Kubota ZD1011 Parts Diagram Overview

When it comes to maintaining and servicing machinery, having a clear understanding of the various elements involved is crucial. A comprehensive visual representation of these components can significantly enhance the efficiency of repairs and replacements. This resource aims to shed light on the intricate arrangement and functionality of essential machinery parts.

For operators and technicians, familiarity with the layout of each segment is vital for troubleshooting and ensuring optimal performance. By delving into detailed illustrations, one can easily identify critical areas and components that may require attention or replacement. Such insights not only facilitate effective maintenance but also contribute to the longevity of the equipment.

In this guide, we will explore the various sections and functionalities of the machine, providing a detailed overview that supports both novice and experienced users alike. Emphasizing clarity and precision, this information will serve as a valuable reference for anyone looking to enhance their understanding of the machinery’s inner workings.

Kubota ZD1011 Overview

This section provides a comprehensive look at a highly efficient lawn care machine designed for professional landscapers and homeowners alike. Known for its durability and performance, this model is built to tackle a variety of tasks, ensuring a well-manicured lawn with minimal effort.

Key Features

- Powerful engine for optimal performance

- Ergonomic design for user comfort

- Advanced cutting technology for precise results

- Fuel efficiency for extended operation

- Robust construction for longevity

Applications

- Residential landscaping

- Commercial lawn maintenance

- Golf course management

- Public park upkeep

This machine stands out in the market, making it a reliable choice for anyone seeking high-quality results in lawn maintenance.

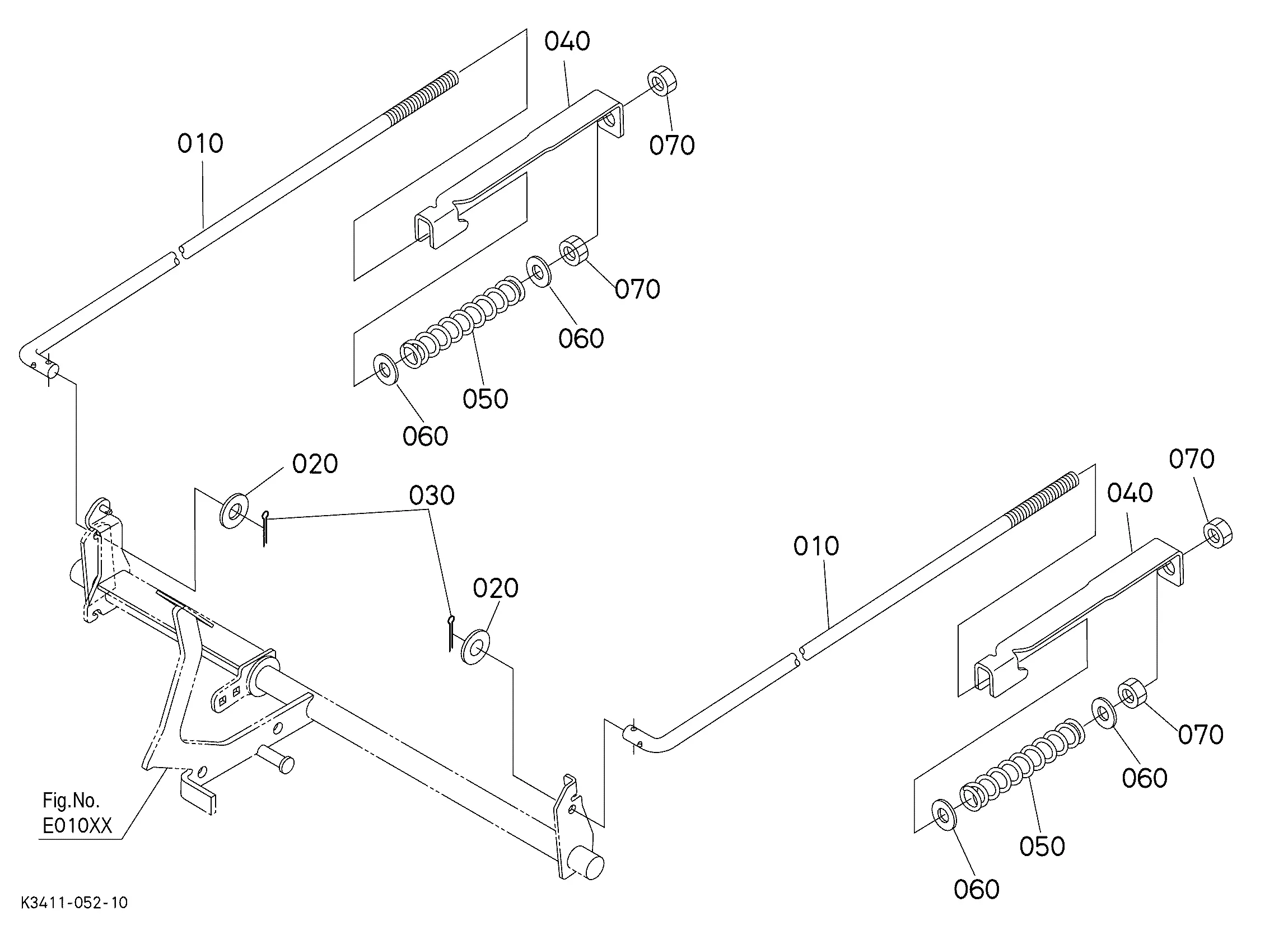

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations of these elements facilitate identification and ensure that technicians can quickly locate what they need. This clarity not only aids in troubleshooting but also enhances overall operational efficiency.

Moreover, detailed visual guides help in minimizing the chances of errors during assembly and disassembly processes. By providing a clear reference, these illustrations support users in comprehending complex configurations and workflows.

| Benefits | Description |

|---|---|

| Efficiency | Reduces time spent on locating components and understanding machinery layout. |

| Accuracy | Minimizes mistakes during repairs and part replacements. |

| Training | Serves as an educational tool for new technicians and operators. |

| Documentation | Provides a reference point for future repairs and modifications. |

In summary, these visual aids are invaluable for anyone involved in the upkeep of machinery, ensuring smooth operations and long-term reliability.

Common Issues with Kubota ZD1011

Owners of certain lawn care machines often encounter a range of challenges that can affect performance and efficiency. Understanding these common problems can aid in timely maintenance and repairs, ultimately prolonging the lifespan of the equipment. This section will outline prevalent issues that users may face, along with potential solutions.

Engine Performance Problems

One of the most frequently reported issues involves engine performance. Users may notice symptoms such as stalling, difficulty starting, or unusual noises. These can be attributed to various factors including fuel system blockages, air filter obstructions, or electrical malfunctions. Regular inspection of the fuel lines and filters, as well as checking battery connections, can help mitigate these concerns.

Mowing Efficiency Concerns

Another common issue relates to mowing efficiency. Grass clippings may not be evenly distributed, leading to unsightly patches in the lawn. This can occur due to dull blades, incorrect cutting height, or buildup of debris under the mower deck. To address this, routine blade sharpening, proper adjustment of cutting height, and cleaning of the deck are recommended practices.

Where to Find Parts Diagrams

Locating detailed illustrations for machinery components can greatly enhance maintenance and repair tasks. These visuals provide clarity on the structure and arrangement of various elements, making it easier to identify specific items needed for servicing. Understanding where to access these resources is crucial for anyone working with such equipment.

Online Resources

- Manufacturer’s Website: Check the official site for technical manuals and resources.

- Specialized Forums: Join communities dedicated to machinery discussions; members often share useful links and files.

- Online Retailers: Some sellers provide downloadable guides along with their inventory.

- Educational Platforms: Websites offering tutorials may also include relevant diagrams for practical learning.

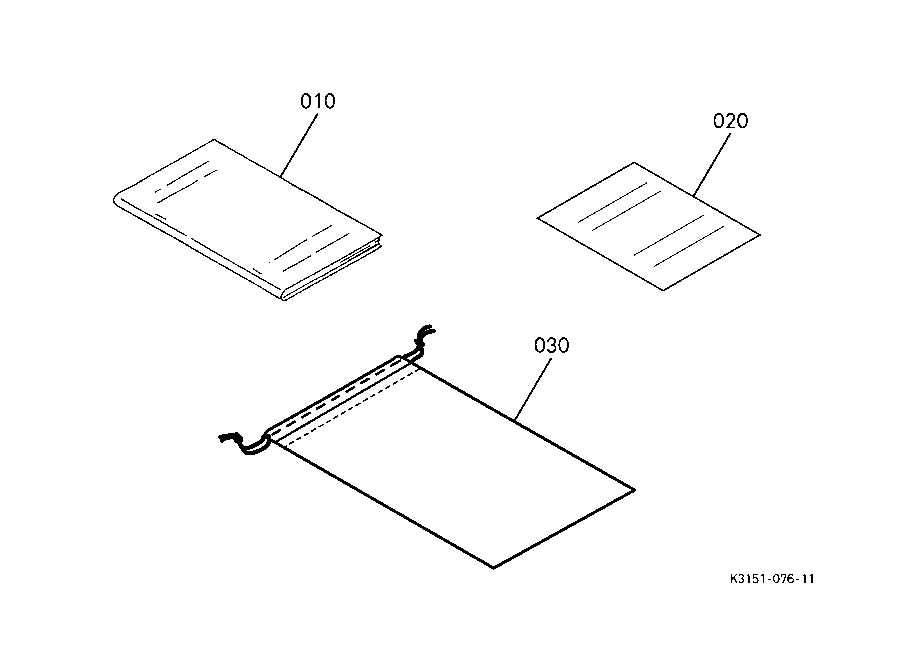

Printed Materials

- User Manuals: Always refer to the manual that came with the equipment; it usually contains detailed illustrations.

- Service Guides: Consider purchasing comprehensive service manuals available in bookstores or online.

- Local Libraries: Some libraries keep archives of technical manuals that can be accessed by the public.

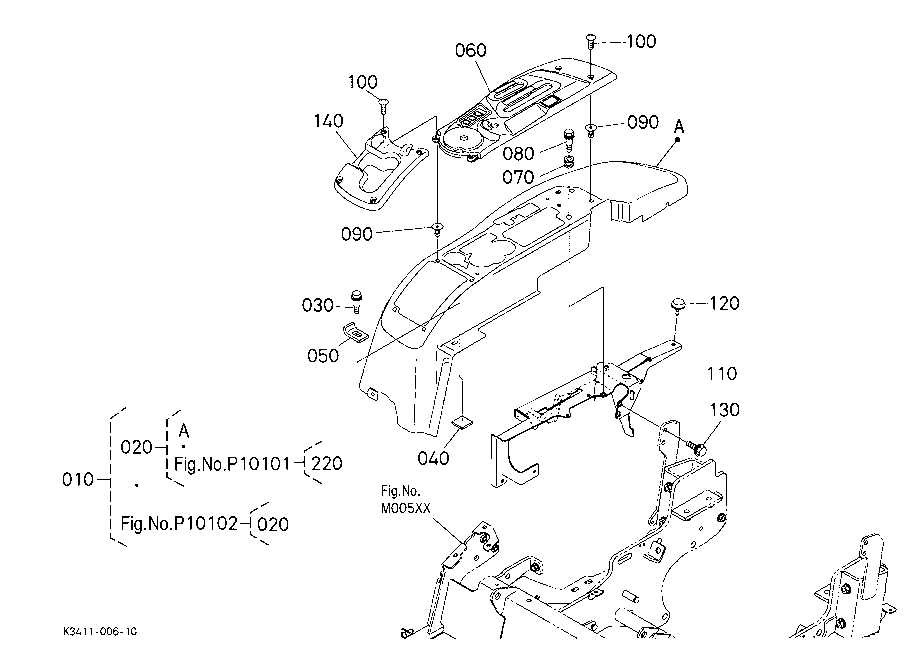

Identifying Key Components

Understanding the essential elements of a machine is crucial for effective maintenance and troubleshooting. Each component plays a specific role in ensuring optimal performance, and recognizing these parts can aid in timely repairs and replacements. This section will delve into the primary features that contribute to the overall functionality of the equipment.

Engine Assembly

The heart of the machinery lies in its engine assembly. This crucial part converts fuel into mechanical energy, powering all operations. Familiarity with the engine’s main components, such as the cylinder head, crankshaft, and oil filter, is vital for diagnosing issues related to performance and efficiency.

Transmission System

The transmission system serves as the link between the engine and the wheels, enabling the transfer of power. Key elements like gears, shafts, and clutches must be understood to maintain smooth operation and ensure that the vehicle responds effectively to driver commands. Regular checks on these components can prevent significant mechanical failures.

Benefits of Using OEM Parts

When it comes to maintaining equipment, opting for original manufacturer components can provide significant advantages. These parts are designed to meet the exact specifications of the machinery, ensuring optimal performance and longevity. By choosing such components, users can experience enhanced reliability and reduced risk of failure, leading to better overall efficiency in operations.

Quality Assurance

Original components are crafted using high-quality materials and undergo rigorous testing processes. This attention to detail guarantees that each piece will function as intended, thereby minimizing the chances of malfunction. Furthermore, OEM items typically come with warranties, providing peace of mind to the users.

Compatibility and Performance

Utilizing original components ensures perfect compatibility with the machinery. This alignment not only helps in maintaining the overall performance but also preserves the integrity of the equipment. When original components are installed, users can expect smoother operation and improved functionality, which are essential for maintaining productivity.

| Benefit | Description |

|---|---|

| Reliability | Enhanced durability and reduced risk of breakdowns. |

| Quality | Manufactured with superior materials and standards. |

| Warranty | Often comes with a manufacturer’s warranty for added assurance. |

| Performance | Ensures optimal functionality and compatibility with existing systems. |

Understanding Maintenance Needs

Effective upkeep of machinery is crucial for ensuring optimal performance and longevity. Regular attention to the various components not only enhances functionality but also prevents costly repairs down the line. Familiarity with the maintenance requirements is essential for any operator aiming to achieve peak efficiency and reliability.

Key Components of Maintenance

To maintain machinery in excellent condition, it’s important to regularly inspect and service critical elements. This includes checking fluids, filters, and belts, as well as monitoring overall wear and tear. Proactive maintenance helps identify potential issues before they escalate, allowing for timely interventions.

Scheduling and Record-Keeping

Establishing a regular maintenance schedule is vital for systematic oversight. Keeping detailed records of services performed can aid in tracking the health of the equipment over time. Documenting maintenance activities not only provides insight into the equipment’s performance but also serves as a valuable reference for future servicing needs.

How to Read Diagrams Effectively

Understanding technical illustrations is crucial for successful troubleshooting and maintenance. These visual representations simplify complex systems, allowing users to identify components and their relationships. Mastering the art of reading these images can enhance your efficiency and accuracy in repairs or modifications.

To begin, familiarize yourself with the symbols and notations used in the illustrations. Each representation often follows specific conventions that denote various elements. This knowledge will provide a strong foundation for interpreting the information presented.

| Symbol | Description |

|---|---|

| Circle | Represents a connection point or junction. |

| Arrow | Indicates the direction of flow or movement. |

| Square | Denotes a component or unit within the system. |

| Dashed Line | Shows an optional or alternate path. |

Next, pay attention to the layout and flow of the illustration. Recognizing how components are organized can help in understanding their function and interconnection. Start from the main unit and work your way through subcomponents, tracing connections as you go.

Lastly, utilize any accompanying legends or notes. These additional resources often provide context and clarification that can enhance your comprehension. By applying these strategies, you will become more proficient in interpreting technical visuals, ultimately leading to more effective problem-solving.

Repair Tips for Kubota ZD1011

Maintaining and fixing your machinery can significantly enhance its performance and longevity. Understanding common issues and implementing effective solutions will help you tackle any challenges that may arise. Below are some practical suggestions to ensure smooth operation and efficient repairs.

Regular Maintenance

Routine upkeep is essential for preventing major breakdowns. Consider the following practices:

- Check and change the oil periodically to ensure optimal engine performance.

- Inspect the air filter and clean or replace it as necessary to maintain airflow.

- Keep the blades sharp to ensure effective cutting and reduce strain on the engine.

- Monitor tire pressure and wear to ensure stability and safety during operation.

Troubleshooting Common Issues

When problems arise, quick diagnosis can save time and resources. Here are some common issues and potential solutions:

- Engine Won’t Start: Check the fuel level and battery connections. Ensure the safety switches are engaged.

- Uneven Cutting: Examine the deck for damage and ensure the blades are properly aligned.

- Overheating: Inspect the cooling system and clean any debris obstructing airflow.

- Strange Noises: Listen for unusual sounds that may indicate loose parts or worn bearings. Tighten or replace components as needed.

By following these tips, you can enhance the efficiency of your equipment and prolong its service life. Regular attention and prompt repairs will keep your machine running smoothly for years to come.

Ordering Replacement Parts Online

Finding and purchasing components for your equipment has never been easier thanks to the convenience of online shopping. With just a few clicks, you can access a wide array of items tailored to your needs. This section will guide you through the process of sourcing high-quality replacements without the hassle of traditional methods.

Steps to Consider

Before making a purchase, it is essential to do your research. Start by identifying the exact item you need, using reference materials or guides to ensure compatibility. Once you have a clear understanding, look for reputable online retailers that specialize in equipment accessories.

Quality and Reliability

When ordering online, prioritize quality over price. While it might be tempting to opt for the cheapest option, investing in reliable components can save you time and money in the long run. Read customer reviews and check for warranties to ensure that you are getting durable and trustworthy products.

In summary, the online marketplace offers a streamlined approach to acquiring necessary components, allowing for informed choices and convenience. Make sure to evaluate your options carefully to achieve the best results for your equipment maintenance needs.