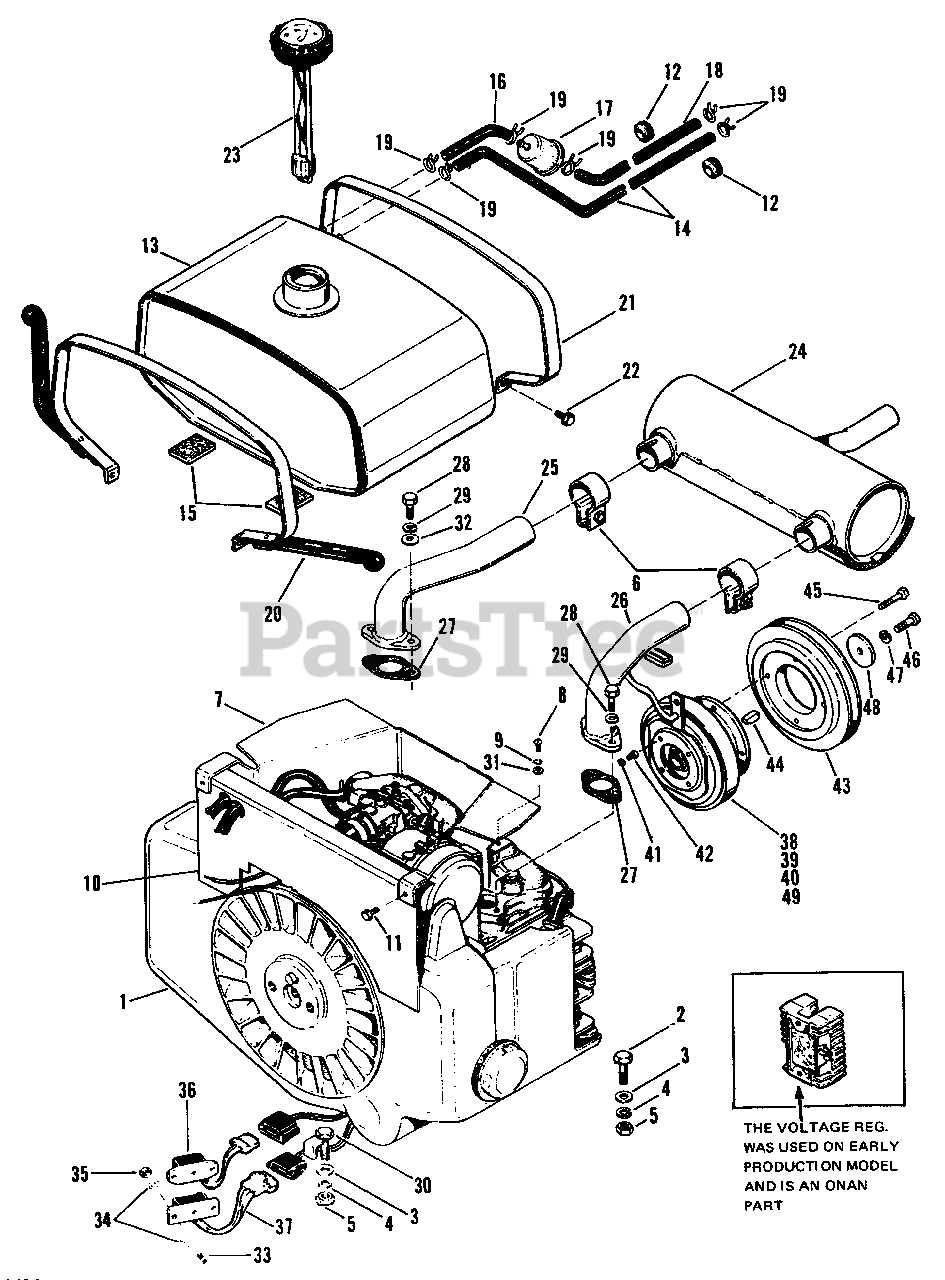

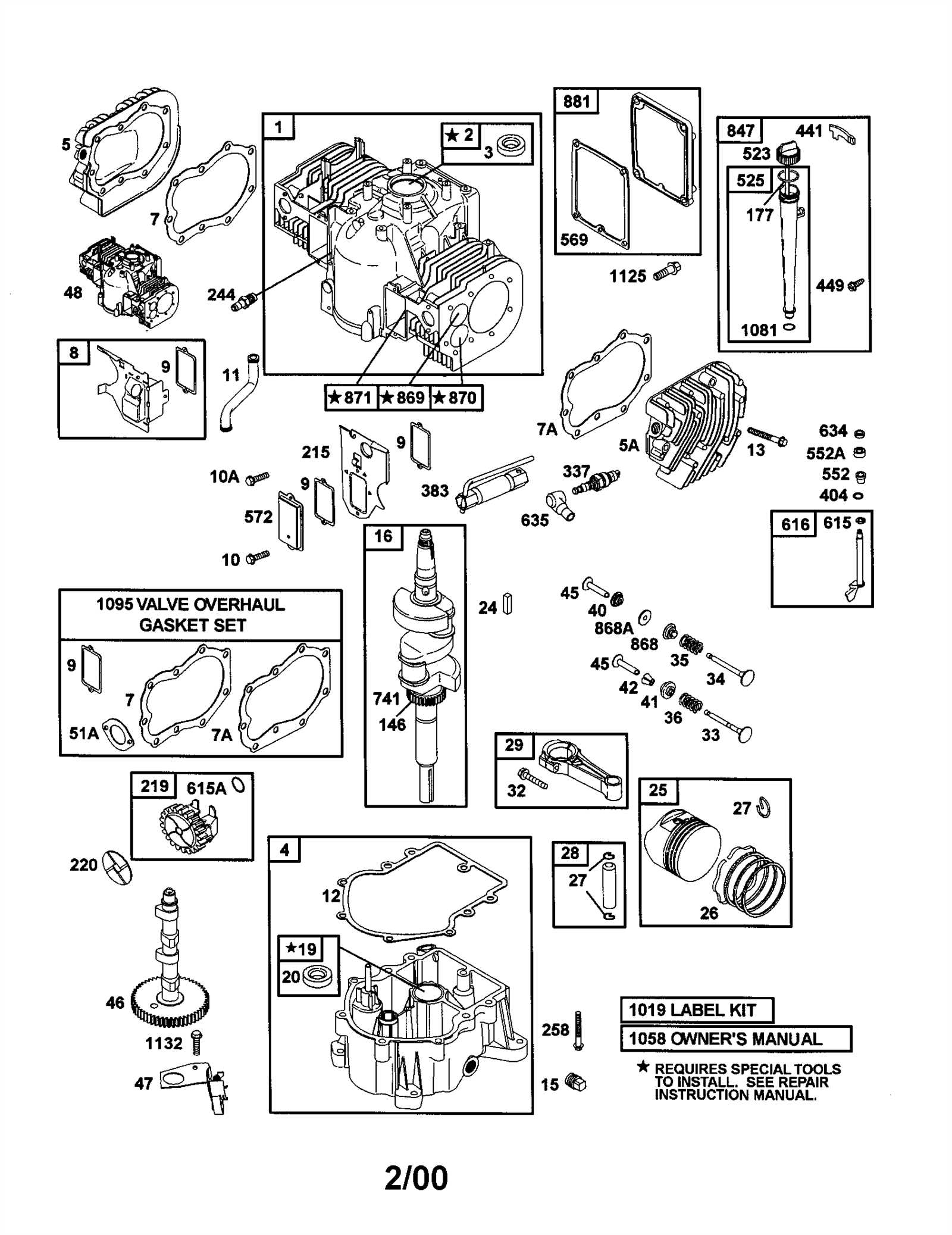

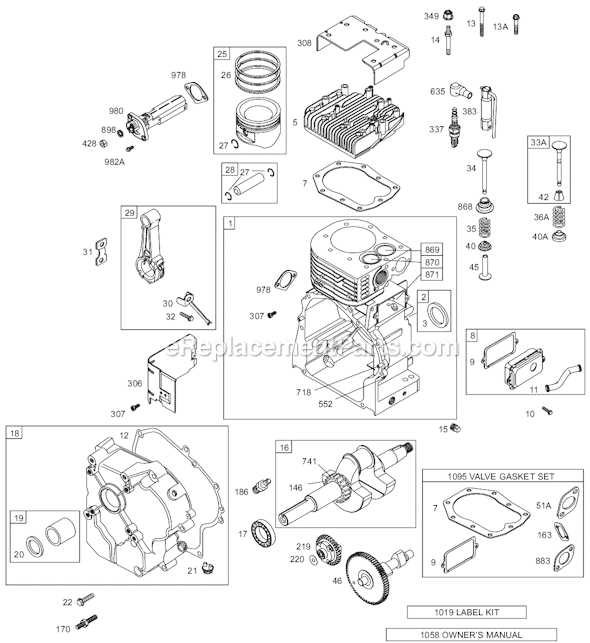

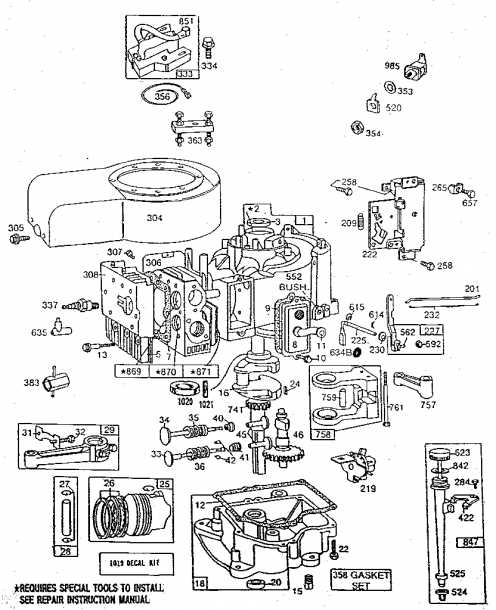

Parts Diagram for 19.5 HP Briggs and Stratton Engine

Exploring the essential elements of small power units can provide valuable insights into their functionality and maintenance. These machines, commonly found in various applications, rely on a multitude of components working together to achieve optimal performance. Familiarity with these elements enhances the user’s ability to troubleshoot and conduct repairs efficiently.

Recognizing the various sections and features of these systems is crucial for anyone looking to gain a deeper understanding of their operation. From the fundamental mechanisms to specialized accessories, each component plays a significant role in ensuring seamless functionality. By delving into the layout and function of these units, users can develop a comprehensive knowledge that aids in both usage and upkeep.

This section delves into the essential elements of a small power unit, highlighting their functions and interrelationships. Understanding these components is vital for maintenance and troubleshooting, ensuring optimal performance and longevity of the machinery.

Key Components and Their Functions

The primary components of a power unit include various assemblies that work together to convert fuel into motion. Each part plays a specific role, contributing to the overall functionality and efficiency of the system.

| Component | Description |

|---|---|

| Fuel Delivery System | Responsible for transporting fuel to the combustion chamber. |

| Ignition Assembly | Initiates the combustion process, igniting the fuel-air mixture. |

| Crankshaft | Converts linear motion into rotational energy. |

| Cooling System | Prevents overheating by dissipating heat during operation. |

| Exhaust System | Channels exhaust gases away from the unit, ensuring efficient operation. |

Understanding Assembly Interactions

Each assembly interacts with others to create a seamless operation. Analyzing these interactions can help identify potential issues and facilitate more efficient repairs and enhancements.

Key Features of 19.5 hp Engine

This powerful small motor is known for its exceptional performance and reliability. Designed for various applications, it combines innovative technology with user-friendly features to ensure efficient operation. The design incorporates several components that work harmoniously, resulting in enhanced power delivery and durability.

Robust Construction

The sturdy build of this motor allows it to withstand rigorous use in demanding environments. High-quality materials are utilized in its construction, providing resilience against wear and tear. This durability ensures a longer lifespan, making it a cost-effective choice for users.

Efficient Fuel Consumption

One of the standout characteristics of this unit is its ability to deliver impressive performance while maintaining low fuel consumption. Advanced engineering techniques contribute to optimized efficiency, allowing users to achieve more with less energy input. This feature not only saves costs but also reduces environmental impact.

Common Replacement Parts Explained

When maintaining small power units, it’s essential to understand the various components that may require substitution over time. Knowing these common elements not only ensures efficient operation but also extends the lifespan of the machinery. This section will explore the typical items often replaced, helping users make informed decisions during upkeep.

Air Filtration Elements

One of the most frequently replaced components is the air filtration unit. This element prevents dust and debris from entering the combustion chamber, ensuring optimal performance. Regular replacement of this part can enhance fuel efficiency and prevent unnecessary wear on the motor.

Fuel Delivery Systems

Another crucial aspect to consider is the fuel delivery mechanism. Over time, components like fuel lines and filters may become clogged or damaged. Replacing these ensures a consistent supply of fuel, which is vital for reliable operation. Neglecting this can lead to starting issues and decreased power output.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. By following a few essential practices, you can significantly extend the lifespan of your equipment. Regular maintenance not only enhances performance but also prevents unexpected breakdowns.

Regular Inspection

Conducting frequent checks is crucial for identifying potential issues early. Here are some key aspects to focus on:

- Examine the oil levels and quality.

- Inspect air filters for dirt and debris.

- Check for signs of wear in belts and hoses.

- Ensure that the cooling system is functioning properly.

Scheduled Servicing

Adhering to a maintenance schedule can help in keeping your equipment in top condition. Consider the following:

- Change the oil at recommended intervals.

- Replace filters as needed to ensure optimal airflow.

- Sharpen blades regularly for efficient operation.

- Clean the exterior to prevent rust and buildup.

Proper Storage

Storing your machinery correctly can make a significant difference in its longevity:

- Keep equipment in a dry and sheltered area.

- Avoid exposure to extreme temperatures.

- Use protective covers to prevent dust accumulation.

How to Read Parts Diagrams

Understanding technical illustrations can significantly enhance your ability to maintain and repair machinery. These visual representations offer a simplified view of complex components, allowing users to identify and locate each element efficiently. Mastering the interpretation of these drawings is essential for anyone looking to engage with mechanical systems effectively.

Familiarize Yourself with Symbols

Every schematic utilizes specific symbols to represent various elements. Familiarity with these symbols can streamline the process of understanding the layout. Common icons may indicate screws, bolts, and connections, each playing a critical role in the assembly or function of the machinery.

Follow the Layout Sequence

Typically, the arrangement of components follows a logical sequence, aiding in understanding how parts interact. Starting from a central element, you can trace the connections outward, observing how each component integrates into the overall system. This approach not only clarifies the assembly process but also aids in troubleshooting issues that may arise.

Tools Needed for Engine Repairs

When it comes to performing maintenance or fixes on small machinery, having the right tools at your disposal is essential. Proper equipment not only facilitates efficient work but also ensures safety and accuracy during the repair process. Below is a guide to the essential tools that every mechanic should have on hand.

Essential Hand Tools

A range of hand tools is crucial for various repair tasks. Basic items include wrenches, screwdrivers, and pliers. These tools allow you to tighten or loosen components and access tight spaces. It’s beneficial to have a set of both metric and standard sizes to accommodate different fittings.

Power Tools for Efficiency

Power tools can greatly enhance the speed and effectiveness of your repairs. A cordless drill is particularly useful for driving screws and drilling holes. Additionally, a reciprocating saw can aid in cutting through stubborn materials. These tools save time and effort, making repairs less labor-intensive.

Identifying Common Issues in Engines

Recognizing frequent problems in mechanical power sources is crucial for effective maintenance and optimal performance. Various factors can contribute to malfunctions, and understanding these can help prevent further complications.

Common Symptoms to Watch For

Being aware of the signs that indicate potential troubles is essential. Here are several symptoms that may suggest underlying issues:

- Unusual noises during operation

- Inconsistent power delivery

- Excessive vibration

- Difficulty starting or stalling

Potential Causes of Malfunctions

Several factors may lead to the symptoms mentioned above. Identifying these causes can assist in effective troubleshooting:

- Fuel quality issues

- Clogged air filters

- Worn-out components

- Improper lubrication

Where to Find Genuine Parts

Locating authentic components for small machinery is essential for maintaining optimal performance and longevity. Whether you are a seasoned technician or a novice enthusiast, ensuring the use of quality replacements can significantly affect the functionality of your equipment. This section provides insights on reliable sources for sourcing these vital components.

Authorized retailers often serve as the best option for acquiring genuine items. They typically offer a comprehensive selection and provide expert guidance on compatibility and installation. Additionally, manufacturer websites are invaluable resources that often feature a catalog of available components tailored for various models.

Online marketplaces also present a viable alternative, enabling users to compare prices and availability from different vendors. However, it’s crucial to verify the authenticity of the sellers to avoid counterfeit products. Reading customer reviews and ratings can help in making informed decisions.

Local repair shops or service centers frequently stock genuine components or can assist in ordering them directly from manufacturers. Engaging with experienced professionals can lead to valuable recommendations on where to purchase reliable replacements tailored to your specific requirements.

Step-by-Step Repair Instructions

This section outlines a comprehensive approach to addressing common issues encountered with a specific small motor. By following these detailed guidelines, users can effectively troubleshoot and resolve various mechanical problems, ensuring optimal functionality and longevity.

Preparation and Safety Measures

Before starting any maintenance work, it is crucial to gather the necessary tools and safety equipment. Make sure to wear protective gloves and eyewear. Additionally, ensure the work area is clean and well-ventilated to prevent any accidents.

Disassembly Process

Begin by carefully removing the outer casing to access internal components. Take note of the arrangement of each part as you proceed. It can be helpful to take pictures or label parts to assist in reassembly. Check for wear and damage while disassembling, and replace any worn components with appropriate alternatives.

After completing the repairs, reassemble the unit by reversing the disassembly steps. Test the machine to confirm that it operates smoothly, and make any necessary adjustments to ensure optimal performance.

Understanding Engine Performance Metrics

The performance of a mechanical power unit is often assessed through various metrics that indicate its efficiency and operational capacity. These measurements provide essential insights into how well the unit performs under different conditions, guiding users in optimizing their machinery for better results. By familiarizing oneself with these metrics, operators can make informed decisions regarding maintenance and upgrades.

Key performance indicators typically include power output, torque, fuel efficiency, and operating temperature. Each of these factors contributes to the overall effectiveness of the machine, affecting its suitability for specific tasks.

| Performance Metric | Description |

|---|---|

| Power Output | The maximum amount of work produced by the unit, usually measured in horsepower. |

| Torque | The rotational force generated, impacting the ability to perform heavy tasks. |

| Fuel Efficiency | The ratio of power produced to fuel consumed, indicating economic operation. |

| Operating Temperature | The temperature at which the unit functions optimally, crucial for preventing overheating. |

Understanding these metrics allows for better monitoring of mechanical performance and aids in diagnosing potential issues before they escalate. By regularly evaluating these factors, operators can ensure their machinery remains reliable and efficient.

Enhancing Engine Efficiency Practices

Improving the performance of a power unit involves a combination of effective maintenance strategies and innovative approaches. By focusing on optimal functionality, operators can ensure that the machinery operates at its best, leading to enhanced productivity and longevity.

Regular Maintenance: Consistent upkeep is essential for maximizing output. This includes routine checks of components, timely oil changes, and the replacement of worn-out parts. Implementing a schedule for maintenance activities can prevent unexpected failures and reduce downtime.

Fuel Quality: Utilizing high-quality fuel significantly influences performance. Clean and efficient fuel ensures better combustion, leading to increased power output. Additionally, considering additives that enhance fuel efficiency can provide an extra edge.

Airflow Optimization: Ensuring proper airflow is critical for combustion efficiency. Regularly cleaning air filters and ensuring unobstructed air passages can help maintain optimal performance levels. This practice allows for better mixing of air and fuel, promoting efficient combustion.

Utilization of Technology: Incorporating advanced monitoring tools can assist in tracking performance metrics. These tools can provide insights into fuel consumption, temperature variations, and other vital statistics, enabling proactive adjustments to maintain efficiency.

Frequently Asked Questions About Engines

This section addresses common inquiries related to power units and their functionality. Understanding these aspects can greatly enhance user experience and maintenance knowledge.

What are the main components of a power unit?

The primary elements include the ignition system, fuel system, lubrication system, and cooling system. Each part plays a vital role in ensuring smooth operation and efficiency.

How often should maintenance be performed?

Regular upkeep is essential for optimal performance. It’s recommended to check the components periodically, change the oil, and replace filters as needed to prevent any issues. Timely maintenance extends the lifespan of the machine.

Knowledge about these aspects will empower users to make informed decisions regarding their machinery.