Bryant Plus 90 Furnace Parts Diagram Overview

When it comes to maintaining a comfortable indoor environment, having a thorough knowledge of essential heating system elements is crucial. This understanding not only aids in efficient operation but also empowers homeowners to tackle basic issues and make informed decisions regarding repairs and upgrades.

In this section, we will explore the intricate layout of a specific heating unit, highlighting various components and their functions. By examining these details, you can delve into the ultimate workings of the system, allowing for better maintenance and enhanced performance.

Whether you are a seasoned technician or a curious homeowner, grasping the arrangement and role of each element can significantly impact the longevity and efficiency of your heating apparatus. Knowledge is indeed power in ensuring optimal heating solutions for your living space.

Understanding Bryant Plus 90 Furnaces

The heating units in modern homes play a crucial role in maintaining comfort during colder months. These systems are designed to efficiently convert fuel into warmth, ensuring a consistent temperature throughout the living space. An understanding of their components and functionality is essential for effective maintenance and troubleshooting.

Key Components of High-Efficiency Heating Systems

High-efficiency heating systems typically consist of several critical components that work in unison. Among these are the heat exchanger, blower motor, and control board. Each element contributes to the overall performance, influencing efficiency and reliability. Regular inspection and knowledge of these parts can enhance the longevity of the system.

Common Issues and Solutions

Homeowners may encounter various challenges with their heating units, such as uneven heating or unusual noises. Identifying these issues promptly can prevent more significant problems. It’s important to consult a professional technician for diagnosis and repairs, ensuring the system operates smoothly and effectively.

Key Components of Bryant Plus 90

This section will explore essential elements that contribute to the efficient operation of a specific heating system. Understanding these components is crucial for anyone looking to maintain or troubleshoot the system effectively.

The heat exchanger is a vital element that facilitates the transfer of heat from the combustion process to the air circulating within a building. Its design ensures optimal efficiency and durability, minimizing energy loss.

The blower motor plays a critical role in moving air through the system, providing comfort by regulating airflow. It is important for this component to function quietly and effectively to maintain a pleasant indoor environment.

The ignition system is responsible for initiating the combustion process safely. This component ensures reliable operation, allowing the unit to start efficiently when heating is needed.

The control board acts as the system’s brain, managing various functions and ensuring that all components work in harmony. A properly functioning control board is essential for maintaining the system’s overall performance.

Understanding these key components allows users to better appreciate their heating system’s functionality and make informed decisions regarding maintenance and repairs.

Importance of Proper Maintenance

Regular upkeep of heating appliances is crucial for optimal performance and longevity. Without appropriate care, these systems may experience inefficiencies, leading to higher energy consumption and potential malfunctions. Ensuring that all components function harmoniously contributes to a comfortable indoor environment.

Neglecting maintenance can result in various issues, including:

- Reduced efficiency, causing increased energy bills.

- Shortened lifespan of the unit.

- Frequent breakdowns requiring costly repairs.

- Increased risk of safety hazards, such as carbon monoxide leaks.

To mitigate these risks, consider implementing the following maintenance practices:

- Schedule regular inspections by a qualified technician.

- Change filters periodically to ensure clean airflow.

- Inspect and clean all components for optimal performance.

- Monitor for unusual noises or performance changes.

Prioritizing proper maintenance not only enhances system reliability but also promotes energy efficiency and safety within your living space.

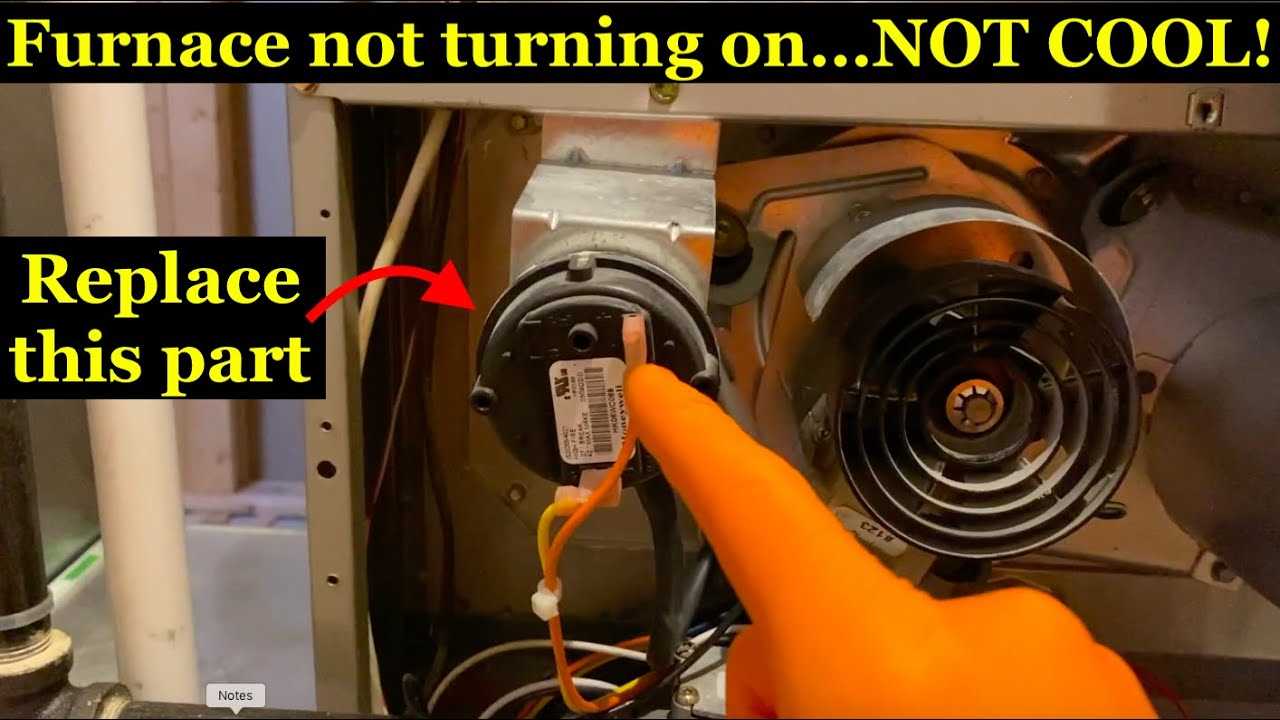

Common Issues with Bryant Furnaces

Heating systems can encounter various challenges that affect their performance and efficiency. Understanding these typical problems can help homeowners identify issues early and seek timely solutions.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Unresponsive Unit | No heat, system does not turn on | Check thermostat settings and power supply |

| Inconsistent Heating | Rooms are at different temperatures | Inspect ductwork and vents for blockages |

| Strange Noises | Banging or rattling sounds | Examine components for loose parts or debris |

| Frequent Cycling | System turns on and off repeatedly | Adjust thermostat or clean filters |

| Bad Odors | Unpleasant smells when system operates | Check for gas leaks or burnt dust |

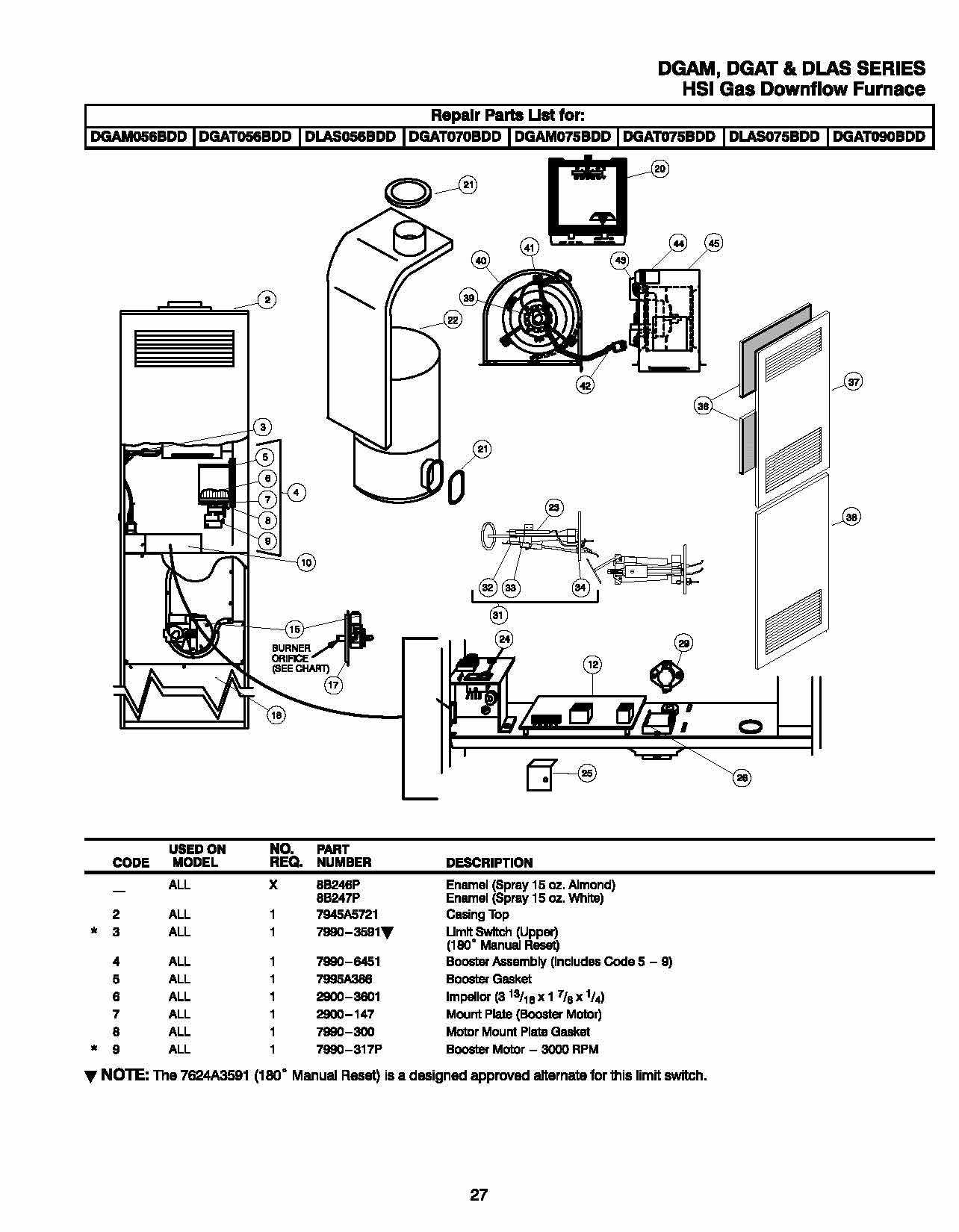

How to Read the Parts Diagram

Understanding a component schematic is essential for effective troubleshooting and maintenance. This visual representation helps you identify various elements and their relationships, making it easier to navigate and comprehend the system’s layout. Familiarizing yourself with this resource allows for a more streamlined approach to repairs and enhancements.

Key Symbols and Notations

Each symbol in the schematic represents a specific element within the system. Recognizing these symbols is crucial for interpreting the layout correctly. Common notations include various shapes and lines that denote connections and functions, guiding users in understanding the flow of the system.

Interpreting the Layout

The arrangement of components in the schematic provides insight into how they interact. Pay attention to the connections and pathways illustrated, as they indicate the operational flow. This can assist in identifying potential issues and understanding how modifications might impact overall performance.

| Symbol | Description |

|---|---|

| Circle | Represents a connection point. |

| Square | Indicates a control unit. |

| Line | Shows electrical pathways or fluid flow. |

Essential Replacement Parts Overview

Understanding the key components of heating systems is crucial for maintaining optimal performance and ensuring longevity. Regular replacement of essential elements can enhance efficiency and prevent unexpected breakdowns, contributing to a comfortable environment in your home.

Key Components for Maintenance

Among the vital elements to monitor are the igniter, blower motor, and control board. Each plays a significant role in the overall functionality of the heating system. The igniter is responsible for initiating the heating process, while the blower motor ensures proper airflow. The control board acts as the system’s brain, managing all operations and responding to environmental changes.

Signs of Wear and Replacement Needs

Recognizing the signs of wear in these components is essential. Common indicators include unusual noises, inconsistent heating, and error codes on the display. Addressing these issues promptly can help avoid more severe problems and maintain the system’s efficiency. Regular inspections and timely replacements are the best strategies for optimal performance.

Tools Needed for Repairs

When undertaking maintenance or fixing issues in heating systems, having the right tools is crucial for a successful outcome. A well-equipped toolkit not only speeds up the repair process but also ensures safety and efficiency during work.

Essential Hand Tools

- Socket set for various fasteners

- Wrenches to tighten or loosen connections

- Screwdrivers for securing and removing panels

- Pliers for gripping and manipulating components

Specialized Equipment

- Multimeter for electrical diagnostics

- Manifold gauge set for pressure measurement

- Thermometer for temperature readings

- Vacuum pump for ensuring system integrity

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues with heating systems. Following these outlined steps can help ensure effective troubleshooting and repair, leading to improved performance and reliability.

Preparation and Safety Measures

Before starting any repair work, it’s essential to prepare adequately and ensure safety. Here are the steps to follow:

- Turn off the power supply to the system.

- Ensure the area is well-ventilated.

- Gather all necessary tools and materials.

- Wear appropriate safety gear, including gloves and goggles.

Troubleshooting Steps

Once preparations are complete, proceed with the troubleshooting process:

- Check the thermostat settings to ensure proper temperature is selected.

- Inspect the electrical connections for any loose or damaged wires.

- Examine the ignition system to verify if it is functioning correctly.

- Look for any blockages in the air intake and exhaust vents.

- Clean or replace filters as needed to maintain optimal airflow.

Safety Tips During Maintenance

Ensuring a safe environment while conducting maintenance on heating equipment is crucial. Proper precautions help prevent accidents and ensure the longevity of the system. Adhering to safety guidelines protects both the user and the equipment during servicing.

1. Disconnect Power: Always disconnect the power supply before starting any maintenance work. This prevents electrical shocks and reduces the risk of injury while inspecting or replacing components.

2. Use Proper Tools: Utilize the appropriate tools for maintenance tasks. Using incorrect tools can lead to damage to the equipment or cause injury. Make sure tools are in good condition and suited for the job.

3. Wear Protective Gear: Don protective equipment such as gloves, safety goggles, and masks. This gear protects against harmful substances and potential injuries while working on the system.

4. Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions when performing maintenance. These guidelines provide essential information regarding safety procedures and specific maintenance practices.

5. Check for Gas Leaks: If working with gas-powered systems, regularly check for leaks. Use a soap solution to detect any escaping gas, and if a leak is found, shut off the gas supply and call a professional.

6. Ensure Adequate Ventilation: Maintain proper ventilation in the work area to prevent the accumulation of harmful gases. Good airflow is essential for both safety and efficient operation of the system.

7. Keep the Work Area Clean: A tidy workspace minimizes hazards and ensures efficient work. Remove any clutter, debris, or flammable materials from the vicinity before starting maintenance tasks.

By adhering to these safety tips, individuals can perform maintenance on heating equipment effectively and securely, ensuring the system operates efficiently and safely.

Finding Authentic Replacement Parts

When it comes to maintaining heating systems, sourcing genuine components is crucial for optimal performance and longevity. Ensuring the integrity of the equipment relies heavily on selecting high-quality alternatives that match the original specifications.

Here are some key points to consider when searching for authentic replacements:

- Verify the manufacturer’s specifications to ensure compatibility.

- Consult certified retailers or authorized dealers for trusted sources.

- Look for warranties or guarantees that accompany the components.

- Research online reviews and feedback from other users.

- Consider purchasing from reputable brands known for their quality.

By following these guidelines, you can enhance the reliability of your heating system and avoid potential issues associated with inferior substitutes.

When to Call a Professional

Understanding the appropriate times to seek expert assistance can greatly enhance the efficiency and longevity of your heating system. While some minor issues may be resolved through basic troubleshooting, there are specific situations that necessitate the skills and experience of a qualified technician.

Signs of a Serious Issue

Unusual sounds, persistent error codes, or inconsistent heating are clear indicators that professional intervention is required. If you notice any of these symptoms, it’s essential to act promptly. Ignoring these warning signs can lead to more severe damage and higher repair costs in the long run.

Routine Maintenance

Regular maintenance is crucial for optimal performance. If you have not scheduled a comprehensive inspection within the last year, it is wise to call a professional. They can ensure that all components are functioning correctly, addressing potential issues before they escalate.