Understanding Deutz Engine Parts Diagram for Better Maintenance

The functionality and efficiency of any mechanical system rely heavily on its intricate assembly of individual elements. A thorough grasp of these components is essential for optimal performance and maintenance. By exploring the layout and relationships among these parts, users can enhance their knowledge and troubleshoot issues more effectively.

In this section, we will delve into the various sections that constitute a typical power unit. Each component plays a crucial role, and understanding their arrangement allows for better insights into operation and repair. Ultimately, this knowledge empowers users to make informed decisions regarding upkeep and enhancements.

With a focus on clarity and accessibility, we aim to provide a comprehensive overview that simplifies the complexities of these assemblies. Whether you are a seasoned technician or a curious enthusiast, this guide serves as a valuable resource for navigating the essential elements of your system.

Understanding Deutz Engine Components

Exploring the intricate elements of machinery reveals a world of precision and functionality. Each component plays a vital role in ensuring optimal performance and efficiency. By examining these crucial sections, one can appreciate the engineering marvels that allow for seamless operation.

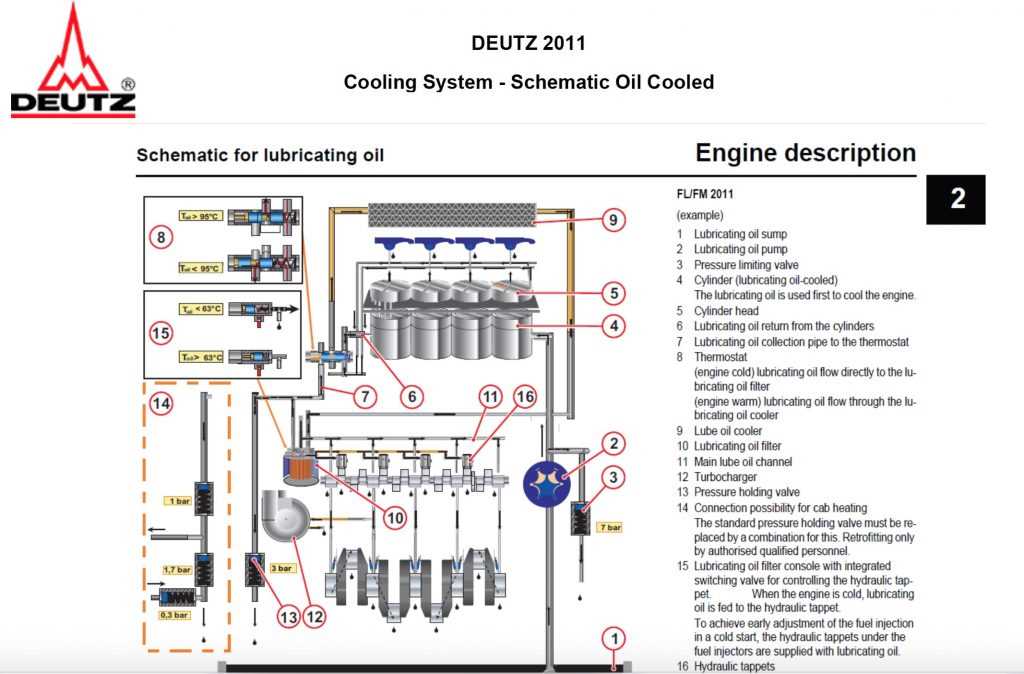

The core of any mechanical system consists of various interconnected units that work in harmony. These segments include everything from power generators to cooling mechanisms, each designed for a specific purpose. Understanding their interplay is essential for maintaining and enhancing overall functionality.

Key components such as pistons, valves, and fuel injectors are critical for the system’s operation. Their design and arrangement contribute significantly to the efficiency and durability of the whole structure. Recognizing how these elements function together enables a deeper insight into the machine’s capabilities.

By delving into the specifics of each section, one can uncover the ultimate potential for performance improvement and troubleshooting. A comprehensive understanding of these components not only aids in repairs but also empowers users to make informed decisions regarding upgrades and maintenance.

Importance of Engine Parts Diagrams

Visual representations of machinery components serve as essential tools for understanding and maintaining complex systems. They provide a clear overview of how various elements interact, facilitating effective troubleshooting and repairs. These illustrations are invaluable for both professionals and enthusiasts alike, ensuring that everyone involved can navigate intricate designs with ease.

Benefits of Visual Representations

- Enhanced Understanding: Illustrations break down complex assemblies, making it easier to comprehend how different components fit together.

- Effective Troubleshooting: Clear visuals help identify potential issues quickly, reducing downtime and improving efficiency.

- Guidance for Repairs: Step-by-step visuals offer essential guidance during maintenance procedures, ensuring tasks are completed accurately.

Applications in Various Fields

- Manufacturing: Accurate representations are crucial for assembly lines, allowing workers to identify and use the correct components.

- Automotive: Mechanics rely on detailed visuals to perform repairs and replacements efficiently.

- Aerospace: Complex systems require precise illustrations to ensure safety and reliability in operations.

Key Features of Deutz Engines

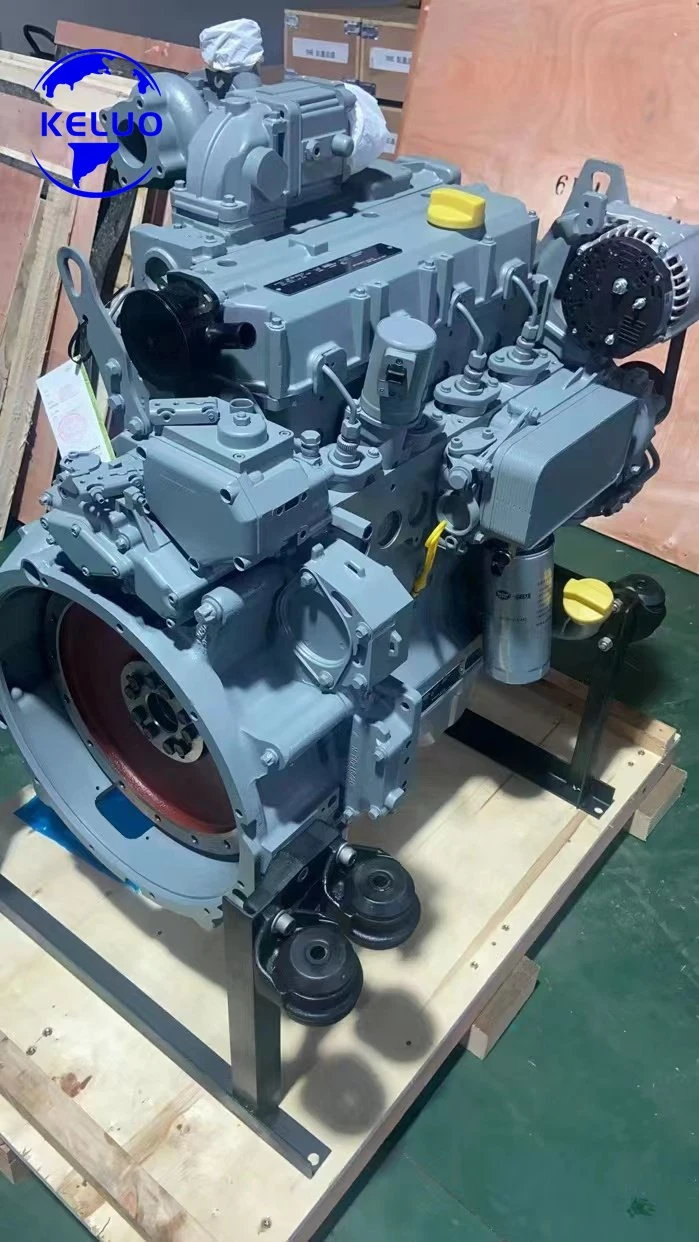

This section explores the distinctive attributes that set apart a renowned brand in the field of power machinery. Known for their robust performance and reliability, these machines are engineered to meet the demanding needs of various industries, ensuring efficiency and longevity.

Exceptional Durability

Constructed with high-quality materials, these units are designed to withstand harsh operating conditions. Their resilience minimizes wear and tear, ultimately leading to reduced maintenance costs and extended service life.

Advanced Technology

Incorporating innovative engineering solutions, these systems offer enhanced fuel efficiency and reduced emissions. The integration of cutting-edge control systems ensures optimal performance, allowing for adaptability in diverse applications.

With a commitment to excellence, this brand continues to set industry standards, providing reliable solutions for users around the globe.

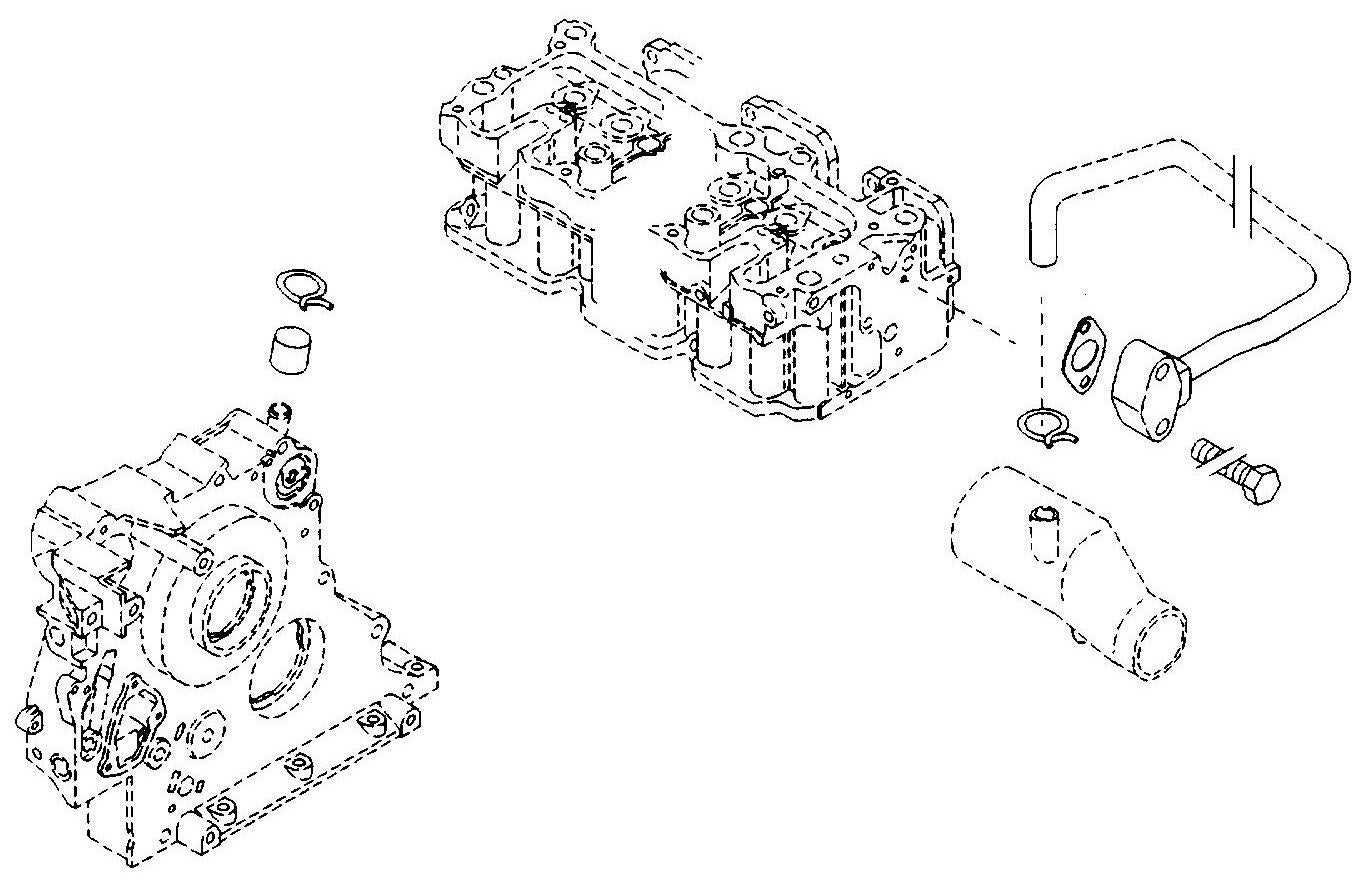

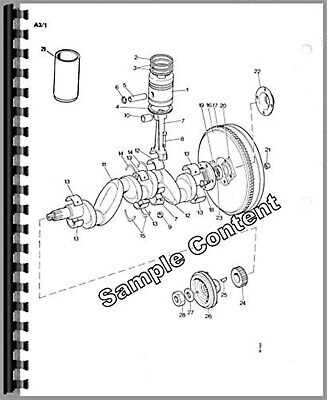

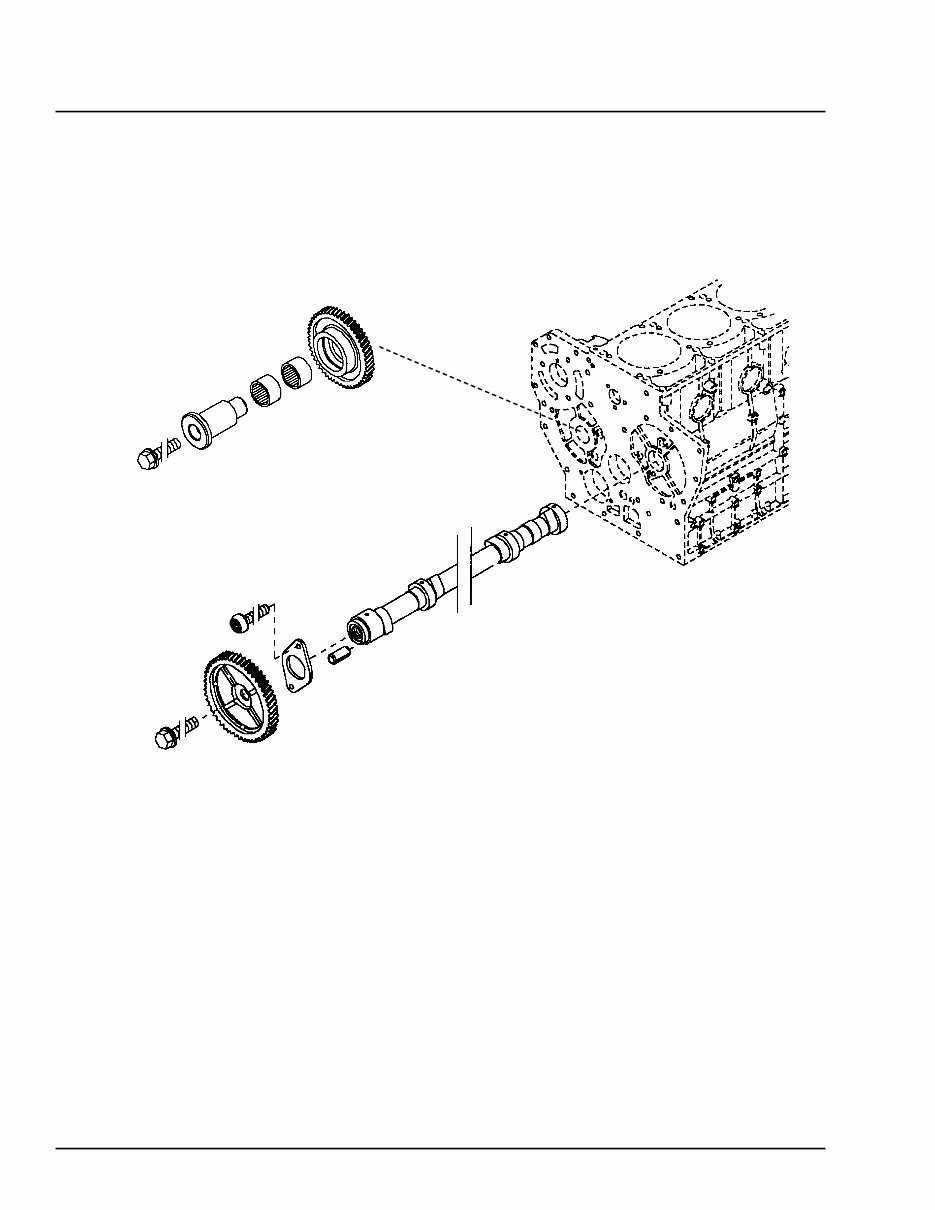

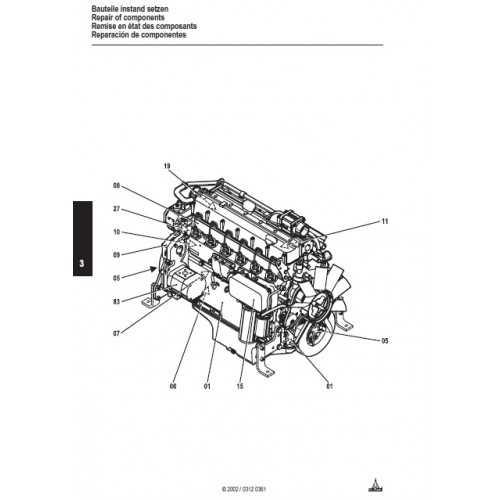

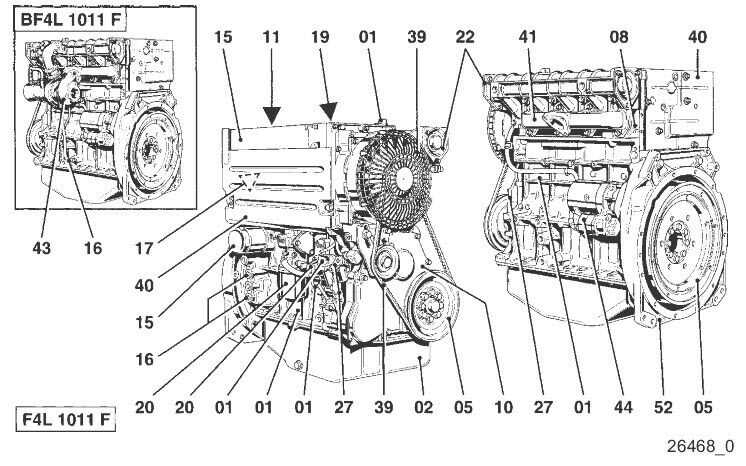

Identifying Each Engine Part

Understanding the components of a power unit is essential for maintenance and repair. Each element plays a vital role in the overall functionality, contributing to efficiency and performance.

- Cylinder Block: The main structure housing the cylinders.

- Pistons: Moving elements that create power through combustion.

- Crankshaft: Converts linear motion into rotational energy.

- Camshaft: Controls the timing of valve openings and closings.

- Valves: Allow air and fuel in, and exhaust out, of the cylinders.

- Fuel Injector: Delivers fuel into the combustion chamber.

Familiarity with these components will ultimately enhance understanding and facilitate better care of the machinery.

Common Issues with Deutz Engines

Many users encounter various challenges with their machinery over time. Understanding these frequent problems can lead to better maintenance and extended lifespan. Identifying symptoms early can save time and resources, making operation more efficient.

Performance Degradation

A noticeable decline in performance is often a primary concern. This may manifest as reduced power output or sluggish response. Factors such as fuel quality and air filtration play critical roles in maintaining optimal functionality. Regular checks and timely replacements can help mitigate these issues.

Overheating Concerns

Overheating is another prevalent problem that can lead to severe damage if not addressed. Common causes include coolant leaks, clogged radiators, and malfunctioning thermostats. Implementing routine inspections and ensuring proper cooling system maintenance are essential to prevent such occurrences.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of machinery requires regular upkeep and attention to detail. Proper maintenance practices not only enhance performance but also extend the lifespan of vital components. Here are some essential strategies to consider for effective preservation.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify wear and tear early, preventing larger issues from developing. |

| Fluid Changes | Change lubricants and cooling fluids as per the manufacturer’s recommendations to ensure optimal functioning. |

| Cleaning | Keep surfaces clean from debris and contaminants to avoid overheating and maintain efficiency. |

| Calibration | Ensure all systems are correctly calibrated to avoid unnecessary strain on components. |

| Training | Provide proper training for operators to minimize misuse and enhance operational efficiency. |

By adhering to these maintenance practices, you can significantly improve the reliability and lifespan of your machinery, ensuring it remains in optimal condition for years to come.

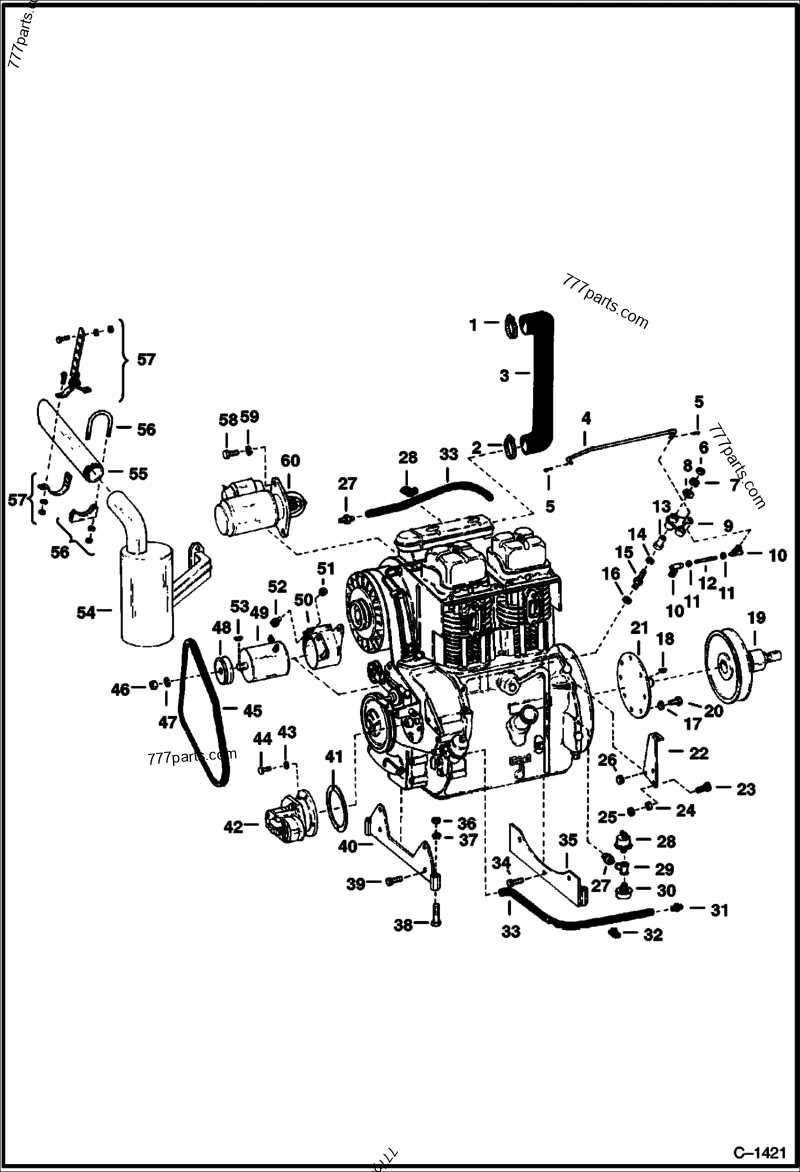

How to Read Diagrams Effectively

Understanding complex visuals is essential for anyone working with machinery. These illustrations serve as a roadmap, guiding users through various components and their functions. Mastering the skill of interpreting these visuals can significantly enhance your troubleshooting and maintenance capabilities.

Key Elements to Focus On

When approaching a visual representation, it’s important to identify specific elements that are crucial for comprehension:

| Element | Description |

|---|---|

| Symbols | Recognize the standard icons used to represent different components and functions. |

| Lines | Analyze how lines connect various symbols, indicating relationships or pathways. |

| Labels | Pay attention to annotations that provide additional context or specifications. |

| Legends | Utilize the legend for a quick reference to the meaning of symbols and colors. |

Practical Tips for Effective Interpretation

To enhance your ability to decode these visuals, consider the following strategies:

- Start by familiarizing yourself with the layout and structure before diving into details.

- Take notes on significant components to build a clearer understanding of the system.

- Practice regularly with different representations to improve your skill set.

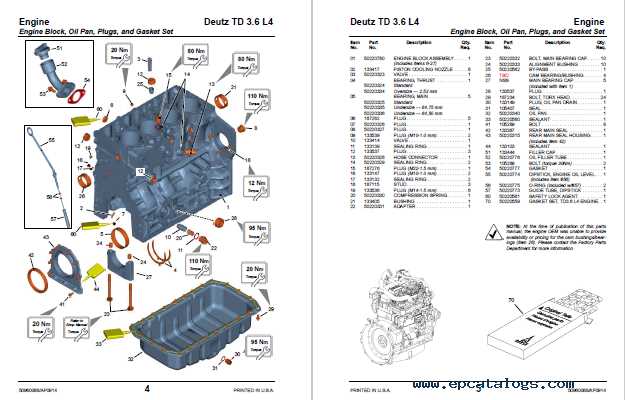

Differences Between Engine Models

When exploring various models of power units, it’s essential to understand how their design and functionality can differ significantly. Each variant is tailored to meet specific performance requirements and operational environments, resulting in unique attributes that cater to diverse applications.

One primary distinction lies in the configuration of components, which affects the overall efficiency and power output. Variations in cylinder arrangement, displacement, and fuel systems contribute to differing torque characteristics and fuel consumption rates. Additionally, advancements in technology lead to differences in emissions control and durability, making some models more suitable for stringent environmental regulations.

Another critical aspect is the compatibility with ancillary systems, such as cooling and lubrication setups. Each type may have unique integration needs, impacting maintenance schedules and operational costs. Understanding these differences helps users select the most appropriate option for their specific needs, ultimately enhancing performance and reliability.

Replacement Parts: What to Know

Understanding the essentials of component swaps is crucial for maintaining machinery efficiency. Whether you’re addressing wear and tear or upgrading to improve performance, knowing what to consider can streamline the process.

When sourcing substitutes, it’s vital to assess compatibility, quality, and availability. Below is a summary of key factors to keep in mind:

| Factor | Description |

|---|---|

| Compatibility | Ensure that the replacement fits your specific model and requirements. |

| Quality | Opt for high-grade components to enhance longevity and reliability. |

| Availability | Check if the item is readily obtainable to avoid downtime. |

| Warranty | Look for warranties that can provide peace of mind and protection. |

Where to Find Diagrams Online

Locating detailed illustrations for machinery components can enhance understanding and facilitate maintenance tasks. Various online resources cater to individuals seeking these valuable visual aids. Here, we explore reliable platforms and tips for effective searches.

Specialized Websites

Numerous websites focus specifically on machinery and its various elements. Sites dedicated to repair manuals often provide high-quality visuals along with descriptions. These resources can be invaluable for users looking for comprehensive guides.

Online Forums and Communities

Joining online forums can be an excellent way to connect with enthusiasts and professionals. Members frequently share links to valuable illustrations and even post their own creations. Engaging with these communities can lead to finding rare and detailed resources.

Repairing vs. Replacing Components

When it comes to maintaining machinery, the decision to repair or replace certain elements is crucial. Each option presents its own set of advantages and challenges that can impact performance, cost, and longevity. Understanding the nuances of both approaches can lead to more informed decisions, ultimately ensuring optimal functionality and efficiency.

Repairing components often involves fixing the existing unit to restore its original state. This approach can be more cost-effective and environmentally friendly, as it minimizes waste. However, it may not always guarantee the same level of reliability, especially if the component has experienced significant wear and tear.

On the other hand, replacing components typically ensures that the new parts meet current performance standards and reliability expectations. Although this option may require a higher initial investment, it can lead to long-term savings by reducing the likelihood of future breakdowns. Below is a comparison of both strategies:

| Criteria | Repairing | Replacing |

|---|---|---|

| Cost | Generally lower initial cost | Higher upfront investment |

| Longevity | Dependent on the extent of damage | Typically longer lifespan |

| Performance | May not fully restore original performance | Meets or exceeds original specifications |

| Environmental Impact | Reduces waste | Involves disposal of old components |

| Time | Can be quicker for minor issues | May require longer lead times |

In conclusion, the choice between repairing and replacing components should be guided by a careful evaluation of the specific situation. Factors such as budget, time constraints, and the criticality of the machinery will play a significant role in making the best decision for maintenance and operational efficiency.

Understanding Engine Performance Metrics

Evaluating the capabilities of a mechanical unit is crucial for optimizing its functionality and longevity. By analyzing specific indicators, one can gain insights into how effectively the system operates under various conditions. These metrics serve as benchmarks, allowing for performance assessment and enhancement.

Key Performance Indicators

Several fundamental metrics play a vital role in performance evaluation. These indicators help in diagnosing issues and ensuring optimal operation.

| Metric | Description |

|---|---|

| Power Output | The measure of work done over time, indicating the system’s capability to perform tasks. |

| Efficiency | Ratio of useful work performed to the total energy consumed, highlighting energy utilization. |

| Torque | The rotational force generated, critical for assessing performance in various applications. |

Importance of Metrics

Understanding these metrics is essential for troubleshooting and optimizing performance. By regularly monitoring them, one can ensure the unit operates at its ultimate potential, minimizing downtime and enhancing productivity.

Future Trends in Engine Technology

The landscape of mechanical propulsion systems is rapidly evolving, driven by innovations aimed at enhancing efficiency, sustainability, and performance. As the world shifts towards greener alternatives, advancements are emerging that promise to redefine traditional concepts and methods, leading to more eco-friendly solutions that meet modern demands.

One prominent trend is the integration of hybrid systems, which combine multiple power sources to optimize energy consumption. This approach not only improves fuel efficiency but also reduces emissions, aligning with global efforts to combat climate change. Additionally, advancements in electric power technology are paving the way for fully electrified systems, offering a clean and sustainable alternative to conventional models.

Another significant development is the incorporation of smart technologies. The use of artificial intelligence and data analytics enables real-time monitoring and management, enhancing operational efficiency and predictive maintenance. This results in reduced downtime and improved performance, ensuring that these systems can adapt to various conditions seamlessly.

Furthermore, research into alternative fuels is gaining momentum, exploring options such as hydrogen and biofuels. These alternatives present the potential to further decrease reliance on fossil fuels, fostering a shift towards more sustainable practices in the industry.

In conclusion, the future of propulsion technologies is characterized by a blend of innovation and sustainability. As these trends continue to unfold, they will not only enhance performance but also contribute to a greener planet, setting new standards for what is possible in the field.