Kubota Three Point Hitch Parts Diagram Guide

In the realm of agricultural machinery, the significance of attachment mechanisms cannot be overstated. These systems facilitate the connection of various implements to the main unit, enhancing versatility and functionality in diverse tasks. Mastery of these components is essential for effective operation and maintenance.

Exploring the intricate layout of these essential elements reveals a wealth of information about their structure and interconnectivity. Familiarity with this arrangement empowers operators to troubleshoot issues efficiently and optimize their equipment’s performance.

Moreover, recognizing the specific functions of each component can lead to improved operational strategies. A comprehensive understanding of the assembly not only aids in maintenance but also contributes to maximizing productivity in the field.

Kubota Three Point Hitch Overview

This section explores the essential components that facilitate the connection between a tractor and various implements, enhancing the machine’s versatility and efficiency. Understanding these elements is crucial for optimal performance and effective operation.

Functionality and Importance

The mechanism serves as a pivotal link, allowing for the seamless attachment of tools. This integration maximizes productivity, enabling tasks ranging from tilling to lifting with ease.

Key Components

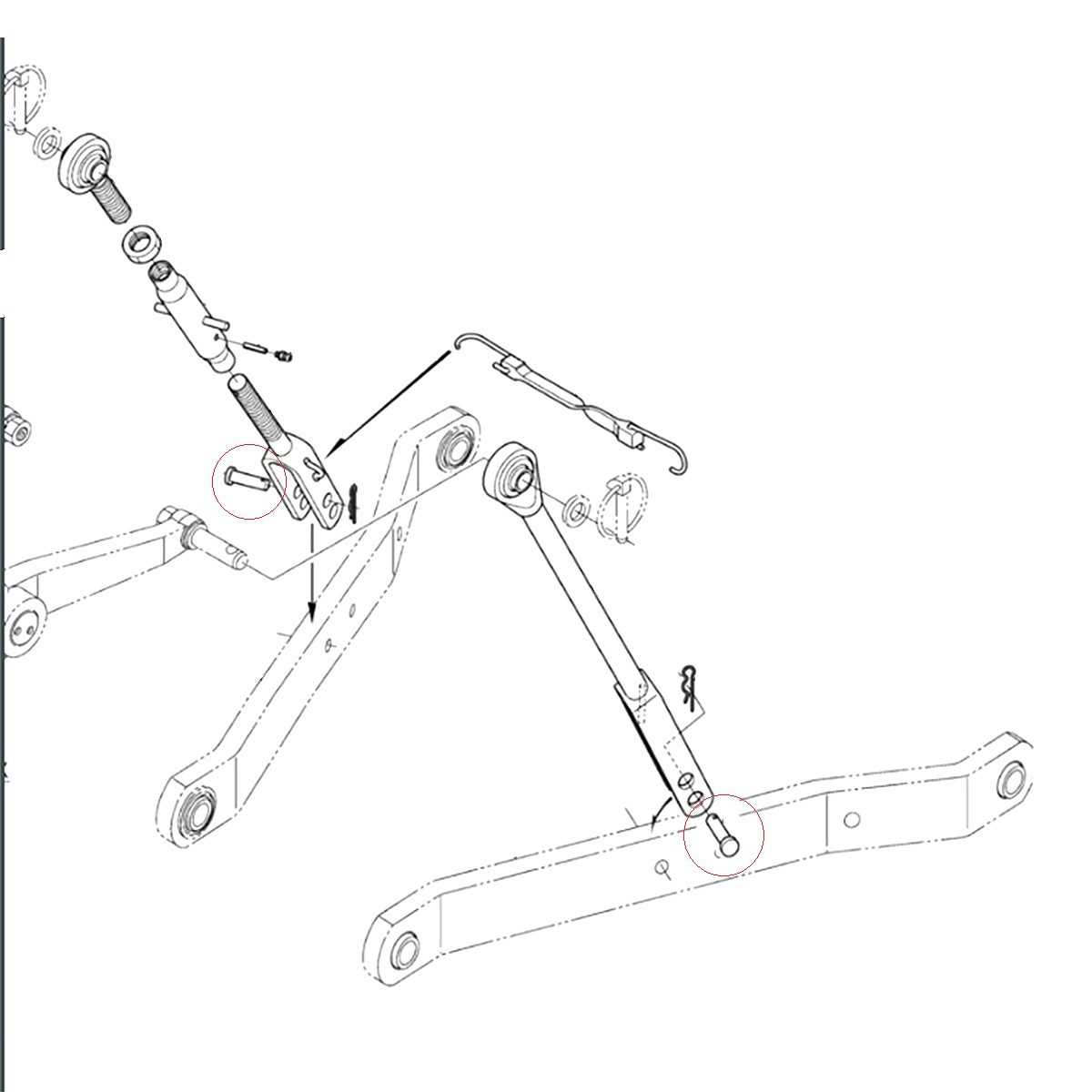

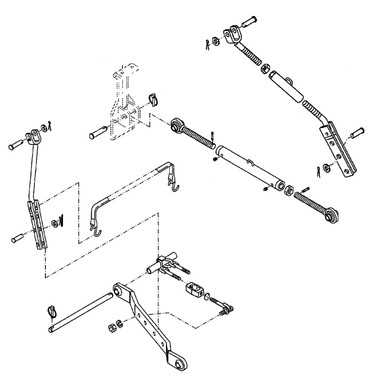

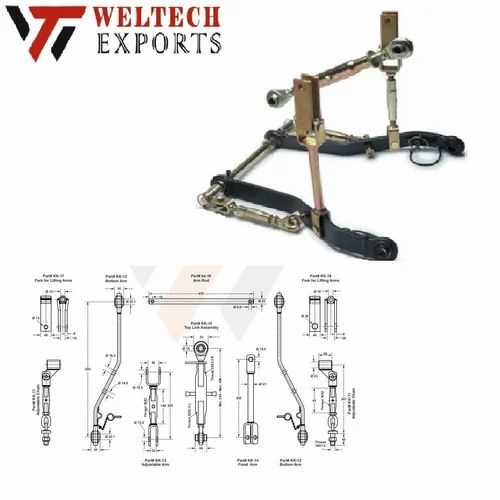

Critical elements include the upper link, lower links, and a leveling device. These components work in unison to ensure stability and precision, making them indispensable for any agricultural operation.

Understanding Three Point Hitch Functionality

The functionality of an attachment system on agricultural machinery is crucial for enhancing productivity and versatility. This mechanism allows for seamless integration of implements, providing operators with the ability to perform various tasks efficiently. Understanding how this system operates can lead to better management and utilization of equipment.

At its core, this setup employs a system of arms and connectors that enable implements to be raised, lowered, and tilted. This flexibility is essential for adapting to different terrain and tasks, making it a vital component for modern farming practices.

Additionally, the design facilitates quick attachment and detachment of tools, reducing downtime and increasing operational efficiency. Operators can easily switch between implements, allowing for a diverse range of agricultural activities without extensive manual effort.

Key Components of the System

Understanding the essential elements of this attachment mechanism is crucial for effective operation and maintenance. Each component plays a vital role in ensuring stability and functionality, contributing to the overall efficiency of the equipment.

- Top Link: This adjustable element allows for precise alignment of the implement, facilitating optimal performance.

- Lower Links: These side arms provide stability and support to the attachment, ensuring it remains securely in place during operation.

- Lift Arm: Responsible for raising and lowering the implement, this component is essential for operational versatility.

- Quick Attach System: This feature simplifies the process of connecting and disconnecting implements, enhancing user efficiency.

- Clevis: This part connects the implement to the lower links, providing a robust attachment point.

Each of these elements must work in harmony to achieve the ultimate effectiveness of the setup, enabling seamless operation across various tasks.

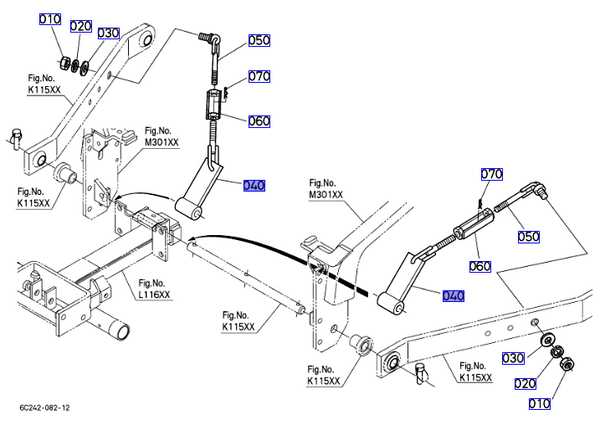

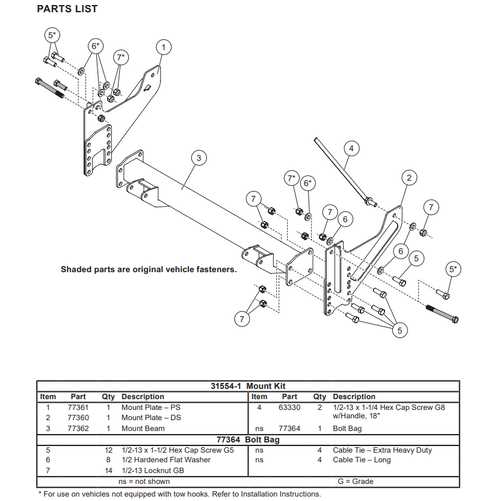

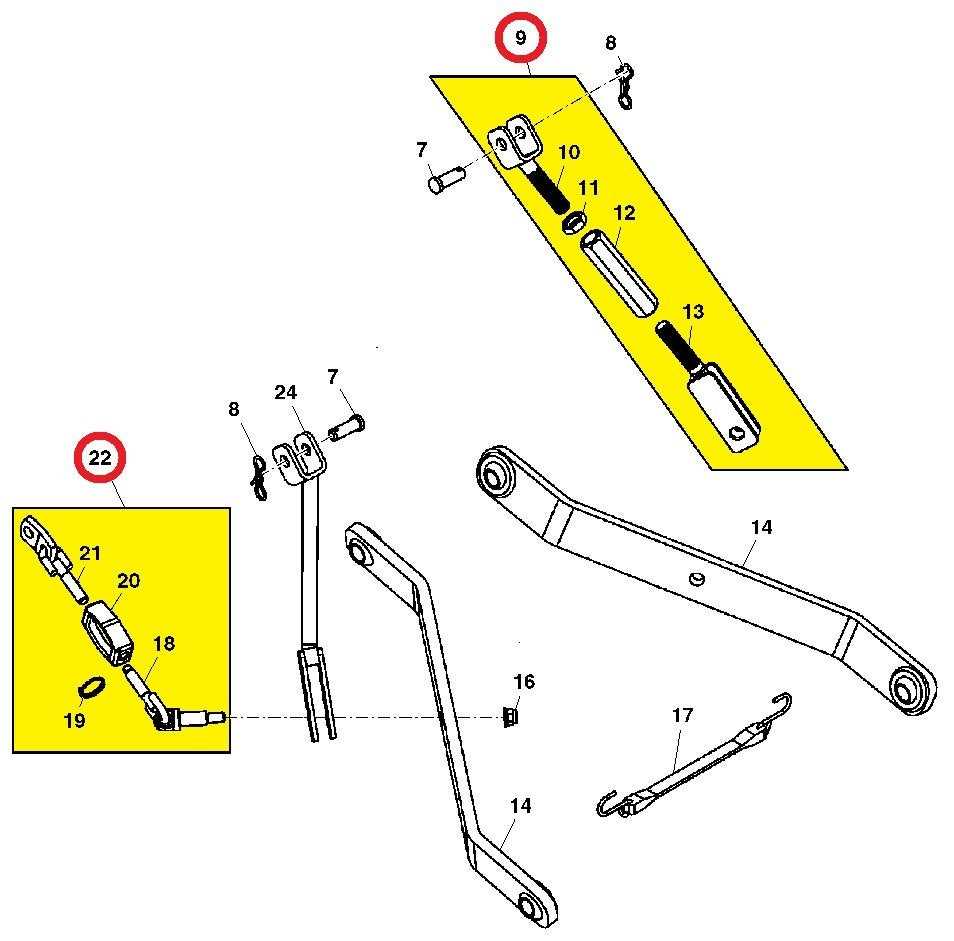

How to Read the Parts Diagram

Understanding the layout of a machinery component illustration is essential for effective maintenance and repairs. Each section typically represents various elements, allowing users to identify and locate specific items easily.

Familiarize yourself with the symbols used in the illustration. These graphical representations often denote different parts and their functions, which is crucial for grasping the overall assembly.

Follow the numbering system or labels carefully. They often correlate with a list or legend, providing detailed descriptions that can guide you in sourcing replacements or making adjustments.

Finally, cross-reference the diagram with your equipment manual. This will enhance your understanding and ensure you are making informed decisions during maintenance or repair tasks.

Maintenance Tips for Hitch Parts

Proper care and upkeep of essential agricultural equipment components are crucial for ensuring longevity and optimal performance. Regular attention can prevent costly repairs and enhance functionality.

Regular Inspections: Conduct frequent examinations to identify any wear or damage. Look for signs of rust, corrosion, or loose connections that may affect performance.

Lubrication: Apply appropriate lubricants to moving elements to minimize friction and wear. This practice promotes smooth operation and reduces the risk of breakdowns.

Cleaning: Keep components free from dirt and debris. Use a soft brush or cloth to remove buildup that could interfere with operation.

Storage: When not in use, store equipment in a dry and protected environment. This helps prevent exposure to elements that can cause deterioration.

Replacement: Be proactive about replacing any worn or damaged components. Timely replacement can avert further issues and maintain efficiency.

By following these maintenance tips, you can ensure that your equipment remains in peak condition, ready to tackle any task efficiently.

Common Issues and Solutions

When operating attachment systems, users may encounter various challenges that can hinder performance. Identifying these problems promptly and knowing effective solutions is crucial for maintaining optimal functionality.

Frequent Problems

| Issue | Description |

|---|---|

| Misalignment | Attachments may not align properly, leading to uneven operation. |

| Hydraulic Leaks | Fluid leakage can reduce effectiveness and pose safety risks. |

| Wear and Tear | Components may deteriorate over time, affecting performance. |

Effective Solutions

Addressing these issues often involves regular maintenance, careful inspection, and timely replacements. Ensuring proper alignment, checking for leaks, and replacing worn components can significantly enhance the system’s performance.

Choosing the Right Accessories

Selecting the appropriate add-ons for your agricultural equipment can significantly enhance its functionality and efficiency. Understanding the specific needs of your tasks is crucial in making informed choices that will optimize performance.

Assessing Your Needs

Before purchasing any accessories, evaluate the primary functions you require. Consider the type of work you’ll be doing and the conditions in which you’ll be operating. This analysis will help in narrowing down your options to the most suitable attachments.

Quality and Compatibility

Always prioritize high-quality components that are compatible with your machinery. Investing in durable accessories not only ensures longevity but also maximizes safety during operation. Research reputable brands and read reviews to make the ultimate decision that meets your requirements.

Installation Guide for New Parts

This section provides a comprehensive overview of how to properly install newly acquired components for your agricultural equipment. Following these guidelines will ensure optimal functionality and longevity of the machinery.

- Gather Necessary Tools:

- Wrench set

- Screwdriver

- Socket set

- Torque wrench

- Review the Manual:

Before starting, carefully read the provided manual specific to the components to understand the installation requirements.

- Prepare the Workspace:

Ensure the area is clean and well-lit, providing ample room to maneuver around the equipment.

- Remove Old Components:

Carefully detach the existing elements using the appropriate tools. Take note of the assembly for reference.

- Install New Components:

Align and secure the new parts according to the instructions, ensuring a tight fit to avoid any future issues.

- Test Functionality:

Once installed, run the equipment at low speed to confirm everything operates correctly. Check for any unusual sounds or movements.

By following these steps meticulously, you will ensure that your machinery is equipped with the latest components, enhancing its overall performance and reliability.

Benefits of Upgrading Your Hitch

Enhancing your connection system can significantly improve your machinery’s performance and versatility. A modernized setup can lead to a multitude of advantages, making your tasks more efficient and enjoyable.

- Increased Efficiency: Upgrading can streamline your workflow, reducing downtime during operations.

- Enhanced Stability: A better connection provides improved balance, minimizing vibrations and wear.

- Broader Compatibility: Newer models often support a wider range of implements, allowing for diverse applications.

- Safety Improvements: Modern designs include features that enhance operator safety and reduce accident risks.

- Durability: Upgraded systems are usually made from higher-quality materials, extending their lifespan.

Investing in a superior connection can yield long-term benefits, optimizing your equipment’s capabilities and ensuring more productive outcomes.

Comparative Analysis of Models

This section delves into the evaluation of various designs within a specific category of agricultural equipment. By examining the distinctive features, capabilities, and functionalities of each model, we aim to provide a clear understanding of their strengths and weaknesses. Such an analysis will aid users in making informed decisions based on their individual requirements and operational contexts.

Performance Metrics

When assessing the efficiency and effectiveness of each design, several performance metrics must be considered. These include load capacity, operational speed, and compatibility with various implements. Each model exhibits unique characteristics that may be better suited for specific tasks or conditions, thus impacting overall productivity in agricultural operations.

User Experience and Maintenance

Another crucial aspect of the comparative analysis is the user experience associated with each model. Factors such as ease of use, comfort, and maintenance requirements play a significant role in the selection process. Understanding how each design addresses these aspects can significantly influence the long-term satisfaction of operators and the sustainability of the equipment in various environments.

Resources for Further Information

For those seeking to expand their knowledge on agricultural equipment components, various resources are available that provide detailed insights and practical guidance. These materials can enhance understanding and assist in effective maintenance and operation.

Online Forums and Communities

Engaging with online communities allows enthusiasts and professionals alike to share experiences and solutions. Websites dedicated to agricultural machinery often have sections where users discuss troubleshooting and modifications, fostering a collaborative learning environment.

Manufacturer Documentation

Official manuals and technical bulletins from manufacturers are invaluable for accurate information on specifications and assembly. These documents offer precise details and often include troubleshooting tips that can be essential for optimal functionality.