Understanding the Jeep Steering Parts Diagram for Better Maintenance

In the intricate world of automotive engineering, the functionality of a vehicle relies heavily on various mechanisms that ensure precision and safety. These elements work in harmony to facilitate smooth navigation and responsive handling, making them essential for any enthusiast or technician. A comprehensive understanding of these components can greatly enhance both maintenance and performance.

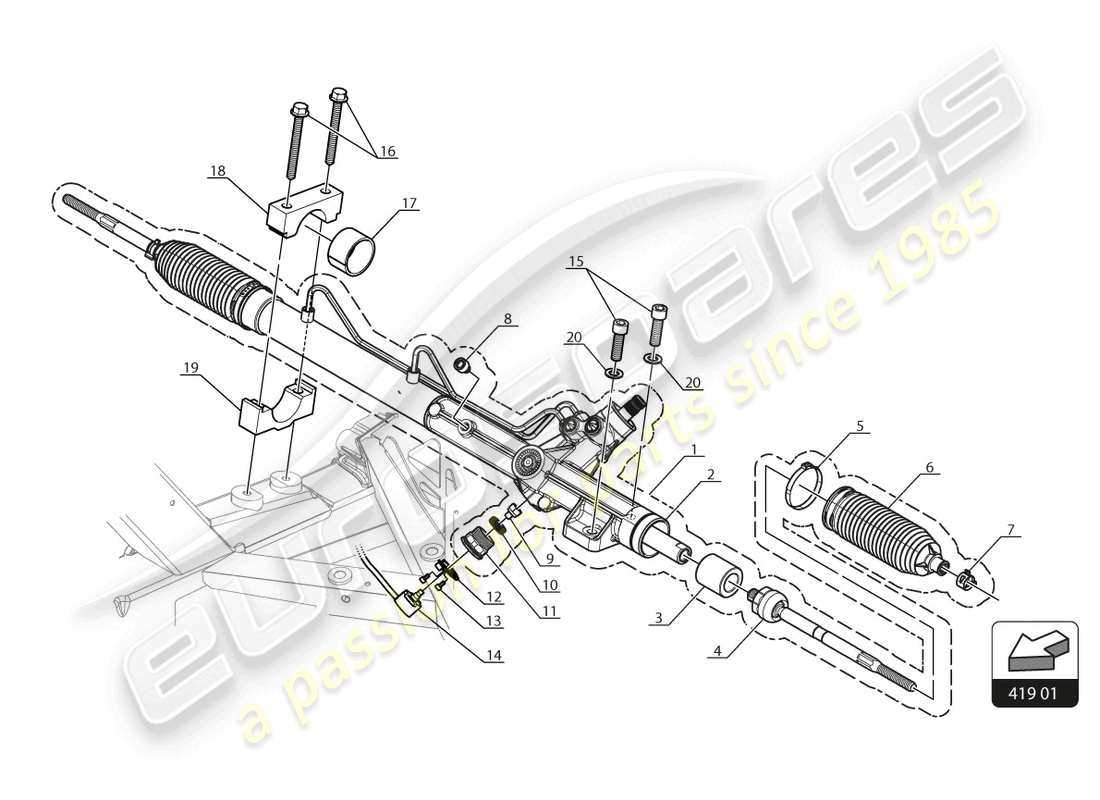

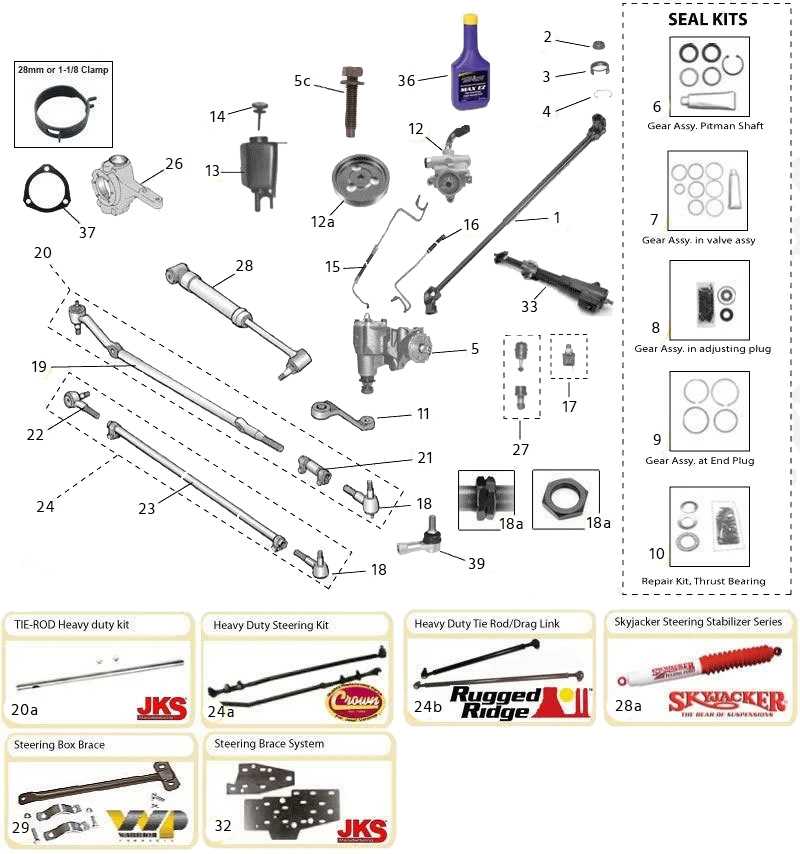

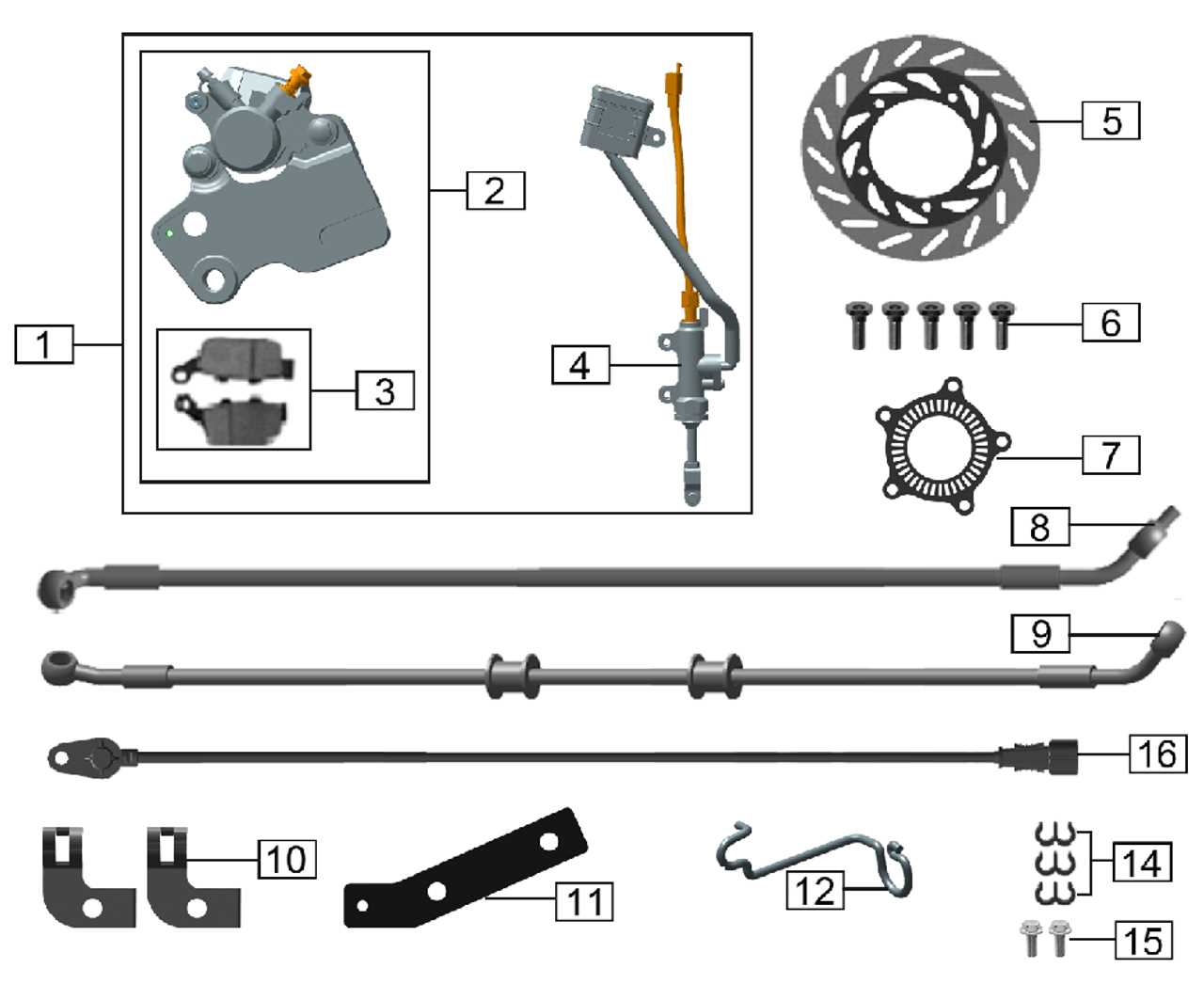

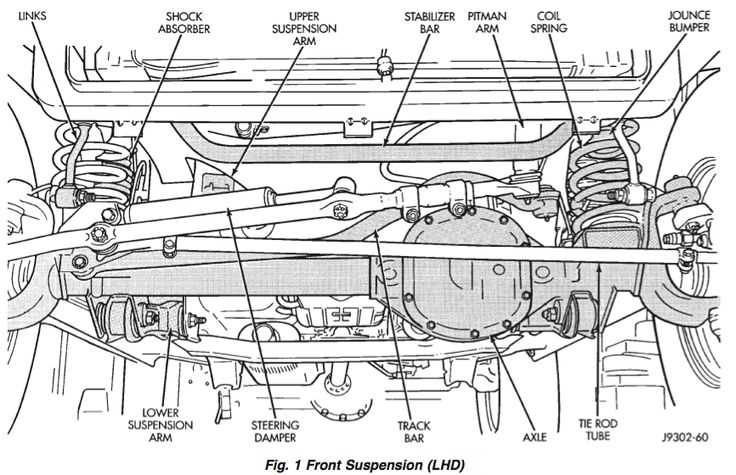

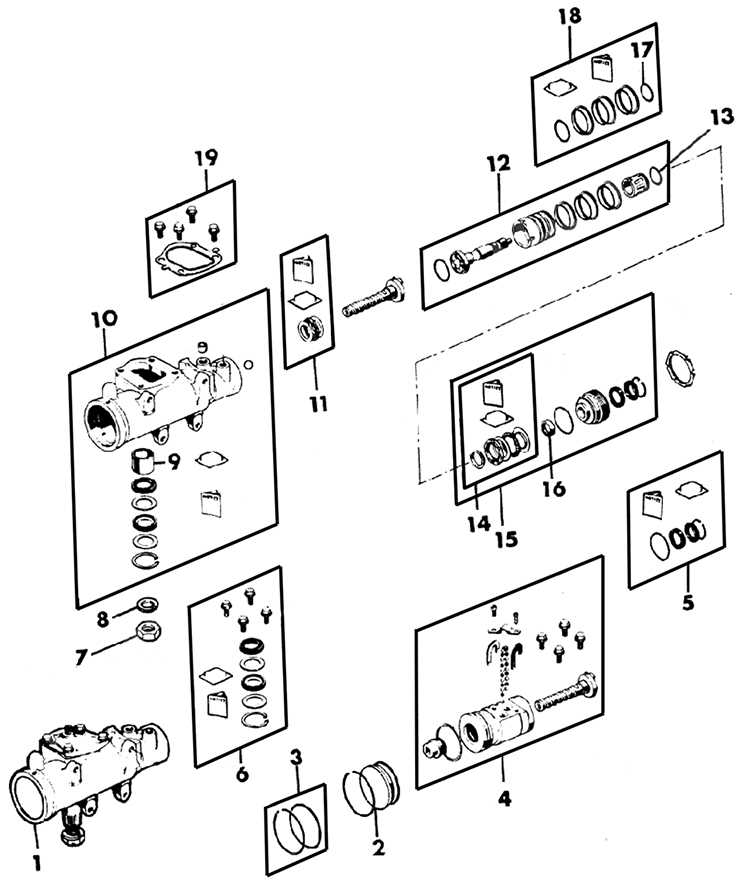

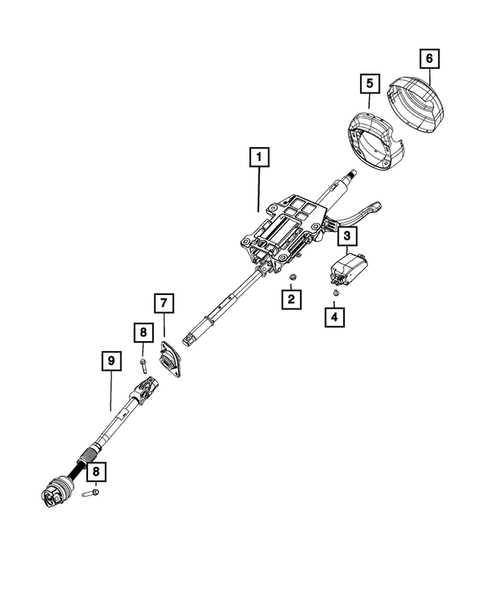

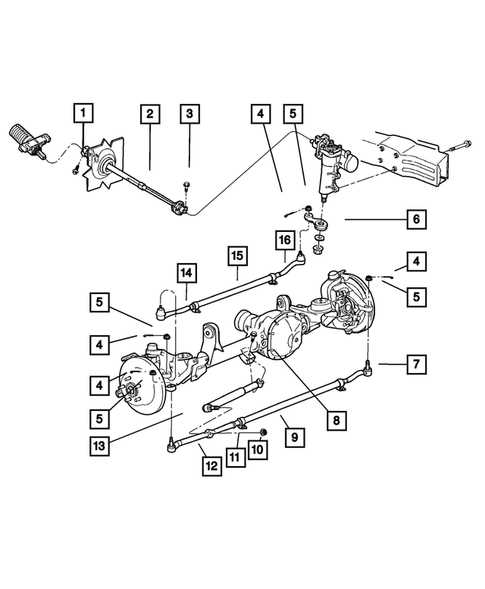

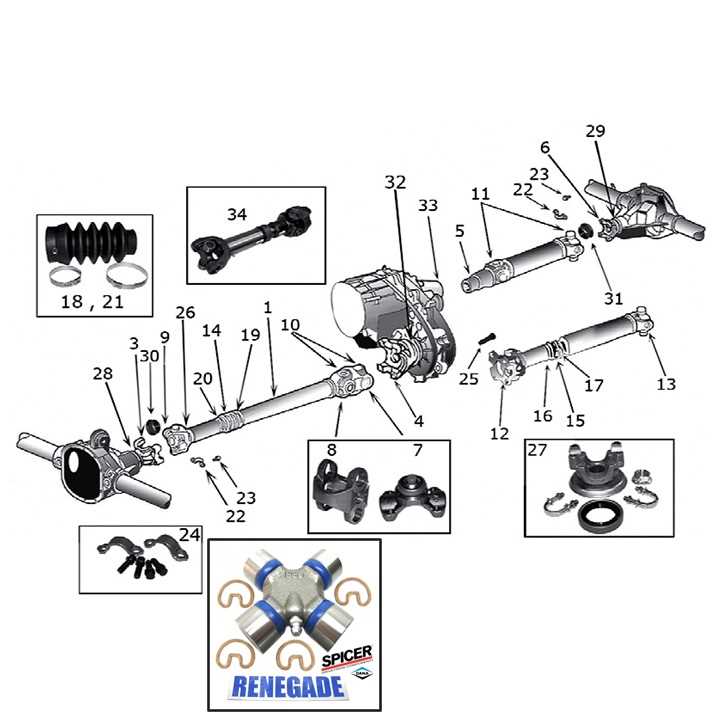

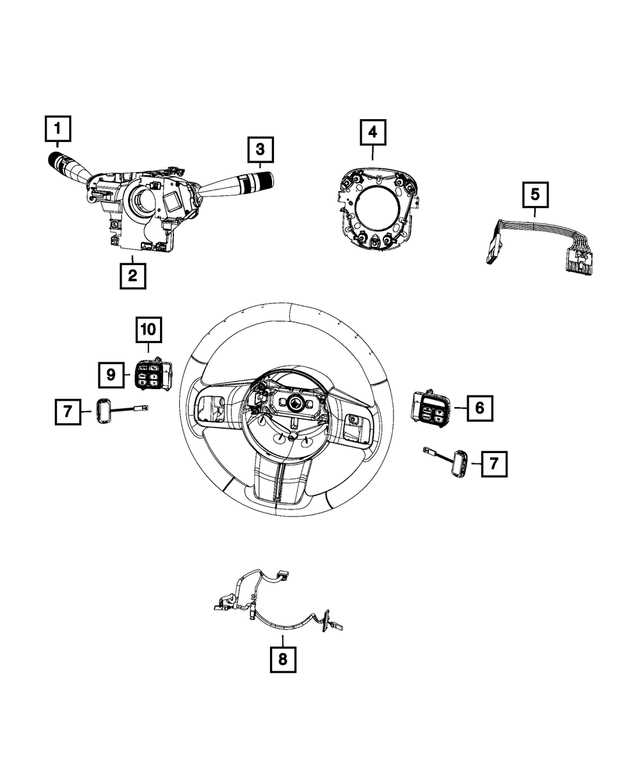

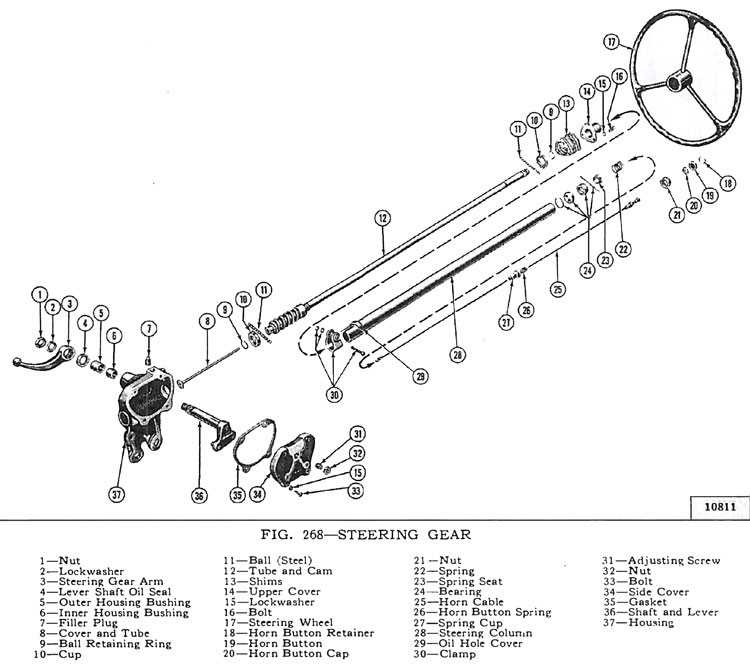

The arrangement of these crucial mechanisms is often represented in detailed illustrations that provide insight into their interconnections and roles. By analyzing these visual aids, one can grasp the significance of each element, from the primary connections to the ancillary features that contribute to overall vehicle dynamics.

Whether you are a seasoned mechanic or a curious owner, familiarizing yourself with these components can lead to better decision-making regarding repairs and upgrades. Gaining knowledge about the structure and operation of these systems empowers individuals to maintain their vehicles with confidence and ensures a safer driving experience.

Understanding Jeep Steering Systems

The mechanism that allows a vehicle to change direction is crucial for both performance and safety. This intricate system comprises various components that work in unison to provide responsive handling and stability on diverse terrains. Gaining insight into how this assembly functions is essential for any enthusiast or owner.

Key elements of this system include:

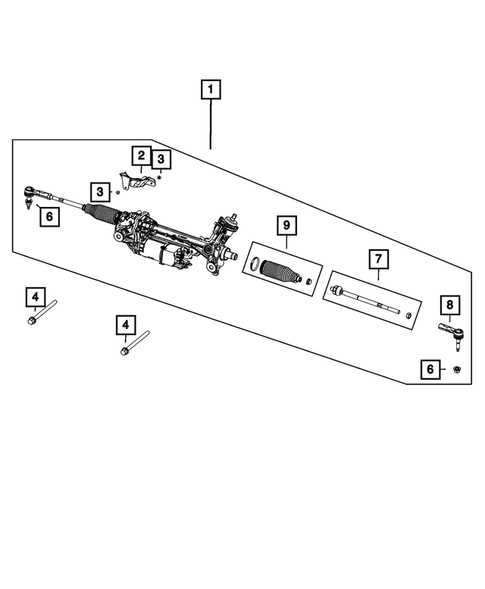

- Rack and Pinion: A common design that converts rotational motion into linear motion, allowing for precise control.

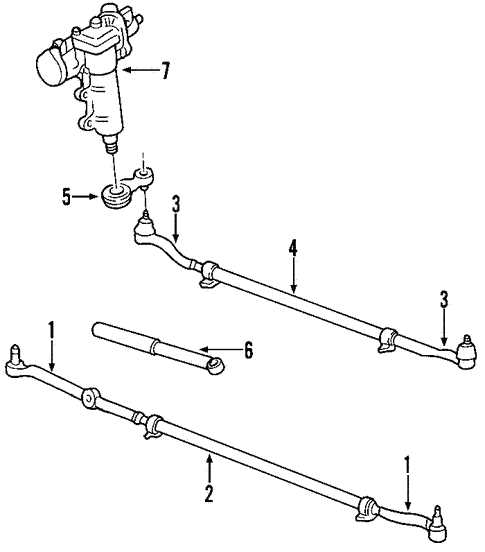

- Linkages: Connectors that transmit force and movement between the driver’s input and the wheels.

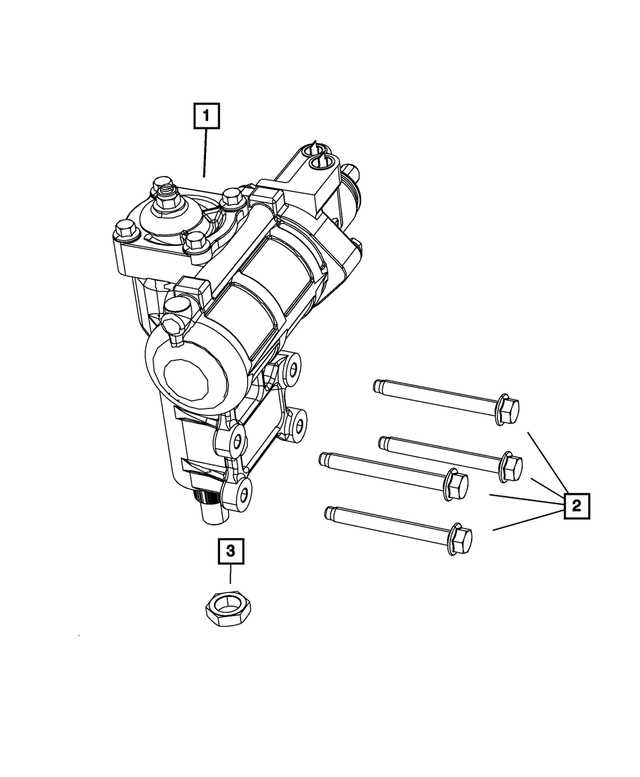

- Box Assembly: Houses gears and other mechanisms that assist in directing the wheels effectively.

- Power Assist: A feature that utilizes hydraulic or electric systems to reduce the effort needed to turn the wheel.

Understanding the roles of these components helps in diagnosing issues and performing maintenance. Regular checks can prevent wear and tear, ensuring the assembly operates smoothly.

- Inspect fluid levels regularly to maintain proper function.

- Check for any signs of wear in linkages and other connectors.

- Ensure alignment is correct to promote even tire wear and enhance control.

By familiarizing yourself with this essential system, you can improve your vehicle’s performance and longevity, making every journey safer and more enjoyable.

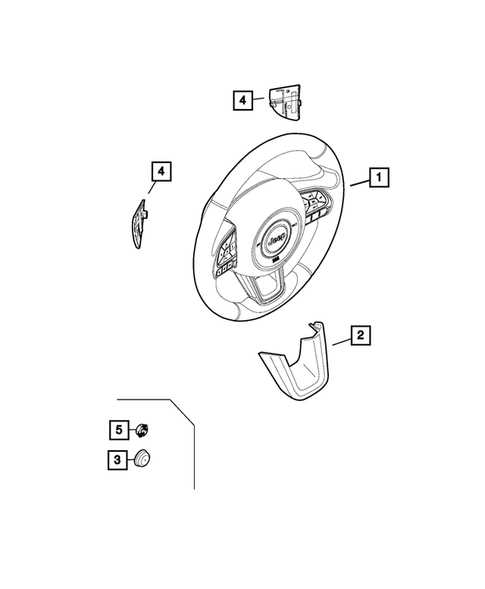

Key Components of Jeep Steering

Understanding the essential elements that contribute to vehicle maneuverability is crucial for both safety and performance. These components work in harmony to ensure precise control and responsiveness while navigating various terrains.

- Wheel Assembly: The primary interface between the vehicle and the road, it influences handling and stability.

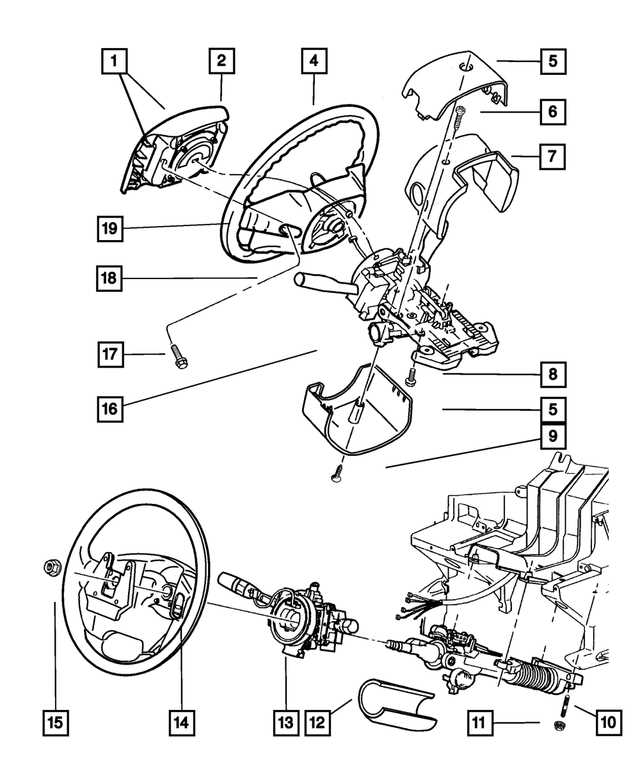

- Column Mechanism: This section connects the wheel to the control system, allowing for smooth directional changes.

- Linkage System: A series of rods and joints that transmit movement from the column to the wheels, enhancing responsiveness.

- Gearbox: Converts the rotational motion of the column into lateral movement, enabling easier turns.

- Control Arms: These components support the wheel assembly, maintaining alignment and absorbing shocks from rough surfaces.

Each of these elements plays a vital role in ensuring optimal functionality and safety. Regular maintenance and understanding of these components can significantly enhance the driving experience.

Common Issues with Steering Parts

Understanding the frequent challenges faced by vehicle directional control components is crucial for maintaining safety and performance. These issues can lead to various driving difficulties and can significantly affect the overall driving experience. Awareness of these common problems enables timely intervention and repair, ensuring optimal functionality.

Wear and Tear

Over time, essential components can experience degradation due to constant use. This deterioration often manifests as looseness or increased play, resulting in diminished responsiveness. Regular inspections can help identify signs of wear, allowing for preventive measures before the situation escalates.

Alignment Problems

Misalignment can occur due to impacts, uneven tire wear, or poor maintenance practices. When components are not properly aligned, it can lead to uneven tire wear and compromised handling. Addressing alignment issues promptly is vital to ensure balanced performance and prolong the lifespan of associated components.

Importance of Proper Alignment

Ensuring that the directional system of a vehicle is correctly set is crucial for optimal performance and safety. Misalignment can lead to various issues that not only affect handling but also contribute to uneven wear and tear on tires and other components. Proper adjustments can enhance the driving experience and prolong the lifespan of essential systems.

Benefits of Correct Alignment

- Improved Handling: Accurate alignment contributes to smoother and more responsive steering, enhancing overall control.

- Extended Tire Life: Proper positioning reduces uneven tire wear, helping to maintain tire integrity for a longer period.

- Fuel Efficiency: Vehicles with correct alignment tend to consume less fuel due to decreased rolling resistance.

- Enhanced Safety: Maintaining proper alignment minimizes the risk of sudden handling issues, which can lead to accidents.

Signs of Misalignment

- Uneven Tire Wear: Check for patches or bald spots on tires.

- Vehicle Pulling: If the vehicle drifts to one side when driving straight.

- Steering Wheel Off-Center: If the steering wheel is not aligned with the vehicle when moving straight.

- Vibration: Experiencing unusual vibrations while driving may indicate alignment issues.

Regular checks and maintenance can prevent significant problems and ensure that the vehicle operates smoothly and safely on the road.

How to Diagnose Steering Problems

Identifying issues related to vehicle maneuverability is crucial for safe operation. Several signs can indicate that something is amiss with the control system. Recognizing these symptoms early can prevent further complications and enhance driving safety.

When experiencing difficulties, start by observing the handling characteristics of your vehicle. Look for unusual behaviors such as difficulty in turning, pulling to one side, or excessive vibration. Each of these may point to specific underlying problems.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Difficulty in turning | Low fluid levels or leaks | Check fluid reservoir and inspect for leaks |

| Pulling to one side | Uneven tire pressure or alignment issues | Check tire pressure and consider an alignment |

| Excessive vibration | Worn components or imbalance | Inspect components for wear and balance tires |

Conducting a thorough examination will help in pinpointing the issue. It is often advisable to consult a professional for a comprehensive assessment to ensure the integrity of the control system remains intact.

Maintaining Jeep Steering Systems

Proper upkeep of the directional control mechanisms is essential for ensuring safety and performance. Regular maintenance not only extends the lifespan of these components but also enhances overall driving experience.

Key aspects to consider in maintaining these systems include:

- Regular Inspections: Frequently check for wear and tear on crucial components to identify any potential issues early.

- Fluid Levels: Ensure that all relevant fluids are at appropriate levels and free from contamination.

- Alignment Checks: Periodically verify alignment to prevent uneven tire wear and improve handling.

- Component Lubrication: Apply suitable lubricants to joints and moving parts to minimize friction and reduce wear.

- Professional Servicing: Consider seeking expert assistance for in-depth inspections and repairs when necessary.

By adhering to these guidelines, vehicle owners can maintain optimal performance and safety of their directional control systems, leading to a more enjoyable driving experience.

Aftermarket vs. OEM Steering Parts

The choice between original components and alternative replacements can significantly influence vehicle performance and maintenance costs. Understanding the differences can help owners make informed decisions tailored to their driving habits and budget considerations.

Quality and Durability

Original equipment components are typically designed to meet the manufacturer’s strict standards, ensuring reliability and longevity. In contrast, alternative options vary widely in quality. While some aftermarket offerings can match or even exceed OEM specifications, others may compromise on materials or construction, potentially leading to premature wear.

Cost Considerations

One of the primary reasons owners consider alternatives is cost. Aftermarket solutions often come at a lower price point, making them an appealing choice for budget-conscious individuals. However, it’s essential to weigh the initial savings against the potential for increased maintenance costs if these replacements do not perform as expected. Investing in original components may result in better long-term value, even if the upfront cost is higher.

In conclusion, whether opting for original or alternative solutions, assessing quality, durability, and cost will guide owners in making the best choice for their vehicles.

Tools Needed for Steering Repairs

When tackling the challenge of restoring the directional control system of your vehicle, having the right instruments at hand is crucial for efficiency and safety. This section outlines essential equipment that facilitates the repair and maintenance of the control components, ensuring optimal performance.

| Tool | Purpose |

|---|---|

| Wrench Set | To loosen and tighten various fasteners. |

| Sockets | For removing and installing bolts in tight spaces. |

| Torque Wrench | To apply the correct amount of force when securing connections. |

| Ball Joint Separator | To detach the ball joints without damage. |

| Puller Set | For removing gears or pulleys from shafts. |

| Grease Gun | To lubricate moving parts effectively. |

| Jack and Stands | To elevate the vehicle securely during work. |

Having these tools ready will streamline the repair process, allowing for thorough inspections and efficient adjustments to restore control functionality. Proper preparation can make all the difference in achieving a successful outcome.

Step-by-Step Steering Component Replacement

Replacing essential components that guide and control the vehicle’s direction is crucial for maintaining safety and performance. This section outlines a systematic approach to removing and installing these critical elements, ensuring a smooth and efficient process.

Preparation and Tools Needed

Before commencing the replacement, gather the necessary tools and equipment. Having everything on hand will streamline the process and reduce downtime.

| Tool | Purpose |

|---|---|

| Wrench Set | To remove bolts and nuts |

| Screwdriver | For securing or loosening screws |

| Jack Stands | To safely elevate the vehicle |

| Pliers | To grip and pull components |

| Replacement Parts | New components for installation |

Replacement Procedure

Follow these steps to ensure a successful replacement:

- Elevate the vehicle securely using jack stands to access the undercarriage.

- Remove any protective covers that may obstruct access to the components.

- Carefully disconnect the old components, noting their arrangement for reference.

- Install the new elements, ensuring they are positioned correctly.

- Reattach any covers or shields, followed by lowering the vehicle.

- Test the functionality to confirm proper installation.

By adhering to this methodical approach, you can effectively replace the necessary elements, enhancing both safety and control of your vehicle.

Upgrading Your Jeep’s Steering System

Enhancing your vehicle’s directional control can significantly improve both performance and comfort. Whether you’re navigating rugged terrains or cruising on highways, a well-optimized mechanism is essential for a smoother experience. Upgrading this system not only boosts handling but also contributes to overall safety and responsiveness.

Benefits of Upgrading

Improved precision and reduced play are just a couple of advantages of modernizing your setup. Advanced components can offer better feedback and stability, ensuring that you maintain control in various driving conditions. Additionally, enhancements can lead to increased durability, allowing for a more enjoyable off-road adventure.

Choosing the Right Components

Selecting the appropriate upgrades involves considering your driving habits and the environment. Options range from heavy-duty assemblies designed for off-road challenges to high-performance alternatives suited for daily commuting. Researching and consulting with experts can help you find the best fit for your vehicle’s unique needs.

Safety Considerations When Repairing Steering

Ensuring a safe working environment is paramount when addressing issues related to vehicle control systems. Neglecting safety protocols can lead to accidents or injuries. This section outlines essential precautions to consider during maintenance tasks.

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots to prevent injuries.

- Work in a well-ventilated area to avoid inhaling harmful fumes from tools or fluids.

- Ensure that the vehicle is securely elevated on jack stands or ramps, never rely solely on a hydraulic jack.

Proper organization of tools and components is crucial to avoid mishaps. Keep your workspace tidy and free of unnecessary clutter.

- Label parts and fasteners to simplify reassembly.

- Store heavy tools properly to prevent accidents when retrieving them.

Before beginning any task, make sure to consult relevant manuals for specific instructions and safety warnings. This will provide insight into unique aspects of the system being repaired.

- Double-check that the vehicle’s ignition is turned off and the key is removed to prevent accidental starts.

- Disconnect the battery to eliminate electrical hazards when working on electronic components.

Finally, don’t hesitate to seek assistance if you’re unsure about any procedure. It’s better to ask for help than to risk injury or damage.

Resources for Jeep Steering Diagrams

Finding accurate visual aids for automotive components is crucial for effective maintenance and repairs. A variety of resources can help enthusiasts and mechanics understand the intricacies of vehicle maneuvering systems. Below is a collection of valuable sources that provide detailed illustrations and information.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Community-driven platforms where users share diagrams, experiences, and advice. | Example Forum |

| Manufacturer Websites | Official sites offering technical documents, including schematics and user manuals. | Example Manufacturer |

| Repair Guides | Comprehensive manuals that feature step-by-step instructions and visual aids. | Example Guides |

| Online Retailers | Websites selling aftermarket components often include technical diagrams for reference. | Example Parts |