Kubota ZD326 Parts Diagram Guide

Maintaining the efficiency of your lawn care equipment requires a thorough understanding of its individual elements. Each component plays a crucial role in ensuring optimal performance and longevity, making it essential for owners to familiarize themselves with their arrangement and functionality.

In this section, we will explore the intricate layout of various mechanisms, emphasizing their interactions and importance. A clear grasp of these connections can greatly enhance troubleshooting and repair processes, ultimately leading to better maintenance practices.

Diving deeper into the specifics of these components can reveal insights into upgrades and replacements, allowing for informed decisions that can boost your machine’s productivity. This knowledge not only saves time but also contributes to a more enjoyable mowing experience.

Understanding Kubota ZD326 Components

This section aims to explore the essential elements of a specific lawn care machine, highlighting their functionality and significance. By gaining insight into each component, users can enhance their maintenance skills and ensure optimal performance.

Key Elements of the Machine

Every unit comprises vital components that contribute to its efficiency. Engines, transmissions, and blades are among the critical parts that require attention for seamless operation. Understanding how these elements interact can lead to better care and longevity.

Maintenance and Care

Regular inspection of these components is crucial for sustaining functionality. Lubrication, cleaning, and timely replacements are essential practices that will prevent premature wear and ensure the ultimate performance of the machine.

Importance of Accurate Parts Diagram

Having a precise representation of components is crucial for efficient maintenance and repairs. It ensures that individuals can identify the necessary elements quickly and understand how they fit together within the overall system. This clarity minimizes the risk of errors during assembly or replacement, ultimately enhancing the performance and longevity of the equipment.

When working with machinery, a detailed illustration of the various pieces allows for streamlined troubleshooting. Users can easily locate faulty items and determine the correct replacements needed. This not only saves time but also reduces costs associated with misdiagnoses and unnecessary purchases.

Moreover, accurate visual guides facilitate communication among technicians and users, enabling them to discuss issues and solutions more effectively. A shared understanding of the layout fosters collaboration and enhances problem-solving efforts, leading to more efficient workflows.

In addition, relying on a well-structured visual representation contributes to better training for new operators. By providing clear visuals, novices can grasp complex systems more readily, reducing the learning curve and promoting safer, more competent handling of the machinery.

How to Access Kubota ZD326 Manuals

Obtaining the necessary documentation for your machinery can significantly enhance your maintenance and operational efficiency. Manuals provide vital information about the equipment, ensuring proper usage and troubleshooting. Here’s a guide to help you find the resources you need.

Online Resources

The internet is a treasure trove of information. Many official websites offer downloadable manuals in PDF format. Simply search for the model along with keywords like “manual” or “user guide” to locate the desired document.

Local Dealers and Service Centers

Your nearest dealership or service center can be a valuable resource. They often have printed manuals available for purchase or may provide them upon request. Don’t hesitate to reach out for assistance or additional resources.

Common Issues and Solutions

This section explores frequent challenges encountered with specific machinery and offers practical solutions to enhance performance and longevity. Understanding these common problems can aid users in maintaining optimal functionality and avoiding costly repairs.

Electrical Failures

Electrical issues can manifest in various forms, including faulty wiring and malfunctioning components. Identifying and addressing these problems promptly is crucial for seamless operation.

| Issue | Solution |

|---|---|

| Blown Fuses | Check for short circuits and replace the blown fuse with a suitable rating. |

| Starter Malfunction | Inspect the battery charge and connections; replace the starter if necessary. |

Hydraulic System Problems

Hydraulic failures can lead to inefficient operation, often stemming from leaks or inadequate fluid levels. Timely intervention can prevent further damage and ensure smooth functioning.

| Issue | Solution |

|---|---|

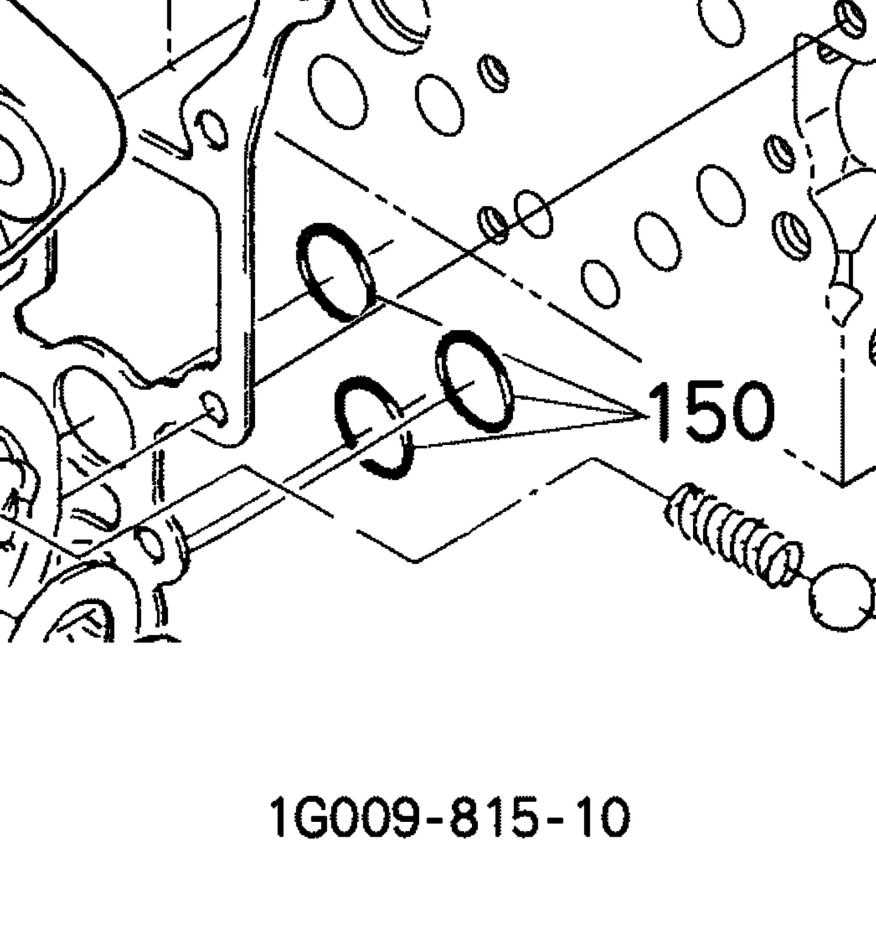

| Fluid Leaks | Identify the source of the leak and replace worn seals or hoses. |

| Poor Performance | Check fluid levels and replace any contaminated fluid. |

Maintenance Tips for Kubota ZD326

Proper upkeep of your equipment ensures optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps in preventing costly repairs down the line. Here are some essential tips to keep your machine in peak condition.

Regular Inspections

Conduct frequent checks of all components to identify wear and tear. Focus on blades, filters, and batteries to ensure everything is functioning correctly. Addressing minor issues early can save you from major disruptions.

Fluid Changes

Timely replacement of oils and fluids is crucial. Check levels of engine oil, hydraulic fluid, and coolant regularly. Following the manufacturer’s schedule for these changes will maintain efficiency and prevent overheating.

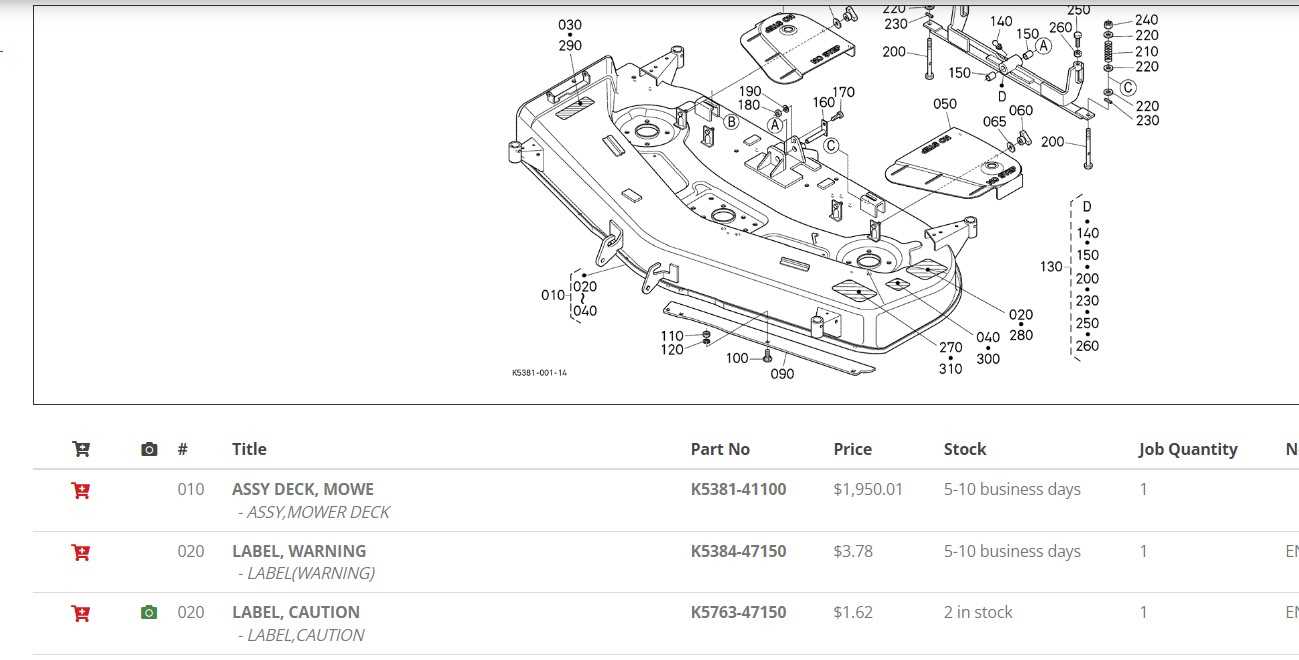

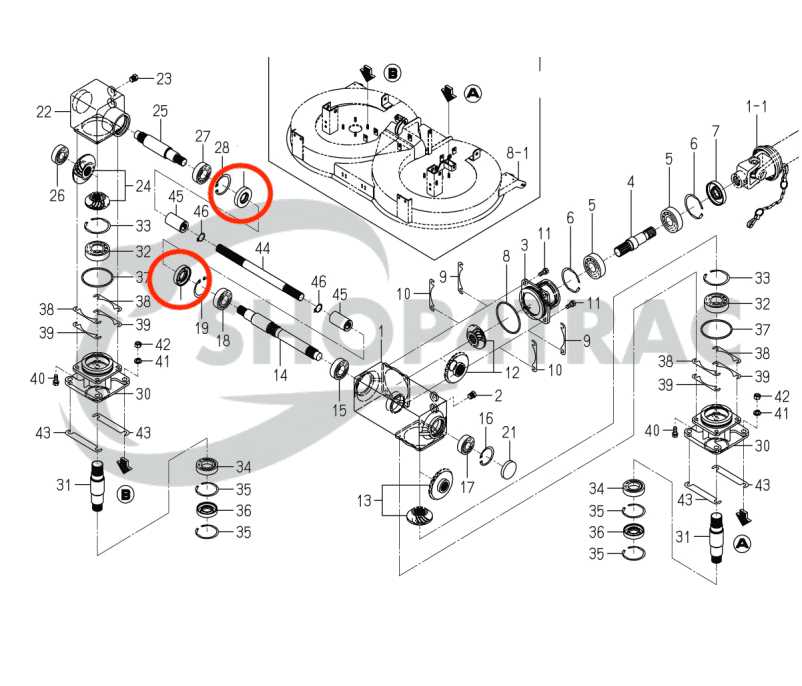

Identifying Parts by Diagram

Understanding how to recognize components through visual representations is crucial for effective maintenance and repair. These illustrations offer a clear view of each element, enabling users to locate and identify items with precision.

When examining a visual guide, consider the following steps:

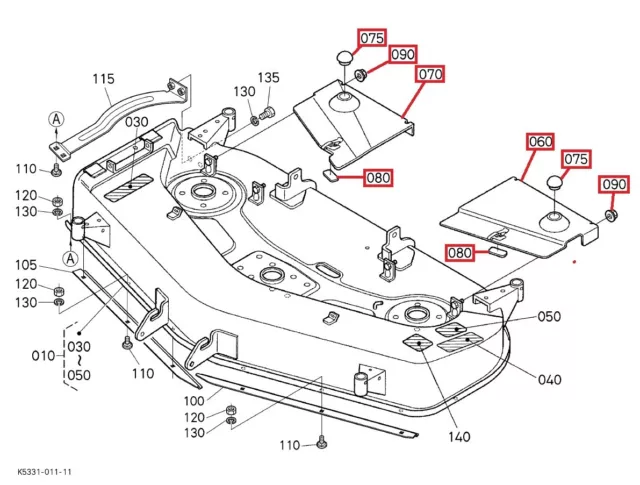

- Study the layout: Familiarize yourself with the overall arrangement of components.

- Note labels and numbers: Pay attention to any annotations that indicate specific parts.

- Refer to the legend: Use the accompanying legend for definitions of symbols and terms.

Benefits of utilizing these illustrations include:

- Enhanced clarity in locating components.

- Increased efficiency during repairs and replacements.

- Better understanding of the overall assembly.

By mastering the art of identifying elements through these guides, one can ensure optimal performance and longevity of equipment.

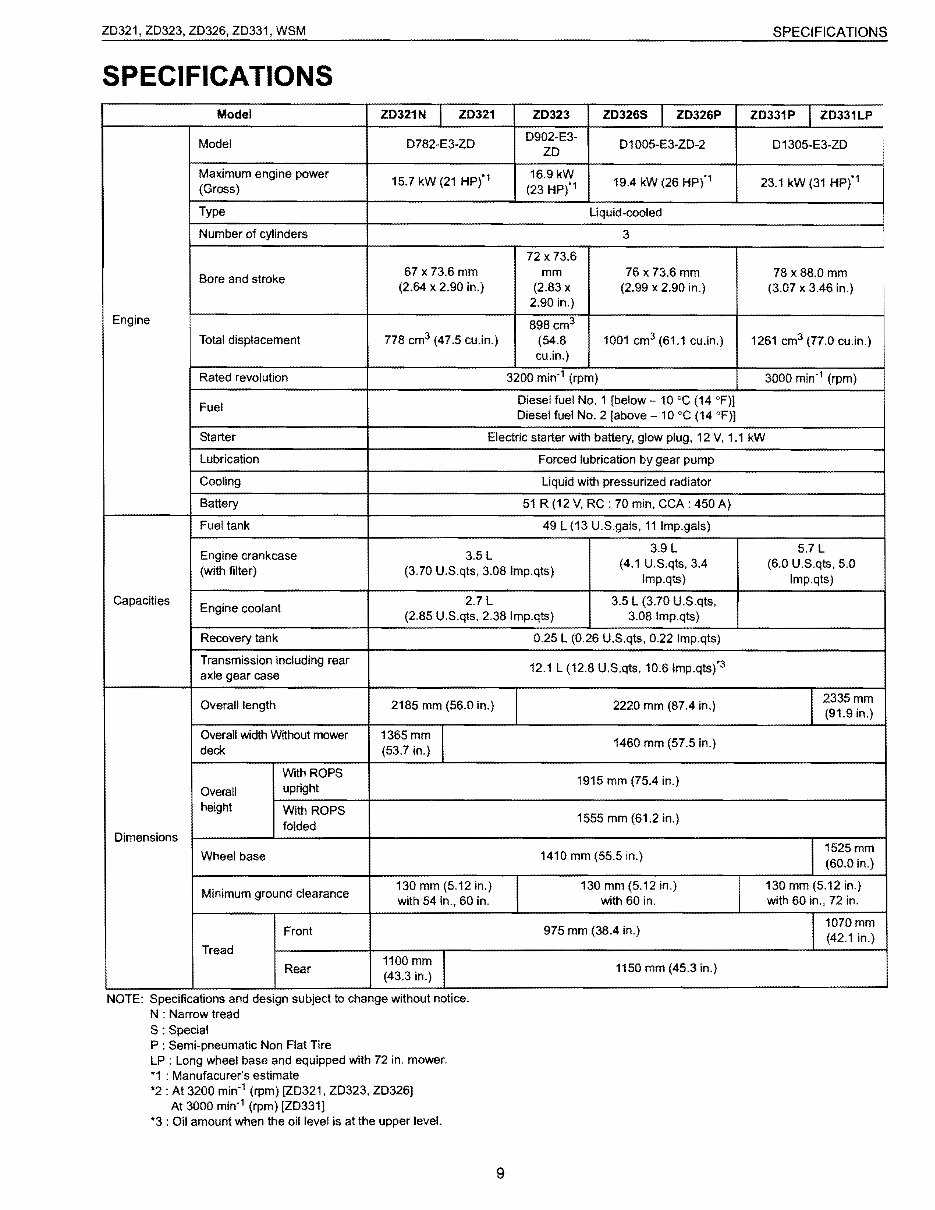

Comparative Analysis of Models

This section aims to explore the differences and similarities among various machinery designs, focusing on their components and functionality. By examining these models, one can gain insights into performance metrics, durability, and user experience.

Key Considerations: When comparing these machines, factors such as engine capacity, maintenance requirements, and operational efficiency come into play. Each model serves a specific purpose, catering to diverse needs in the agricultural and landscaping sectors.

Performance Metrics: Analyzing power output and fuel efficiency can reveal the ultimate suitability of each design for particular tasks. Understanding these attributes helps users make informed decisions based on their operational demands.

Durability and Maintenance: The longevity of each model largely depends on the quality of materials used and the ease of maintenance. Models that facilitate straightforward servicing tend to have a competitive edge in user satisfaction.

User Experience: Lastly, feedback from operators provides valuable insights into usability, comfort, and reliability, all of which play a crucial role in determining the best fit for specific applications.

Where to Buy Genuine Parts

Finding authentic components for your machinery is crucial for ensuring optimal performance and longevity. Utilizing reliable sources not only guarantees quality but also supports the overall maintenance of your equipment.

Authorized Dealers

Visiting authorized dealerships is one of the best ways to secure original components. They provide:

- Expert guidance on selecting the right items

- Access to the latest models and inventory

- Warranty and service options for peace of mind

Online Retailers

Many reputable online platforms offer a wide range of authentic items. When shopping online, consider:

- Checking for customer reviews to gauge reliability

- Ensuring the site offers return policies

- Looking for certified sellers for assurance of authenticity

Impact of Quality on Performance

The relationship between quality and performance is crucial in determining the effectiveness of any mechanical system. High-quality components contribute significantly to the reliability and efficiency of machinery, ensuring that it operates smoothly and meets the expected standards. When subpar materials or construction methods are used, the overall functionality can be compromised, leading to increased downtime and maintenance costs.

Factors Influencing Quality

Several elements play a vital role in the quality of components. These include the materials used, manufacturing processes, and adherence to industry standards. Each of these factors can greatly influence the durability and performance of the equipment.

Consequences of Low Quality

Investing in low-quality parts can result in various negative outcomes, including frequent repairs, reduced efficiency, and a shorter lifespan of the machinery. Understanding the impact of quality helps manufacturers and users make informed decisions about their investments.

| Quality Level | Performance Impact | Long-term Effects |

|---|---|---|

| High Quality | Optimal Efficiency | Increased Lifespan |

| Moderate Quality | Adequate Functionality | Frequent Repairs |

| Low Quality | Poor Performance | High Maintenance Costs |

Customer Reviews on Parts Replacement

The process of replacing components in machinery often elicits a variety of opinions from users. Feedback can provide valuable insights into the quality, durability, and effectiveness of various replacements. Understanding customer experiences helps others make informed decisions when it comes to maintenance and upgrades.

| Customer Name | Rating | Review |

|---|---|---|

| John D. | 5/5 | Excellent quality! The replacement worked perfectly, restoring my machine’s performance. |

| Linda S. | 4/5 | Good part, but installation was a bit tricky. Still, very satisfied with the outcome. |

| Mike T. | 3/5 | Average experience. The component functioned well, but it arrived later than expected. |

| Emma R. | 5/5 | Top-notch! This replacement exceeded my expectations in both performance and durability. |

| Sam K. | 2/5 | Disappointed. The part did not fit as described, leading to additional issues. |

User reviews highlight the importance of quality and compatibility in replacement components. Overall, sharing experiences helps create a more informed community dedicated to enhancing machine longevity.

Future Upgrades for ZD326 Owners

Enhancing the functionality and efficiency of your equipment can significantly improve your overall experience. Whether for professional landscaping or personal use, considering upgrades can help you achieve better performance, comfort, and versatility. This section explores potential enhancements that can elevate your machine’s capabilities.

Performance Enhancements

- Engine Modifications: Upgrading components such as air filters or exhaust systems can lead to better airflow and increased power.

- Transmission Improvements: Consider options for smoother gear transitions or enhanced torque performance.

- Hydraulic System Upgrades: Installing advanced hydraulic components can boost lifting capabilities and operational speed.

Comfort and Usability Features

- Cab Enclosures: Adding weather-resistant enclosures can protect operators from the elements.

- Ergonomic Seating: Upgrading to more comfortable seating can reduce fatigue during extended use.

- Technology Integration: Incorporating GPS or advanced monitoring systems can enhance navigation and operational efficiency.

By investing in these upgrades, owners can ensure that their machines remain reliable and efficient, adapting to various tasks and improving productivity in the long run.