Comprehensive Guide to Mercruiser 5.7 Engine Parts Diagram

For enthusiasts and professionals alike, comprehending the intricate details of a watercraft’s propulsion system is essential. This knowledge not only enhances performance but also aids in efficient maintenance. Each segment plays a pivotal role in ensuring smooth operation and reliability during voyages.

In this section, we will explore a comprehensive visual representation of the various elements that make up this specific type of marine power source. From the core machinery to auxiliary components, understanding their arrangement and function can significantly impact the overall functionality.

Whether you are troubleshooting an issue or simply curious about the mechanics at play, delving into the specifics of these assemblies will provide valuable insights. Mastering the layout and interconnections will empower you to optimize your vessel’s performance and prolong its lifespan.

Understanding Mercruiser 5.7 Engine Components

Grasping the intricacies of a marine propulsion system requires a keen awareness of its various elements and their interrelations. Each component plays a crucial role in ensuring optimal performance and reliability. By examining these elements, one can appreciate how they work together to facilitate smooth operation in challenging aquatic environments.

Core Elements and Their Functions

At the heart of any propulsion mechanism lies a collection of vital components, each with specific functions. The combustion chamber ignites fuel to create power, while the cooling system prevents overheating, safeguarding the integrity of the unit. Additionally, the transmission system enables effective power transfer to the propeller, allowing for efficient navigation.

Maintenance and Upkeep

Regular maintenance of these essential components is paramount for longevity and performance. Routine inspections can identify wear and tear, while timely replacements ensure that the system operates smoothly. Understanding the unique characteristics of each element not only aids in maintenance but also enhances overall operational knowledge, empowering users to troubleshoot issues as they arise.

Essential Parts of Mercruiser 5.7

Understanding the key components of a marine propulsion system is crucial for optimal performance and maintenance. Each element plays a vital role in ensuring smooth operation, longevity, and efficiency on the water. From power generation to fluid management, these essential components work together seamlessly.

Power Unit: The heart of the system, this component is responsible for converting fuel into mechanical energy. Its design significantly impacts performance and responsiveness.

Cooling Mechanism: Proper temperature regulation is critical. This part circulates coolant to prevent overheating, ensuring that the system operates within safe limits.

Fuel Delivery System: This assembly ensures that the right amount of fuel reaches the combustion chamber. Its efficiency directly affects power output and fuel consumption.

Ignition Assembly: This component initiates the combustion process. A reliable ignition system is essential for starting and sustaining optimal performance.

Exhaust Management: Efficient removal of exhaust gases is vital for maintaining performance. This system minimizes back pressure and enhances the overall efficiency of the unit.

Transmission Setup: This element connects the power unit to the propeller, allowing for the transfer of power while managing torque and speed effectively.

By familiarizing oneself with these fundamental components, one can better appreciate the intricacies of marine propulsion technology and enhance maintenance practices.

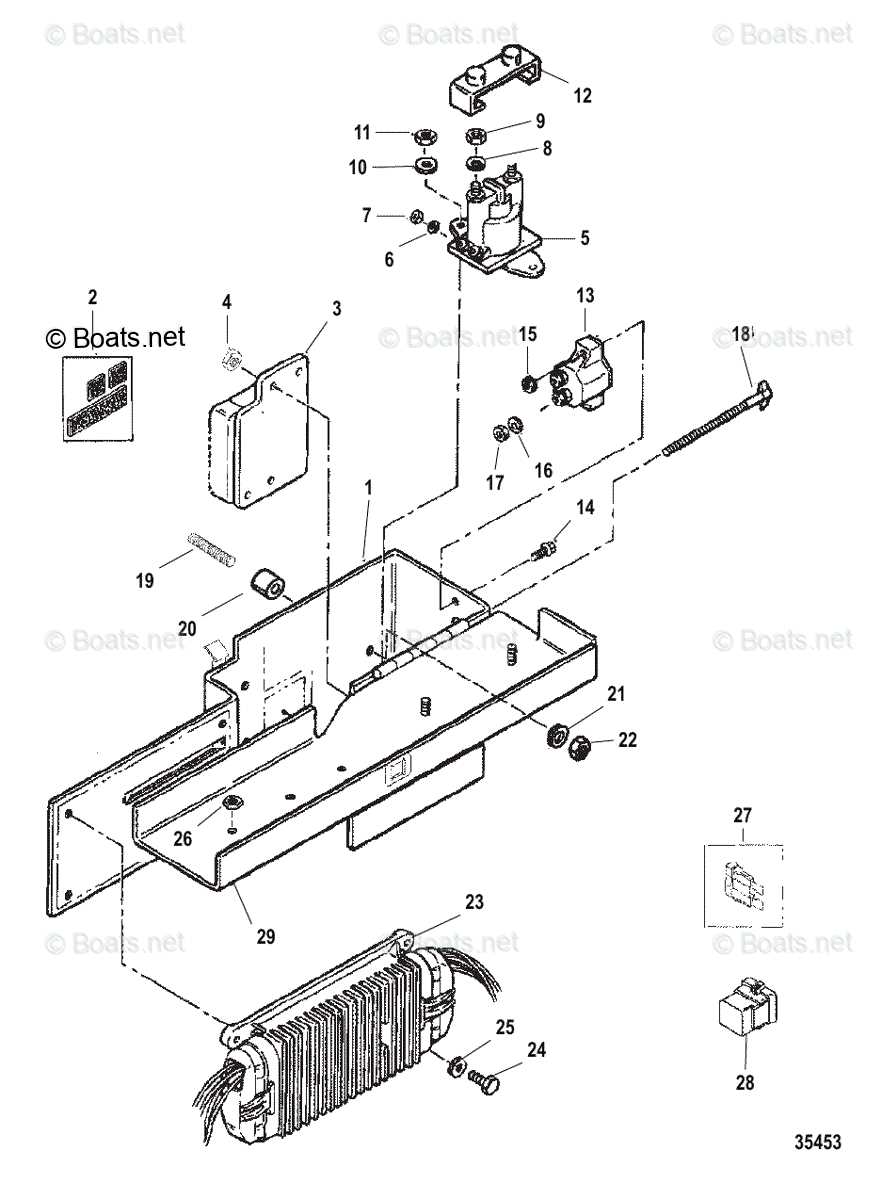

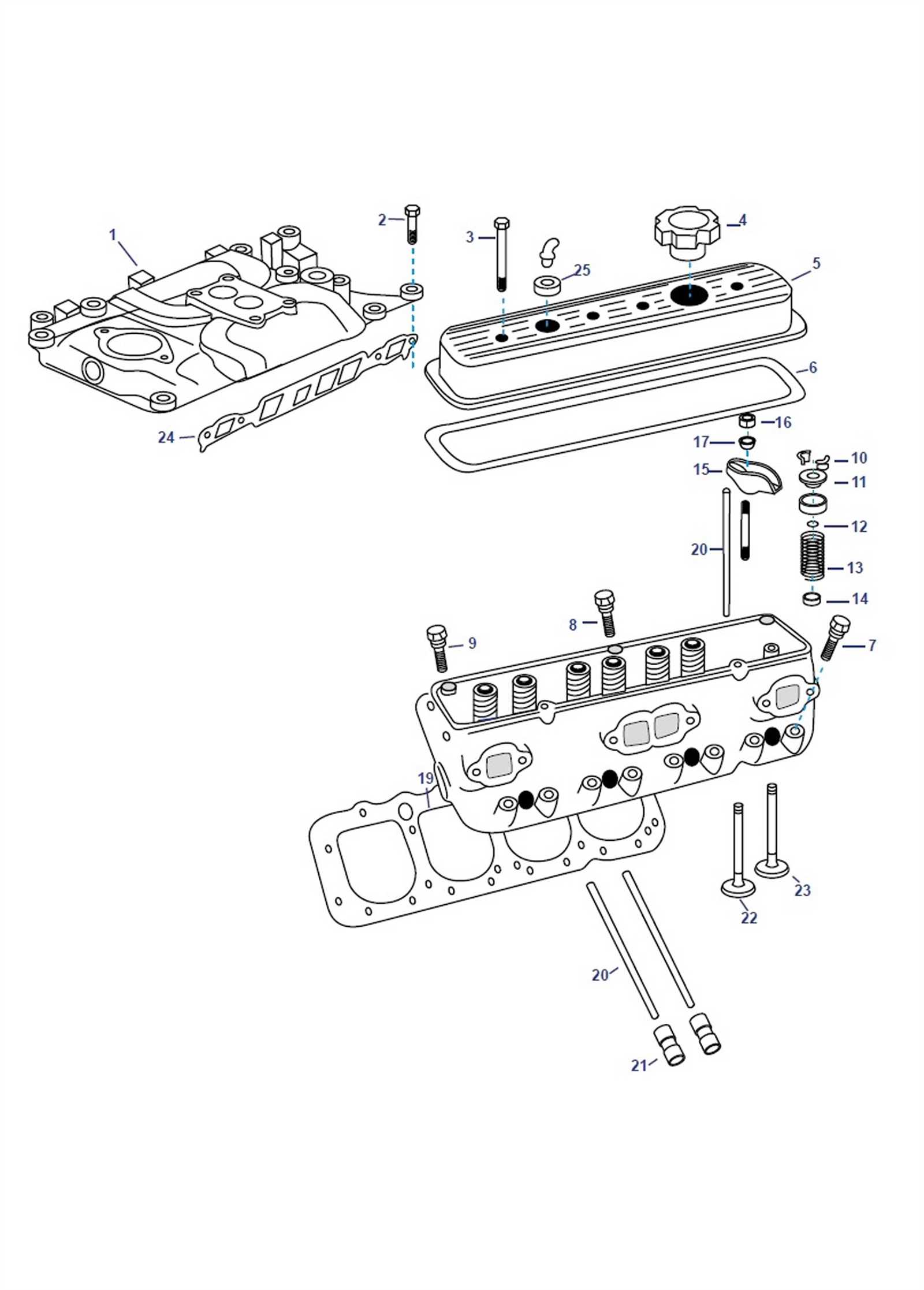

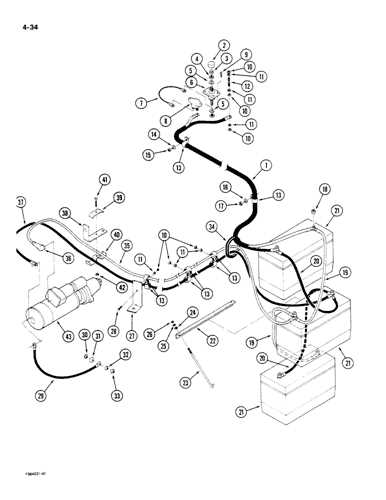

Exploring the Engine’s Diagram Layout

Understanding the arrangement of components within a mechanical system is crucial for effective maintenance and troubleshooting. This layout provides a visual representation that simplifies the complexity of various elements, allowing for easier identification and comprehension of their functions. By dissecting the structure, one can appreciate the intricate relationships between different sections and how they contribute to overall performance.

Component Relationships

Each section within the schematic serves a specific role, working in harmony to ensure optimal functionality. By examining the interactions among these elements, users can gain insights into how modifications or repairs in one area might impact others. This knowledge is vital for maintaining efficiency and preventing potential issues.

Practical Applications

Utilizing the visual representation effectively can enhance repair strategies and maintenance routines. Technicians and enthusiasts alike benefit from having a clear overview, as it enables them to pinpoint areas that require attention and streamline their work processes. A thorough understanding of the layout ultimately leads to improved operational reliability.

Common Issues with 5.7 Engine Parts

In any mechanical system, certain challenges can arise that may compromise performance and reliability. Understanding these common problems is crucial for maintaining optimal function and ensuring longevity. This section highlights frequent complications encountered in this specific power unit’s components.

Wear and Tear

Over time, natural deterioration of materials can lead to significant issues. Components may experience friction and corrosion, which can result in diminished efficiency. Regular inspection is essential to identify signs of wear early, preventing more serious damage.

Cooling System Failures

The cooling mechanism plays a vital role in maintaining safe operational temperatures. If this system becomes compromised, overheating may occur, potentially damaging internal components. It is advisable to check for leaks, blockages, and the overall condition of the cooling elements to ensure they function effectively.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your marine power unit requires a proactive approach to upkeep. Regular maintenance not only enhances performance but also prevents potential issues that could lead to costly repairs. Here are essential practices to keep your watercraft running smoothly.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 50 hours of operation | Improves lubrication, reduces wear, and enhances efficiency. |

| Coolant Check | Annually | Prevents overheating and protects internal components. |

| Fuel Filter Replacement | Every season | Ensures clean fuel supply, optimizing combustion and power. |

| Spark Plug Inspection | Every 100 hours | Enhances ignition, leading to better fuel efficiency and performance. |

| Belt and Hose Inspection | Monthly | Detects wear and tear early, preventing breakdowns. |

By adhering to these guidelines, you can significantly improve the reliability and functionality of your marine vessel. Regular attention to these areas not only extends the lifespan of your machinery but also ensures enjoyable and safe experiences on the water.

Identifying Key Parts in Diagrams

Understanding technical illustrations is essential for anyone involved in maintenance or repair tasks. These visuals serve as a roadmap, highlighting critical components and their relationships within a mechanical assembly. By familiarizing oneself with the symbols and layout used in these representations, one can efficiently navigate through the complexity of various systems.

To effectively identify significant elements, it’s important to recognize common features and the context in which they are presented. Here’s a breakdown of typical categories found in technical visuals:

| Category | Description |

|---|---|

| Structural Elements | These are the framework components that provide support and shape to the overall assembly. |

| Functional Components | Parts that perform specific roles, such as generating power or facilitating movement. |

| Connection Points | Locations where different elements meet, often indicated by symbols or lines. |

| Fluid Pathways | Routes for liquids or gases, crucial for understanding system dynamics. |

| Control Mechanisms | Devices that regulate operation, vital for maintaining efficiency and safety. |

By categorizing these elements, one can more readily interpret the schematic and apply this knowledge in practical situations, leading to more effective troubleshooting and repairs.

Replacement Parts for Mercruiser Engines

Maintaining optimal performance in marine power units is essential for ensuring reliability and longevity. When components wear out or fail, timely replacement is crucial to avoid further damage and maintain efficient operation. Understanding the various alternatives available can aid in making informed choices, enhancing both functionality and safety on the water.

Quality substitutes can be sourced from numerous suppliers, ranging from original manufacturers to aftermarket vendors. Each option offers unique advantages, such as cost-effectiveness or superior materials. It’s vital to evaluate the compatibility and specifications of replacements to ensure they meet the required standards for your specific application.

Regular inspection and proactive replacement of critical components can prevent unexpected breakdowns and extend the lifespan of the system. Commonly replaced items often include belts, pumps, and sensors, which are essential for the seamless operation of the entire unit. By prioritizing maintenance and utilizing high-quality substitutes, boat owners can enjoy enhanced performance and peace of mind while navigating the waters.

Upgrading Your 5.7 Engine Effectively

Enhancing the performance and efficiency of your marine power unit can significantly improve your boating experience. Strategic modifications not only boost horsepower but also optimize fuel consumption, leading to a more enjoyable and cost-effective journey on the water. This section will explore various methods to upgrade your propulsion system effectively.

To begin, consider evaluating the air intake and exhaust systems. Upgrading these components can enhance airflow, resulting in improved combustion and power output. Aftermarket filters and performance exhausts are excellent options to explore. Additionally, tuning the ignition system can lead to more efficient spark timing, further maximizing the power generated.

Another key area for enhancement is the fuel delivery mechanism. Upgrading fuel injectors and pumps can increase the amount of fuel supplied to the combustion chambers, which is essential for achieving higher performance levels. It’s also wise to invest in a quality fuel management system to ensure optimal air-fuel ratios under varying operating conditions.

Moreover, addressing the cooling system is crucial when making modifications. A more efficient cooling system can help maintain optimal operating temperatures, reducing the risk of overheating and extending the life of your equipment. Consider upgrading the thermostat, water pump, and radiator for better performance.

Lastly, don’t overlook the importance of regular maintenance and tuning after any upgrades. Periodic checks and adjustments will ensure that all components work harmoniously, allowing you to enjoy the benefits of your enhancements without compromising reliability. By taking these steps, you can effectively elevate the capabilities of your power unit, enhancing both performance and enjoyment on the water.

Comparing Mercruiser 5.7 to Other Models

This section aims to explore the distinctions and similarities between a specific power unit and its counterparts in the marine industry. By examining various characteristics, we can gain a deeper understanding of performance, efficiency, and usability across different configurations.

Performance Metrics

When evaluating different propulsion systems, several key metrics come into play. These include horsepower output, torque delivery, and fuel efficiency. Each model has its unique strengths, making it suitable for various boating applications.

| Model | Horsepower | Torque (lb-ft) | Fuel Efficiency (mpg) |

|---|---|---|---|

| Model A | 300 | 400 | 3.5 |

| Model B | 350 | 450 | 3.2 |

| Model C | 320 | 420 | 3.0 |

Maintenance and Reliability

Reliability and ease of maintenance are critical factors for any propulsion system. The design and quality of components influence how frequently servicing is required and the overall longevity of the unit. Some configurations may require specialized tools or knowledge, affecting the practicality for owners.

Tools Needed for Engine Repair

When embarking on mechanical repairs, having the right tools at your disposal is essential for success. A well-equipped workshop can significantly enhance efficiency and precision, allowing for a smoother workflow and more effective troubleshooting. Understanding which instruments are necessary can save time and prevent potential damage to components.

Basic Hand Tools: A set of quality wrenches, screwdrivers, and pliers forms the foundation of any repair kit. These tools are indispensable for loosening or tightening fasteners and accessing hard-to-reach areas.

Torque Wrench: Properly tightening bolts to the manufacturer’s specifications is crucial. A torque wrench ensures that each connection is secured without the risk of over-tightening, which can lead to stripped threads or broken parts.

Socket Set: A comprehensive socket set allows for versatile use across various fasteners. Different sizes and types enable quick changes and adaptability for different tasks.

Diagnostic Tools: Using diagnostic equipment, such as scan tools or multimeters, can help identify issues quickly. These devices provide valuable data that aids in pinpointing problems that may not be immediately visible.

Safety Equipment: Don’t forget the importance of safety gear. Gloves, goggles, and protective clothing protect against potential hazards, ensuring a safe working environment.

Equipping yourself with these fundamental tools not only prepares you for repairs but also fosters a more enjoyable and efficient hands-on experience.

Expert Insights on Engine Longevity

Understanding the factors that contribute to the durability and reliability of a power unit is essential for maintaining optimal performance over time. Key elements such as routine maintenance, quality components, and proper usage all play a crucial role in extending the lifespan of any mechanical system. Experts emphasize that proactive measures can significantly reduce the likelihood of failures and costly repairs.

Routine Maintenance Practices

Regular servicing is vital for ensuring that all components function seamlessly. This includes oil changes, filter replacements, and inspections of critical systems. Adhering to a scheduled maintenance plan helps identify potential issues before they escalate, allowing for timely interventions that can save both time and money.

Quality Components and Their Impact

Utilizing high-quality components can make a substantial difference in performance and longevity. When selecting replacement parts, opting for reputable brands ensures reliability and compatibility, reducing the risk of malfunctions. Moreover, understanding the specifications and requirements of the system can guide better purchasing decisions, ultimately leading to enhanced durability.