Comprehensive Guide to Echo HCA-266 Parts Diagram

When it comes to maintaining outdoor machinery, a thorough comprehension of their structural elements is essential. Knowledge of how each component interrelates not only aids in efficient troubleshooting but also enhances overall performance. This guide will explore the intricacies of a specific model, shedding light on its mechanical configuration.

Recognizing the individual parts and their functions can empower users to make informed decisions during repairs or upgrades. By delving into the organization of these components, one can appreciate the engineering behind them, ultimately leading to better care and longevity of the equipment. This exploration serves as a valuable resource for enthusiasts and professionals alike.

Moreover, understanding the layout of these mechanical structures provides insights into potential modifications or enhancements. As we break down the essential elements, readers will gain a clearer perspective on how to optimize their machinery for peak performance. This knowledge not only fosters a deeper connection with the equipment but also cultivates a proactive approach to maintenance.

Understanding Echo HCA-266 Components

The intricacies of machinery often lie in the various elements that come together to create a functional whole. A comprehensive grasp of these individual components is essential for effective maintenance and optimal performance. This section delves into the key features that contribute to the overall functionality of the equipment, providing insight into how each part interacts with others to ensure seamless operation.

Each component plays a crucial role, from the engine’s heart to the external casing. Power units serve as the driving force, while supporting structures maintain integrity and alignment. Understanding the mechanical linkages that connect these units is vital, as they facilitate energy transfer and movement, making them essential for operational efficiency.

Furthermore, control systems allow users to manage performance effectively. Familiarity with these elements enables operators to troubleshoot issues promptly and make informed decisions regarding repairs and upgrades. By exploring the functionality of these parts, one can enhance the lifespan and reliability of the machinery, ensuring it continues to perform at its best.

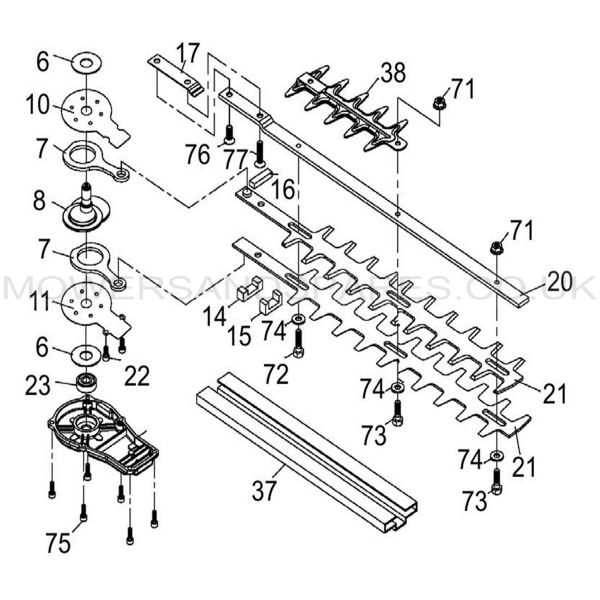

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations that illustrate each element can significantly enhance clarity and accessibility for users, enabling them to navigate complex systems with ease.

These visual aids offer numerous benefits:

- Clarity: Clear depictions help identify individual pieces and their functions.

- Efficiency: Quick reference to parts saves time during troubleshooting and repairs.

- Organization: Structured layouts allow for better comprehension of assembly and disassembly processes.

- Accuracy: Helps ensure that the correct components are utilized for repairs, reducing errors.

Furthermore, familiarity with these illustrations can empower users to perform maintenance tasks more confidently. This not only prolongs the life of the equipment but also enhances overall performance.

In summary, well-designed visual representations are crucial for anyone involved in the upkeep and operation of machinery, fostering both understanding and efficiency.

Common Issues with Echo HCA-266

When operating outdoor power equipment, users often encounter a range of problems that can hinder performance and efficiency. Recognizing these common issues can help in timely maintenance and repair, ensuring the longevity of the device.

- Starting Difficulties: Many users report challenges in getting the engine to start, which can be attributed to various factors such as stale fuel, a clogged air filter, or issues with the spark plug.

- Power Loss: A noticeable drop in power output can occur due to fuel delivery issues, blockages in the exhaust, or a worn-out ignition system.

- Vibration Problems: Excessive vibrations during operation may indicate loose components or imbalances in the cutting attachment, affecting comfort and control.

- Overheating: If the engine frequently overheats, it might be a result of insufficient lubrication, debris blocking air vents, or prolonged use without breaks.

- Fuel Leaks: Leaking fuel can pose safety hazards and is often caused by worn gaskets, damaged fuel lines, or improper connections.

Addressing these common issues promptly can lead to a more efficient and safe operating experience. Regular maintenance and inspections are essential to prevent minor problems from escalating into significant repairs.

Where to Find Replacement Parts

Finding the right components for your equipment can be a daunting task. However, with the right resources, you can easily source high-quality alternatives to keep your machinery running smoothly. Here are some effective strategies to locate the items you need.

Online Retailers

Numerous online platforms specialize in offering a wide range of components. These websites often provide detailed descriptions and compatibility information, making it easier for you to find what you are looking for.

- Check major e-commerce sites for a variety of options.

- Visit specialized websites that focus on outdoor power tools.

- Utilize customer reviews to gauge the quality of items.

Local Dealers and Repair Shops

Your local suppliers and service centers can be invaluable resources. They often have firsthand experience with the products and can recommend suitable replacements.

- Contact nearby dealerships for authentic components.

- Visit repair shops that may carry aftermarket alternatives.

- Ask about inventory and special order options if the item is not readily available.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing issues with your equipment. By following these organized steps, you can efficiently identify problems and restore functionality, ensuring optimal performance for your tool.

Begin by gathering the necessary tools and materials before starting the repair process. Make sure to work in a well-lit area to enhance visibility. Always prioritize safety by wearing appropriate protective gear.

Here is a simplified table of the steps to follow:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to ensure safety during repairs. |

| 2 | Examine the equipment thoroughly for visible signs of damage or wear. |

| 3 | Remove any necessary components to access the internal mechanisms. |

| 4 | Inspect individual parts for defects and replace any that are faulty. |

| 5 | Reassemble the tool, ensuring all components are securely fitted. |

| 6 | Reconnect the power source and conduct a test run to verify functionality. |

By systematically following these steps, you can effectively resolve issues and maintain the longevity of your equipment. Document any changes made for future reference and continue to monitor performance regularly.

Tools Needed for Maintenance

Proper upkeep of equipment requires specific instruments to ensure efficiency and longevity. Utilizing the right tools can facilitate the process, making tasks easier and more effective. Below is a list of essential instruments that will assist in routine maintenance and repairs.

Essential Instruments

- Wrenches: For loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for various screws.

- Pliers: Useful for gripping and bending components.

- Grease Gun: For applying lubrication to moving parts.

- Cleaning Brushes: To remove debris and buildup.

- Oil Can: For adding necessary fluids to machinery.

Additional Tools

- Socket Set: For accessing hard-to-reach fasteners.

- Tape Measure: To ensure accurate dimensions during repairs.

- Flashlight: For better visibility in dimly lit areas.

- Safety Gear: Gloves and goggles for personal protection.

Having these tools readily available will streamline maintenance tasks and contribute to the overall performance of your equipment.

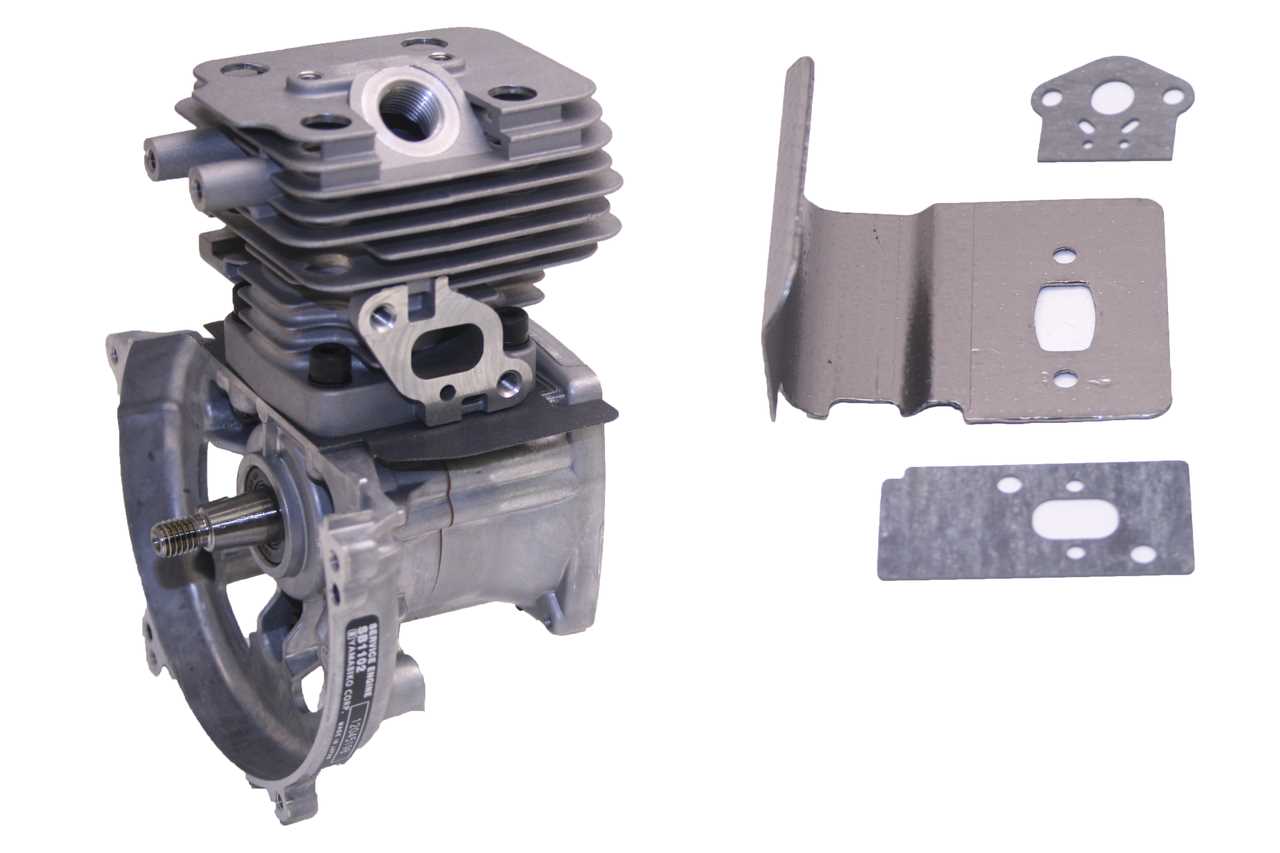

Identifying Genuine Parts

When it comes to maintaining outdoor equipment, ensuring the authenticity of components is crucial for optimal performance and longevity. Genuine components are designed to meet specific standards and are tested for quality, offering peace of mind to users who rely on their tools.

To distinguish authentic items from counterfeits, one should start by examining packaging. Original items typically come in well-branded, high-quality packaging with clear labeling and product information. Look for serial numbers and manufacturer logos, which can often be verified through official channels.

Another indicator of authenticity is the materials used. Genuine components are made from durable, high-quality materials that enhance performance and resilience. If the product feels lightweight or poorly constructed, it may be a sign of a knockoff.

Furthermore, consider the source of purchase. Authorized dealers and reputable retailers are more likely to offer authentic items. Researching the seller and reading reviews can provide insight into their credibility.

Lastly, consult user manuals or manufacturer websites for reference images and specifications. This knowledge can help you recognize subtle differences that indicate whether a component is genuine or not.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety and the integrity of the equipment is paramount. Proper precautions can prevent accidents and injuries, allowing for a smoother repair process. Familiarizing oneself with safety guidelines is essential for both novice and experienced individuals.

Personal Protective Equipment

Utilizing appropriate protective gear is crucial. Always wear gloves to safeguard your hands from sharp objects and chemicals. Safety goggles should be worn to protect your eyes from debris or harmful substances. Additionally, consider wearing a dust mask if you anticipate exposure to dust or fumes during the repair.

Work Environment Considerations

Ensure your workspace is clean and well-lit to minimize risks. Keep tools organized and free from clutter to avoid accidents. If working outdoors, be mindful of the weather conditions and secure any loose items that may become projectiles. Always have a first aid kit readily available in case of emergencies.

Maintenance Tips for Longevity

To ensure the extended lifespan and optimal performance of your equipment, regular upkeep is essential. Implementing a few straightforward practices can prevent premature wear and enhance functionality. Adopting a proactive approach to maintenance not only saves time and resources but also contributes to the overall efficiency of your tools.

1. Regular Cleaning: Keeping your equipment clean is crucial. After each use, remove debris and dirt that can cause blockages or damage. Use a soft brush or cloth to avoid scratching surfaces.

2. Check and Replace Filters: Clogged filters can impede performance. Inspect them periodically and replace as needed to ensure airflow and optimal operation.

3. Lubrication: Proper lubrication minimizes friction between moving parts. Use manufacturer-recommended lubricants and apply them according to guidelines to maintain smooth functionality.

4. Inspect Components: Regularly examine various parts for signs of wear or damage. Addressing small issues early can prevent larger problems down the line.

5. Store Properly: When not in use, store your equipment in a dry, protected area. Avoid exposure to extreme temperatures and humidity, which can lead to corrosion or degradation.

6. Follow Manufacturer Guidelines: Always adhere to the recommended maintenance schedule and procedures outlined in the user manual. These guidelines are designed to maximize the lifespan and performance of your equipment.

By incorporating these practices into your routine, you can significantly enhance the durability and efficiency of your tools, ensuring they serve you well for years to come.

Comparison with Other Echo Models

When evaluating various models within the same brand, it’s essential to understand the differences in design, functionality, and performance. Each model caters to specific needs, which can influence choice based on user requirements and preferences. This comparison highlights key features and characteristics that set these models apart, aiding in informed decision-making.

One significant aspect is engine power, which varies among different units. Some models offer enhanced horsepower, making them suitable for heavier tasks, while others focus on efficiency and ease of use for lighter applications. Additionally, weight and ergonomics play a crucial role; certain designs are streamlined for maneuverability, whereas others prioritize stability.

Durability is another factor worth considering. Different models may utilize varying materials and build quality, impacting their longevity and performance under tough conditions. Users who frequently work in rugged environments may benefit from more robust options.

Furthermore, maintenance requirements can differ. Some versions are designed with easier access to critical components, simplifying upkeep, while others may necessitate more frequent servicing. This aspect can significantly affect user experience and long-term satisfaction.

Lastly, technology integration varies, with some models featuring advanced systems for enhanced precision and control. Understanding these distinctions ensures that users can select a unit that best aligns with their operational demands and preferences.

User Reviews and Experiences

Understanding the insights and feedback from users is essential when evaluating any tool or equipment. Personal accounts not only highlight the strengths but also uncover potential shortcomings, helping prospective buyers make informed decisions. This section delves into the diverse experiences shared by individuals who have utilized this particular equipment.

Positive Feedback

Many users praise the reliability and performance of the device, noting its efficiency in tackling various tasks. One user remarked on how easily it handled tough vegetation, transforming their yard work into a more manageable task. Additionally, the lightweight design has been a common highlight, allowing for extended use without excessive fatigue. Several reviews emphasize the ease of operation, making it suitable for both beginners and seasoned users alike.

Constructive Criticism

While there is much appreciation, some reviews point out areas for improvement. A few users have mentioned the need for enhanced durability, particularly with certain components that may wear down over time. Another aspect raised is the learning curve associated with certain features, which could be challenging for those unfamiliar with similar tools. Overall, this feedback serves as a valuable resource for manufacturers to consider future enhancements.

FAQs About Echo HCA-266 Parts

This section aims to address common inquiries regarding the components associated with the specified model. Understanding the frequently asked questions can help users make informed decisions and enhance their experience with the equipment.

Common Questions

- What types of components are available for replacement?

- How can I identify the correct part for my model?

- Are there any maintenance tips to extend the lifespan of these components?

Replacement and Maintenance

- Where can I purchase authentic components?

- How do I install a new component safely?

- What should I do if a part is not functioning properly?