Cub Cadet SC300 Parts Diagram Overview

For enthusiasts and professionals alike, maintaining a lawn mower is essential for optimal performance and longevity. Recognizing the various elements that make up these machines is crucial, as it allows for effective troubleshooting and repair. A thorough comprehension of how each part functions can significantly enhance your experience and ensure a well-kept yard.

When you have a clear visual representation of the machine’s components, it simplifies the process of identifying issues or planning maintenance. This resource not only provides insight into the assembly but also highlights the relationships between individual elements, fostering a deeper understanding of the mower’s operation.

In this section, we will explore the intricate details of the mower’s configuration, offering a detailed overview that aids in both repair and optimization. Whether you are a seasoned technician or a casual user, having access to this information is invaluable for enhancing your mower’s efficiency and reliability.

Understanding the Cub Cadet SC300

This section provides insight into a popular model of lawn care equipment, focusing on its design and functionality. By exploring various components and their roles, users can gain a comprehensive understanding of its operation and maintenance. Knowing the intricacies of the machine enhances the overall experience and ensures optimal performance.

Key Features

The machine is equipped with several notable features that contribute to its efficiency. Each element plays a vital role in delivering a reliable performance during yard maintenance tasks.

| Feature | Description |

|---|---|

| Engine | Powerful motor designed for robust cutting. |

| Cutting Deck | Durable construction for extended lifespan and effective grass trimming. |

| Height Adjustment | Easy modification for different grass lengths. |

| Handle Ergonomics | Comfortable grip to reduce user fatigue during operation. |

Maintenance Tips

- Check oil levels regularly to ensure proper engine function.

- Clean the cutting deck after each use to prevent grass buildup.

- Inspect the blades for sharpness and replace when necessary.

- Store in a dry place to avoid rust and damage during off-season.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of individual elements help users identify specific items, ensuring that they can locate and address issues with precision. This approach streamlines the repair process and enhances overall efficiency.

Facilitating Repairs

When individuals can easily reference a visual guide, they are better equipped to troubleshoot problems. These illustrations provide clarity, allowing for quick identification of required components and reducing the time spent searching for information. This efficiency is especially crucial in urgent repair situations.

Enhancing Knowledge

Visual aids not only assist in repairs but also contribute to a deeper understanding of the equipment. By studying these representations, users can learn about the function and relationship of each component. This knowledge empowers them to make informed decisions regarding maintenance and upgrades, ultimately extending the lifespan of their machinery.

Common Issues with SC300 Components

Many users encounter a range of challenges with various elements of their equipment, which can affect overall performance and reliability. Identifying these common problems is essential for maintaining optimal functionality and extending the lifespan of the machinery. Below are some frequently reported issues associated with specific components.

Engine Performance Problems

One of the most prevalent concerns involves engine operation. Users may notice difficulty starting, uneven idling, or unexpected shutdowns. These symptoms can often be traced back to fuel delivery issues, clogged air filters, or spark plug malfunctions. Regular maintenance and inspections can help mitigate these problems.

Deck and Blade Issues

The cutting deck and blades are crucial for achieving a clean cut. Common issues include uneven cutting, excessive vibration, or blade wear. These problems can result from dull blades, misalignment, or debris buildup. Ensuring proper maintenance, such as regular sharpening and cleaning, can significantly enhance cutting performance.

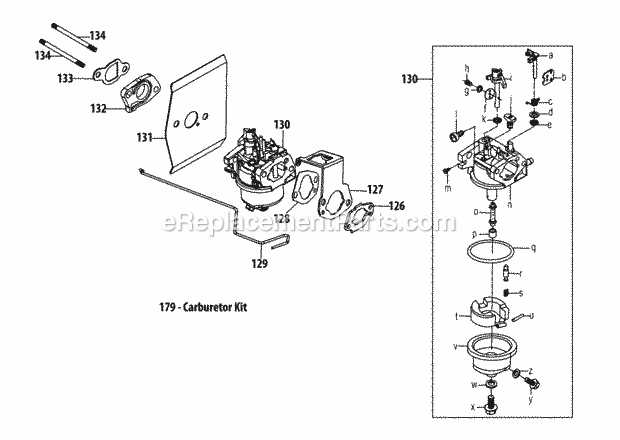

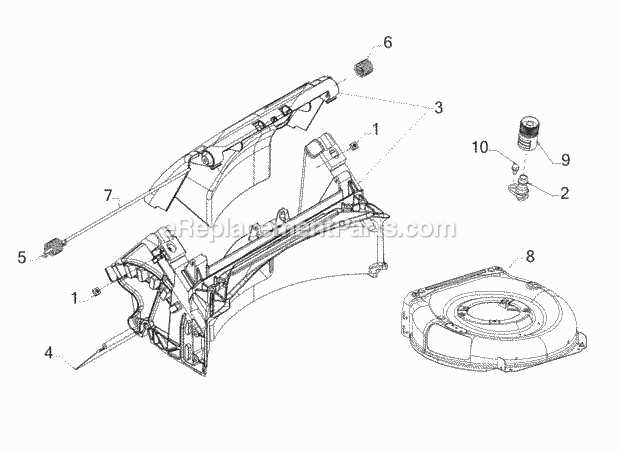

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair tasks. These visual representations provide a detailed overview of components, their arrangement, and how they interact within a system. By mastering this skill, you can streamline your repair process and ensure that every piece is correctly identified and utilized.

To begin, familiarize yourself with the layout. Typically, the image is divided into sections, each representing a specific area of the machinery. Pay attention to labels and reference numbers, as these are key for locating and ordering individual components. Often, a corresponding list will accompany the illustration, providing additional details such as part names and specifications.

Next, observe the connections between elements. Arrows and lines may indicate how parts fit together or highlight movement paths. Understanding these relationships is essential for troubleshooting and assembly. Additionally, note any notes or instructions that might be included; they often contain valuable information regarding the installation or removal processes.

Lastly, take your time to analyze each segment methodically. It can be helpful to cross-reference with the manufacturer’s manual or online resources. This practice not only enhances your comprehension but also builds your confidence in handling repairs efficiently.

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right equipment is crucial. Proper tools not only make the job easier but also ensure that repairs are done correctly and efficiently. Below is a list of must-have tools that can help you tackle various tasks with confidence.

- Wrenches: Essential for loosening and tightening bolts and nuts.

- Screwdrivers: A variety of sizes and types (flathead and Phillips) are necessary for different screws.

- Socket Set: Offers versatility for working with fasteners in tight spaces.

- Pliers: Useful for gripping, twisting, and cutting wire or small parts.

- Multimeter: An indispensable tool for diagnosing electrical issues.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Safety Gear: Includes gloves, goggles, and masks to protect yourself while working.

Investing in high-quality tools can save time and enhance the quality of repairs. Whether you’re a seasoned mechanic or a beginner, these essentials will equip you for a variety of maintenance challenges.

Finding Replacement Parts Online

In today’s digital age, sourcing components for your equipment has become more accessible than ever. With a few clicks, you can explore various platforms that offer a wide selection of necessary items, ensuring your machine runs smoothly and efficiently. This convenience saves time and often provides better pricing options compared to local retailers.

When searching online, it’s crucial to utilize reputable websites that specialize in outdoor machinery supplies. Look for detailed listings that include specifications, compatibility information, and user reviews. This approach not only helps in identifying the correct items but also provides insights into the reliability of the vendor.

Another valuable tip is to utilize online forums and community groups. Enthusiasts and professionals often share their experiences and recommendations, guiding you to trustworthy sources. Engaging in these communities can also offer troubleshooting advice and maintenance tips that enhance your understanding of your equipment.

Always double-check the return policies and warranty options before making a purchase. This ensures that if the component doesn’t meet your needs, you have the flexibility to return it without hassle. By following these steps, you can confidently navigate the online marketplace and find the right replacements for your machinery.

Maintenance Tips for Longevity

Proper care and attention are essential for ensuring the longevity and efficient operation of your outdoor equipment. By following a regular maintenance schedule and implementing best practices, you can enhance performance and extend the lifespan of your machine. Here are some key tips to help you achieve optimal results.

Regular Cleaning

Keeping your equipment clean is vital. After each use, remove grass clippings, dirt, and debris from the exterior and undercarriage. This not only prevents rust but also maintains airflow and cooling efficiency. Use a soft brush or compressed air for hard-to-reach areas.

Routine Inspections

Conduct regular inspections to identify wear and tear before they become major issues. Check belts, cables, and blades for signs of damage or fraying. Replacing worn parts promptly can prevent further complications and ensure your machine operates smoothly. Additionally, verify that all fasteners are tightened and secure to avoid any operational mishaps.

By implementing these maintenance practices, you can ensure your equipment remains reliable and efficient for many seasons to come.

Identifying Parts by Model Number

Understanding the specific components of a machine is crucial for effective maintenance and repairs. By utilizing model numbers, users can pinpoint exact pieces required for their equipment, ensuring compatibility and optimal performance. This systematic approach aids in avoiding errors and enhances the overall efficiency of repair processes.

Why Model Numbers Matter

Model numbers serve as unique identifiers for each machine, providing essential information about its design and specifications. Here are key reasons to focus on model numbers:

- Ensures accuracy in ordering replacements.

- Facilitates the search for user manuals and maintenance guides.

- Aids in identifying compatible accessories and upgrades.

How to Find Model Numbers

Locating the model number on your equipment can vary based on the manufacturer. Follow these steps to find it easily:

- Check the user manual; it often lists the location.

- Inspect the frame or body; it may be stamped or printed.

- Look for a label on the engine or motor.

- Search online resources provided by the manufacturer for guidance.

Comparing SC300 with Other Models

In the realm of outdoor power equipment, assessing various models can reveal significant differences in performance, durability, and user experience. This section delves into how a particular model stacks up against its peers, highlighting key features that may influence consumer choices.

Performance and Efficiency

When evaluating machinery, performance metrics such as engine power, cutting width, and fuel efficiency are critical. Some models may excel in speed and handling, while others prioritize energy conservation. A thorough comparison will illuminate which options offer superior results for specific lawn care needs.

Durability and Maintenance

Another essential aspect is the longevity and upkeep of the equipment. Variations in materials used and construction methods can lead to significant disparities in durability. Understanding the maintenance requirements of each model, including ease of access to components for repairs, can help users make informed decisions about their investments.

Cost Analysis of Replacement Parts

When it comes to maintaining outdoor equipment, understanding the financial implications of component replacements is crucial. The cost of these essential items can vary significantly based on quality, brand, and availability. This analysis provides insights into how to navigate these expenses effectively, ensuring that users can make informed decisions.

Factors Influencing Pricing

Several elements play a pivotal role in determining the cost of components. Brand reputation often affects price; well-known manufacturers typically charge a premium due to their reliability and warranty offers. Additionally, material quality can lead to disparities in pricing, with more durable options often costing more upfront but potentially saving money in the long run through reduced frequency of replacements.

Long-term Investment Considerations

Investing in higher-quality replacements may seem more expensive initially, but this can result in lower maintenance costs over time. It’s essential to evaluate the overall lifecycle of the equipment and consider how often components may need to be changed. Budgeting for these replacements should account for both immediate costs and the potential for increased longevity and performance.