Ariens Snow Thrower Parts Diagrams for Easy Repair and Maintenance

When it comes to maintaining outdoor machinery, having a clear understanding of the various components involved is essential for optimal performance. A thorough examination of the intricate layouts can significantly enhance the efficiency of repairs and upkeep. This section delves into the visual representations that detail each element of the equipment, providing a comprehensive guide for users and technicians alike.

Effective maintenance hinges on familiarity with individual parts and their arrangement within the machine. By studying these visual schematics, one can easily identify specific components, troubleshoot issues, and plan for necessary replacements. This resource serves as a valuable tool for both seasoned professionals and enthusiastic homeowners who seek to keep their devices running smoothly.

Furthermore, understanding the layout not only aids in repairs but also enhances overall safety during operation. With the right knowledge at hand, users can approach their tasks with confidence, ensuring that each element is properly aligned and functioning as intended. Empowering oneself with this information transforms the often-daunting task of maintenance into a manageable and informed process.

Ariens Snow Thrower Parts Overview

This section aims to provide a comprehensive look at the various components essential for the efficient operation of outdoor winter machinery. Understanding each element’s role and function can significantly enhance performance and longevity.

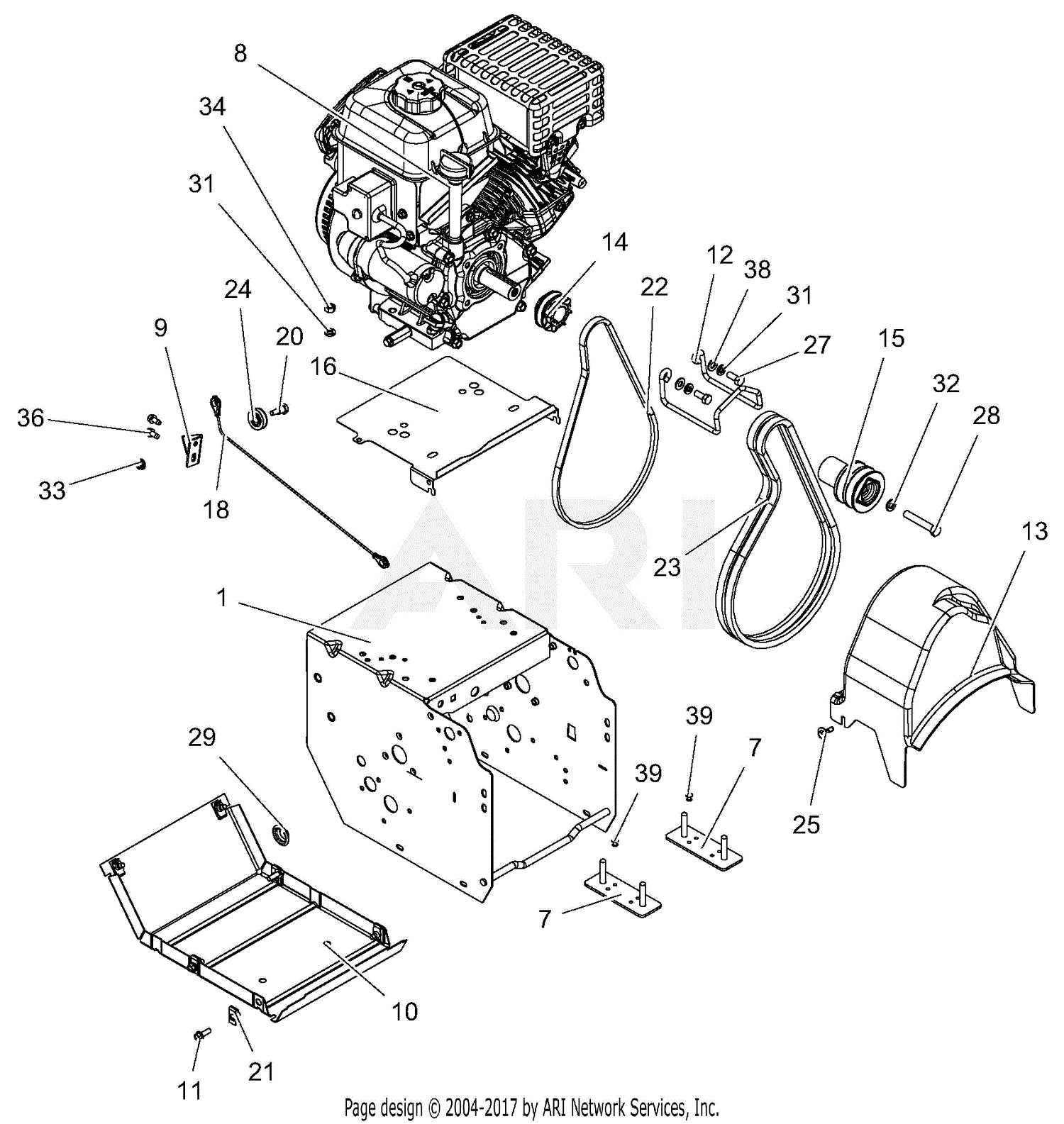

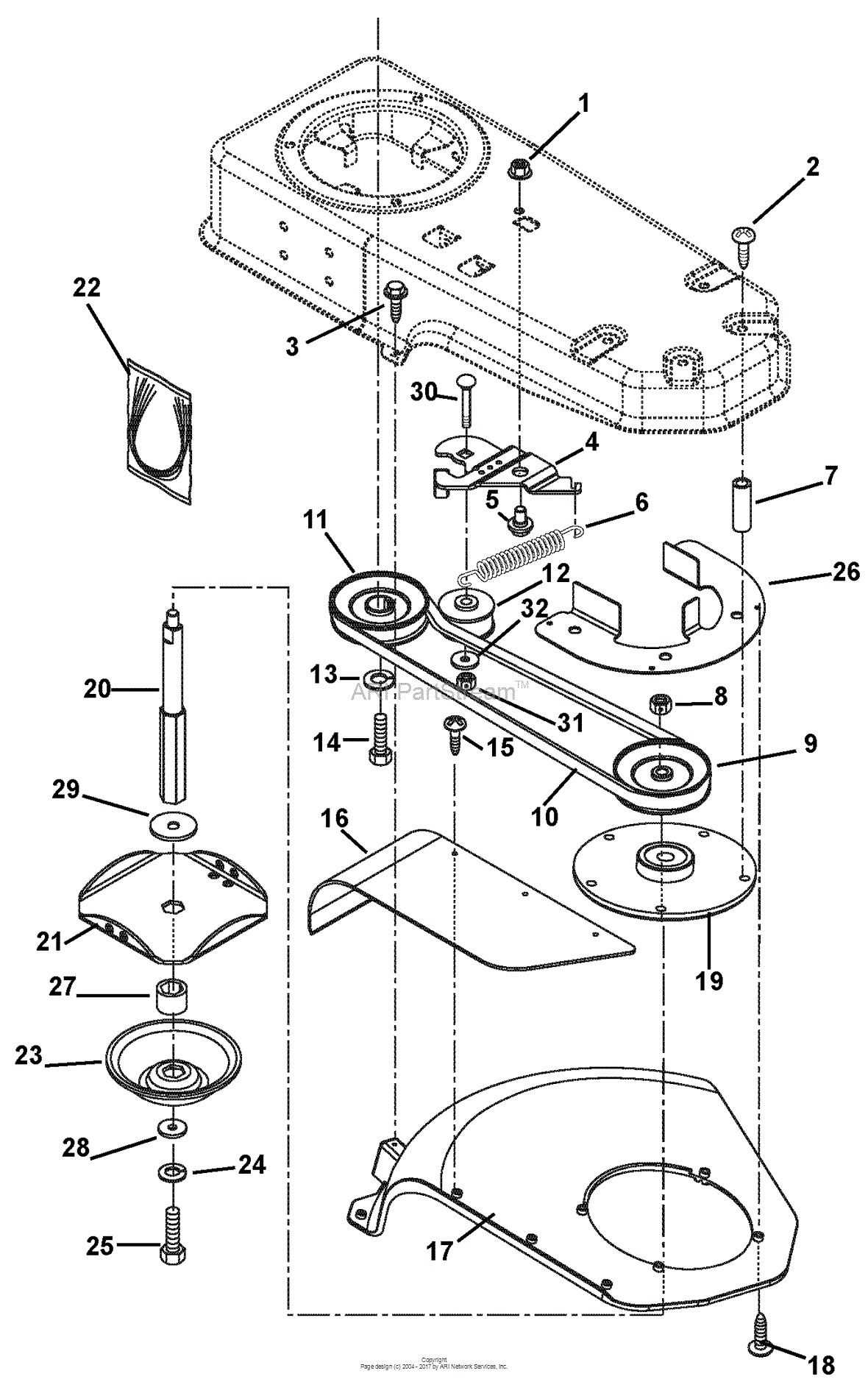

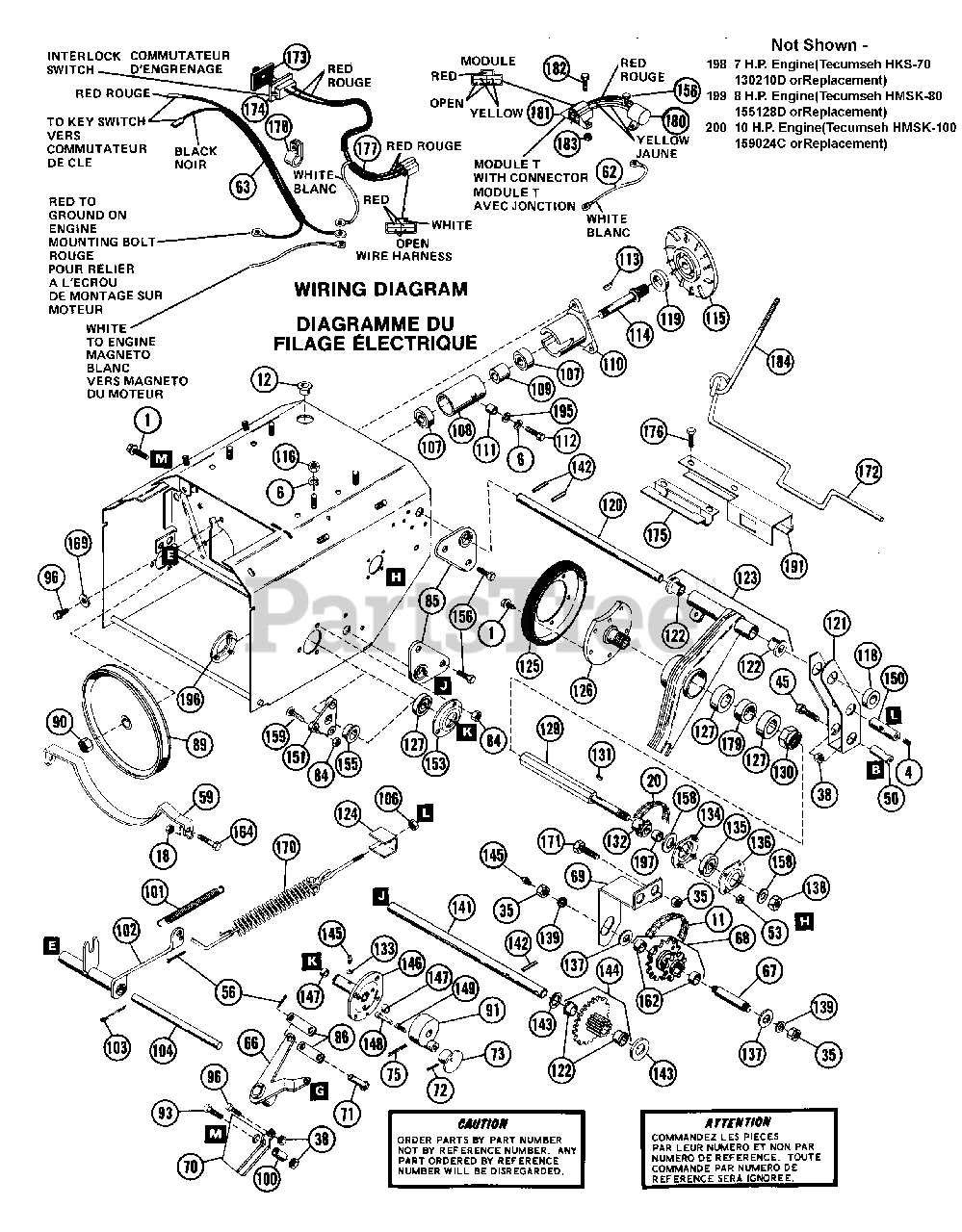

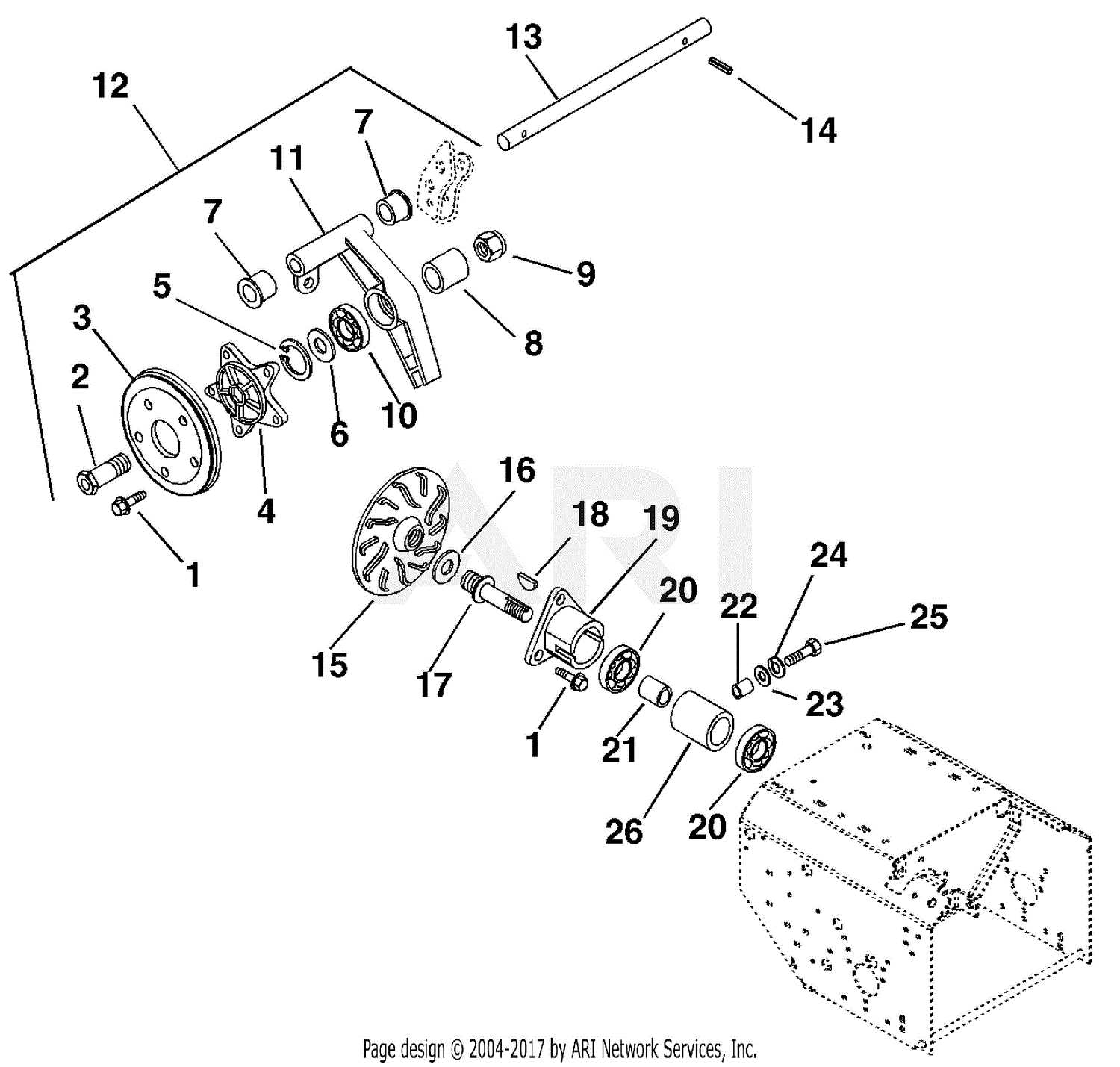

Core Components: At the heart of these machines lies the engine, which powers the entire system. Additionally, the auger assembly is crucial for gathering and directing the material, while the impeller ensures effective discharge.

Operational Accessories: Various attachments and tools play a vital role in enhancing usability. Skids, shoes, and deflectors are designed to improve maneuverability and control, allowing users to adapt to different conditions.

Maintenance Essentials: Regular upkeep is critical for sustained performance. Belts, cables, and filters must be monitored and replaced as needed to prevent breakdowns and ensure optimal functionality.

Understanding these components not only aids in effective operation but also empowers users to perform necessary maintenance and repairs, thereby extending the lifespan of their equipment.

Importance of Parts Diagrams

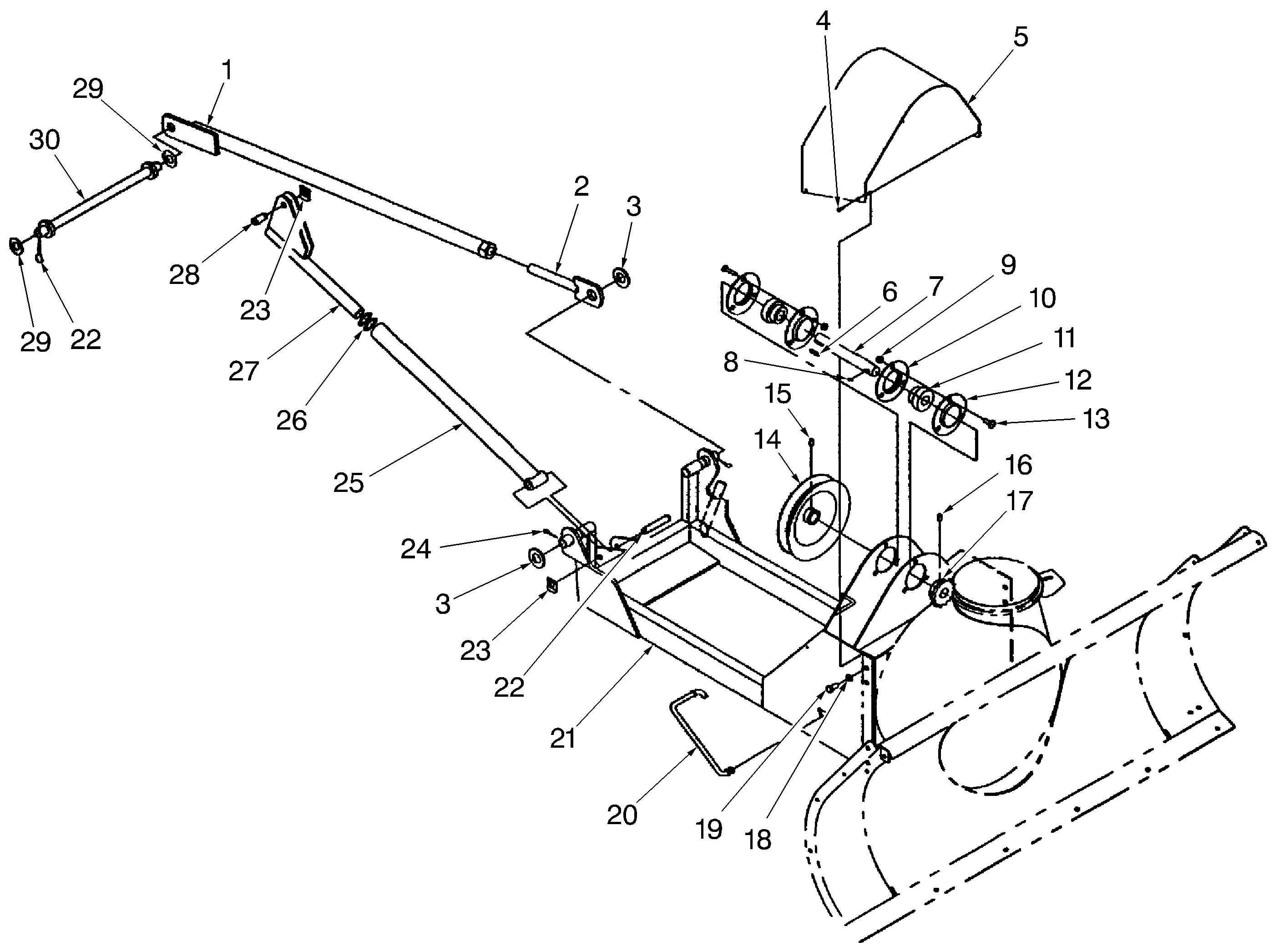

Understanding the structure and functionality of machinery is crucial for effective maintenance and repair. Visual representations of components not only simplify the identification of each element but also enhance the troubleshooting process. These illustrations serve as valuable tools for both professionals and DIY enthusiasts, ensuring that everyone can approach repairs with confidence.

Enhanced Clarity

Visual guides provide a clear overview of how various components fit together, reducing confusion that may arise from textual descriptions alone. By breaking down complex assemblies into manageable sections, users can easily locate the necessary parts and understand their relationships within the whole system.

Streamlined Repairs

Utilizing these visual aids can significantly speed up the repair process. With a clear roadmap, individuals can quickly gather the required elements, minimizing downtime. Moreover, they can prevent potential mistakes during reassembly, ultimately leading to more efficient and effective maintenance practices.

In summary, visual representations of machinery components play a vital role in facilitating maintenance and repair tasks. Their ability to provide clarity and streamline processes makes them indispensable tools for anyone involved in the upkeep of mechanical systems.

Common Ariens Snow Thrower Models

This section highlights popular models known for their reliability and performance in harsh winter conditions. Each design caters to different user needs, ensuring efficient handling of snow removal tasks.

Compact Series

The Compact Series features lightweight machines that are easy to maneuver, making them ideal for residential driveways and sidewalks. Their smaller size does not compromise on power, offering excellent clearing capabilities.

Deluxe Series

The Deluxe Series stands out with advanced features and enhanced durability. Designed for larger areas, these models provide superior performance and versatility, equipped to tackle even the heaviest of snowfalls.

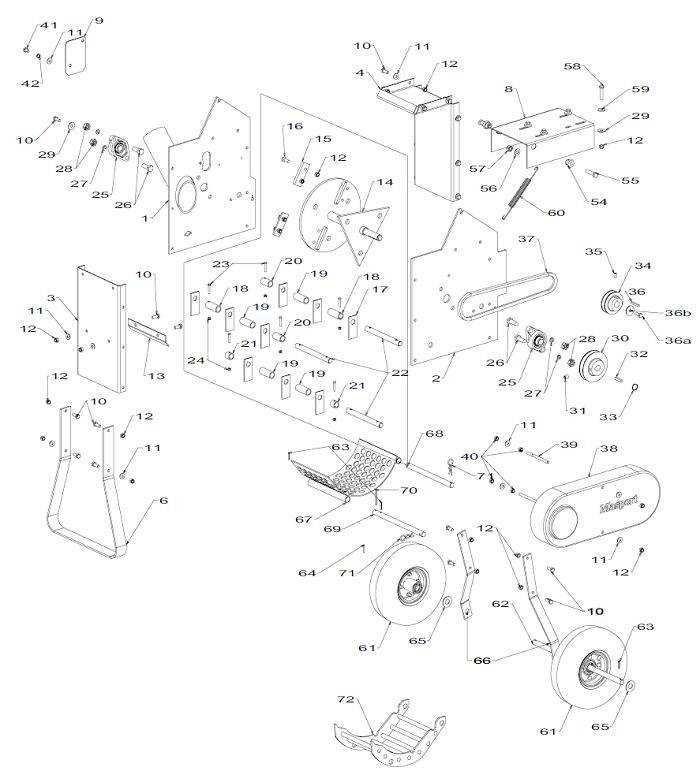

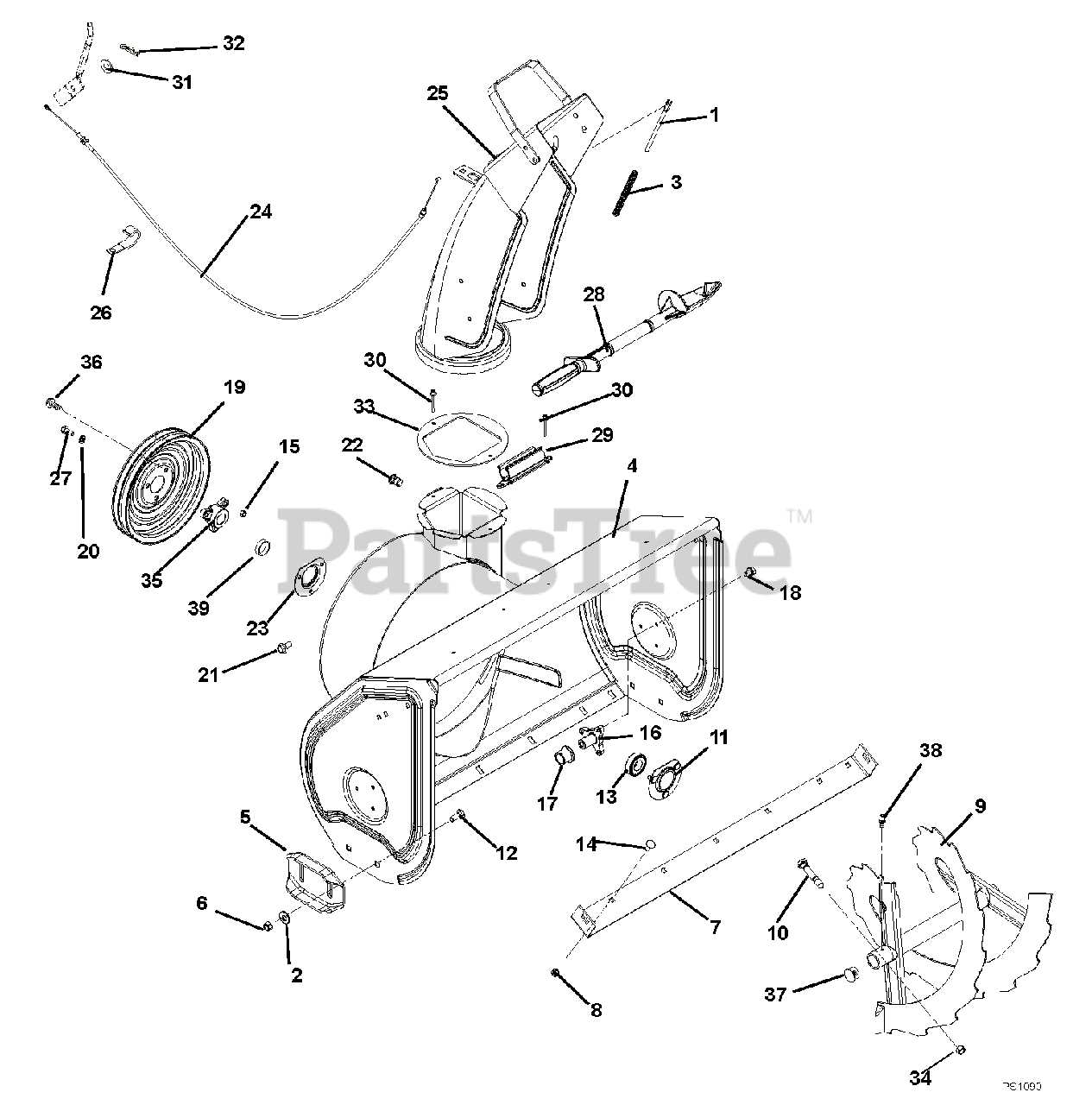

Identifying Key Components

Understanding the essential elements of your machine is crucial for effective maintenance and operation. Familiarity with these components can enhance performance and prolong longevity.

- Engine: The powerhouse responsible for driving the entire unit.

- Chassis: The frame that supports and houses various elements.

- Auger: The component designed to move material efficiently.

- Impeller: Responsible for expelling the collected material away from the unit.

- Control Panel: The interface that allows you to operate and adjust settings.

Recognizing these key components can significantly impact your efficiency and effectiveness when utilizing the machine.

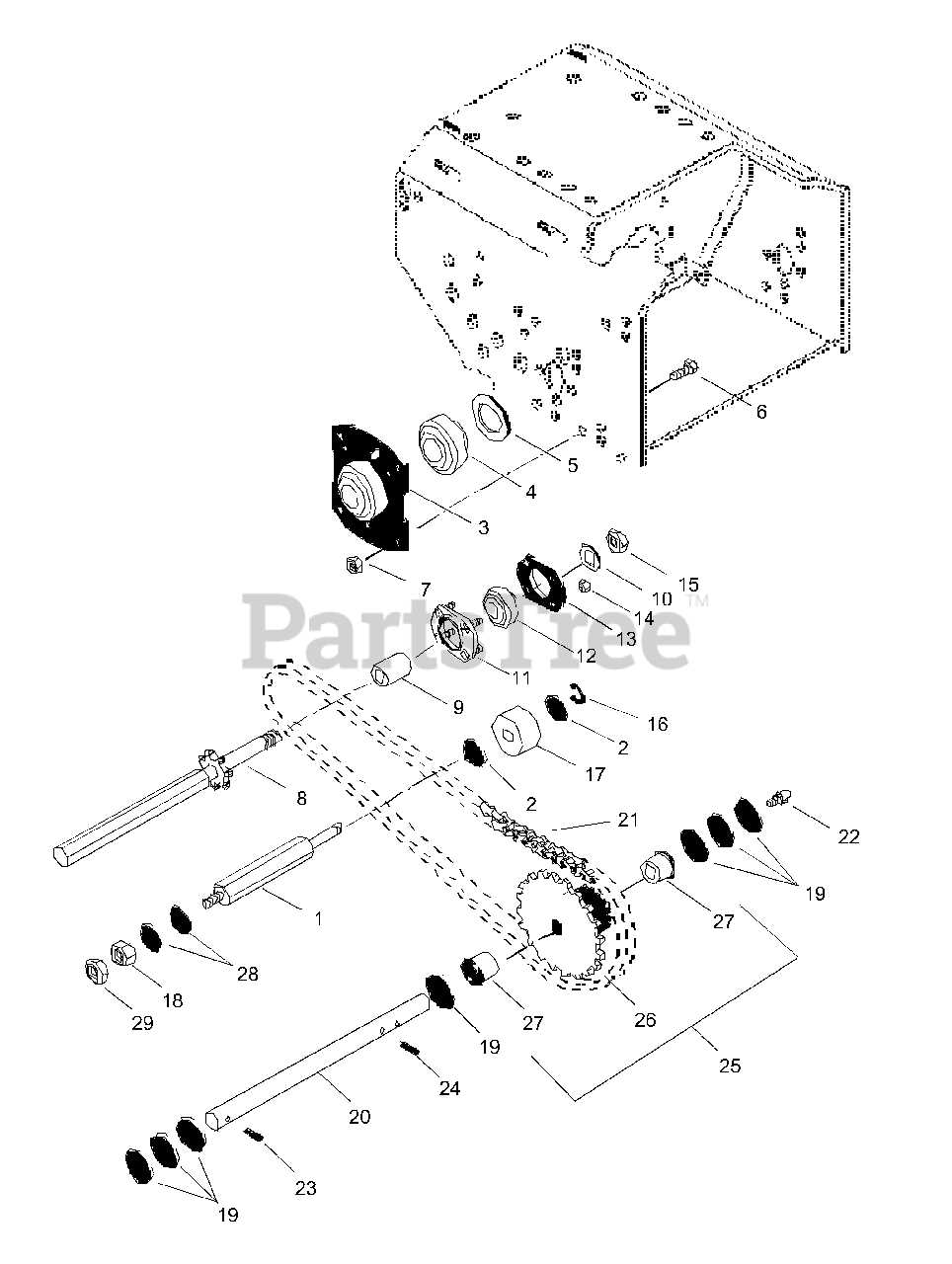

How to Read Parts Diagrams

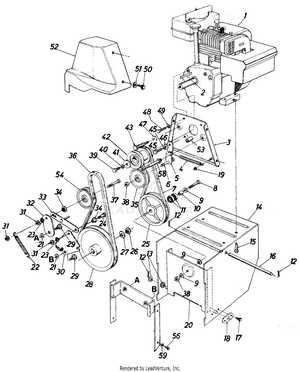

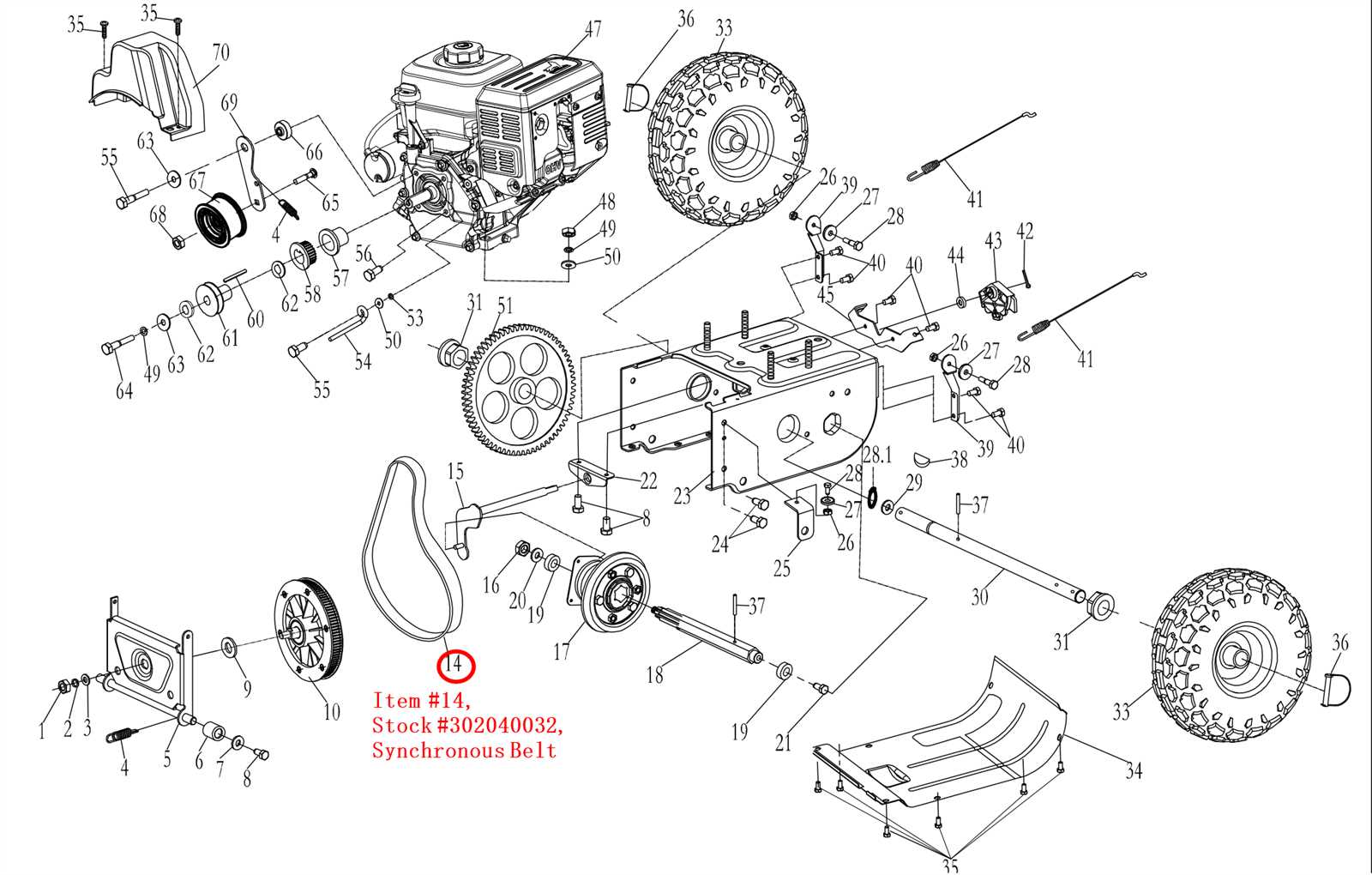

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations provide crucial insights into the assembly and organization of various elements within a machine. By grasping the structure of these visuals, one can identify the necessary components and their relationships to each other.

Begin by familiarizing yourself with the layout. Typically, the illustration will feature a detailed overview of the equipment, highlighting different sections and components with labels. Each labeled item corresponds to a specific part number, which can be cross-referenced in a list for ordering or identification.

Pay attention to the orientation and arrangement of the components. This helps in understanding how parts fit together and can assist in troubleshooting issues. Look for any special symbols or color coding that may indicate particular functions or statuses of the parts.

Additionally, note any notes or legends provided alongside the visuals. These annotations can offer valuable information regarding assembly instructions, maintenance tips, or specific warnings that are crucial for safe operation.

Finally, practice interpreting these visuals regularly. The more familiar you become with the format and terminology, the easier it will be to navigate and utilize these resources effectively in your repair and maintenance endeavors.

Finding Replacement Parts Online

Locating the right components for your equipment can be a straightforward process when you know where to look. The online marketplace offers a plethora of resources, making it easier to identify and acquire the necessary items for maintenance and repairs.

Here are some effective strategies to help you in your search:

- Manufacturer’s Website: Always start by visiting the official site. It often provides comprehensive catalogs and guides for specific models.

- Online Retailers: Explore e-commerce platforms that specialize in hardware and machinery supplies. They usually have a wide selection and competitive prices.

- Forums and Community Groups: Engage with user communities. Members often share experiences and recommendations about reliable vendors.

- Parts Lookup Tools: Utilize online tools designed to help users find the right components by entering model numbers or descriptions.

Remember to verify the compatibility of any item before making a purchase. Taking the time to ensure that the part fits your equipment can save you time and money in the long run.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment involves regular care and attention. By following a few key practices, you can significantly extend the life of your machinery and maintain its optimal performance.

- Regular Cleaning: Keep the exterior free from debris and dirt to prevent corrosion and damage.

- Lubrication: Apply appropriate lubricants to moving parts to minimize wear and tear.

- Inspect Components: Routinely check belts, cables, and other essential elements for signs of wear.

- Fluid Checks: Monitor oil and fuel levels; replace as necessary to ensure efficient operation.

- Storage Practices: Store in a dry, sheltered environment to protect from weather elements.

By incorporating these practices into your routine, you can achieve the ultimate performance and longevity of your machinery.

Ordering from Authorized Dealers

When seeking components for your equipment, it’s essential to source them from certified vendors. This ensures quality, reliability, and proper compatibility with your machinery. Authorized dealers not only provide genuine items but also offer expertise and support throughout the purchasing process.

Here is a helpful comparison of benefits when ordering from authorized dealers versus non-certified sources:

| Aspect | Authorized Dealers | Non-Certified Sources |

|---|---|---|

| Quality Assurance | High | Variable |

| Compatibility | Guaranteed | Often Uncertain |

| Customer Support | Available | Limited |

| Warranty | Included | Not Always |

By choosing to order from authorized dealers, you can ultimately ensure the longevity and performance of your machinery while receiving reliable service.

Understanding Warranty Options

When investing in outdoor equipment, comprehending the protection plans available is essential for ensuring longevity and performance. These plans typically outline the terms and conditions that safeguard your purchase against defects and malfunctions.

It’s crucial to consider the following aspects:

- Duration: How long is the coverage period?

- Scope: What specific components or issues are included?

- Exclusions: Are there any limitations or items not covered?

- Transferability: Can the warranty be transferred to a new owner?

- Claim Process: What steps are necessary to file a claim?

By delving into these elements, you can make an informed decision that ultimately protects your investment.

DIY Repairs and Troubleshooting

Maintaining your equipment can often be a straightforward task if you possess the right knowledge and tools. Understanding the common issues that may arise and how to address them empowers you to tackle repairs confidently. This section delves into practical solutions and preventive measures to ensure optimal performance and longevity.

Identifying Common Problems: Start by recognizing the typical malfunctions, such as unusual noises, poor performance, or failure to start. Each symptom can lead you to a specific area that requires attention.

Basic Troubleshooting Steps: Before diving into repairs, conduct a thorough inspection. Check fuel levels, ensure all connections are secure, and examine the condition of essential components. Often, minor adjustments can resolve major issues.

Essential Tools: Equip yourself with a few basic tools like wrenches, screwdrivers, and a multimeter. Having the right instruments at hand simplifies the repair process significantly.

Consulting Resources: Utilize manuals and online guides for detailed instructions tailored to your equipment. These resources can provide valuable insights and diagrams to assist in your repair journey.

Regular maintenance is crucial in preventing future complications. By addressing issues promptly and performing routine checks, you can enhance the reliability and functionality of your machine.

Safety Precautions During Repairs

When undertaking maintenance on machinery, ensuring safety is paramount. Proper precautions can significantly reduce the risk of accidents and injuries. Adopting a systematic approach not only protects the individual performing the repairs but also enhances the overall efficiency of the task.

First and foremost, always disconnect the power source before beginning any work. This simple step prevents unintended activation of the equipment, safeguarding the technician. Additionally, wear appropriate protective gear, such as gloves and goggles, to shield against potential hazards.

Furthermore, keeping your workspace organized is essential. A clutter-free area minimizes distractions and the chance of accidents. It’s also wise to consult the manufacturer’s guidelines for specific safety measures related to the equipment being serviced.

Lastly, always have a first aid kit readily accessible. In case of any mishap, immediate assistance can make a significant difference. By prioritizing safety, you ensure that repairs are conducted smoothly and effectively.

Customer Support and Resources

This section aims to provide valuable assistance and information to users seeking help with their equipment. It includes various channels for support, comprehensive guides, and essential tools to enhance user experience and ensure efficient operation.

Support Channels

Access to knowledgeable representatives is crucial for addressing inquiries and resolving issues. Here are the primary methods to reach customer support:

| Contact Method | Description |

|---|---|

| Phone | Speak directly with a support agent for immediate assistance. |

| Send detailed inquiries to receive thorough responses. | |

| Live Chat | Engage in real-time conversations for quick solutions. |

Additional Resources

For users seeking further information, a wealth of resources is available, including user manuals, instructional videos, and FAQs. These materials are designed to empower users with knowledge and facilitate smooth operation of their equipment.