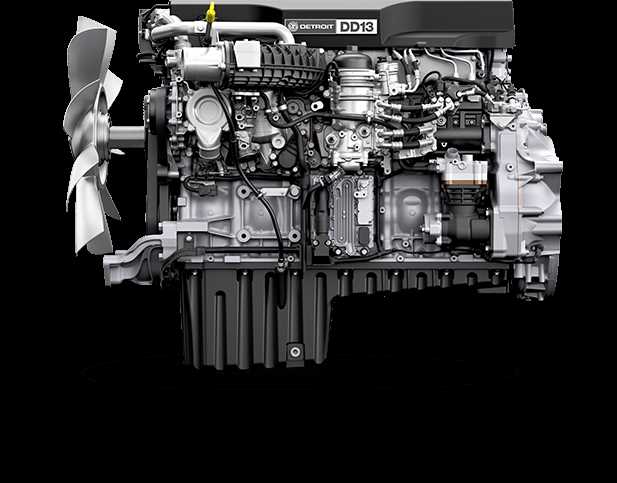

Comprehensive Guide to Dd13 Engine Parts Diagram

In the realm of industrial machinery, comprehending the intricate layout and functionality of essential components is crucial for optimal performance and maintenance. Each section plays a significant role in ensuring efficiency and reliability, contributing to the overall effectiveness of the system. A clear visualization of these elements can greatly enhance the understanding of their interrelations and operational significance.

By exploring the arrangement of various mechanisms, one can appreciate how each piece works in harmony to generate the desired output. This knowledge not only aids in troubleshooting but also facilitates informed decision-making during repairs or upgrades. A detailed overview can serve as a valuable resource for technicians and enthusiasts alike.

In this section, we will delve into the specifics of a particular assembly, highlighting the crucial aspects that drive its functionality. Whether you are a seasoned professional or a curious learner, familiarizing yourself with these details will empower you to navigate the complexities of heavy-duty machinery with confidence.

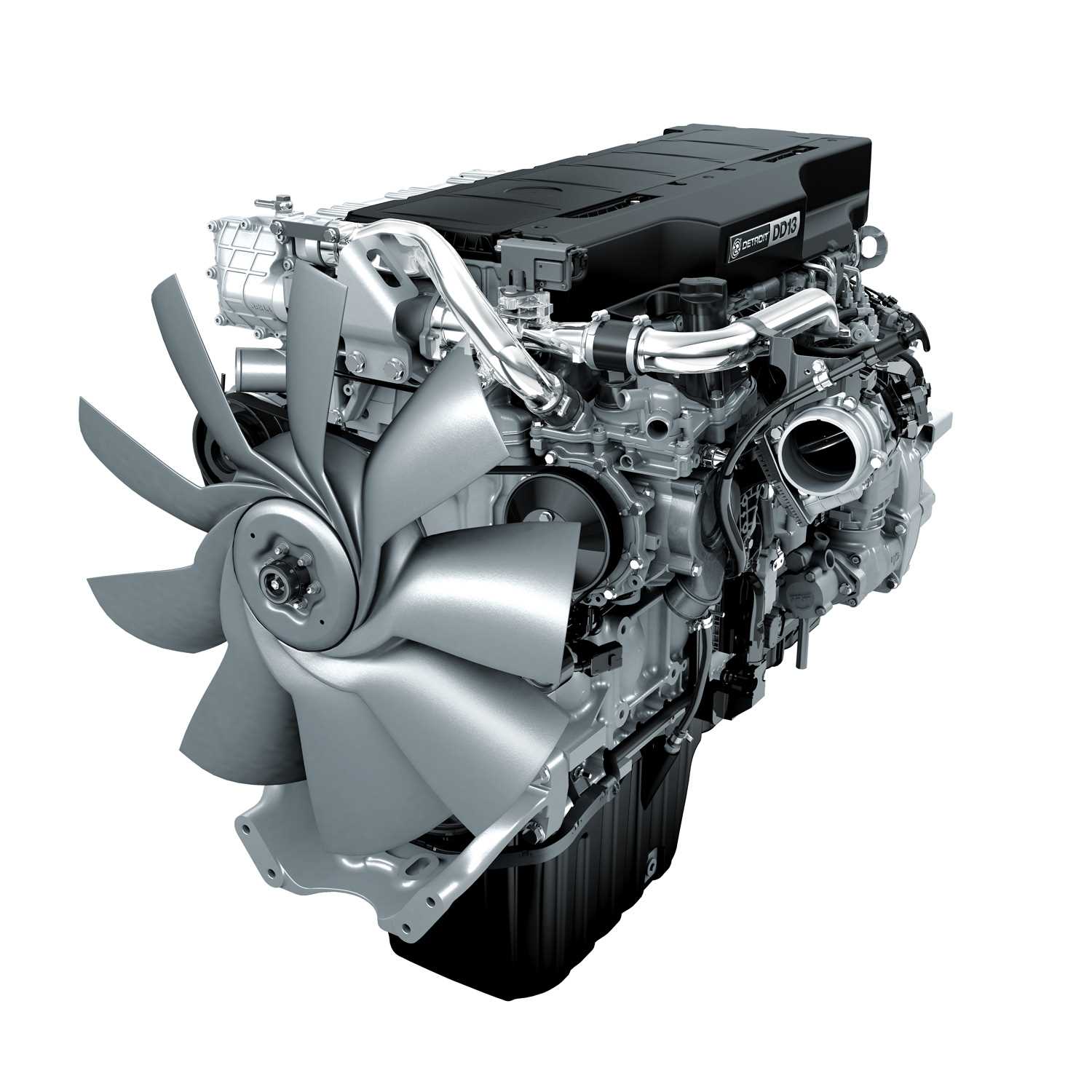

Understanding Dd13 Engine Basics

This section provides a foundational overview of a specific mechanical system designed for high performance and efficiency. It explores the core components and their functions, ensuring optimal operation under various conditions. A thorough comprehension of this system is crucial for maintenance and troubleshooting.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and provides structural integrity. |

| Pistons | Convert combustion energy into mechanical motion. |

| Crankshaft | Transforms linear motion from pistons into rotational motion. |

| Fuel System | Delivers fuel to the combustion chamber for ignition. |

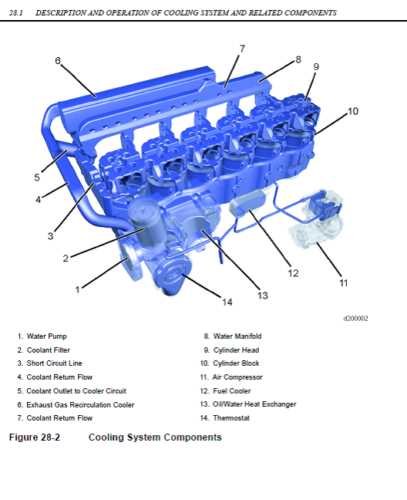

| Cooling System | Maintains optimal temperature to prevent overheating. |

Key Components of the Dd13 Engine

This section delves into the essential elements that contribute to the overall functionality and performance of a specific power unit. Understanding these vital components is crucial for maintenance, troubleshooting, and enhancing operational efficiency.

Primary Elements

- Cylinder Head: Responsible for sealing the combustion chamber and housing essential components like valves and fuel injectors.

- Block: The main structure that houses cylinders, providing support and containing the engine’s moving parts.

- Crankshaft: Converts linear motion from the pistons into rotational force, crucial for power delivery.

- Pistons: Move within the cylinders, facilitating the combustion process and converting fuel energy into mechanical work.

Supporting Components

- Turbocharger: Enhances air intake to improve combustion efficiency and increase power output.

- Fuel System: Delivers the necessary fuel to the combustion chamber, ensuring optimal performance.

- Cooling System: Maintains temperature regulation, preventing overheating and ensuring longevity.

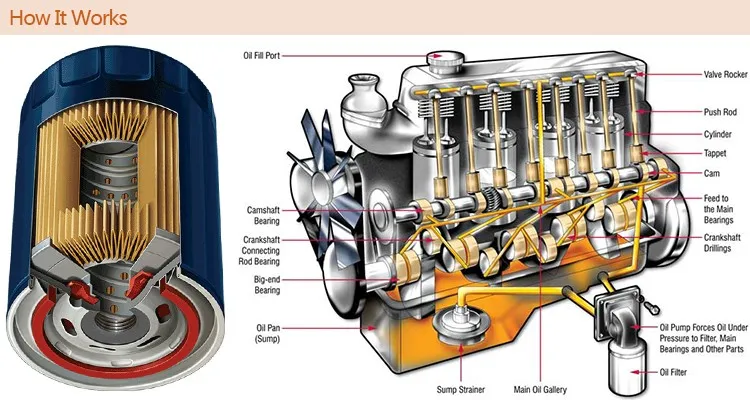

- Lubrication System: Reduces friction between moving parts, providing protection and ensuring smooth operation.

Common Applications of Dd13 Engines

This section explores the diverse settings where these robust power units are utilized, highlighting their adaptability and reliability across various industries.

Transport and Logistics

- Heavy-duty trucks

- Freight carriers

- Long-haul transportation

Construction and Agriculture

- Excavators

- Bulldozers

- Farm machinery

These applications demonstrate the ultimate versatility and performance that these power sources offer, making them integral to many sectors.

Maintenance Tips for Dd13 Parts

Ensuring the longevity and efficiency of complex machinery requires diligent upkeep and attention to detail. Regular maintenance not only enhances performance but also helps prevent costly repairs down the line. This section provides practical guidance on how to care for crucial components, ensuring they remain in optimal condition.

Regular Inspection

Frequent checks are vital to identify potential issues early. Inspecting various elements for wear and tear can prevent unexpected breakdowns. Look for signs of corrosion, cracks, or any unusual noises that could indicate malfunction.

Lubrication and Cleaning

Keeping components clean and well-lubricated is essential for smooth operation. Use the appropriate lubricants and ensure that any debris or contaminants are removed regularly. A clean environment contributes significantly to the efficiency and lifespan of the system.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Look for signs of wear and damage. |

| Lubrication | Monthly | Use manufacturer-recommended products. |

| Cleaning | Every 3 months | Remove dirt and debris thoroughly. |

| Professional Checkup | Annually | Have a certified technician evaluate all systems. |

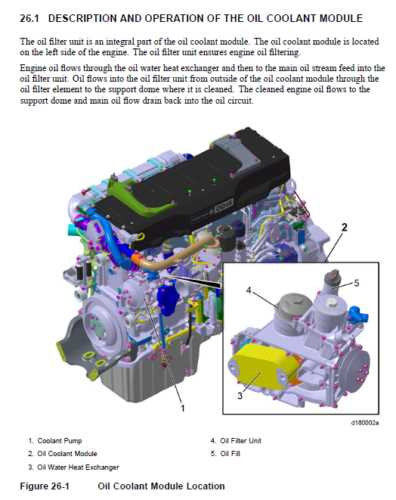

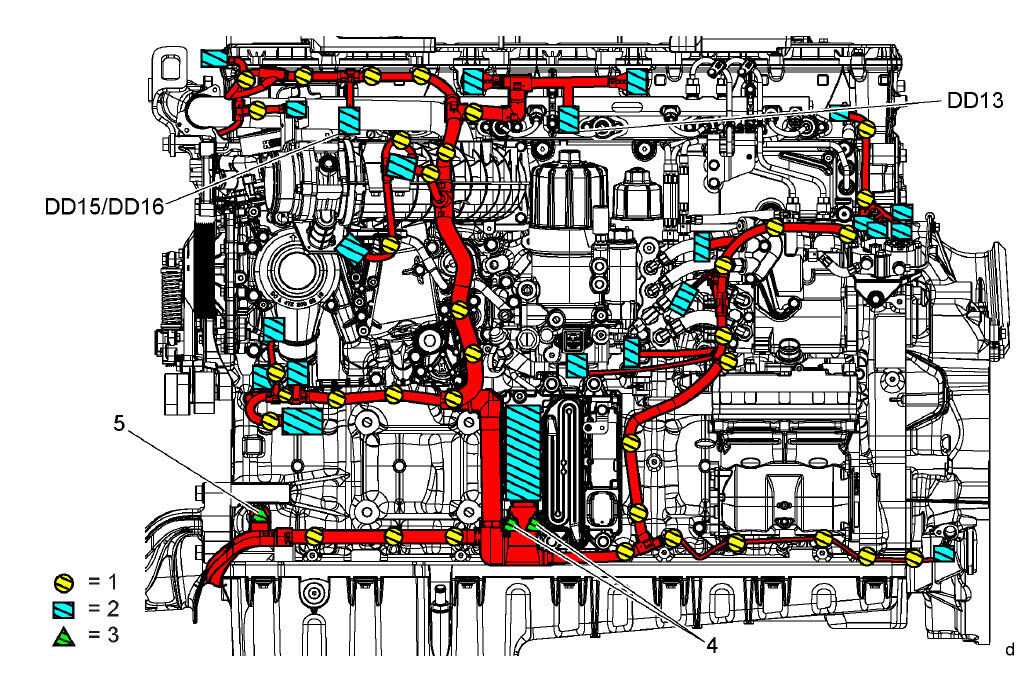

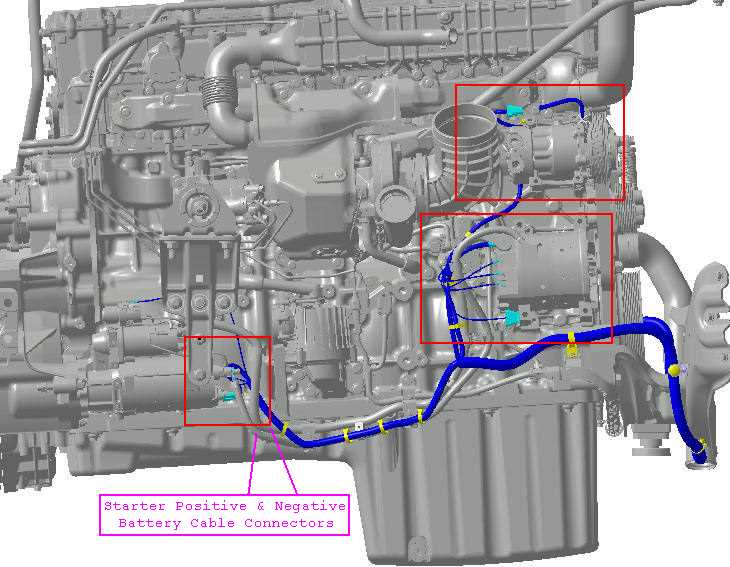

Visualizing the Dd13 Parts Diagram

Understanding the intricate components of a complex machinery system is essential for effective maintenance and troubleshooting. A detailed representation serves as a valuable reference, allowing individuals to identify and locate each element efficiently.

Key Components Overview

- Fuel system elements

- Cooling mechanisms

- Lubrication structures

- Electrical connections

Benefits of Detailed Visualization

- Enhances comprehension of interrelationships between components.

- Facilitates quicker repairs and replacements.

- Improves overall system reliability through better understanding.

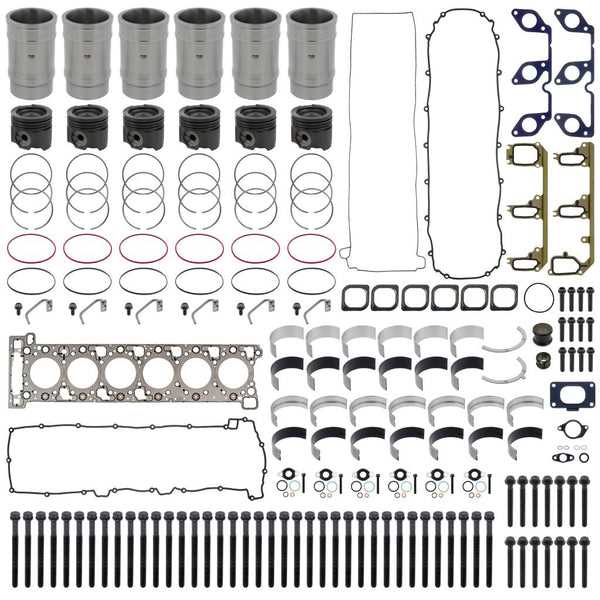

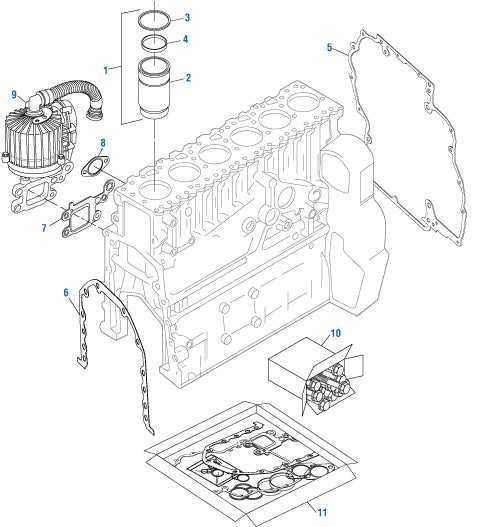

Replacing Dd13 Engine Components

Maintaining the performance of your vehicle often requires attention to various mechanical elements. Over time, certain components may wear out and need replacement to ensure optimal functionality. Understanding the process of swapping out these vital parts is essential for any vehicle owner or technician.

When undertaking the task of replacing components, it’s important to follow a systematic approach. This includes identifying the parts that require attention, gathering the necessary tools, and understanding the assembly layout to ensure everything fits correctly. Below is a helpful table outlining some common components that may need replacement, along with their respective functions and signs of wear.

| Component | Function | Signs of Wear |

|---|---|---|

| Piston | Converts fuel energy into mechanical motion | Loss of power, excessive noise |

| Gasket | Seals joints between components | Leaks, engine overheating |

| Fuel Injector | Delivers fuel to the combustion chamber | Misfires, reduced fuel efficiency |

| Turbocharger | Increases engine power output | Whining noises, lag in acceleration |

| Cooling System Components | Regulates engine temperature | Overheating, coolant leaks |

By being proactive about replacements and understanding the function of each component, vehicle owners can significantly enhance performance and longevity. Regular inspections and timely interventions are key to preventing larger issues down the line.

Diagnosing Issues in Dd13 Engines

Identifying problems in heavy machinery requires a systematic approach to ensure optimal performance. By understanding common indicators and utilizing appropriate diagnostic tools, one can effectively pinpoint issues and enhance reliability.

Common Symptoms to Observe

Look for signs such as unusual noises, fluctuating power levels, or irregular emissions. Vigilance in monitoring these symptoms is crucial, as they often signal underlying malfunctions that demand immediate attention.

Effective Diagnostic Techniques

Utilizing advanced diagnostic equipment can greatly assist in revealing hidden faults. Performing regular checks on key components will not only prolong lifespan but also ensure that the machinery operates at its ultimate efficiency.

Performance Enhancements for Dd13 Models

Improving the efficiency and power output of a heavy-duty vehicle can significantly enhance its overall performance. There are several strategies to achieve these enhancements, focusing on optimizing various components to work in harmony.

Upgrading the air intake system can lead to better airflow, which helps in maximizing combustion efficiency. A high-performance filter can improve airflow while reducing restrictions.

Another key area is the exhaust system. By replacing the stock components with a more efficient setup, one can decrease back pressure, allowing for smoother exhaust flow and improved power delivery.

Additionally, reprogramming the control unit can unlock hidden potential within the existing setup. Fine-tuning fuel maps can lead to a more responsive throttle and enhanced torque delivery.

Finally, incorporating upgraded turbochargers can significantly increase boost pressure, contributing to greater power and efficiency. These modifications work together to provide the ultimate performance enhancements, ensuring a more robust and reliable vehicle on the road.

Comparing Dd13 with Other Engines

When evaluating the performance and efficiency of various power units, it is essential to consider their design features, functionality, and suitability for different applications. Each type of machinery has its unique characteristics that cater to specific operational needs, leading to diverse preferences among users.

Performance Metrics

Performance is often measured in terms of power output, torque delivery, and fuel efficiency. Some models excel in torque, providing better acceleration for heavy loads, while others may focus on maximizing fuel economy. Understanding these metrics helps in selecting the most appropriate unit for a given task.

Technological Advancements

Innovation plays a crucial role in enhancing the capabilities of these systems. Recent advancements include improved fuel injection systems, turbocharging, and emission control technologies. These enhancements not only boost efficiency but also reduce environmental impact, making them increasingly relevant in today’s market.

Essential Tools for Dd13 Repairs

When tackling maintenance and repair tasks, having the right instruments at your disposal is crucial for efficiency and effectiveness. Various tools cater to different needs, from diagnostics to assembly, ensuring that every aspect of the job is handled with precision.

Basic hand tools such as wrenches and screwdrivers are foundational, providing the means to fasten and loosen components. Advanced diagnostic equipment is equally vital, allowing for real-time monitoring and troubleshooting. Additionally, specialized implements like torque wrenches help ensure that all fittings are secure and up to specifications, preventing future issues.

Safety gear, including gloves and goggles, should not be overlooked, as they protect the technician during hands-on work. Investing in quality tools not only enhances the repair experience but also contributes to the longevity of the machinery.

Aftermarket Parts for Dd13 Engines

The availability of alternative components plays a crucial role in maintaining and enhancing vehicle performance. These replacements often provide improved durability and cost-effectiveness, appealing to a wide range of enthusiasts and professionals alike. Exploring various options can lead to significant upgrades and customization opportunities.

Benefits of Alternative Components

Choosing aftermarket solutions can result in enhanced efficiency and longevity. Many of these options are designed to surpass original specifications, ensuring superior functionality and reliability. Cost savings are another significant advantage, as these alternatives are frequently more affordable than OEM products.

Considerations When Selecting Alternatives

When opting for non-original replacements, it is essential to evaluate quality and compatibility. Not all alternatives are created equal, so researching reputable brands and customer reviews is vital. Additionally, ensure that the chosen components align with your specific performance goals and maintenance needs.

Expert Insights on Dd13 Efficiency

Achieving optimal performance in heavy machinery involves a deep understanding of how various components interact to maximize fuel economy and reduce emissions. Industry experts emphasize the importance of precision engineering and regular maintenance to enhance overall functionality.

Key Factors Influencing Performance

Several critical elements contribute to the efficiency of high-performance vehicles. Airflow management is vital; ensuring proper intake and exhaust systems can significantly impact combustion quality. Additionally, the use of advanced fuel injection systems promotes better atomization, leading to more efficient fuel usage.

Maintenance Practices for Longevity

Regular upkeep is essential for sustaining high efficiency levels. Monitoring fluid levels, replacing filters, and checking for leaks can prevent minor issues from escalating into costly repairs. Furthermore, investing in high-quality lubricants ensures that moving parts operate smoothly, reducing friction and wear over time.