Comprehensive Parts Diagram for Mercury 15 HP 4 Stroke Outboard Motor

When it comes to maintaining and troubleshooting your 15 hp marine engine, a clear visualization of its components is essential. Grasping how each part fits into the overall assembly not only aids in repairs but also enhances your knowledge of the machinery. A comprehensive overview can make the difference between minor adjustments and significant overhauls.

In this section, we will explore the intricate details of the various elements that contribute to the engine’s performance. By examining the layout and interconnections, you’ll be better equipped to identify issues and implement effective solutions. A thorough understanding of each component’s function will empower you as a boater and ensure the longevity of your vessel.

Whether you’re a seasoned sailor or a novice enthusiast, knowing the specifics of your engine’s configuration can enhance your boating experience. With the right information, you can confidently tackle maintenance tasks and optimize the efficiency of your watercraft.

Understanding Mercury 15 HP Outboard

This section aims to provide a comprehensive overview of a specific 15 horsepower marine engine, exploring its key features, functionalities, and components. Understanding these elements is essential for maintenance, repair, and optimal performance on the water.

Key Features

This powerful engine is designed for efficiency and reliability. Its lightweight construction allows for easy maneuverability, while the advanced technology enhances fuel economy. Users can expect a robust performance, making it suitable for various boating activities.

Maintenance Considerations

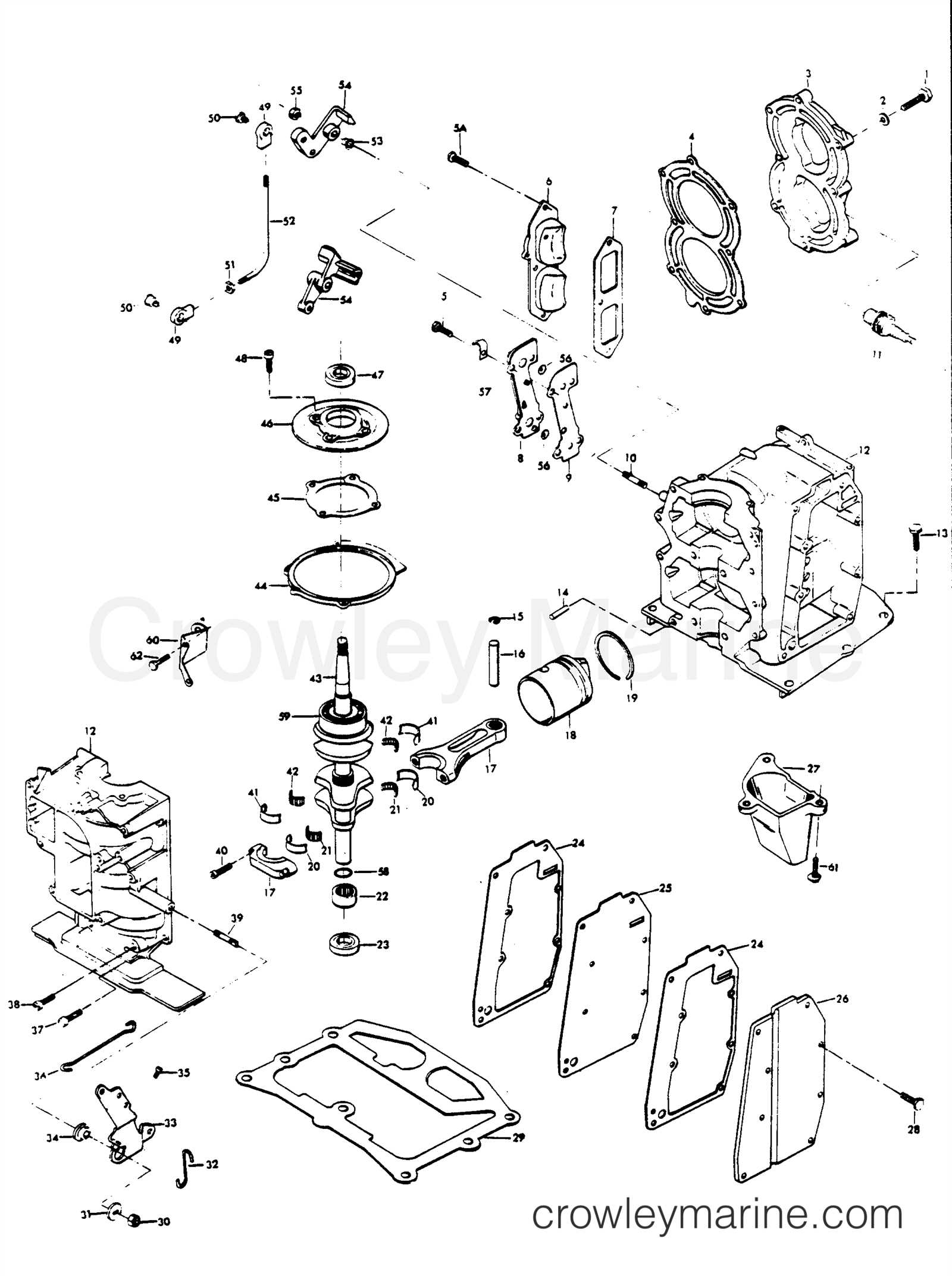

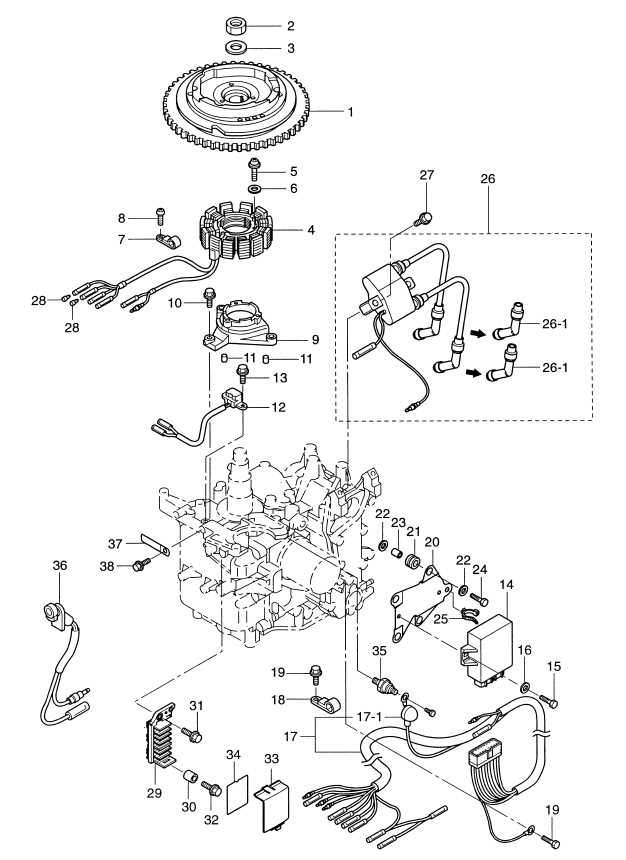

Key Components of the Engine

Understanding the fundamental elements of an engine is crucial for maintenance and performance optimization. Each component plays a vital role in ensuring the overall efficiency and functionality of the machine. Below are the essential parts that contribute to its operation.

- Fuel System: This includes the fuel tank, pump, and injectors, which are responsible for delivering fuel to the combustion chamber.

- Ignition System: Comprising spark plugs and ignition coils, this system ignites the air-fuel mixture, initiating combustion.

- Cooling System: Typically involving a water pump and thermostat, this system prevents the engine from overheating by regulating temperature.

- Lubrication System: Oil pumps and filters are essential for reducing friction between moving parts, ensuring smooth operation.

- Exhaust System: This consists of the exhaust manifold and muffler, directing harmful gases away from the engine and reducing noise.

Each of these elements must work harmoniously to achieve optimal performance and reliability. Regular inspection and maintenance of these components can enhance the longevity of the engine and prevent unexpected failures.

Importance of Regular Maintenance

Key benefits of regular maintenance include:

- Enhanced performance and reliability

- Increased lifespan of components

- Improved fuel efficiency

- Early detection of potential problems

- Compliance with safety regulations

Ultimately, dedicating time to regular service not only preserves the equipment but also guarantees a safer and more enjoyable experience for users.

Identifying Common Issues

When operating marine engines, enthusiasts often encounter a variety of challenges that can hinder performance. Recognizing these issues early can prevent more severe damage and ensure a smoother experience on the water. Here, we will explore some prevalent problems and their potential indicators.

Common Symptoms

Engine malfunctions may manifest through various symptoms. Below is a table outlining typical issues and their associated signs.

| Issue | Symptoms |

|---|---|

| Fuel System Blockage | Poor acceleration, sputtering, or stalling |

| Overheating | Unusual sounds, warning alarms, or steam |

| Electrical Failures | Inconsistent starting, dim lights, or no response |

| Excessive Vibration | Shaking during operation, unusual noises |

Troubleshooting Steps

To address these issues effectively, one can follow several troubleshooting steps. Begin by inspecting fuel lines and filters for blockages. Next, check the cooling system for debris or leaks. Electrical connections should be examined for corrosion or loose wires. Finally, ensure that all components are securely fastened to minimize vibrations. By taking these proactive measures, users can enhance reliability and performance.

Parts Replacement Guidelines

Maintaining the functionality of your marine engine requires careful attention to component swapping. This section provides essential advice for ensuring that replacements are performed effectively, promoting optimal performance and longevity.

Identify the Component: Before initiating a replacement, accurately determine which element needs attention. Reference manuals or expert resources can assist in this process.

Gather Necessary Tools: Ensure you have the right tools at hand to facilitate a smooth replacement. Proper equipment minimizes the risk of damage and enhances efficiency.

Follow Manufacturer Instructions: Adhere strictly to the guidelines provided by the manufacturer. These instructions are designed to ensure safe and effective replacement, preserving the integrity of your engine.

Check Compatibility: Always verify that the new component is compatible with your specific model. Mismatched parts can lead to further issues and reduced performance.

Regular Maintenance: After replacing components, engage in routine checks. Regular upkeep prevents potential failures and extends the life of your equipment.

Seek Professional Help: If uncertain about any steps, consult with a professional. Expert assistance can save time and prevent costly mistakes.

Tools Needed for Repairs

Performing maintenance and fixing issues requires a specific set of instruments to ensure efficiency and effectiveness. Proper tools not only facilitate the repair process but also enhance safety and precision. Here is a list of essential tools that are typically needed for such tasks.

Essential Tools

- Wrenches: A variety of sizes for loosening and tightening components.

- Screwdrivers: Both flathead and Phillips types are necessary for various screws.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts.

- Socket set: Provides the ability to work with different nut sizes quickly.

- Torque wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

Additional Equipment

- Multimeter: Essential for diagnosing electrical issues.

- Cleaning tools: Brushes and cloths to remove dirt and debris.

- Safety gear: Gloves and goggles to protect against potential hazards.

- Jack stands: To safely elevate and support equipment during repairs.

- Storage containers: To keep small parts organized and easily accessible.

Finding OEM vs. Aftermarket Parts

When it comes to sourcing components for your engine, understanding the difference between original equipment manufacturer (OEM) and alternative market offerings is essential. Each option presents distinct advantages and potential drawbacks, which can significantly impact both performance and maintenance costs.

OEM Components

OEM components are produced by the same manufacturer as the original assembly. These pieces are designed to meet specific standards and quality controls, ensuring compatibility and reliability. Users often favor them for their durability and warranty benefits.

Aftermarket Offerings

Aftermarket offerings are made by third-party manufacturers. While they can provide cost savings and a wider selection, the quality can vary significantly. It’s important to research and select reputable brands to ensure that these components perform well and do not compromise the integrity of your engine.

| Aspect | OEM | Aftermarket |

|---|---|---|

| Quality | High, standardized | Variable, depends on brand |

| Price | Typically higher | Generally lower |

| Availability | Limited to manufacturer | Widely available |

| Warranty | Usually included | Varies by manufacturer |

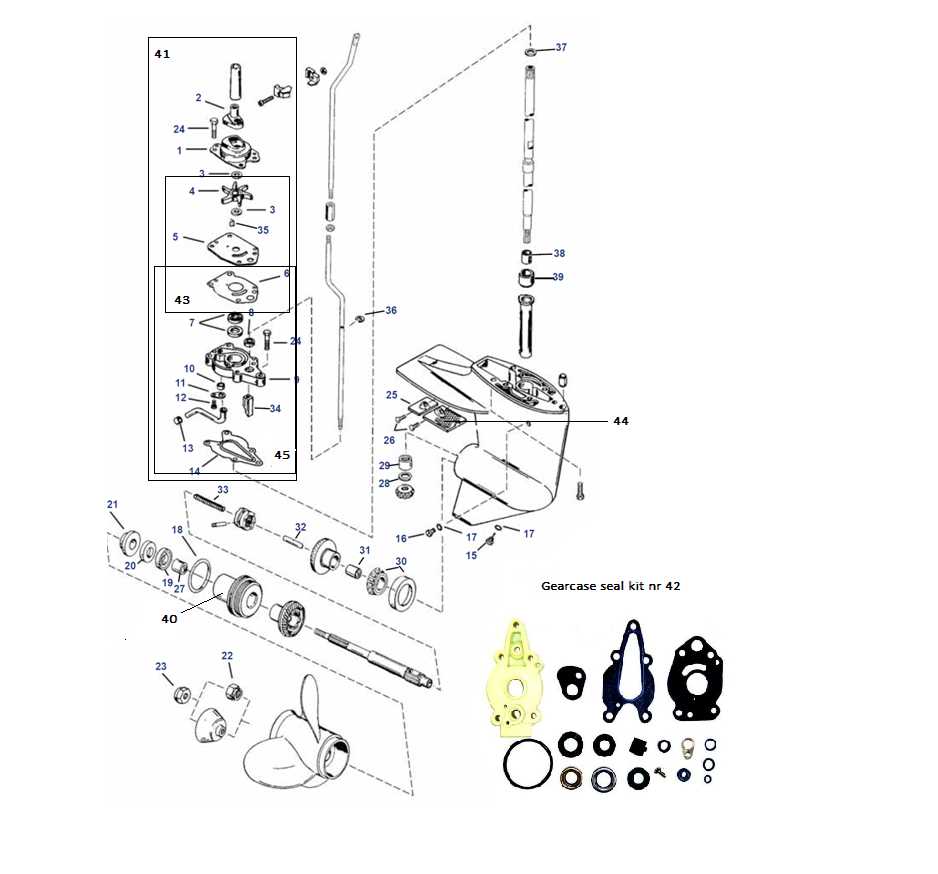

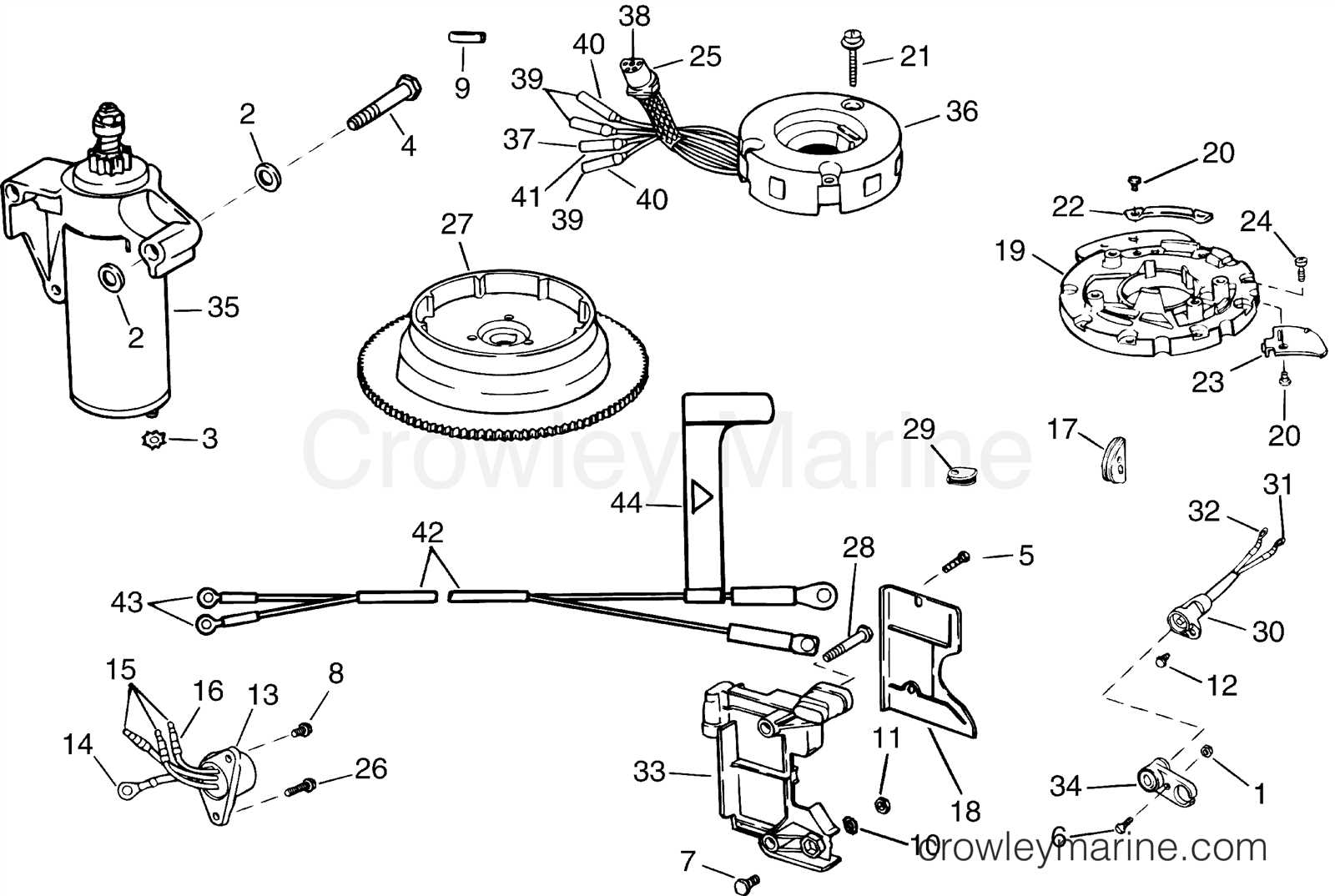

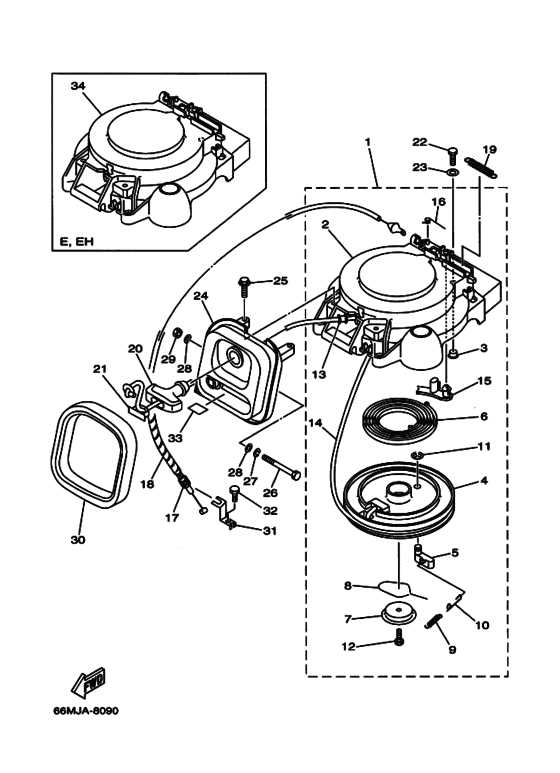

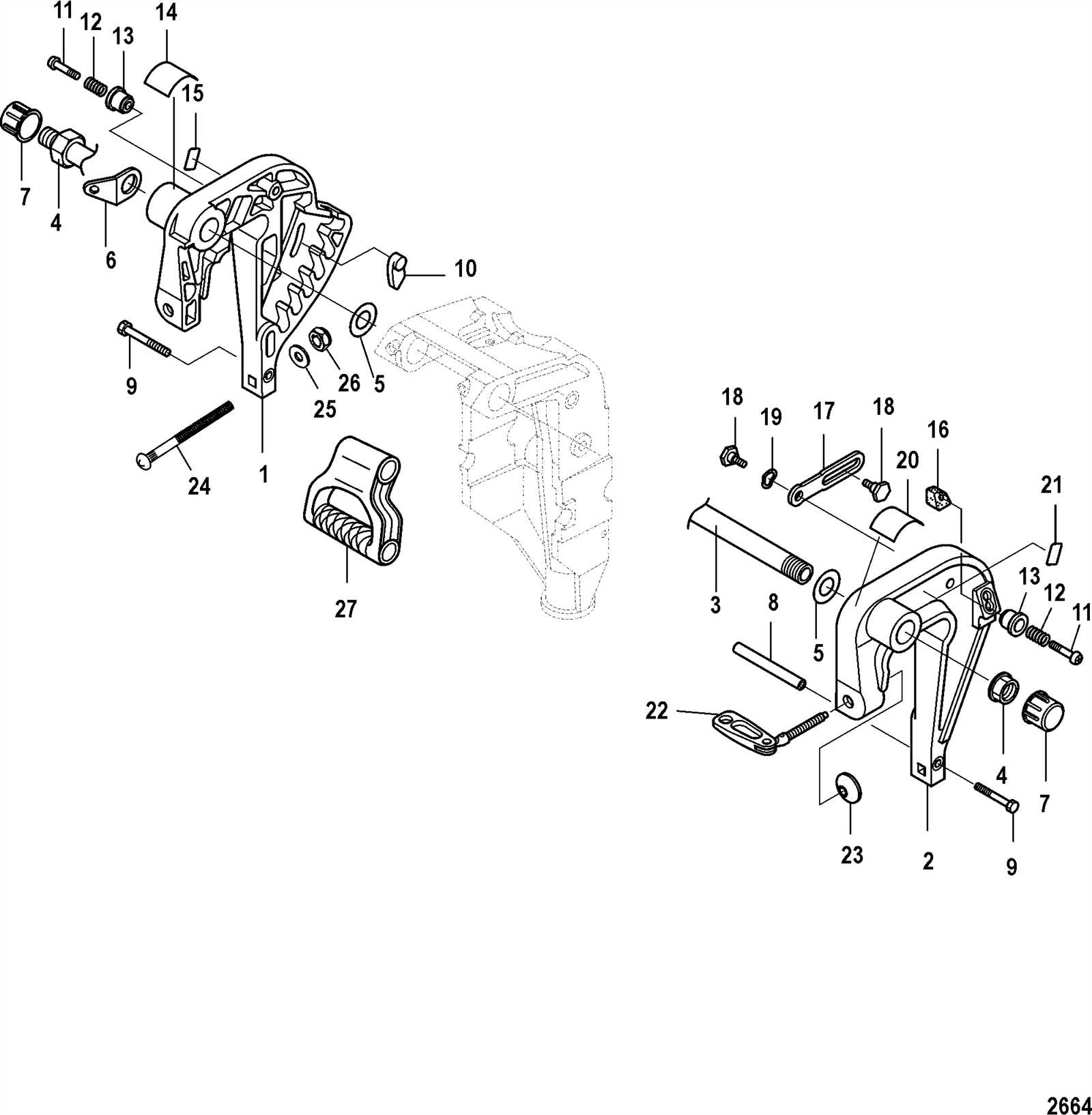

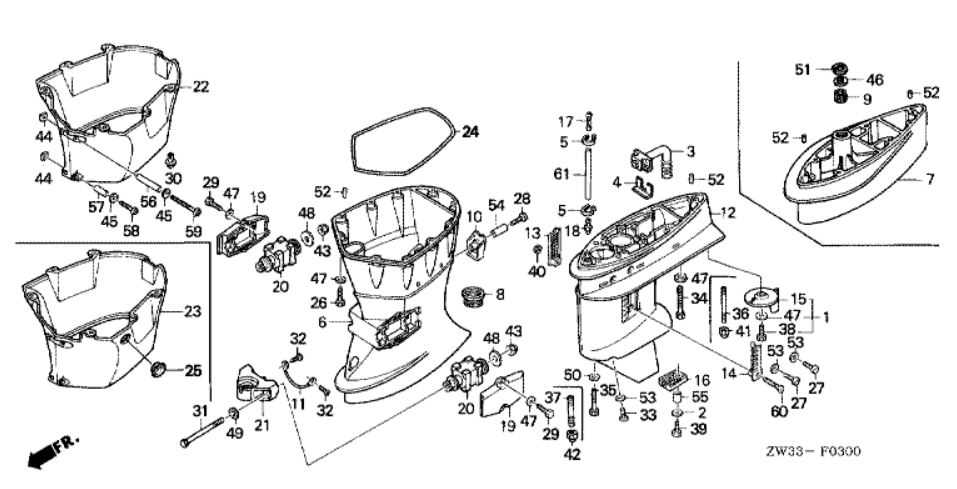

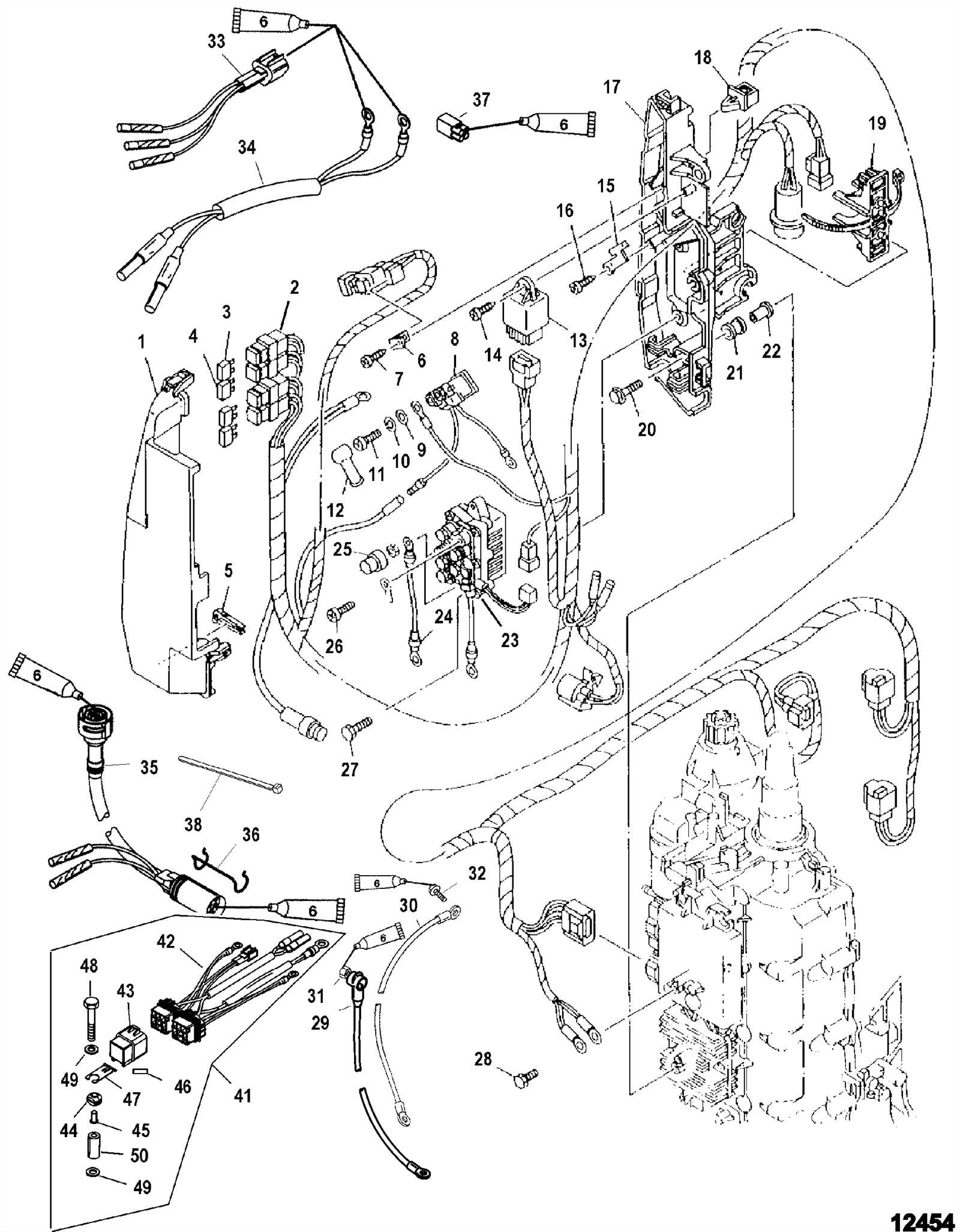

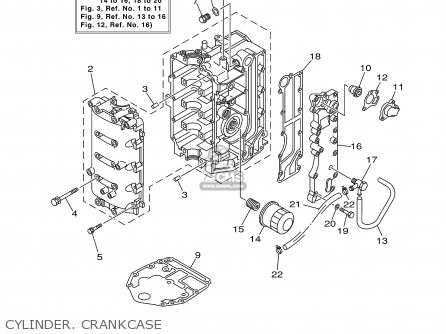

Diagram Interpretation Techniques

Understanding technical illustrations is crucial for effective maintenance and repair tasks. Mastering the ability to decipher these visuals can significantly enhance efficiency and accuracy in identifying components and their functions.

Key Elements to Consider

When examining a technical illustration, focus on symbols, labels, and lines that connect various elements. Symbols often represent specific components, while labels provide essential information regarding their characteristics. Lines may indicate connections or relationships, revealing how different parts interact within the system.

Practical Strategies for Analysis

To successfully navigate these visuals, consider using a systematic approach. Begin by identifying the main sections of the illustration, then gradually delve deeper into the finer details. Cross-referencing with a glossary of symbols can also aid in clarifying any unfamiliar notations.

Safety Tips During Repairs

When undertaking maintenance or repair tasks, prioritizing safety is essential. Proper precautions not only protect you but also ensure the longevity of the equipment. Below are important guidelines to follow while working on your machinery.

- Wear Protective Gear: Always use appropriate safety equipment, including gloves, goggles, and steel-toed boots to shield against injuries.

- Work in a Well-Ventilated Area: Ensure adequate airflow to avoid inhaling harmful fumes or gases that may be released during repairs.

- Disconnect Power Sources: Before starting any work, disconnect batteries or unplug devices to prevent accidental starts.

- Use Proper Tools: Utilize the correct tools for the job to avoid damaging components or causing personal injury.

- Keep the Workspace Organized: Maintain a clean and clutter-free area to reduce the risk of accidents and misplaced items.

Following these safety measures will help you conduct repairs effectively while minimizing potential hazards.

Upgrades for Enhanced Performance

Improving the efficiency and power of your marine engine can significantly enhance your overall experience on the water. Various modifications can lead to better speed, fuel efficiency, and responsiveness.

- Propeller Upgrade: Switching to a high-performance propeller can optimize thrust and improve acceleration.

- Intake System Enhancements: Installing a more efficient air intake can boost combustion and power output.

- Fuel System Modifications: Upgrading fuel injectors or using high-quality fuel can lead to better performance.

- Exhaust System Improvements: A performance exhaust can reduce back pressure and enhance engine efficiency.

- Weight Reduction: Minimizing unnecessary weight can improve handling and speed.

These upgrades can work together to deliver the ultimate performance, allowing for a more enjoyable time on the water.

Resources for Further Assistance

When it comes to maintaining and repairing your marine equipment, having access to reliable information is crucial. Various resources can enhance your understanding and provide guidance on resolving issues effectively.

Online Forums: Engaging with communities focused on marine machinery can yield valuable insights. Experienced users often share troubleshooting tips and advice that can save time and effort.

Manufacturer Support: Directly contacting the manufacturer can provide you with specialized assistance. Their resources often include manuals and technical support for specific queries.

Repair Guides: Comprehensive guides available online can help you navigate repairs step by step. Look for videos or articles that offer detailed explanations and visuals.

Local Dealers: Visiting a certified dealer can connect you with experts who have extensive knowledge of the equipment. They can offer professional assistance and genuine components if needed.

Workshops: Participating in workshops or training sessions can enhance your skills. These events often cover various topics related to maintenance and repair.

Utilizing these resources can ultimately empower you to tackle challenges with confidence and improve the longevity of your equipment.