Powerhorse 2000 Generator Parts Diagram Explained

Every efficient device relies on a series of interconnected elements that work harmoniously to ensure optimal performance. Grasping the layout and function of these components is crucial for anyone seeking to maintain or repair their equipment effectively.

Visual aids play a pivotal role in this understanding, offering a clear representation of how each piece fits into the whole. By delving into the intricacies of these illustrations, users can enhance their knowledge and tackle maintenance tasks with confidence.

Ultimately, having a comprehensive overview of the various sections not only simplifies troubleshooting but also empowers individuals to make informed decisions regarding upgrades and replacements. With the right information at hand, managing your machinery becomes a far less daunting endeavor.

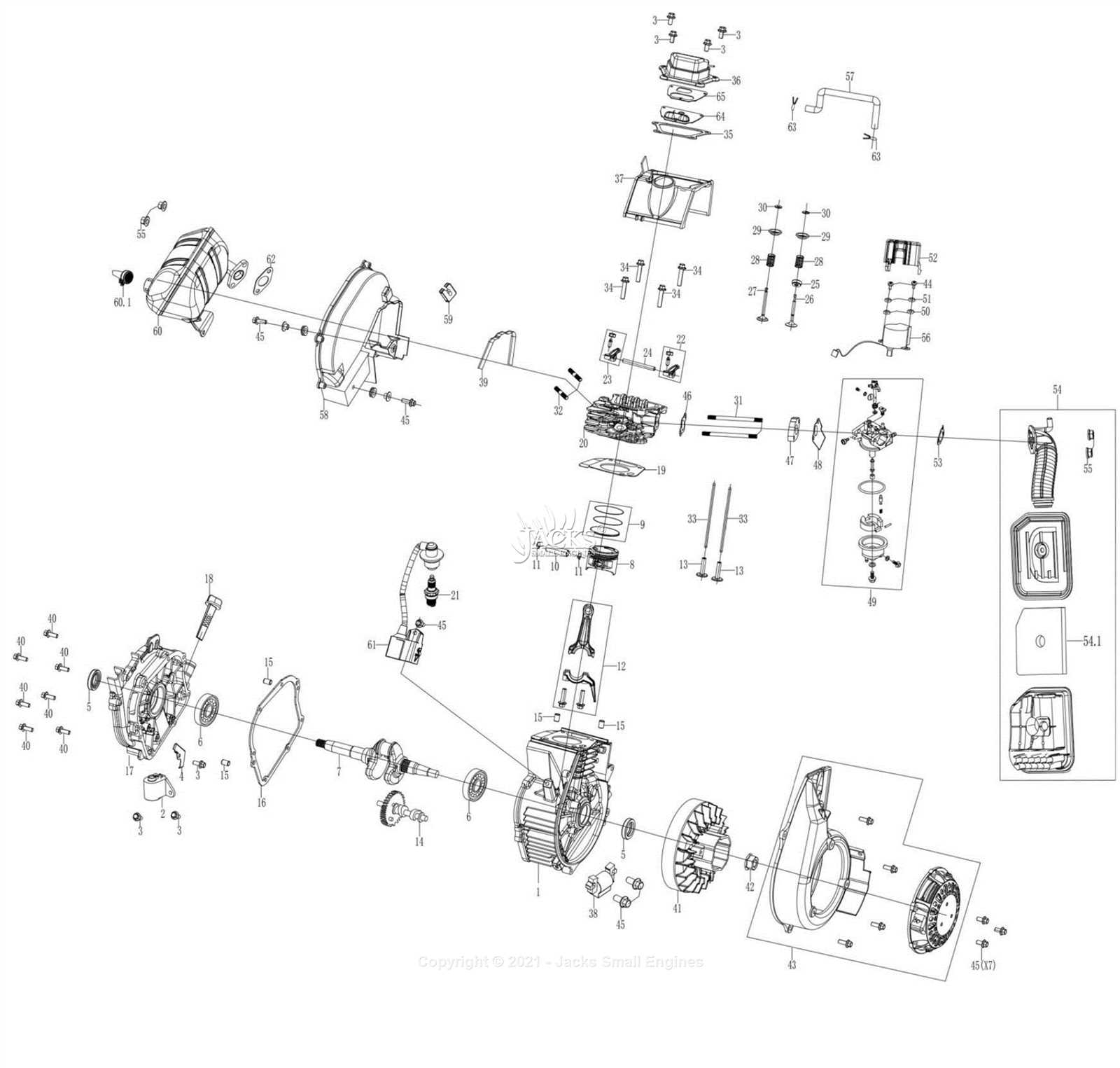

Understanding Powerhorse 2000 Generator Components

To effectively operate any machine designed for power generation, one must grasp the various elements that contribute to its functionality. Each component plays a crucial role, ensuring optimal performance and longevity. This section aims to explore the essential elements that make up these systems.

Key Elements

- Engine

- Alternator

- Fuel Tank

- Control Panel

- Exhaust System

Functionality of Components

- Engine: Provides the necessary power for operation.

- Alternator: Converts mechanical energy into electrical energy.

- Fuel Tank: Stores the energy source required for operation.

- Control Panel: Allows users to monitor and manage performance.

- Exhaust System: Channels waste gases away from the unit.

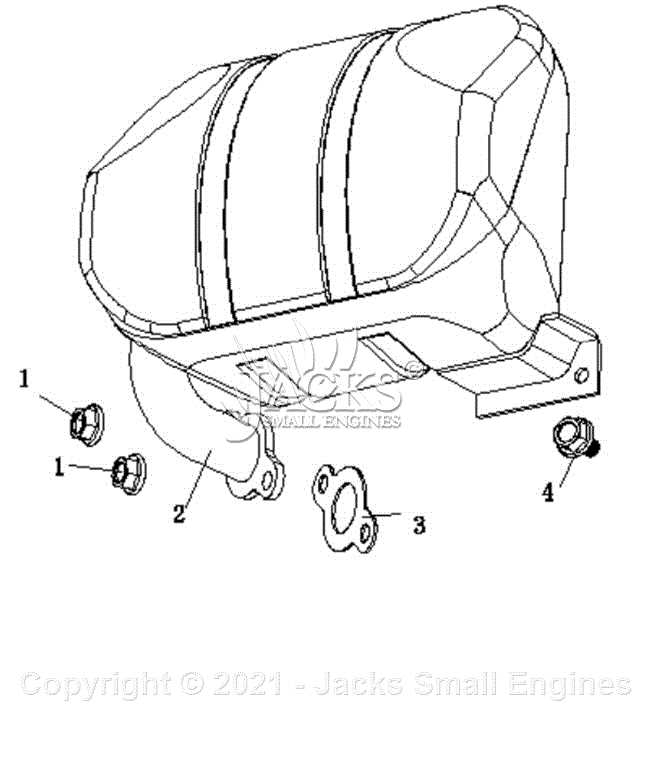

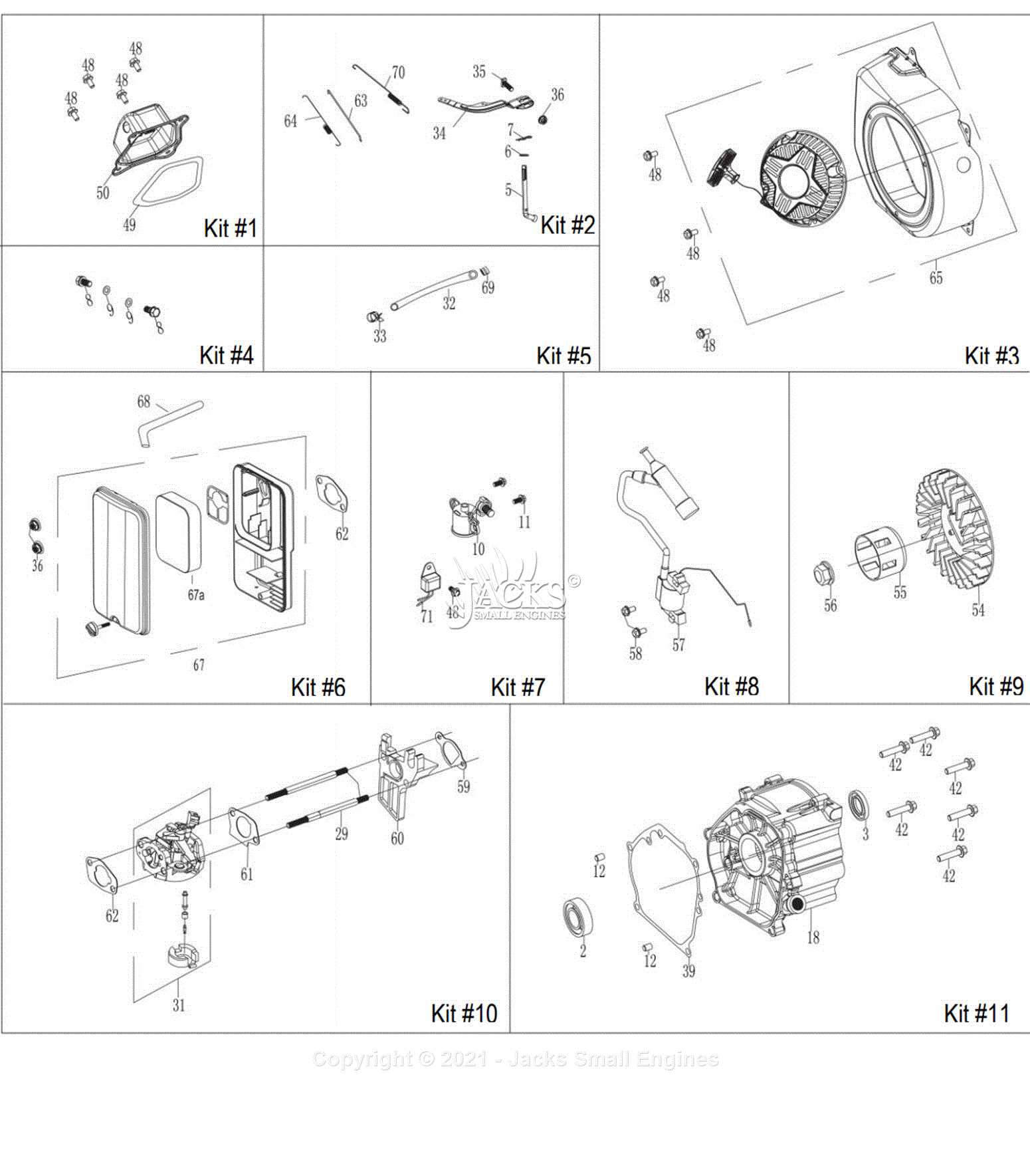

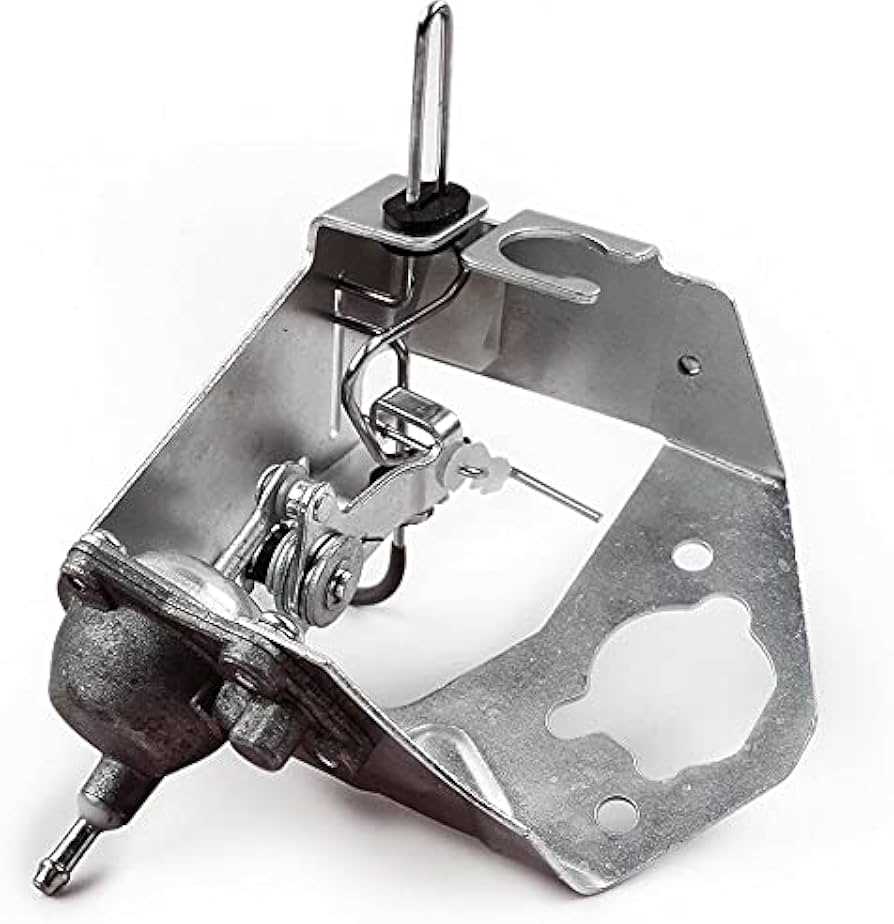

Importance of a Parts Diagram

Understanding the structure and components of any machine is crucial for effective maintenance and repair. A visual representation aids users in identifying essential elements, ensuring they can address issues efficiently. This clarity enhances the overall longevity and performance of the equipment.

Facilitates Troubleshooting

- Quickly locate malfunctioning components.

- Understand the relationships between different elements.

- Streamline the repair process by providing clear references.

Enhances Maintenance

- Promotes regular inspections by highlighting key areas.

- Assists in planning necessary replacements.

- Supports safe handling during servicing.

Common Issues with Generator Parts

In the realm of portable energy sources, various components can encounter difficulties that hinder performance. Recognizing these challenges is essential for effective troubleshooting and maintenance. Common malfunctions may arise from wear, improper use, or external factors, impacting efficiency and reliability.

Frequent Malfunctions

One of the primary issues involves fuel delivery. Blockages in the lines or filters can restrict flow, leading to inadequate power generation. Additionally, electrical components may suffer from corrosion or loose connections, disrupting the current supply.

Maintenance Tips

Regular inspections and cleanings can significantly reduce the likelihood of these issues. Ensure that all connections are tight and free of debris. Implementing a consistent maintenance routine will enhance longevity and performance.

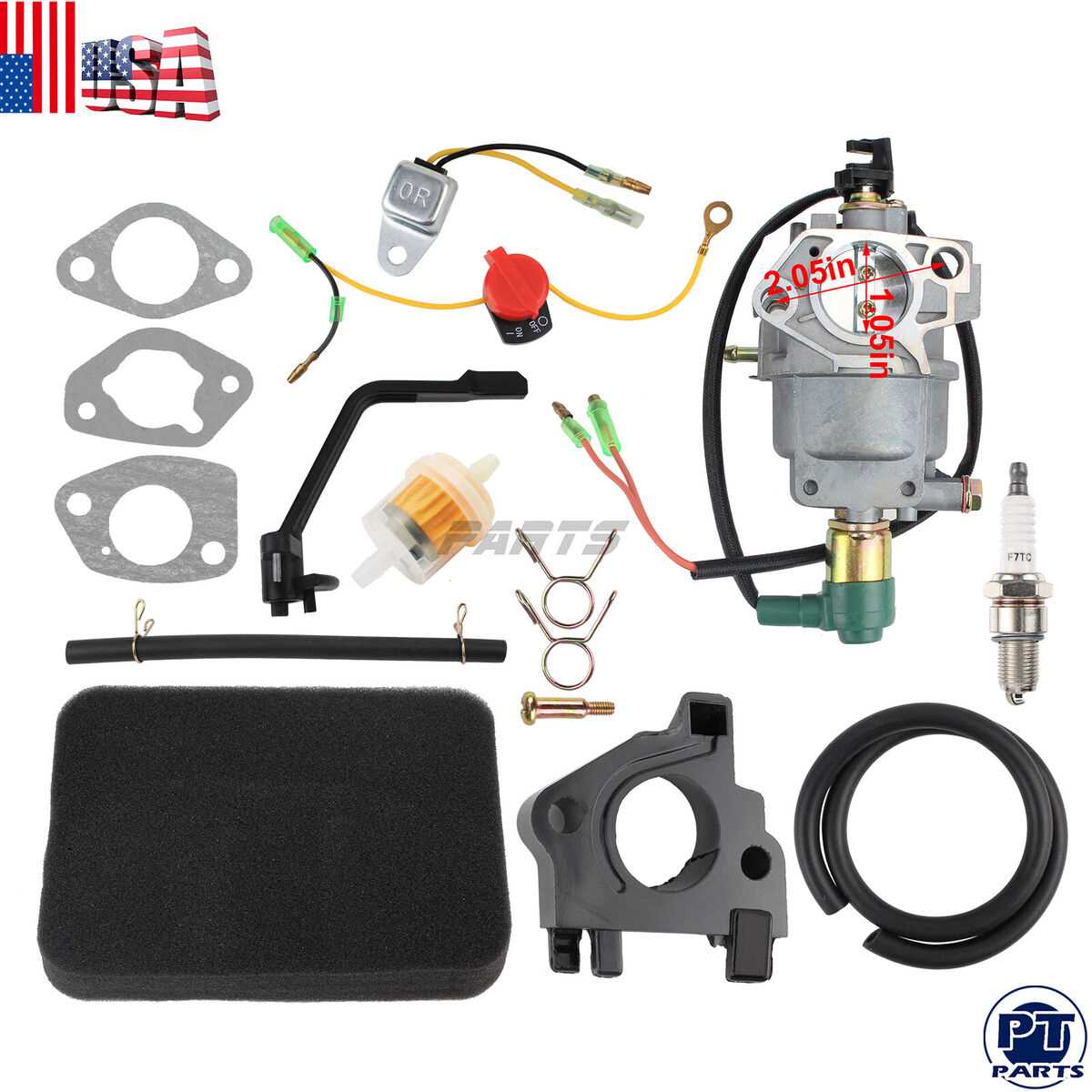

Where to Find Replacement Parts

Locating the necessary components for your machinery can significantly enhance its longevity and performance. Understanding where to search for these items is crucial for any maintenance or repair work.

Online Retailers

The internet is a treasure trove of options. Numerous online stores specialize in aftermarket items, offering a vast selection at competitive prices. Be sure to check customer reviews to ensure reliability and quality.

Local Repair Shops

Visiting nearby maintenance centers can provide valuable insights and resources. Local experts often stock common components and can assist you in identifying the right ones for your needs.

How to Interpret Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear layout of the various elements involved, allowing users to identify and locate specific pieces easily. Grasping the nuances of these visuals can significantly enhance the efficiency of troubleshooting and assembling machinery.

Start by familiarizing yourself with the overall layout. Typically, these visuals are organized logically, showcasing components in their respective arrangements. Pay attention to any labels or numbers that correspond to a list of items, as they often provide critical information about each element’s function and compatibility.

Next, analyze the connections between different elements. Understanding how parts interact can help you diagnose issues more accurately and determine the correct sequence for disassembly or assembly. Look for arrows or lines indicating movement or relationships, which can clarify how each piece contributes to the overall operation.

Additionally, take note of any additional notes or symbols present in the illustration. These can indicate special instructions, warnings, or maintenance tips that are vital for proper handling. By thoroughly reviewing these annotations, you can avoid common pitfalls and ensure a smoother repair process.

Lastly, practice makes perfect. The more you work with these visual aids, the more intuitive they will become. Over time, you’ll develop a keen eye for recognizing essential components and understanding their roles within the larger system.

Maintenance Tips for Your Generator

Regular upkeep is essential for ensuring the longevity and efficiency of your power supply unit. By following a few simple practices, you can prevent potential issues and maintain optimal performance. Here are some key maintenance recommendations to keep your equipment running smoothly.

| Task | Frequency | Details |

|---|---|---|

| Check Oil Level | Monthly | Ensure the oil is at the recommended level to prevent engine damage. |

| Inspect Air Filter | Every 3 Months | Clean or replace the filter to ensure proper airflow and efficiency. |

| Examine Fuel System | Every 6 Months | Check for leaks and ensure fuel is clean to avoid clogs. |

| Test Battery | Monthly | Verify that the battery is charged and in good condition. |

| Run Unit | Monthly | Operate the equipment under load to keep components in working order. |

Implementing these tips will help you avoid unexpected breakdowns and extend the life of your equipment. Consistent care not only improves performance but also ensures safety during operation.

Signs You Need a Replacement Part

Understanding when components require replacement is crucial for maintaining the efficiency and longevity of your machinery. Recognizing early signs of wear can prevent further damage and ensure optimal performance. Here are some key indicators to look out for.

Unusual Noises

If you notice strange sounds such as grinding, squeaking, or rattling during operation, it may signal that certain elements are wearing out or failing. These noises can indicate loose or damaged components that need immediate attention.

Decreased Performance

A noticeable drop in efficiency or power output can be a clear sign that something is amiss. If your equipment struggles to operate as it should, it’s essential to investigate further. This decline often points to parts that may no longer function effectively, warranting replacement.

Monitoring these signs closely can help you maintain your machinery in peak condition. Taking action at the right time not only saves you from costly repairs but also enhances the overall reliability of your equipment.

Comparing Powerhorse Models and Parts

When assessing various models in the realm of portable energy solutions, it’s essential to consider the unique characteristics and components that differentiate them. Each model is designed with specific features that cater to diverse user needs, whether for home backup, outdoor activities, or construction sites. Understanding these differences can help users select the most suitable option for their requirements.

| Model | Power Output | Runtime | Weight | Special Features |

|---|---|---|---|---|

| Model A | 1500 Watts | 8 hours | 45 lbs | Eco-friendly mode |

| Model B | 2500 Watts | 10 hours | 65 lbs | Electric start |

| Model C | 3000 Watts | 12 hours | 80 lbs | Dual fuel capability |

Each variant serves a different purpose, providing users with options that balance power needs, portability, and additional functionalities. By comparing specifications, one can determine which unit aligns best with specific tasks, ensuring efficiency and satisfaction in usage.

DIY Repairs for Generator Components

Maintaining and repairing essential machinery at home can save both time and money. Understanding how to troubleshoot and fix common issues can empower users to extend the life of their devices. This section covers straightforward approaches to managing repairs effectively.

Common Issues and Solutions

- Fuel System Problems:

- Check for clogs in the fuel lines.

- Replace old or contaminated fuel with fresh gasoline.

- Inspect and clean the fuel filter regularly.

- Electrical Failures:

- Examine the wiring for any signs of wear or damage.

- Ensure connections are secure and free of corrosion.

- Test the battery and replace if necessary.

- Starting Issues:

- Check the spark plug for wear and replace if needed.

- Inspect the starter mechanism for any obstructions.

- Ensure the choke is functioning properly.

Tools and Materials Needed

- Basic hand tools (screwdrivers, wrenches).

- Replacement parts (filters, spark plugs).

- Cleansing agents (carburetor cleaner, degreasers).

- Protective gear (gloves, goggles).

By tackling these repairs with the right approach, individuals can not only resolve issues but also gain a deeper understanding of their equipment. Regular maintenance prevents problems from escalating, ensuring reliable operation when needed most.

Safety Precautions When Repairing Generators

Ensuring a safe environment during maintenance work is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing repairs but also safeguard the equipment being serviced.

General Safety Measures

- Always wear appropriate personal protective equipment (PPE), such as gloves and goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Keep a fire extinguisher nearby, especially when dealing with fuel-related tasks.

- Disconnect the power source before beginning any repair work.

Electrical Safety Guidelines

- Use insulated tools to prevent electrical shock.

- Ensure that all connections are secure before reactivating the power.

- Be aware of any exposed wires or components during the repair process.

Resources for Generator Owners

Owning a power backup system can be a rewarding experience, offering peace of mind during outages. To ensure optimal performance and longevity, access to quality information and resources is essential for maintenance and troubleshooting.

Essential Guides

- User manuals for operational insights

- Maintenance schedules for regular upkeep

- Troubleshooting guides for common issues

Community and Support

- Online forums for owner discussions

- Social media groups for shared experiences

- Local workshops for hands-on training