Comprehensive Guide to Huayi Carburetor Parts Diagram PDF

Exploring the intricate world of fuel delivery mechanisms reveals a fascinating interplay of components that ensure optimal engine performance. Each element plays a crucial role in managing the flow and mixture of fuel and air, which ultimately impacts the efficiency and power output of various machinery.

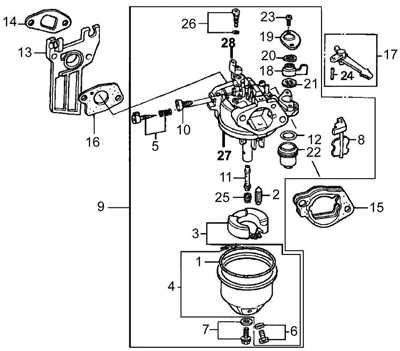

For enthusiasts and professionals alike, having access to detailed visual representations can greatly enhance the understanding of these systems. These illustrations serve as invaluable resources, offering insight into the arrangement and functionality of the individual components, allowing for better maintenance and troubleshooting.

Whether you are a seasoned technician or a curious hobbyist, mastering these representations is key to achieving the ultimate performance from your engine. By delving into the specifics, one can uncover the subtle nuances that make all the difference in fuel delivery efficiency.

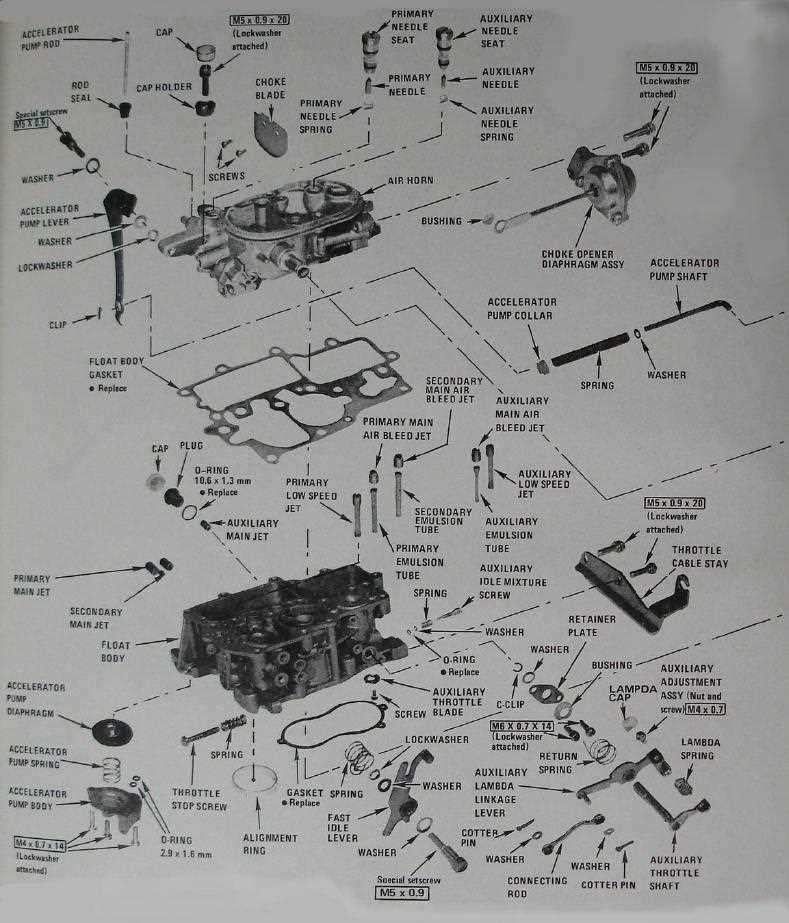

Understanding Huayi Carburetors

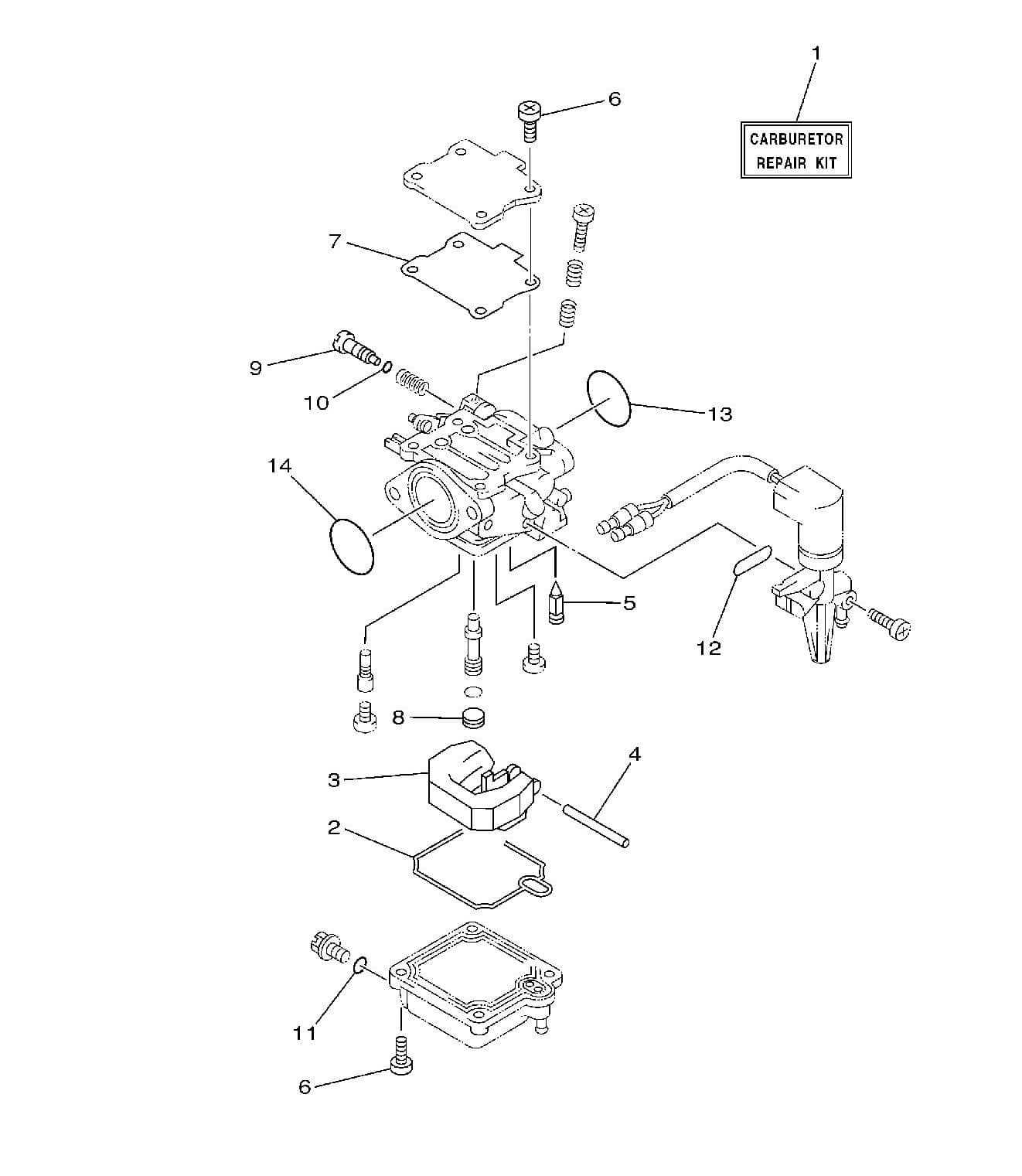

This section aims to explore the intricacies of a specific type of fuel mixing device commonly used in small engines. These mechanisms play a crucial role in ensuring optimal performance by regulating the air-fuel mixture, which is essential for efficient combustion.

Key Components

- Float Chamber

- Needle Valve

- Venturi

- Throttle Plate

Operation Principles

- Air enters the device through the intake.

- Fuel is drawn from the reservoir into the air stream.

- The mixture is adjusted based on engine demand.

- The resulting blend is then delivered to the combustion chamber.

Understanding these elements allows for better maintenance and troubleshooting, ultimately enhancing performance and longevity.

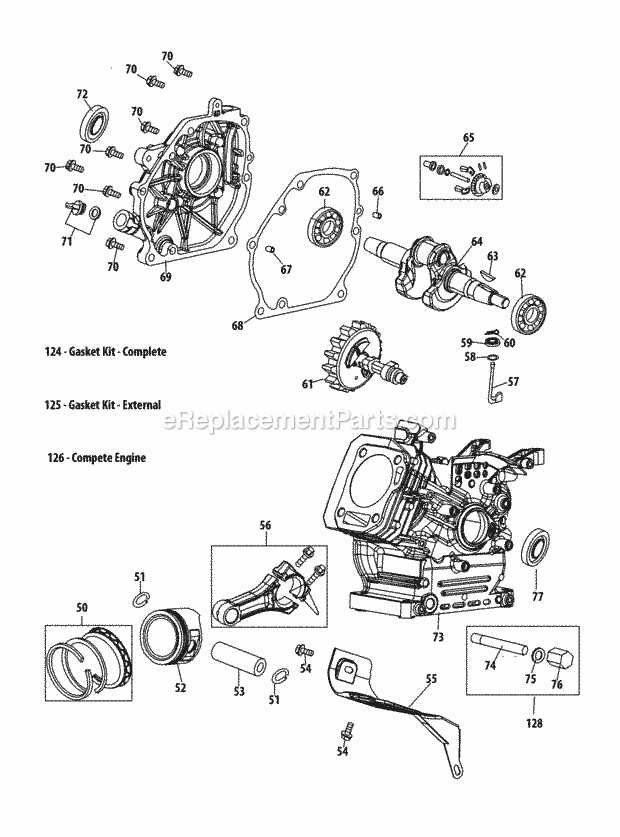

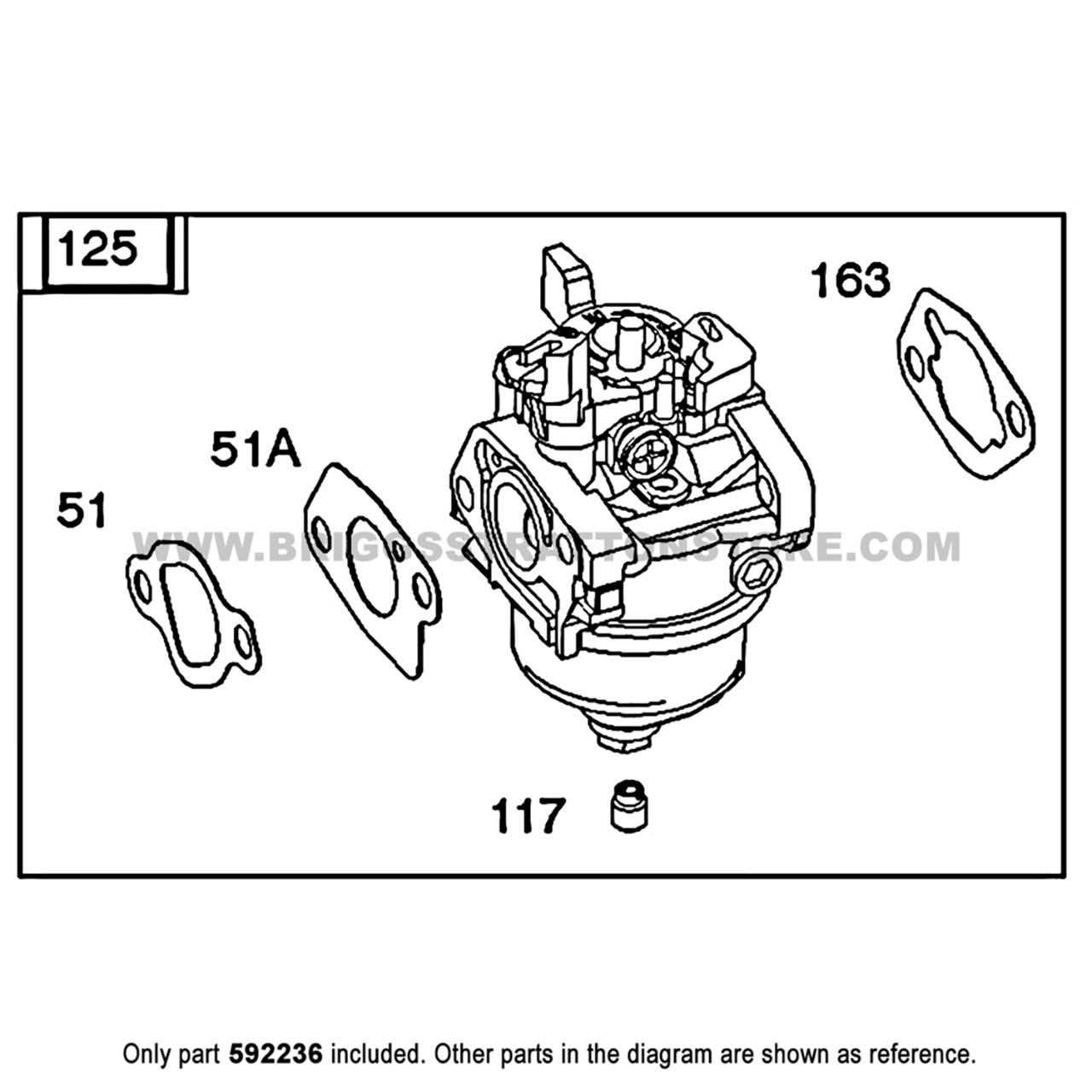

Key Components of Huayi Models

This section explores the essential elements that contribute to the efficiency and functionality of various models. Understanding these components helps users maintain and troubleshoot their equipment effectively.

Main Elements

- Fuel Delivery System

- Air Intake Mechanism

- Adjustment Screws

- Float Chamber

Supporting Components

- Throttle Valve

- Choke Lever

- Gaskets and Seals

- Spring Mechanism

Each of these elements plays a crucial role in ensuring optimal performance and longevity.

Importance of Carburetor Maintenance

Regular upkeep of the fuel mixing system is essential for optimal engine performance and longevity. Neglecting this critical component can lead to various issues that affect both efficiency and functionality.

- Enhances fuel efficiency by ensuring proper air-fuel mixture.

- Prevents engine wear and tear through consistent operation.

- Reduces emissions by maintaining clean combustion.

- Avoids costly repairs resulting from neglect.

Overall, prioritizing the maintenance of this system is key to achieving the ultimate performance from your engine.

How to Access Parts Diagrams

Finding detailed illustrations for various mechanical components can significantly enhance your understanding and facilitate repairs. Accessing these visual guides is essential for both professionals and enthusiasts, as they provide crucial insights into assembly and functionality.

Online Resources

The internet is a treasure trove of information. Numerous websites specialize in providing access to technical visuals. Here are some options:

- Manufacturer Websites: Often, official sites will host extensive documentation.

- Specialized Forums: Communities dedicated to specific equipment can be invaluable.

- DIY Platforms: Websites focused on do-it-yourself projects frequently share valuable resources.

Using Search Engines

Effective search strategies can lead you to the desired visuals quickly. Consider the following tips:

- Use specific keywords related to the component you are interested in.

- Include terms like “schematic,” “illustration,” or “blueprint” in your search.

- Filter results by date to find the most recent updates and information.

Common Issues with Huayi Carburetors

Many users encounter several typical challenges when dealing with these essential fuel delivery devices. Understanding these common problems can lead to more efficient troubleshooting and maintenance, ultimately improving performance and reliability.

| Issue | Description | Possible Solution |

|---|---|---|

| Fuel Leakage | Excess fuel can escape from seals or gaskets, causing spills and potential fire hazards. | Inspect and replace worn seals or gaskets. |

| Starting Difficulties | Engines may struggle to start, often due to improper fuel mixture or blockages. | Check the mixture settings and clean any clogged passages. |

| Uneven Idling | Inconsistent engine speed can indicate airflow or fuel delivery issues. | Adjust the idle settings and clean the intake ports. |

| Stalling | Unexpected engine shutdowns may occur from fuel starvation or ignition problems. | Ensure fuel flow is consistent and inspect ignition components. |

| Excessive Smoke | Smoke from the exhaust can indicate a rich mixture or oil contamination. | Adjust the fuel ratio and check for oil leaks. |

Repairing vs. Replacing Components

When faced with malfunctioning machinery, one often encounters the dilemma of whether to fix existing elements or to acquire new replacements. This decision hinges on several factors, including cost, availability, and the expected longevity of the components in question. Both approaches have their merits and drawbacks, and understanding these can guide one toward a more informed choice.

Benefits of Repairing

Repairing can often be a cost-effective solution. By restoring the original parts, one may extend the life of the equipment without the financial burden of purchasing new items. Additionally, repairing components can enhance familiarity with the machinery, leading to improved maintenance practices in the future. In many cases, specialized tools and skills can allow for effective fixes that preserve the original design.

Advantages of Replacing

On the other hand, replacement may be the better option when the damage is extensive or when parts are outdated. New components often come with warranties and improved technology, potentially enhancing performance and efficiency. Furthermore, obtaining new items may ensure compatibility with other elements, reducing the risk of future issues. While the initial investment may be higher, the long-term reliability can justify the expense.

Ultimately, the choice between repair and replacement should consider not only immediate costs but also the broader implications for performance and longevity.

Where to Find PDF Resources

Accessing detailed technical documentation can greatly enhance your understanding of various components and their functionalities. A wealth of information is available online, making it easier for enthusiasts and professionals alike to locate valuable resources.

Online Platforms

- Manufacturer Websites: Often, official sites provide downloadable materials directly related to their products.

- Technical Forums: Community-driven forums are excellent for sharing and finding user-generated documents.

- Document Sharing Sites: Websites dedicated to sharing files can host a variety of technical resources.

Search Techniques

- Utilize specific keywords relevant to the components you are researching.

- Combine terms with “manual,” “guide,” or “schematic” to refine search results.

- Check academic databases for detailed research papers and articles that might include diagrams.

Understanding Carburetor Functionality

At the heart of many internal combustion engines lies a device responsible for mixing fuel and air in precise proportions. This essential mechanism ensures optimal combustion, thereby influencing engine performance, efficiency, and emissions. A thorough understanding of how this system operates is crucial for both enthusiasts and professionals alike.

Basic Principles of Fuel-Air Mixture

The primary role of this assembly is to achieve an ideal blend of fuel and air. This process involves several components that work in harmony to regulate the flow and pressure of both substances. The mixture’s quality directly affects the engine’s power output and responsiveness, making it vital for smooth operation across various speeds and loads.

Impact on Engine Performance

Tools Required for Repairs

To effectively address maintenance tasks, having the right equipment is essential. A well-equipped workspace can significantly enhance the efficiency and quality of repairs.

- Wrenches: A set of various sizes for loosening and tightening components.

- Screwdrivers: Both flathead and Phillips types for different fasteners.

- Pliers: Useful for gripping and manipulating small parts.

- Torque wrench: Ensures that fittings are secured to the proper specifications.

- Cleaning tools: Brushes and solvents to maintain cleanliness during repairs.

Additionally, consider the following items:

- Safety goggles: Protect your eyes from debris.

- Gloves: Safeguard your hands while handling materials.

- Measuring tools: Calipers or rulers for precision measurements.

Having these tools readily available will streamline the repair process and contribute to successful outcomes.

Identifying Specific Model Parts

Understanding the components of various machinery models is essential for effective maintenance and repair. Each model has unique features and assemblies that require careful examination to ensure compatibility and optimal performance. By familiarizing oneself with these elements, one can streamline the process of identification and replacement.

Recognizing Key Components

Start by obtaining a clear visual representation of the assembly in question. Pay attention to the shapes, sizes, and configurations of the individual elements. This knowledge allows for accurate comparisons when sourcing replacements or upgrades. Identifying the function of each component is equally important, as it provides insight into its role within the overall system.

Using Reference Materials

Consulting reference materials such as manuals or visual guides can significantly aid in the identification process. These resources often highlight specific characteristics and numbers associated with each element, making it easier to match them with available options in the market. Additionally, online forums and communities can be valuable for gathering information from experienced users who can share their insights and tips.

Tips for Effective Troubleshooting

Effective diagnosis of mechanical issues requires a systematic approach. By following a few essential guidelines, one can identify problems more efficiently, ensuring optimal performance and longevity of the equipment.

1. Understand the System

Familiarize yourself with the overall operation of the machinery. Knowing how components interact allows for quicker identification of anomalies. Documentation can be invaluable in this process.

2. Observe and Test

Carefully observe the performance during operation. Look for irregularities such as unusual noises or inefficiencies. Use diagnostic tools to conduct tests that can provide insights into the underlying issues.

Compatibility with Other Engine Models

Understanding the interchangeability of components across various engine types is crucial for maintenance and upgrades. Compatibility not only enhances performance but also simplifies repairs by allowing the use of widely available components. This section explores how certain features and designs align with different engine models, offering insights for users looking to optimize their systems.

Key Factors in Compatibility

- Design Specifications: Dimensions, mounting points, and overall structure play a significant role in ensuring parts can be fitted correctly.

- Performance Characteristics: The functionality and efficiency of components must align with the engine’s specifications to prevent operational issues.

- Material Quality: Durability and resistance to wear are essential for compatibility, as substandard materials may lead to premature failure.

Common Compatible Models

- Model A: Known for its robust performance and similar dimensional attributes.

- Model B: Often utilized for its efficiency and ease of integration with various components.

- Model C: Offers a reliable alternative due to its shared design elements.

By considering these aspects, users can make informed decisions when seeking to enhance their engines through compatible options, ensuring both reliability and performance efficiency.

Best Practices for Carburetor Care

Maintaining optimal performance of your fuel delivery system is crucial for engine efficiency and longevity. By adhering to certain practices, you can ensure that the components function smoothly, reducing wear and preventing costly repairs.

Regular Cleaning

Routine maintenance involves cleaning the internal elements to eliminate residue and buildup. Utilize appropriate solvents and tools to achieve thorough cleaning without damaging delicate components.

Inspection and Adjustment

Frequent inspections allow for early detection of wear or misalignment. Adjusting settings according to manufacturer specifications can enhance performance and fuel efficiency.