Understanding the Honda GCV190 Parts Diagram

Having a comprehensive understanding of the layout of engine components is crucial for anyone involved in maintenance or repair. Whether you are a seasoned mechanic or a novice enthusiast, familiarizing yourself with the arrangement of different elements can significantly enhance your efficiency and effectiveness in tackling repairs.

This section aims to provide insights into the various components found within a small engine. By grasping how these parts interact and their specific functions, you can make informed decisions when servicing or replacing them. Additionally, visual aids can serve as valuable tools in identifying each component and its placement.

Ultimately, a well-organized reference for engine elements allows you to approach any repair task with confidence. As you navigate through the intricate layout of the engine, you will gain the knowledge necessary to ensure optimal performance and longevity of the equipment.

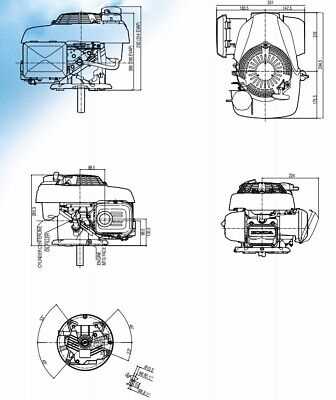

This section provides a comprehensive overview of the engine’s structure, emphasizing its various components and their functions. Understanding the layout and organization of the engine aids in maintenance and troubleshooting, ensuring optimal performance and longevity.

Key Components of the Engine

- Power Unit: Central to the engine’s operation, this part generates energy.

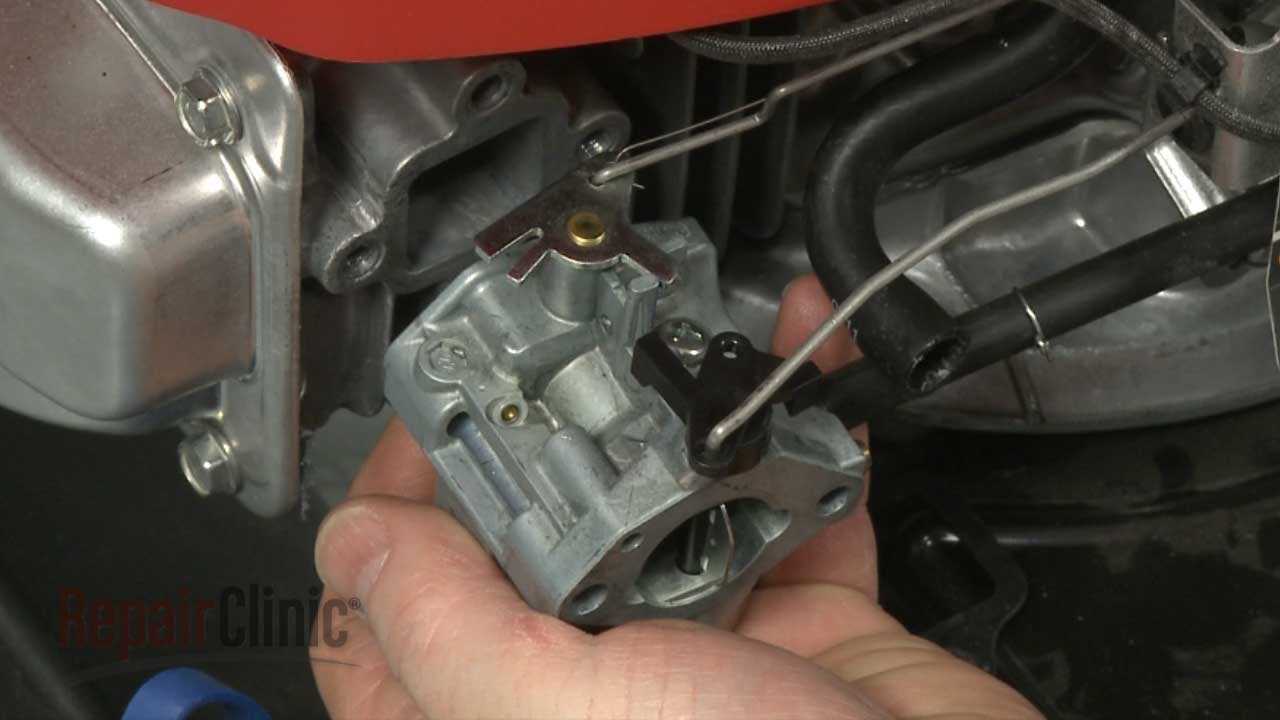

- Fuel System: This system delivers fuel to the combustion chamber, allowing for efficient energy production.

- Cooling Mechanism: Essential for regulating the engine’s temperature and preventing overheating.

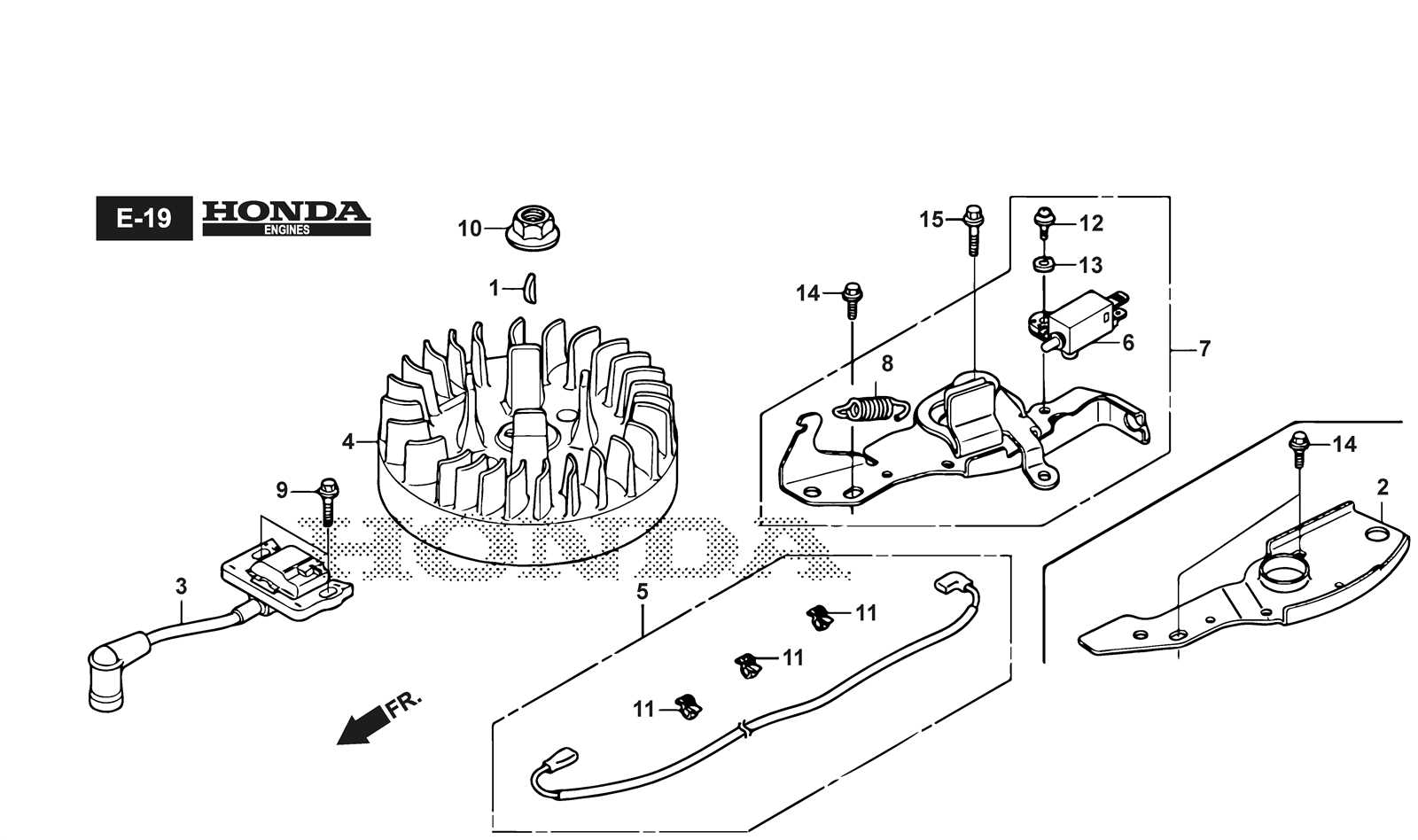

- Ignition Assembly: Responsible for starting the combustion process and ensuring smooth operation.

- Exhaust System: Manages the expulsion of gases produced during combustion.

Maintenance Considerations

- Regular Inspection: Frequent checks help identify wear and potential issues early.

- Fluid Levels: Ensuring optimal levels of oil and coolant is crucial for performance.

- Filter Replacement: Timely changes of air and fuel filters contribute to efficiency.

- Clean Components: Keeping parts clean prevents buildup that could impair function.

Key Components of the GCV190

This section explores the essential elements that contribute to the functionality and efficiency of this engine model. Understanding these components is crucial for maintenance and optimal performance.

At the core, the engine comprises a robust power unit, responsible for generating the necessary force. Additionally, there are various systems involved in fuel delivery, which ensure that the engine receives the right amount of fuel for combustion. An effective ignition system also plays a pivotal role, providing the spark needed to ignite the fuel-air mixture.

Furthermore, the cooling mechanism is vital for regulating temperature, preventing overheating during operation. A filtration system works in tandem to keep contaminants at bay, ensuring the longevity of the internal components. Lastly, the chassis and mounting elements provide stability and support, allowing the engine to function seamlessly within its intended applications.

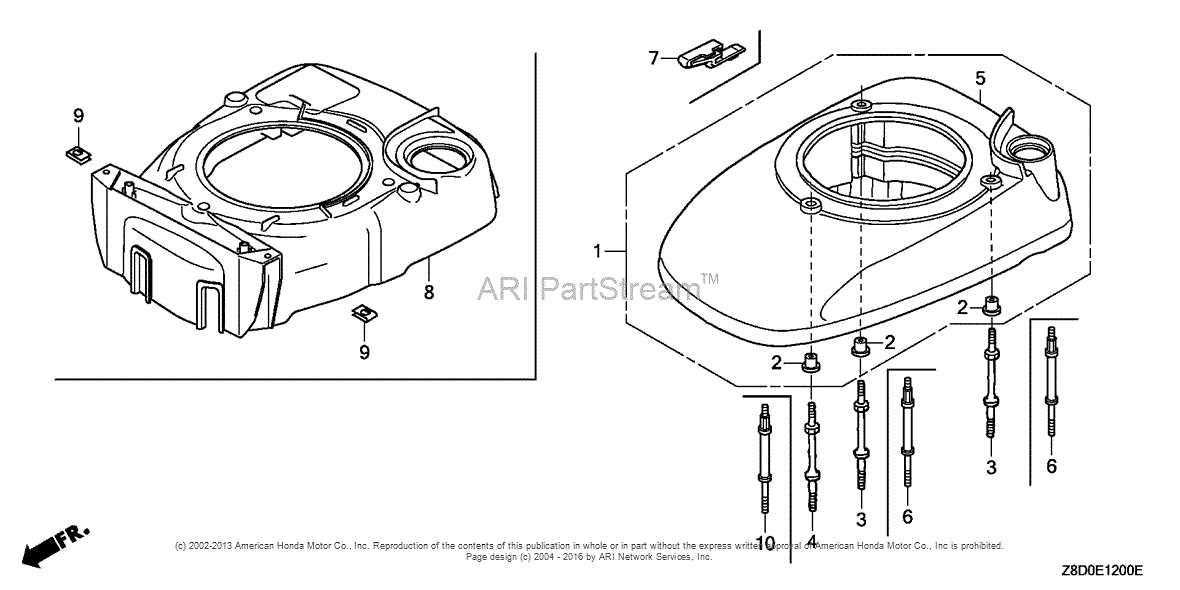

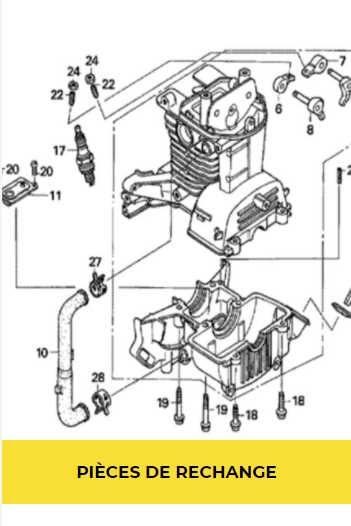

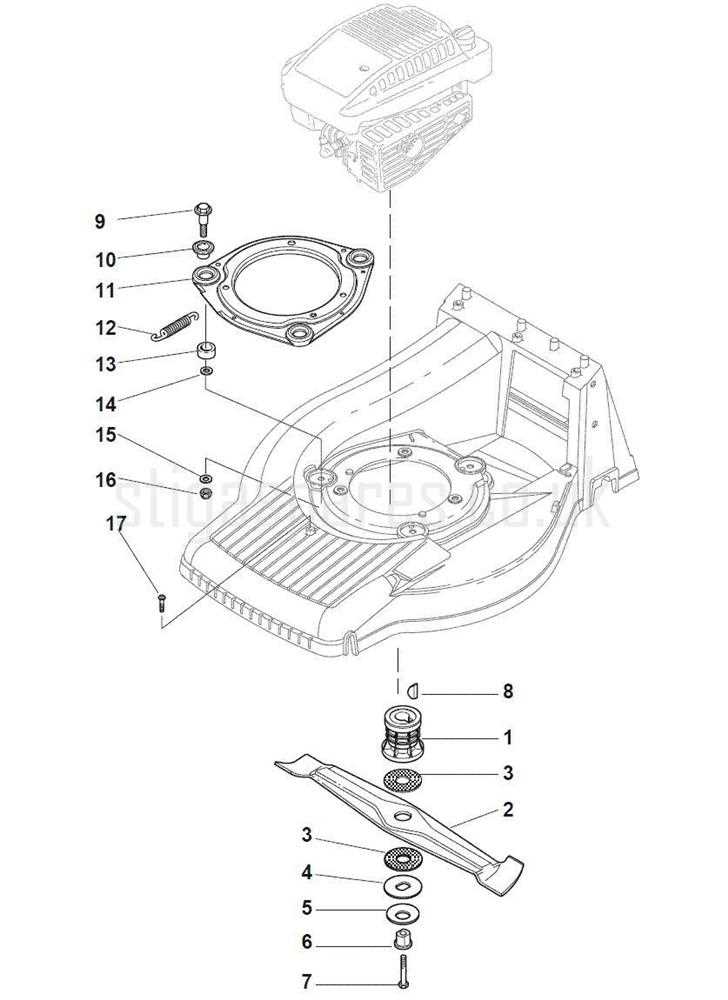

How to Read Parts Diagrams

Understanding visual representations of components is crucial for efficient maintenance and repair tasks. These illustrations offer a detailed view of each element, allowing users to identify and locate parts quickly. Familiarizing yourself with these visuals enhances your ability to work on machinery effectively.

Identifying Key Elements

Each illustration typically includes various sections that correspond to specific components. Look for labels or numbers that indicate the location of each item. These identifiers serve as a guide to help you understand the arrangement and functionality of each piece within the system.

Utilizing Reference Guides

Many visual aids come with accompanying reference materials that explain the components in detail. Consult these resources to gain a deeper understanding of each element’s role and how they interact. This knowledge is invaluable when it comes to troubleshooting or replacing parts.

Common Parts for Maintenance

Regular upkeep of small engine equipment involves understanding the essential components that require attention. Familiarity with these elements ensures optimal performance and longevity, enabling users to keep their machinery in prime condition.

Key Components for Care

Several critical components need routine inspection and replacement. These items play a vital role in the effective functioning of the equipment and should be regularly checked for wear and tear.

Essential Maintenance Elements

| Component | Function |

|---|---|

| Air Filter | Prevents debris from entering the engine, ensuring clean airflow. |

| Spark Plug | Ignites the air-fuel mixture for combustion. |

| Fuel Filter | Filters impurities from the fuel to protect the engine. |

| Oil Filter | Removes contaminants from engine oil, promoting smooth operation. |

| Blades | Ensures efficient cutting and performance in lawn maintenance. |

Troubleshooting Engine Issues

Addressing engine malfunctions requires a systematic approach to identify the root cause of performance problems. Understanding common symptoms can aid in diagnosing various conditions that affect the functionality of the machinery.

Common Symptoms to Observe

- Difficulty starting the engine

- Unusual noises during operation

- Excessive vibration

- Inconsistent power output

- Fuel leaks or visible damage

Steps for Diagnosis

- Check the fuel level and quality, ensuring it meets required specifications.

- Inspect the air filter for clogs or contamination, replacing if necessary.

- Examine electrical connections for wear or corrosion.

- Review the spark plug condition, replacing if fouled or worn.

- Test the ignition system components to ensure they function properly.

Replacement Parts Availability

Ensuring that essential components are readily accessible is crucial for maintaining the functionality of any machine. Various suppliers offer an extensive range of replacement items, making it easier for users to find what they need. This section discusses the sources and options available for obtaining these essential components.

Authorized Dealers

Authorized retailers are often the best choice for acquiring genuine items. They provide assurance of quality and compatibility. Here are some advantages of sourcing through these dealers:

- Access to original equipment manufacturer (OEM) items.

- Expert assistance for selecting the correct component.

- Warranty on the products purchased.

Aftermarket Suppliers

In addition to authorized dealers, there are many alternative suppliers that offer compatible components at competitive prices. While these may not always be OEM, they can be viable options. Consider the following points:

- Cost-effective alternatives for budget-conscious users.

- A wide variety of choices to suit different needs.

- Availability of user reviews to gauge quality and performance.

Importance of Genuine Parts

Utilizing authentic components is crucial for maintaining the efficiency and longevity of machinery. Original items are specifically designed to fit and function perfectly within the system, ensuring optimal performance and reliability. Using non-genuine alternatives may lead to complications, including reduced effectiveness and potential damage to the equipment.

High-quality, genuine components not only enhance the operational capabilities but also contribute to safety and compliance with industry standards. Investing in these elements can prevent unnecessary repairs and extend the lifespan of the machine, ultimately saving time and resources in the long run.

| Benefits of Authentic Components | Risks of Non-Genuine Alternatives |

|---|---|

| Designed for perfect compatibility | Potential for improper fit |

| Enhanced durability | Increased likelihood of failure |

| Improved efficiency | Reduced operational performance |

| Manufacturer support and warranty | No support for alternative products |

Comparing Aftermarket Options

When it comes to maintaining small engines, exploring alternatives to original manufacturer components can provide both cost savings and performance benefits. Aftermarket solutions often offer a variety of choices that cater to different needs and preferences. This section delves into the factors to consider when assessing these alternatives, ensuring informed decisions that enhance equipment longevity and efficiency.

Quality vs. Cost

Evaluating the balance between quality and expense is crucial when selecting replacements. While some alternatives may come at a lower price, it’s essential to analyze their durability and reliability. Investing in higher-quality options may lead to better performance and longer service life.

Compatibility Considerations

Not all aftermarket options are created equal in terms of compatibility. Ensuring that the chosen replacements fit seamlessly with existing equipment is vital. Researching specifications and reviews can help determine the best match for your specific model.

| Option | Price Range | Durability | Compatibility |

|---|---|---|---|

| Option A | $10 – $15 | Moderate | High |

| Option B | $5 – $10 | Low | Medium |

| Option C | $15 – $20 | High | High |

Assembly Instructions for GCV190

Properly assembling the engine components is crucial for optimal performance and longevity. This section outlines the essential steps for correctly putting together the various elements of the motor, ensuring a smooth operation. Following these instructions will help achieve efficient functionality and reliability.

Preparation Steps

Before starting the assembly process, gather all necessary tools and components. Ensure that each part is clean and free of debris. Familiarize yourself with the assembly sequence to avoid any confusion during the process. Having a well-organized workspace will facilitate a smoother assembly experience.

Assembly Procedure

Begin by securing the base frame, ensuring it is stable and level. Proceed to attach the engine block, ensuring all connections are tight and aligned. Follow the specific order for adding components, referring to your reference material for precise details. Double-check all connections and fittings before finalizing the assembly.

Tips for Efficient Repairs

When tackling maintenance tasks, it’s essential to adopt a methodical approach. Having a clear strategy can significantly streamline the process, reducing both time and effort involved in the repairs. Here are some effective techniques to enhance your efficiency during these activities.

Preparation is Key

Before starting any repair work, ensure you are well-prepared. Here are a few steps to consider:

- Gather all necessary tools and materials in advance.

- Read through any available manuals or guides to understand the procedure.

- Establish a clean workspace to avoid losing parts and improve focus.

Follow a Systematic Approach

Having a step-by-step method will help in maintaining order throughout the repair process. Consider the following:

- Start by diagnosing the issue thoroughly.

- Make a list of parts or components that require attention.

- Perform repairs systematically, ensuring each step is completed before moving on.

By adhering to these guidelines, you can make your repair tasks more effective and less stressful.