Understanding the Craftsman 21 Inch 179cc Snowblower Parts

When tackling the challenges of winter, having a reliable machine to clear your path is crucial. Each component plays a vital role in ensuring the system functions smoothly, allowing you to effortlessly handle even the heaviest accumulations. Understanding how these elements interact can provide better insight into maintaining and repairing the machine.

By recognizing the purpose and position of individual elements, you can extend the lifespan of your equipment. This knowledge simplifies the process of identifying necessary replacements and upgrades. Whether it’s related to performance or upkeep, having a clear layout of these components is invaluable.

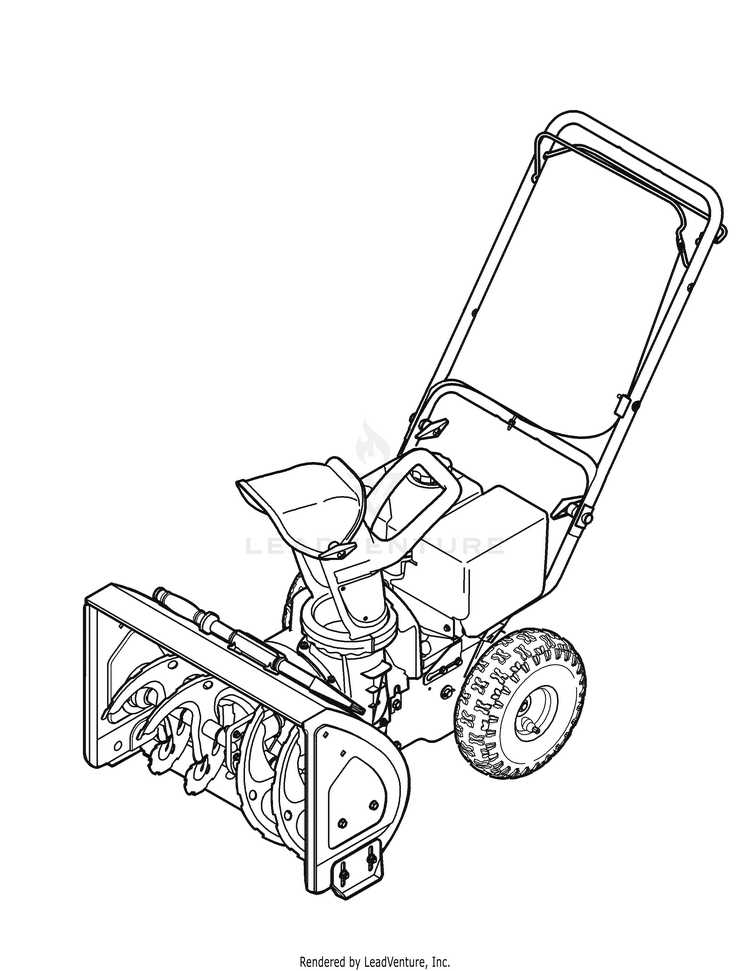

Craftsman 21 Inch Snowblower Overview

This compact winter machine is designed to handle challenging conditions and keep walkways clear during heavy snowfall. Equipped with a powerful engine, it ensures efficient performance, making it a practical choice for home use. With a focus on reliability and ease of use, this equipment is built for long-term durability.

Design and Functionality

The equipment features a streamlined design, allowing it to navigate narrow paths with ease. Its ergonomic controls simplify operation, even in tough winter conditions. Built to manage dense snow, it offers consistent results, making it an excellent choice for those looking for both power and convenience.

Performance Features

Equipped with an engine capable of delivering strong power output, the machine offers high efficiency in snow clearing. It is designed to optimize fuel usage while maintaining robust performance, ensuring that even large tasks can be handled with minimal effort.

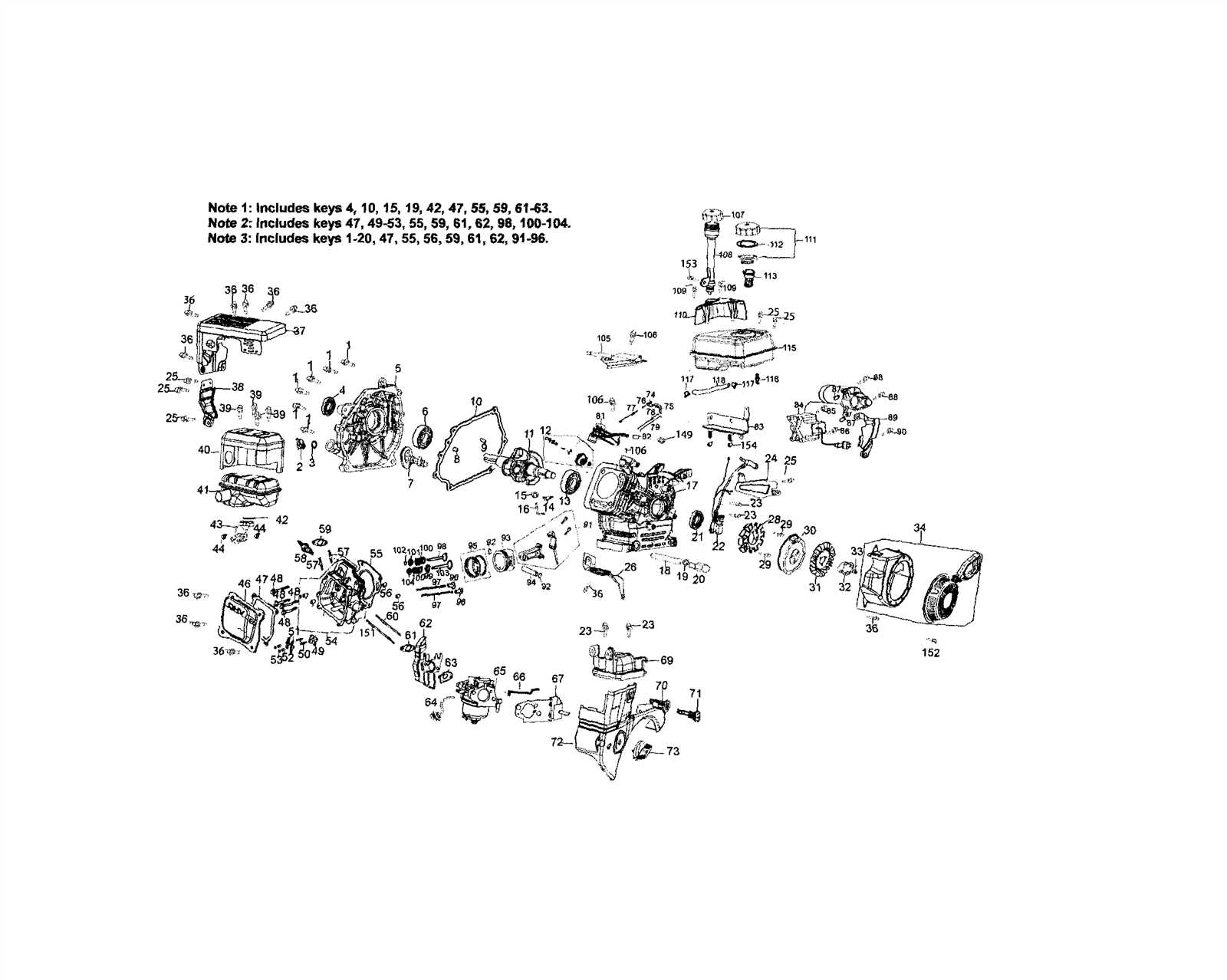

Key Components of the 179cc Engine

The core elements of a small gas-powered engine work together to ensure smooth and reliable performance. Understanding the fundamental parts of this machine helps in maintaining it and enhancing its longevity, ensuring efficiency in tough conditions.

- Cylinder Block: The foundation of the engine, it houses the moving parts and is crucial for the combustion process.

- Piston: Responsible for transferring energy from combustion to mechanical movement, enabling the engine’s operation.

- Crankshaft: Converts the linear motion of the piston into rotational motion, driving the machine forward.

- Camshaft: Coordinates the opening and closing of the engine’s valves, ensuring precise fuel intake and exhaust release.

- Effective for breaking down compacted layers

- Ensures constant intake for uninterrupted flow

Exploring the Auger and Impeller System

The mechanism responsible for efficiently gathering and moving snow includes two key components, each with distinct roles. Understanding how these elements work together is essential for grasping the overall operation of the machine, ensuring a smooth and effective performance in challenging conditions.

The Role of the Auger

The first stage of the clearing process is driven by a rotating blade designed to scoop and funnel material into the machine. This component continuously spins, drawing in the accumulation from the surface and channeling it toward the next phase.

Understanding the Impeller

The second key element is a high-speed fan that propels the collected material out through the chute. Its rapid rotation expels the snow with force, allowing it to be discharged at a distance away from the cleared path.

- Gather the necessary tools, including wrenches, screwdrivers, and replacement parts.

- Disconnect the equipment from any power source to ensure safety during the replacement process.

- Carefully remove the worn components by unscrewing or unclipping them as needed.

- Install the new parts, ensuring they fit securely and function correctly.

- Reconnect the power source and conduct a thorough test to confirm that everything operates smoothly.

Handle and Control Panel Breakdown

The structure and layout of the control area play a crucial role in the overall operation of the equipment. It includes various levers, buttons, and grips that allow the user to maneuver and control the machine effectively. Understanding how these elements are organized helps in ensuring smooth functionality and ease of use.

Main Handle Features

The main handle offers a firm grip and stability during operation, designed for comfort and ease of control. Various settings and controls are often positioned within reach, allowing quick adjustments without interrupting the workflow.

Control Panel Layout

The control panel provides access to essential functions, such as speed regulation and directional changes. It houses several key components like levers and switches, designed for intuitive use. Proper alignment of these elements is important for ensuring that the equipment responds accurately to user input.

Understanding the Drive System Mechanism

The propulsion system plays a crucial role in ensuring smooth and efficient movement, transferring power from the engine to the wheels. By understanding its components and how they interact, you can better maintain and troubleshoot any issues that arise. The mechanism operates using a combination of gears, belts, and other elements that work in harmony to provide the necessary force for movement.

Key Components of the Drive System

The driving force is transmitted through a series of interconnected parts. A critical element is the transmission, which helps control the speed and direction of movement. Additionally, belts are essential in linking the power source to the motion mechanisms, ensuring effective force distribution.

Maintaining the Drive System

Regular upkeep of the propulsion setup ensures longevity and smooth operation. Inspecting belts for wear and tear, checking gears for alignment, and keeping the system lubricated can prevent common issues and prolong the system’s functionality. Proper maintenance reduces the likelihood of breakdowns and ensures reliable performance.

Snow Discharge Chute Parts and Assembly

The efficient movement of frozen precipitation relies heavily on the various components of the discharge chute. This crucial assembly directs the expelled snow, ensuring optimal performance and preventing blockages. Understanding the individual elements involved in this system can greatly enhance its functionality and maintenance.

The main components of the chute assembly play a vital role in its operation. Below is a breakdown of these elements and their respective functions:

| Component | Description |

|---|---|

| Chute Housing | The outer shell that contains and guides the snow as it is expelled. |

| Deflector | Adjustable piece that controls the height and direction of the discharged snow. |

| Crank Handle | Manual control used to adjust the angle of the deflector for precise snow placement. |

| Mounting Brackets | Support structures that secure the chute to the main body, ensuring stability during operation. |

| Rotating Shaft | Enables the movement of the chute assembly, allowing for directional adjustments while in use. |

Proper assembly and regular inspection of these components are essential for maintaining peak efficiency. Familiarizing oneself with each part’s function allows for quicker troubleshooting and more effective upkeep of the entire system.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of outdoor machinery. By following a few straightforward practices, you can extend the lifespan of your equipment and enhance its performance during the winter months.

Firstly, always check and change the oil according to the manufacturer’s recommendations. Clean oil minimizes wear on the internal components and keeps the engine running smoothly. Additionally, inspect and replace air filters regularly to prevent debris from clogging the system, which can lead to overheating.

Furthermore, sharpen or replace the cutting blades as needed. Dull blades can strain the motor and reduce efficiency. Ensure that all screws and bolts are tightened to prevent loose parts from causing damage during operation.

Finally, storing your equipment in a dry place and using protective covers can help shield it from harsh weather conditions. Regularly cleaning the exterior also prevents rust and corrosion, preserving its appearance and functionality.

Common Issues and Their Solutions

In the realm of outdoor machinery, various challenges may arise during operation, impacting performance and efficiency. Identifying these common problems and understanding how to address them is essential for maintaining optimal functionality and longevity. Below are some frequent concerns encountered by users and practical solutions to resolve them.

Engine Not Starting

A prevalent issue is the inability of the engine to ignite. This could stem from several factors, such as fuel supply problems, a faulty spark plug, or a drained battery. To troubleshoot, ensure that the fuel is fresh and that the tank is filled. Check the spark plug for wear and replace it if necessary. Additionally, inspect the battery connections to confirm they are secure.

Insufficient Snow Clearing

Another common challenge is the machine’s failure to clear snow effectively. This may result from dull blades, improper height settings, or clogs in the discharge chute. To enhance performance, regularly sharpen or replace the blades, adjust the height settings according to the snow depth, and clear any debris from the chute to ensure unobstructed flow.

How to Replace Worn-Out Components

Maintaining your outdoor equipment involves ensuring that all its elements function optimally. Over time, certain components may wear out, affecting performance and efficiency. Knowing how to identify and replace these worn-out parts is crucial for keeping your machinery in excellent working condition.

Identifying Worn Components

The first step in the replacement process is to assess the various components of your equipment. Look for signs of wear such as cracks, rust, or unusual noises during operation. Regular inspections can help you catch potential issues early, allowing for timely replacements and preventing further damage.

Steps for Replacement

Once you have identified the components that need replacing, follow these steps for a successful replacement:

Detailed Belt and Pulley Diagram

The intricate relationship between belts and pulleys is crucial for the efficient operation of machinery. This section explores the layout and functionality of these components, which work together to transfer power and facilitate movement within the system. Understanding how these elements interact is essential for maintenance and troubleshooting.

Belt systems are designed to connect various parts of a machine, enabling them to function cohesively. The pulleys play a vital role in this setup by changing the direction of force and optimizing the speed of the connected components. Each element’s position and alignment are significant for overall performance, highlighting the importance of an accurate representation.

To ensure longevity and proper operation, regular inspection of these components is recommended. Identifying wear or misalignment early can prevent more significant issues, contributing to the reliability of the entire machine.

Safety Features and Operational Guidelines

When operating outdoor machinery, understanding the essential safety features and following proper guidelines is crucial for ensuring both personal safety and optimal functionality. Adhering to these practices can prevent accidents and enhance the performance of the equipment.

Protective mechanisms are designed to safeguard the user during operation. These may include features such as automatic shutoff systems, safety guards, and controls that require both hands to operate. Familiarizing oneself with these elements is vital for effective and secure use.

Before beginning work, it is important to read the manual thoroughly. This document provides detailed instructions regarding safe operation, maintenance routines, and troubleshooting tips. Regular checks for wear and tear on components can significantly reduce the risk of malfunction during use.

Additionally, wearing appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, is recommended to minimize the risk of injury. Maintaining a clean work area free of debris will also contribute to a safer environment.

By prioritizing safety features and adhering to operational guidelines, users can ensure a productive experience while effectively handling their outdoor equipment.