John Deere CT332 Parts Overview

When working with heavy machinery, having a clear view of the internal configuration is crucial for maintenance and repairs. Knowing the structure and placement of various elements can help streamline tasks, minimize downtime, and enhance operational efficiency. This section aims to provide an overview of key components and their interconnections, allowing for a better understanding of the overall system.

Each machine is made up of numerous essential parts that work together to ensure proper functionality. Recognizing how these elements are linked and where they are located can simplify troubleshooting and repair processes. It also enables operators to identify potential issues before they become major problems.

Regular upkeep involves not only routine checks but also the replacement of worn-out or damaged elements. A comprehensive view of the system layout can significantly assist in identifying the right components, ensuring that maintenance is carried out effectively and safely.

Understanding the John Deere CT332 Diagram

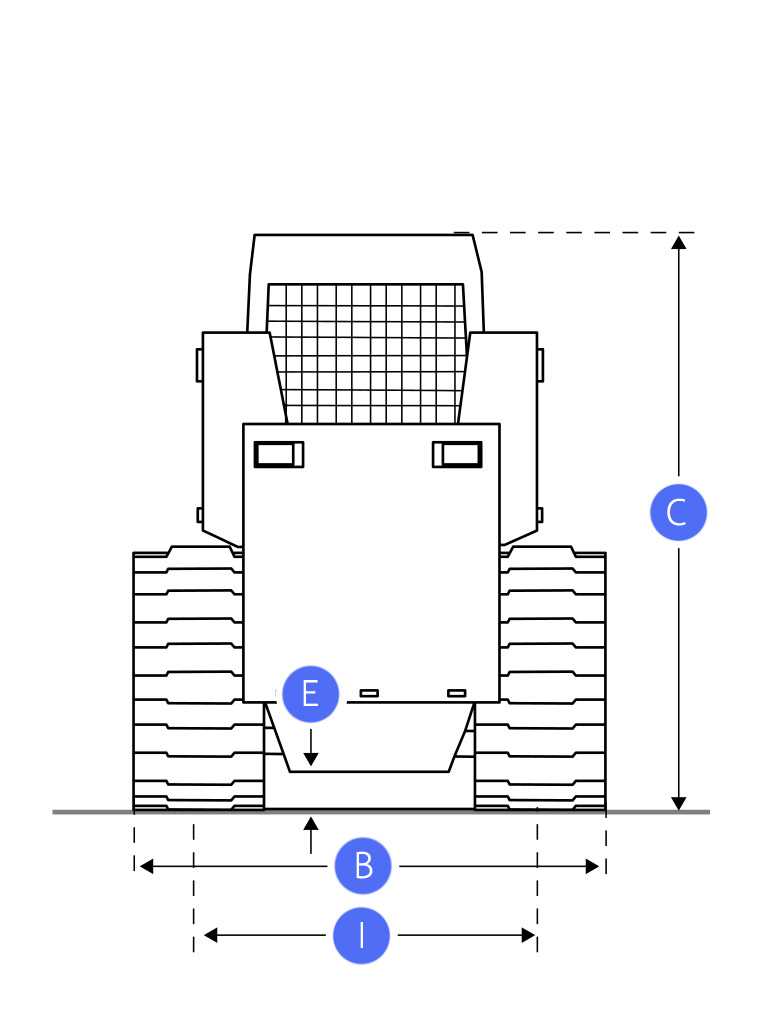

Exploring the illustration of this machinery can provide valuable insights into its structure and functionality. By breaking down the image, one can gain a clearer understanding of how the different elements connect and work together. The visual representation helps to simplify the process of identifying specific components, which can be crucial for maintaining and troubleshooting.

Key Sections of the Illustration

The visual guide is typically divided into several sections, each representing different areas of the equipment. These segments allow users to quickly locate the necessary details and understand the placement of various elements. The layout often includes numbered labels or annotations that correspond to specific items within the image, making it easier to follow along.

Benefits of Using a Diagram

Utilizing an illustration not only saves time but also aids in avoiding errors during maintenance or repairs. It acts as a step-by-step map, providing a detailed overview of how the elements fit together. This can be especially useful for individuals who may not be familiar with the internal workings of the machine.

| Section | Description | ||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | Shows the layout of the power unit and connected components

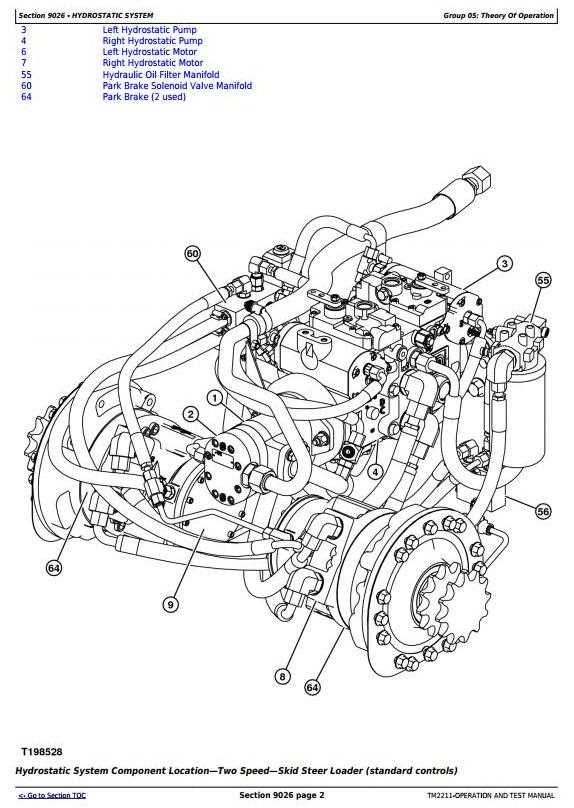

Key Components of the CT332Understanding the primary elements of this heavy machinery is essential for efficient operation and maintenance. Each component plays a crucial role in ensuring smooth functionality and optimal performance, making it vital to recognize the purpose and function of various mechanical and hydraulic systems. Engine System: The power source drives all essential operations, offering the strength needed to tackle challenging tasks. Its robust design ensures reliability under demanding conditions. Hydraulic Circuit: Responsible for transferring energy to different parts, this system allows precise control over movements and attachments. It includes various valves, pumps, and hoses that work together to manage fluid flow and pressure. Track Assembly: Provides stability and traction, enabling the machine to navigate diverse terrains. The assembly includes rollers, sprockets, and rubber tracks, which together ensure a secure grip on various surfaces. Operator’s Cab: The control center where all commands are executed. It features a user-friendly layout with essential controls and displays for monitoring system performance and adjusting settings as needed. Cooling System: Maintains the optimal operating temperature by circulating coolant and reducing heat buildup. The system’s radiators, fans, and hoses work together to prevent overheating during prolonged use. Common Replacement Parts for Maintenance

Regular upkeep of heavy machinery requires the timely replacement of certain key components. These elements help ensure the equipment operates efficiently and remains reliable in demanding conditions. Understanding which components may need attention during routine maintenance can significantly extend the service life of the machine and prevent unexpected downtime. Engine and Cooling System ComponentsThe engine, being the heart of the equipment, often demands special attention. Filters such as air, oil, and fuel filters are crucial for maintaining engine cleanliness and performance. Additionally, coolant hoses and radiators should be inspected regularly, as they play a vital role in preventing overheating and ensuring the engine runs smoothly. Wearable Parts and HydraulicsParts that experience constant movement and friction, like belts and seals, are subject to wear and should be checked frequently. The hydraulic system also requires regular maintenance, including replacing hydraulic filters and inspecting lines for potential leaks, to maintain optimal fluid pressure and functionality. Hydraulic System Overview and FunctionsThe hydraulic system plays a crucial role in providing power for various functions, utilizing fluid pressure to transmit force efficiently. Understanding how this system operates helps in maintaining performance and diagnosing potential issues. This section covers the essential aspects of the hydraulic components and their primary roles. Main Hydraulic ComponentsThe hydraulic system consists of several key elements, each contributing to fluid control and pressure management. These components work together to ensure smooth operation and efficient energy transfer.

|