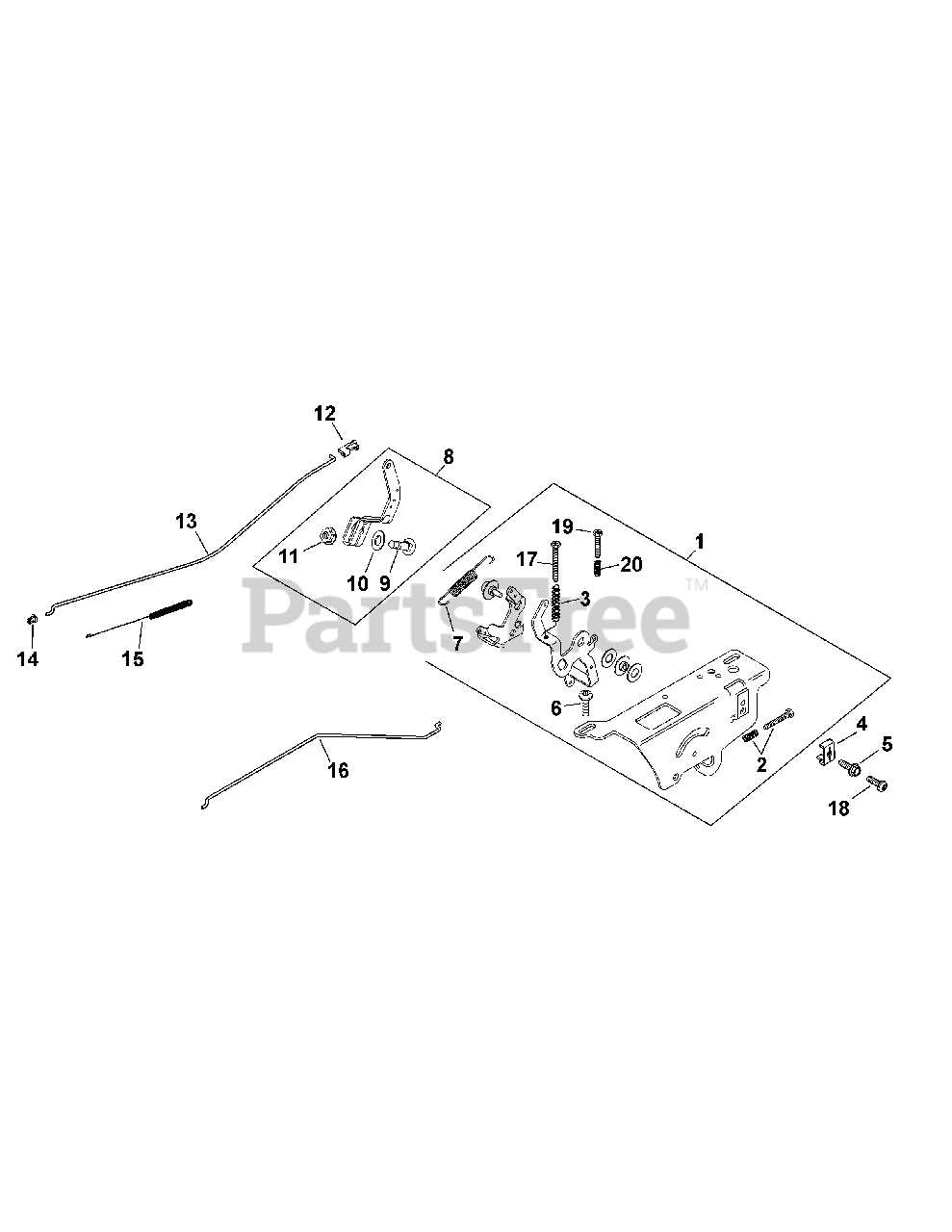

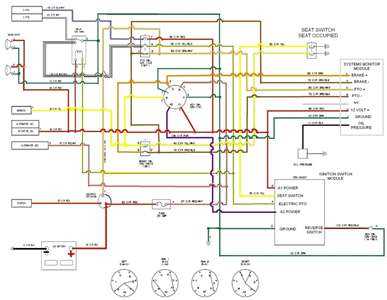

Cub Cadet LT1045 Parts Diagram Overview

When it comes to maintaining and repairing your lawn care machinery, having a clear understanding of its components is essential. A well-organized visual representation of all the parts can greatly simplify the process of identifying and replacing worn or damaged elements. This is particularly crucial for enthusiasts and professionals alike, as it aids in efficient troubleshooting and ensures optimal performance.

In this section, we will explore the intricate layout of various machinery elements, focusing on their arrangement and functionality. Recognizing how each component interacts with the others can enhance your ability to perform repairs and maintenance tasks effectively. This knowledge not only extends the life of your equipment but also contributes to a healthier and more beautiful lawn.

Whether you are a seasoned technician or a homeowner seeking to understand your tools better, familiarizing yourself with the essential parts will empower you to tackle any challenge that may arise. By delving into the specifics of these elements, you can confidently manage your equipment and ensure it operates at peak efficiency.

Overview of the Lawn Tractor

This section provides a comprehensive look at a popular lawn care machine designed for efficiency and reliability. Known for its robust construction and user-friendly features, this model caters to homeowners looking to maintain their yards with ease. The combination of performance and comfort makes it a favored choice among gardening enthusiasts.

Key Features

Equipped with a powerful engine, this lawn tractor offers exceptional cutting capabilities, allowing for a clean and even finish on various terrains. The intuitive control layout ensures that users can easily navigate and adjust settings as needed. Additionally, the spacious seat and ergonomic design enhance the overall experience, reducing fatigue during extended use.

Maintenance Considerations

Regular upkeep is essential to prolong the lifespan of this machine. Basic tasks include checking fluid levels, inspecting the blades for sharpness, and cleaning the chassis to prevent debris buildup. By adhering to a maintenance schedule, users can ensure optimal performance and reliability throughout the mowing season.

Importance of Parts Diagrams

Understanding the components of any machinery is essential for effective maintenance and repairs. Visual representations of these elements serve as vital tools for technicians and enthusiasts alike. They provide clarity, streamline the identification process, and enhance the overall efficiency of service work.

Key benefits of utilizing these visual guides include:

- Enhanced Clarity: Detailed illustrations eliminate confusion, making it easier to locate specific items.

- Time Efficiency: Quick reference saves valuable time during troubleshooting and repairs.

- Accurate Replacements: Ensures the correct parts are ordered and installed, reducing the risk of errors.

- Improved Understanding: Aids users in grasping how different components interact within the system.

In summary, visual aids play a crucial role in maintaining and repairing machinery, ensuring that users can work confidently and accurately.

Identifying Key Components

Understanding the essential elements of any machine is crucial for effective maintenance and troubleshooting. By recognizing each part and its function, users can ensure optimal performance and longevity of their equipment. This section will highlight the primary components, their roles, and how they interconnect to facilitate smooth operation.

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for generating power. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Deck | Houses the cutting blades, ensuring a clean and even cut. |

| Wheels | Support mobility and stability, crucial for maneuvering across various terrains. |

| Control Panel | Central hub for user inputs, allowing adjustments to settings and operations. |

How to Read a Diagram

Understanding visual representations is crucial for effective maintenance and repair. These illustrations provide detailed information about components and their interconnections, making it easier to identify and locate parts. Familiarizing yourself with the symbols and layout is the first step towards mastering the information presented.

Start with the Legend: Many visuals include a legend or key that explains the symbols used. Familiarize yourself with this section to understand what each symbol represents, whether it’s a component, connection, or action.

Follow the Flow: Pay attention to the flow of connections and processes. Arrows and lines often indicate movement or relationships between different elements. Understanding these pathways can clarify how each part interacts within the whole system.

Identify Key Components: Focus on the main elements highlighted in the illustration. These are usually more prominent and can guide you in locating the necessary areas when performing maintenance or troubleshooting.

Check for Annotations: Many visuals include notes or annotations that provide additional context or instructions. Read these carefully, as they often contain crucial information that aids in the understanding of the layout.

By practicing these strategies, you will enhance your ability to interpret and utilize these valuable resources effectively.

Common Issues and Solutions

Every machine can encounter problems over time, and understanding these issues can lead to effective solutions. By identifying common challenges, users can take proactive steps to ensure smooth operation and longevity of their equipment. Here are some frequent concerns and their corresponding remedies.

Engine Problems

One of the most common issues involves the engine failing to start. This can be due to several factors, such as a drained battery, clogged fuel lines, or a faulty ignition system. To address this, first check the battery charge and connections. If the battery is functional, inspect the fuel system for blockages and ensure the spark plug is in good condition. Regular maintenance can prevent many engine-related issues.

Cutting Performance

Another prevalent concern is subpar cutting performance, which can result from dull blades or uneven tire pressure. Dull blades can lead to tearing rather than clean cuts, so sharpening or replacing them is essential. Additionally, maintaining proper tire pressure ensures an even cutting height. Regular checks and adjustments can significantly improve performance and efficiency.

Where to Find Replacement Parts

Finding suitable components for your machinery is crucial for maintaining its performance and longevity. Numerous avenues exist for sourcing these essential elements, ensuring that you can restore your equipment efficiently.

Online Retailers

Many websites specialize in offering a wide selection of components for outdoor equipment. Here are some popular options:

- Amazon – A large marketplace with various sellers.

- eBay – A platform for new and used items, often at competitive prices.

- Manufacturer’s Website – Direct access to original components.

- Specialty Stores – Websites focusing specifically on outdoor machinery.

Local Suppliers

Visiting nearby shops can provide immediate access to necessary components. Consider the following:

- Authorized Dealers – Ensure quality and compatibility.

- Hardware Stores – Often carry basic components.

- Salvage Yards – A resource for hard-to-find items at lower prices.

Utilizing these resources will help you locate the required items to keep your equipment running smoothly.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the lasting performance and efficiency of your equipment. By following a few simple practices, you can significantly extend its lifespan and maintain optimal functionality.

- Perform routine inspections to identify any wear and tear.

- Change the oil and filter as recommended by the manufacturer.

- Sharpen blades regularly to ensure clean cuts.

- Clean the exterior and undercarriage to prevent rust and debris buildup.

- Check tire pressure and condition frequently for stability.

Additionally, storing your equipment in a dry, sheltered area can protect it from the elements and reduce the risk of damage. Following these steps will help you achieve the ultimate performance and longevity from your machinery.

Understanding the Engine Assembly

The engine assembly serves as the heart of any machinery, playing a crucial role in its overall functionality. This complex unit comprises various components that work together to convert fuel into mechanical energy, driving the entire system. A thorough grasp of each element within the assembly can enhance maintenance efforts and improve performance.

Safety Precautions During Repairs

When engaging in maintenance or fixing machinery, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also ensure that the equipment remains in optimal condition. Familiarizing oneself with safety protocols is an essential step in the repair process.

Essential Safety Gear

Before starting any repair work, wearing the appropriate personal protective equipment (PPE) is necessary. This includes items such as gloves, goggles, and sturdy footwear to minimize the risk of injuries.

| Type of Gear | Purpose |

|---|---|

| Gloves | Protect hands from cuts and chemicals |

| Goggles | Shield eyes from debris and harmful substances |

| Steel-toed Boots | Prevent foot injuries from falling objects |

Work Area Safety

Maintaining a clean and organized workspace is vital. Ensure that tools and parts are properly stored to avoid tripping hazards. Additionally, always work in a well-ventilated area to minimize exposure to fumes and ensure adequate airflow.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their availability. Understanding the intricacies of machinery can significantly enhance maintenance and repair efforts, ensuring longevity and optimal performance.

What should I consider when purchasing components?

When acquiring elements, it’s essential to evaluate compatibility, quality, and warranty options. Always opt for reliable sources to guarantee authenticity and performance.

How can I identify the correct component for my equipment?

Utilizing reference manuals and visual aids can assist in recognizing the appropriate piece. Additionally, consulting with knowledgeable professionals can provide further clarity and guidance.