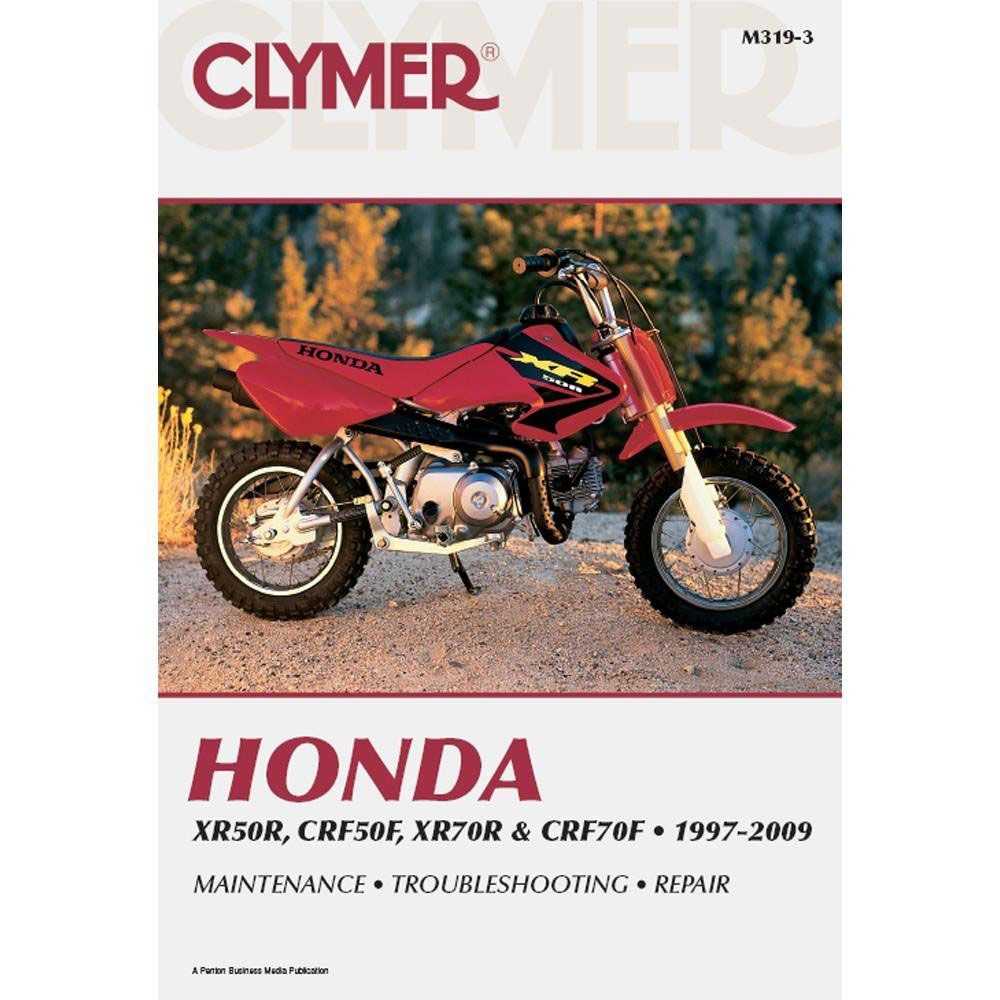

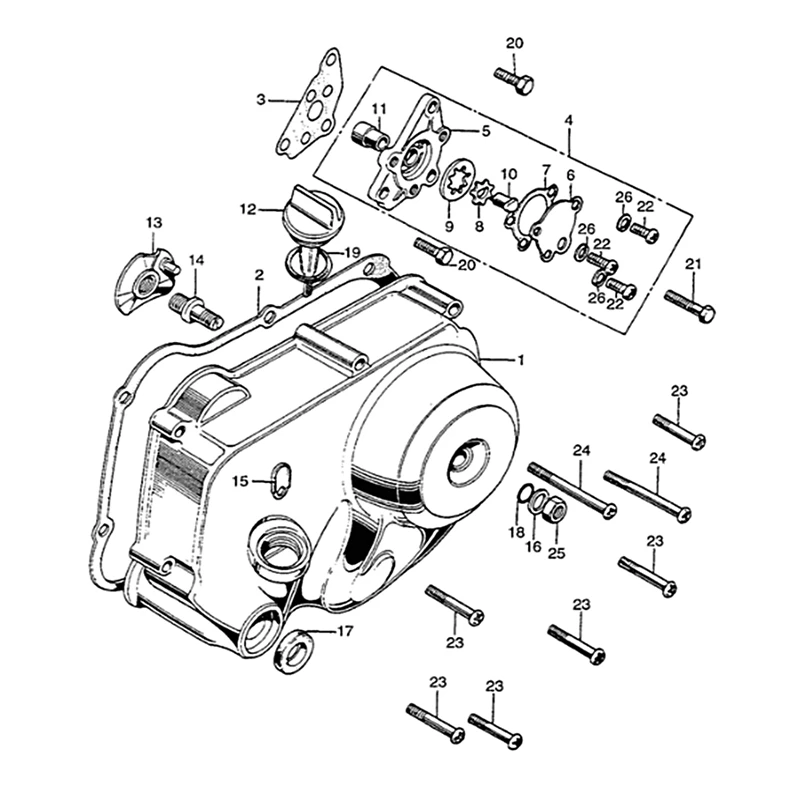

Honda XR50 Parts Diagram Overview

In this section, we will explore the essential components of a small off-road motorcycle, focusing on their arrangement and interaction. Having a clear understanding of how each part fits together is key to maintaining and repairing the vehicle effectively.

Whether you are a beginner or an experienced enthusiast, knowing the individual elements and their connections can simplify the process of troubleshooting or upgrading your machine. This guide will provide a structured overview to help you identify each part and its function within the overall system.

Detailed insights will be provided to ensure you can quickly familiarize yourself with the various systems. By understanding the layout and relationships between different pieces, you will gain confidence in handling repairs or enhancements with greater precision.

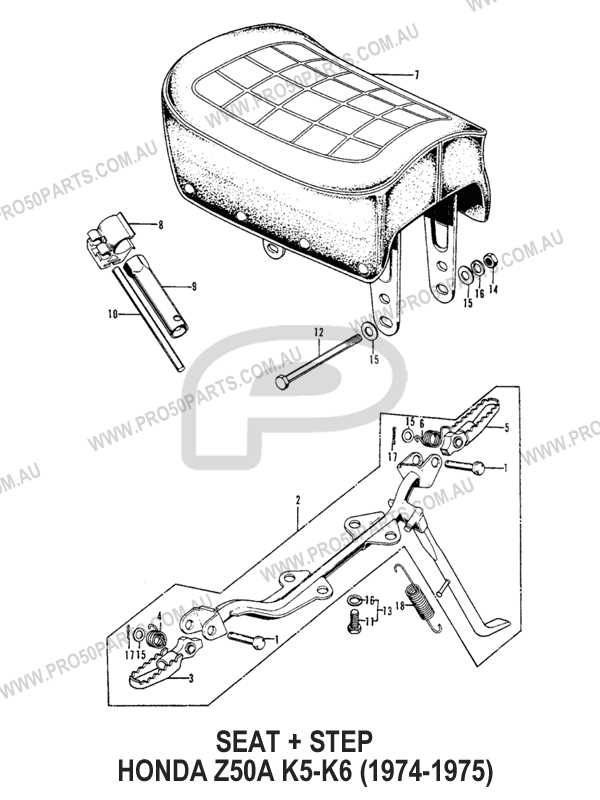

The foundation of any small motorcycle plays a crucial role in its performance, stability, and overall handling. A well-designed frame ensures that the bike can endure various terrains while providing comfort and control for the rider. Here, we explore the significant aspects that define the structure of this compact two-wheeler.

Durability and Strength

The construction material and design choices contribute significantly to the resilience of the framework. Key elements include:

- Robust Frame: Made from high-strength steel or aluminum, enhancing longevity and resistance to wear.

- Reinforced Joints: Critical stress points are strengthened to withstand rigorous riding conditions.

- Lightweight Design: Ensures improved maneuverability without compromising structural integrity.

Handling and Performance

The chassis design directly affects how the vehicle responds during operation. Important features are:

- Geometry: Optimized angles for better cornering and stability at high speeds.

- Suspension System: Advanced components that enhance shock absorption, providing a smoother ride.

- Center of Gravity: A low center of gravity allows for easier handling and improved balance.

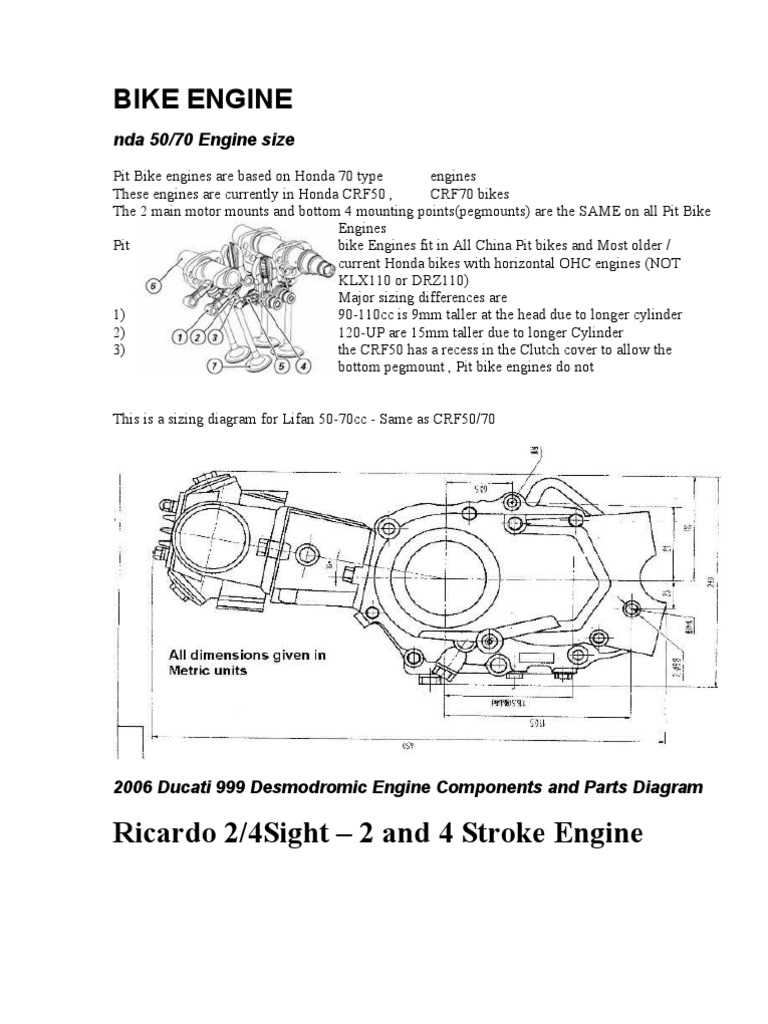

Transmission System Explained

The transmission system is a crucial component responsible for transferring power from the engine to the wheels. It allows the vehicle to move efficiently by adjusting the engine’s output to match the desired speed and load. Understanding how the transmission works can help in maintaining optimal performance and addressing any mechanical issues that may arise.

- Gears: The gears within the system work together to regulate the speed and torque of the vehicle. They are engaged in different combinations to provide the necessary output for various riding conditions.

- Clutch: The clutch connects and disconnects the engine from the transmission, enabling smooth changes in gears without damaging the components.

- Shifter: The shifter is responsible for manually selecting the gear ratio, allowing the rider to control the vehicle’s speed and power delivery.

- Chain or Shaft Drive: The final drive system transfers power from the transmission to the wheels, typically through a chain or shaft that engages the rear sprocket or wheel assembly.

Proper maintenance of these components is vital for smooth operation and longevity of the vehicle. Regular inspections and timely repairs will prevent unnecessary wear and improve the overall riding experience.

How to Identify Suspension Parts

Recognizing the components that make up a vehicle’s shock-absorbing system is essential for maintenance and repair. This system plays a critical role in ensuring smooth handling and stability during rides. Identifying the correct elements requires an understanding of how they function together to provide comfort and control on uneven terrain.

Key Elements of the Suspension

The suspension system consists of several distinct parts, including the fork, shock absorbers, and linkages. Forks are responsible for absorbing impact on the front end, while shock absorbers handle the rear. Each of these parts may vary in design depending on the vehicle type, but their primary function remains consistent. Understanding the differences between each can help in choosing the right replacements.

Visual and Physical Checks

Start by inspecting the shape and size of the shock-absorbing elements. Look for markings, numbers, or brand labels that could give clues to the exact specifications. Also, assess their condition; any signs of wear, rust, or leaking fluid can indicate damage. Finally, measuring the length and thickness of the parts can help identify them more accurately.

Essential Electrical Components Overview

The electrical system of a small off-road vehicle plays a critical role in ensuring its efficient operation. This section provides a detailed look into the key electrical components that power essential functions, from ignition to lighting. Understanding these elements is crucial for proper maintenance and troubleshooting, allowing the rider to keep the machine in optimal working condition.

Key Electrical Elements

- Ignition Coil: Responsible for generating the spark that ignites the fuel-air mixture in the engine.

- Stator: A crucial component that generates electrical power to charge the battery and support other electrical systems.

- Regulator/Rectifier: Converts alternating current (AC) to direct current (DC) and ensures the battery is charged correctly.

- Battery: Powers electrical components such as lights, horn, and the ignition system when the engine is off.

- Fuse: Protects the electrical circuit from overload by disconnecting the flow of power in case of a short circuit.

Wiring and Connections

- Wiring Harness: A collection of wires that connect various electrical components, ensuring that power is delivered effectively.

- Connectors: Essential parts that ensure a secure connection between wires, preventing short circuits or disconnections.

- Switches: Allow the rider to control different systems, such as lights or the ignition system, ensuring efficient operation.

Maintenance of Honda XR50 Wheels

Regular upkeep of the wheels is essential for ensuring smooth and safe operation of any off-road vehicle. Proper maintenance not only extends the lifespan of the wheels but also contributes to optimal performance and handling. Keeping an eye on various components such as tires, rims, and bearings is necessary to avoid potential issues during rides.

- Tire Inspection: Regularly check the tires for signs of wear, cuts, or punctures. Proper tire pressure should be maintained to ensure even wear and proper traction.

- Rim Condition: Inspect the rims for any cracks or bends that could affect the wheel’s balance. If any issues are noticed, replacement or professional repair may be necessary.

- Bearings and Hubs: Lubricate the wheel bearings periodically to keep them functioning smoothly. Worn-out bearings should be replaced to avoid unnecessary strain on the wheel.

By following these simple guidelines, you can ensure the wheels remain in optimal condition, reducing the risk of unexpected breakdowns and enhancing your riding experience.

Handlebars and Controls Breakdown

The handlebar assembly and its related controls are essential components that directly influence the maneuverability and ease of operation of a two-wheeled vehicle. This section provides a detailed look into the individual elements that make up the steering mechanism and control systems, from the grips to the various levers and switches, ensuring smooth and safe handling during rides.

Handlebar Components

The handlebars are not only for steering; they house several important elements that provide functionality and control. Below is a breakdown of the major parts that make up the handlebar assembly:

| Component | Description |

|---|---|

| Grips | Rubber coverings that provide traction and comfort for the rider’s hands. |

| Bar End Plugs | End caps that cover the open ends of the handlebars, often designed for safety. |

| Handlebar Clamps | Fasteners that secure the handlebars to the top triple clamp and ensure stability. |

Control Mechanisms

The controls attached to the handlebars are responsible for operation, from throttle response to braking. These parts are crucial for the rider’s control over the vehicle’s speed and stopping power.

| Control | Function |

|---|---|

| Throttle Grip | Adjusts the engine speed by twisting the grip, controlling acceleration. |

| Front Brake Lever | Activates the front brake system to slow down or stop the vehicle. |

| Clutch Lever | Engages and disengages the clutch, allowing for smooth gear changes. |

Fuel and Carburetor Assembly Guide

In this section, we will explore the essentials of assembling the fuel system and carburetor for a small off-road vehicle. Proper installation and maintenance are crucial to ensure optimal performance and efficiency. A well-functioning fuel delivery system ensures that the engine receives the correct air-fuel mixture, while the carburetor plays a vital role in regulating the mixture for varying engine speeds.

The following table provides a step-by-step breakdown of the components involved in the fuel and carburetor assembly process:

| Step | Component | Description |

|---|---|---|

| 1 | Fuel Tank | Ensure the fuel tank is securely mounted and connected to the fuel lines for proper fuel flow. |

| 2 | Fuel Lines | Check for leaks and make sure the lines are connected tightly to prevent fuel loss. |

| 3 | Carburetor | Install the carburetor to the intake manifold, ensuring that the gaskets are properly seated to avoid air leaks. |

| 4 | Air Filter | Fit the air filter onto the carburetor to ensure proper filtration of the incoming air, promoting clean combustion. |

| 5 | Fuel Shutoff Valve | Install the fuel shutoff valve in an easily accessible location to control fuel flow when necessary. |

Once all components are assembled and secured, ensure that the fuel system is primed and test the engine for any irregularities. Adjust the carburetor settings if necessary to fine-tune the engine’s air-fuel mixture for smooth operation.

Braking System Insights

The braking system of a small off-road bike is crucial for ensuring rider safety and control. Understanding the key components that contribute to effective stopping power can help in maintaining and optimizing the vehicle’s performance. This section explores the essential elements of the braking system, including the mechanical aspects, materials, and maintenance tips.

Key Components

The braking system consists of several components that work in unison to reduce speed and bring the bike to a halt. These parts include the brake levers, calipers, pads, and the wheel hubs. The interaction between these elements is vital for a responsive and reliable braking experience.

| Component | Function |

|---|---|

| Brake Lever | Engages the braking mechanism when pulled by the rider. |

| Brake Pads | Creates friction against the wheel, converting kinetic energy into heat. |

| Calipers | Holds the brake pads in place and applies pressure to them. |

| Wheel Hubs | The mounting point for the braking system, where friction is applied. |

Maintenance Tips

Regular maintenance of the braking system ensures optimal performance and extends the life of its components. It is recommended to check the brake pads for wear, ensure the calipers are functioning smoothly, and verify the proper alignment of the braking components. Regularly lubricating the brake levers and inspecting the system for any damage will help maintain safety standards.

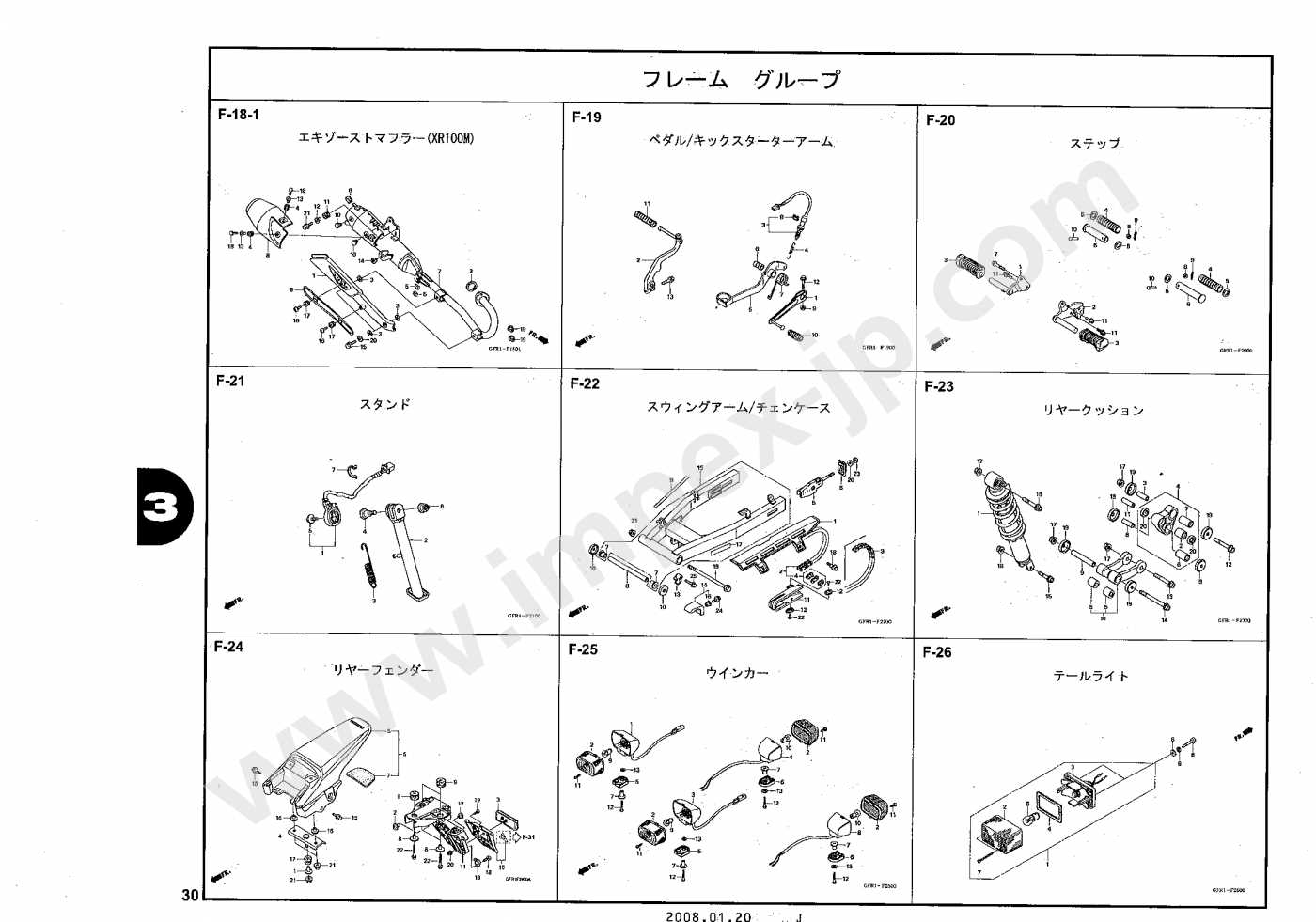

Understanding the Exhaust System

The exhaust system is a critical component of any small engine. It serves multiple essential functions, from reducing engine noise to efficiently expelling combustion gases. Without a properly functioning exhaust, the engine’s performance and lifespan can be compromised.

Key parts of this system include:

- Exhaust pipe: Directs gases away from the engine.

- Muffler: Reduces noise produced by the engine.

- Exhaust manifold: Collects gases from the cylinders and channels them into the exhaust pipe.

Maintaining this system is important to ensure the engine runs smoothly and avoids overheating. Here are a few maintenance tips:

- Check for any cracks or leaks in the exhaust components.

- Ensure the muffler is not clogged, which can lead to decreased performance.

- Inspect mounting bolts and fastenings to prevent vibrations that could cause damage.

Proper care of the exhaust system ensures the engine runs at peak efficiency while minimizing environmental impact.