Understanding the Parts Diagram of Polaris Glacier II Plow

When it comes to effective snow management, having a comprehensive grasp of the crucial elements that contribute to the functionality of your machinery is vital. Each component plays a significant role in ensuring optimal performance, especially in challenging winter conditions. Familiarity with these parts not only enhances efficiency but also aids in maintenance and repairs.

Identifying the various sections of your equipment can simplify troubleshooting and promote longevity. Whether you are a seasoned operator or a newcomer, knowing how these pieces interconnect will empower you to address issues as they arise. Additionally, having access to detailed schematics provides clarity and aids in the assembly process.

In this exploration, we will delve into the intricacies of these components, offering insights into their functions and importance. With a focus on clarity and understanding, you’ll be better prepared to tackle winter challenges head-on, ensuring that your snow management tools are always ready for action.

Understanding Polaris Glacier II Plow

This section aims to explore the intricacies of a specific snow-moving apparatus designed for enhancing winter productivity. By examining its components and functionality, users can gain insight into the essential features that contribute to its effectiveness in harsh weather conditions.

Key Components

The equipment consists of several crucial elements that work in harmony to achieve optimal performance. Each segment plays a vital role, ensuring durability and reliability. Understanding these components allows users to maintain and utilize the device effectively.

Maintenance and Care

Proper upkeep is essential for longevity. Regular inspections and timely replacements of worn parts enhance functionality. Following maintenance guidelines not only improves performance but also ensures safety during operation.

Components of the Plow System

The efficiency of a snow removal apparatus relies on various integral elements that work together to ensure optimal performance. Understanding these components helps users maintain and troubleshoot their equipment effectively.

| Component | Description |

|---|---|

| Blade | The primary element that interacts with snow, designed for durability and precision in clearing. |

| Mounting Frame | Secures the blade to the vehicle, ensuring stability and alignment during operation. |

| Hydraulic System | Facilitates the lifting and angling of the blade for enhanced maneuverability. |

| Controller | The interface for the operator, allowing for adjustments and settings during use. |

| Wear Bar | A replaceable strip that protects the blade and enhances its longevity while maintaining effective scraping. |

Importance of Regular Maintenance

Benefits of Consistent Upkeep

Frequent maintenance offers numerous advantages, such as enhanced safety, reduced operational costs, and improved efficiency. By addressing minor problems early, operators can prevent them from developing into significant repairs, thereby saving time and money.

Key Maintenance Practices

| Practice | Frequency | Benefits |

|---|---|---|

| Inspection | Monthly | Identifies wear and tear |

| Lubrication | Weekly | Reduces friction |

| Cleaning | Bi-weekly | Prevents buildup |

| Parts Replacement | As needed | Ensures functionality |

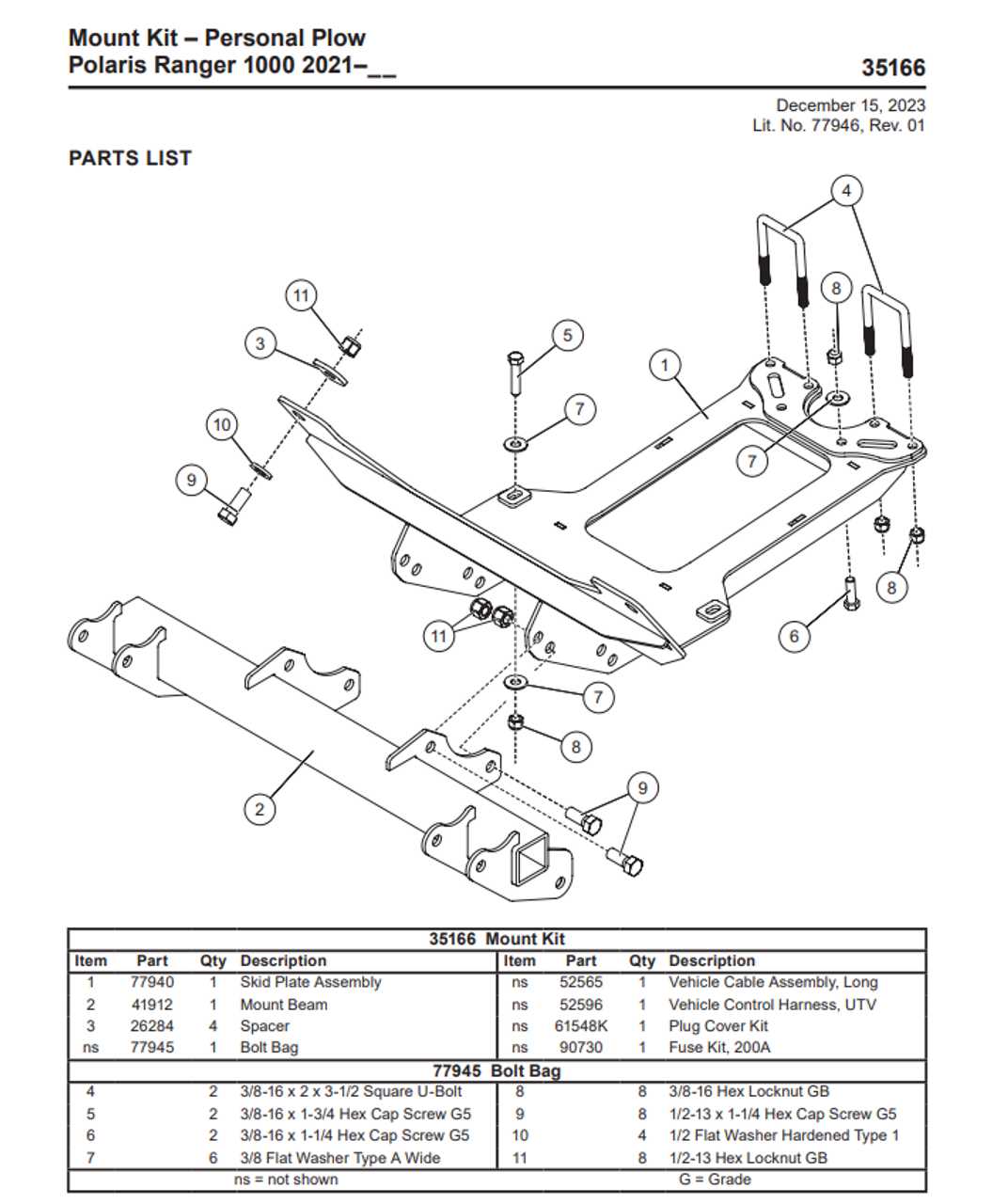

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. Such illustrations simplify complex assemblies, enabling users to identify each element’s function and position within the system.

Key Elements to Identify

Begin by recognizing the various symbols and labels used in the illustration. Each element is typically accompanied by a reference number, correlating with a list of components, which provides additional details such as specifications and availability.

Interpreting Connections

Pay attention to how the components connect with one another. Lines and arrows often indicate relationships or pathways, guiding you through the assembly process. Understanding these connections can significantly enhance your ability to troubleshoot and resolve issues efficiently.

Identifying Common Wear Parts

Understanding the components that experience significant degradation during use is essential for maintaining optimal performance. These elements are crucial for the efficiency and safety of the equipment, often requiring regular inspection and timely replacement to ensure longevity.

Commonly, one will find that cutting edges and rubber elements tend to wear down first due to their direct interaction with surfaces. Additionally, pivot points and attachment mechanisms may experience wear from constant movement and stress, necessitating attention to avoid operational failures.

Another critical area is the hydraulic components, which can develop leaks or decreased responsiveness over time. Monitoring these parts is vital for maintaining effective functionality. Ultimately, recognizing these commonly affected components can enhance overall operational efficiency and prolong the lifespan of the machinery.

Steps for Plow Assembly and Disassembly

This section provides a comprehensive guide for the proper assembly and disassembly of your snow clearing equipment. Following these steps ensures that the unit functions efficiently and can be safely stored or transported when not in use.

Assembly Procedure

To begin the assembly, gather all necessary components and tools. Start by aligning the primary frame with the attachment points on the vehicle. Ensure that all bolts and fasteners are free of dirt and corrosion to achieve a secure fit.

Next, attach the hydraulic mechanisms if applicable. Make sure to check that all connections are tight and free from leaks. Following this, proceed to install the cutting edge, ensuring it is aligned correctly to maximize performance during operation. Finally, conduct a thorough inspection to confirm that all components are securely fastened and functioning as intended.

Disassembly Procedure

For disassembly, begin by safely detaching any hydraulic lines or electrical connections. It is crucial to relieve any pressure in the system before proceeding. Next, remove the cutting edge and set it aside for maintenance or storage.

Then, carefully detach the main frame from the vehicle, taking care to avoid any damage to both the frame and the attachment points. Organize all components and hardware to facilitate easy reassembly in the future. Before storing, clean all parts to prevent rust and deterioration.

Replacement Parts: What to Consider

When it comes to maintaining and enhancing the efficiency of your equipment, understanding the nuances of component replacement is crucial. Selecting the right substitutes can significantly influence performance, durability, and overall satisfaction. Here are several key factors to keep in mind during the selection process.

Quality vs. Cost

One of the primary considerations is the balance between quality and affordability. While it might be tempting to opt for cheaper alternatives, investing in high-quality replacements can lead to better longevity and reliability. Consider the long-term benefits versus immediate savings.

Compatibility and Specifications

Ensure that the replacements are compatible with your equipment. This includes checking dimensions, materials, and functionality. Mismatched components can lead to inefficiencies or even damage. Always refer to the manufacturer’s guidelines for specifications before making a purchase.

Safety Tips for Plow Operation

When engaging in the operation of snow-moving equipment, ensuring safety is paramount. Proper precautions not only protect the operator but also others in the vicinity. Adhering to guidelines can significantly reduce the risk of accidents.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and insulated clothing.

- Conduct a thorough inspection of the equipment before use, checking for any potential mechanical issues.

- Familiarize yourself with the equipment’s controls and functions to ensure efficient operation.

- Maintain a clear line of sight while maneuvering and be aware of your surroundings.

- Use caution when working on inclines or uneven surfaces to prevent tipping.

Following these guidelines can help create a safer environment during operations, allowing for a more efficient and enjoyable experience.

Winter Preparation for Your Vehicle

As the cold season approaches, ensuring your automobile is ready for harsh weather conditions is essential. Proper preparation not only enhances safety but also optimizes performance during challenging environments. A well-maintained vehicle can navigate snow-covered roads and icy surfaces more effectively, providing peace of mind for drivers and passengers alike.

Start with an inspection. Examine your tires to ensure they have sufficient tread depth and are appropriately inflated. Consider switching to winter tires if you live in an area prone to heavy snowfall. Next, check the battery; cold temperatures can significantly affect its performance. Ensure that the connections are clean and secure.

Fluid levels are also crucial. Replace any old oil with a winter-grade alternative to ensure smooth engine operation. Make sure your coolant is at the right level and mixed appropriately to prevent freezing. Additionally, keep your windshield washer fluid topped up with a solution designed for low temperatures.

Don’t forget the wipers. Inspect and, if necessary, replace your windshield wipers to ensure clear visibility during snowy conditions. It’s also wise to keep an ice scraper and snow brush in your vehicle for emergencies. Finally, pack an emergency kit that includes blankets, a flashlight, food, and water to stay prepared for unexpected situations.

Upgrades for Enhanced Performance

Enhancing the efficiency and capability of your equipment is essential for achieving optimal results in challenging environments. By focusing on key modifications, you can significantly improve functionality, durability, and overall user experience.

Key Modifications

Consider the following upgrades to elevate performance:

| Upgrade | Description |

|---|---|

| Improved Blade Material | Switching to high-grade steel increases longevity and reduces wear. |

| Enhanced Hydraulic System | Upgrading components for faster response and better lifting capacity. |

| Advanced Control System | Implementing modern electronics for precise operation and ease of use. |

| Heavy-Duty Suspension | Installing robust suspension for improved stability on uneven terrain. |

Benefits of Upgrades

Investing in these enhancements not only boosts performance but also extends the lifespan of your equipment, ensuring you tackle any task with confidence and efficiency.

Finding Quality Replacement Parts

When it comes to maintaining outdoor equipment, sourcing high-quality components is essential for ensuring optimal performance and longevity. The right substitutes not only enhance functionality but also provide peace of mind during use.

Here are some tips for locating superior alternatives:

- Research Reputable Suppliers: Look for well-established vendors known for their reliability and customer service.

- Check Reviews: Read feedback from other users to gauge the quality and performance of the items you are considering.

- Compare Prices: While affordability is important, be wary of prices that seem too good to be true; quality often comes at a reasonable cost.

Additionally, consider these strategies:

- Consult Experts: Seek advice from professionals or enthusiasts who have experience with your specific type of equipment.

- Verify Compatibility: Ensure that any substitute you consider fits perfectly and matches the specifications of your original component.

- Look for Warranties: Quality replacements often come with guarantees, offering assurance of their durability and performance.

By taking the time to find trustworthy alternatives, you can enhance the functionality and lifespan of your machinery, making your outdoor tasks more efficient and enjoyable.

Frequently Asked Questions about Plows

This section addresses common inquiries related to snow removal equipment, focusing on functionality, maintenance, and operational best practices. Understanding these aspects can enhance efficiency and longevity, ensuring optimal performance during winter conditions.

Common Issues and Solutions

| Issue | Solution |

|---|---|

| Difficulty lifting | Check hydraulic fluid levels and connections. |

| Ineffective clearing | Inspect blade alignment and adjust if necessary. |

| Unusual noises | Examine for loose bolts and worn components. |

Maintenance Tips

Regular upkeep is essential for performance. Ensure to lubricate moving parts, inspect for wear and tear, and store equipment properly during off-seasons to maximize its lifespan.