining the condition of your machinery. Ensure that your equipment is stored in a dry, covered area to protect it from the elements.

- Cleaning: Keep the exterior clean to prevent rust and corrosion.

- Lubrication: Regularly lubricate moving parts to reduce friction and wear.

By following these maintenance practices, you can significantly extend the lifespan of your agricultural machinery and ensure reliable performance throughout the seasons.

How to Read a Parts Diagram

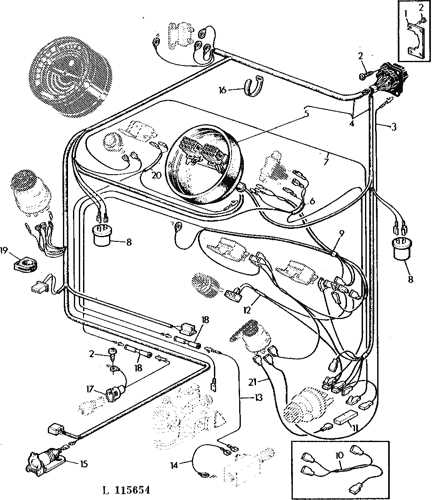

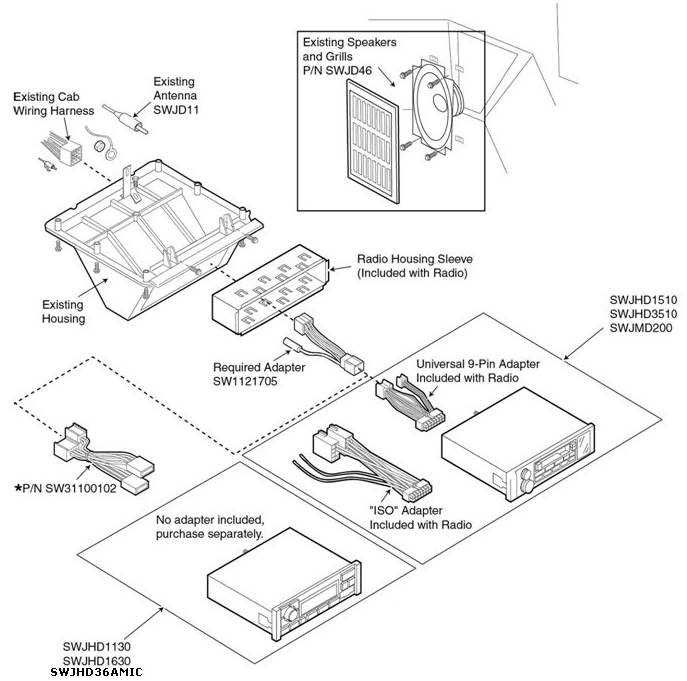

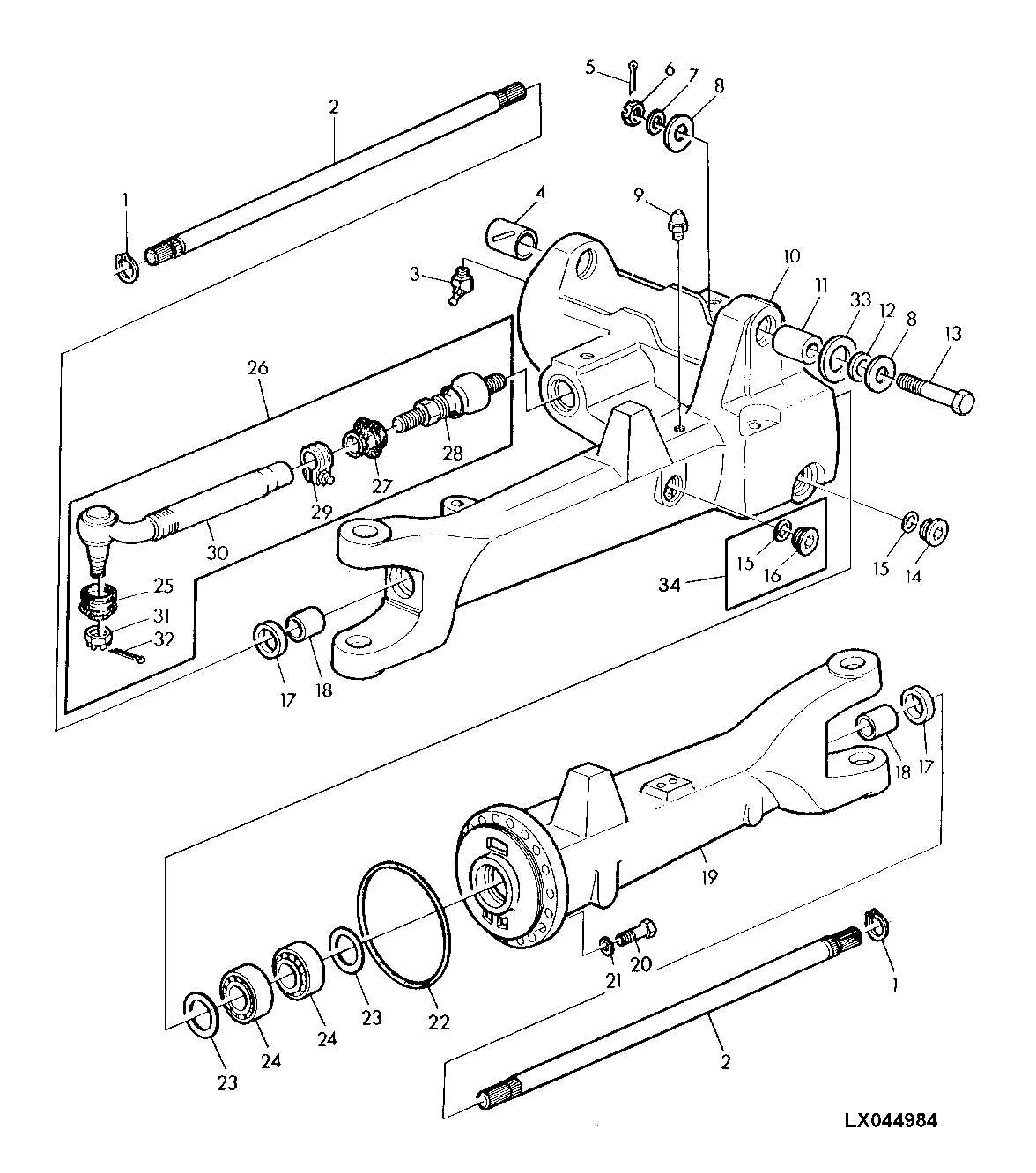

Understanding an assembly representation is crucial for effective maintenance and repair. These visual aids provide a detailed overview of components, their arrangement, and how they interact within a system. By familiarizing yourself with the structure and notation used, you can streamline your troubleshooting and ordering processes.

To interpret an assembly representation effectively, follow these key steps:

- Identify the Components: Look for labels or numbers that correspond to individual elements. This will help you recognize each part’s role.

- Understand the Connections: Pay attention to lines or arrows that indicate how components are linked. This can reveal functional relationships.

- Refer to the Legend: Many representations include a key that explains symbols and abbreviations. Consult it for clarity.

- Note the Sequence: Some diagrams present parts in the order they are assembled or disassembled. Follow this sequence for proper procedures.

By mastering these techniques, you’ll be better equipped to navigate any assembly representation and ensure accurate repairs or replacements.

Identifying Compatible Replacement Parts

Ensuring optimal performance of your machinery often requires finding the right substitutes when components wear out or break. This process involves understanding the specifications and compatibility of different elements to maintain efficiency and functionality. With numerous options available in the market, identifying suitable alternatives can significantly enhance the longevity and effectiveness of your equipment.

Researching Specifications

Start by gathering detailed information about the original components. This includes dimensions, material types, and performance ratings. Utilizing manuals or manufacturer resources can provide essential insights to aid in the selection of appropriate replacements. Knowledge of these specifications allows for a more informed choice, reducing the risk of incompatibility.

Utilizing Comparison Tables

Comparison tables can be invaluable tools in identifying alternatives. They allow for a side-by-side evaluation of various options based on key characteristics. Below is a sample table illustrating how to assess different components based on critical factors:

| Component | Manufacturer | Dimensions | Material | Compatibility |

|---|---|---|---|---|

| Component A | Brand X | 5×10 cm | Steel | Model 1, Model 2 |

| Component B | Brand Y | 5×10 cm | Aluminum | Model 1, Model 3 |

| Component C | Brand Z | 6×11 cm | Steel | Model 2, Model 3 |

By leveraging this information and utilizing comparison tools, you can effectively navigate the market for reliable replacements that meet your operational needs.

Tools Needed for Repairs

Effective maintenance of machinery requires a well-equipped toolkit. Proper tools not only facilitate repairs but also ensure safety and efficiency during the process. Understanding the essential equipment can make a significant difference in achieving optimal performance.

Essential Hand Tools

Having a selection of hand tools is crucial for any repair job. Common tools include wrenches, screwdrivers, and pliers. These are foundational for tightening, loosening, and adjusting various components.

Power Tools and Equipment

For more demanding tasks, power tools can significantly reduce effort and time. Drills, grinders, and impact wrenches can handle tougher jobs that hand tools might struggle with.

| Tool Type | Purpose |

|---|---|

| Wrench | Tightening or loosening nuts and bolts |

| Screwdriver | Driving screws into place |

| Pliers | Gripping and bending materials |

| Drill | Boring holes or fastening |

| Impact Wrench | Applying high torque for tough fasteners |

Customer Reviews on 2950 Components

This section explores the feedback from users regarding various components of a well-known agricultural machine. Insights gathered from real experiences provide potential buyers with valuable information about durability, performance, and overall satisfaction.

Users often highlight several key aspects in their reviews:

- Durability: Many users appreciate the robust construction of the components, noting their ability to withstand heavy use over time.

- Ease of Replacement: Several reviews mention the straightforward process for swapping out worn parts, making maintenance less of a hassle.

- Cost-Effectiveness: Buyers frequently comment on the reasonable pricing of these components compared to alternatives, providing good value for money.

- Performance: Numerous users report enhanced efficiency and productivity after upgrading specific parts, leading to more effective operations.

In summary, customer experiences suggest a high level of satisfaction with the components associated with this agricultural machine. Overall, positive feedback emphasizes reliability and effectiveness, making these products a solid choice for users in the field.

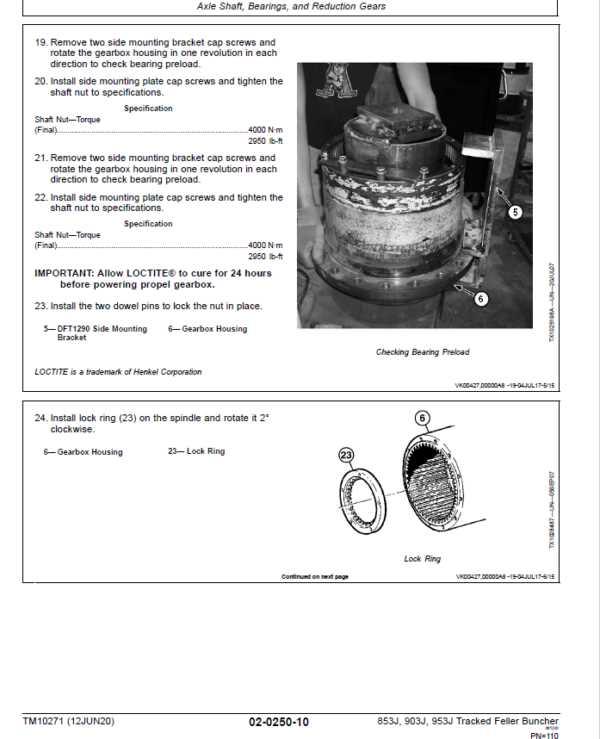

Assembly Instructions for Key Parts

This section provides detailed guidance on assembling crucial components of your machinery. Proper installation ensures optimal performance and longevity. Follow the outlined steps carefully to achieve successful assembly.

| Component | Assembly Steps | Tools Required |

|---|---|---|

| Transmission Unit |

1. Align the unit with the main frame. 2. Secure using the provided bolts. 3. Ensure proper alignment before tightening. |

Wrench set, Torque wrench |

| Hydraulic Pump |

1. Position the pump on the designated mount. 2. Connect hoses as per the schematic. 3. Fasten with clamps and ensure no leaks. |

Screwdriver, Pliers |

| Cooling System |

1. Attach the radiator to the frame. 2. Connect all hoses securely. 3. Fill with coolant and check for proper circulation. |

Socket set, Coolant |

Following these instructions will facilitate a smooth assembly process. Always refer to the specific manuals for additional details and safety precautions.