Comprehensive Guide to John Deere 3140 Parts Diagram

In the realm of agricultural machinery, having a comprehensive understanding of each element is crucial for effective maintenance and optimal performance. This section aims to provide clarity on the various components that constitute these powerful machines, ensuring that users can identify and address any issues that may arise.

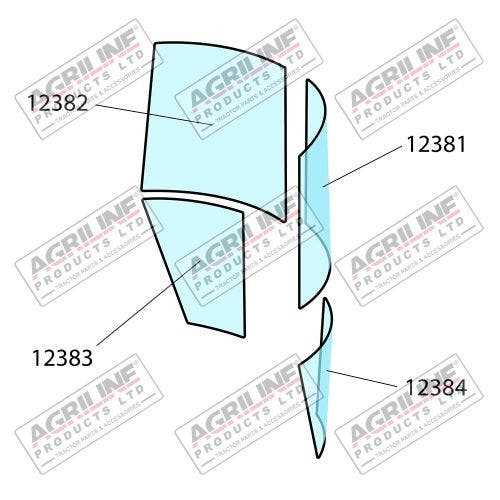

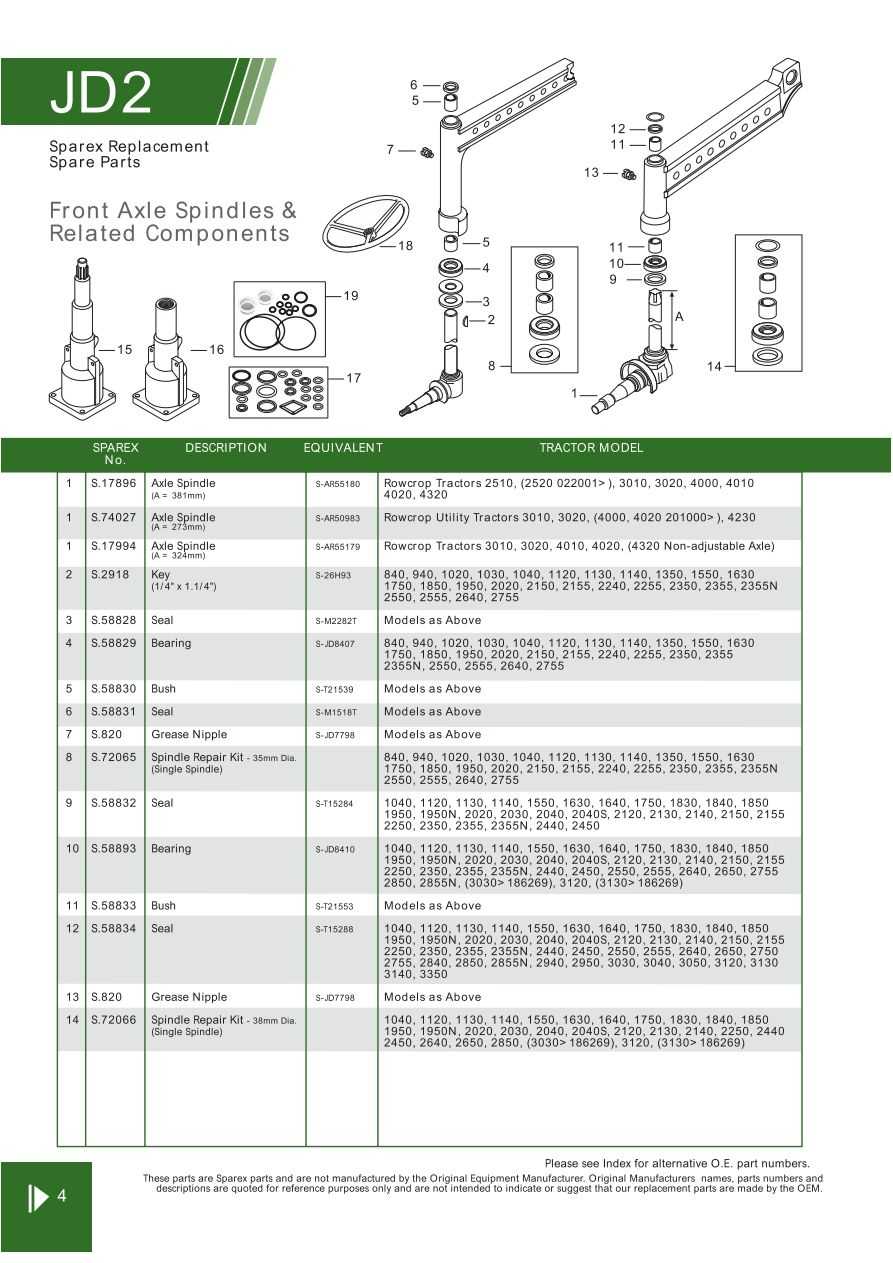

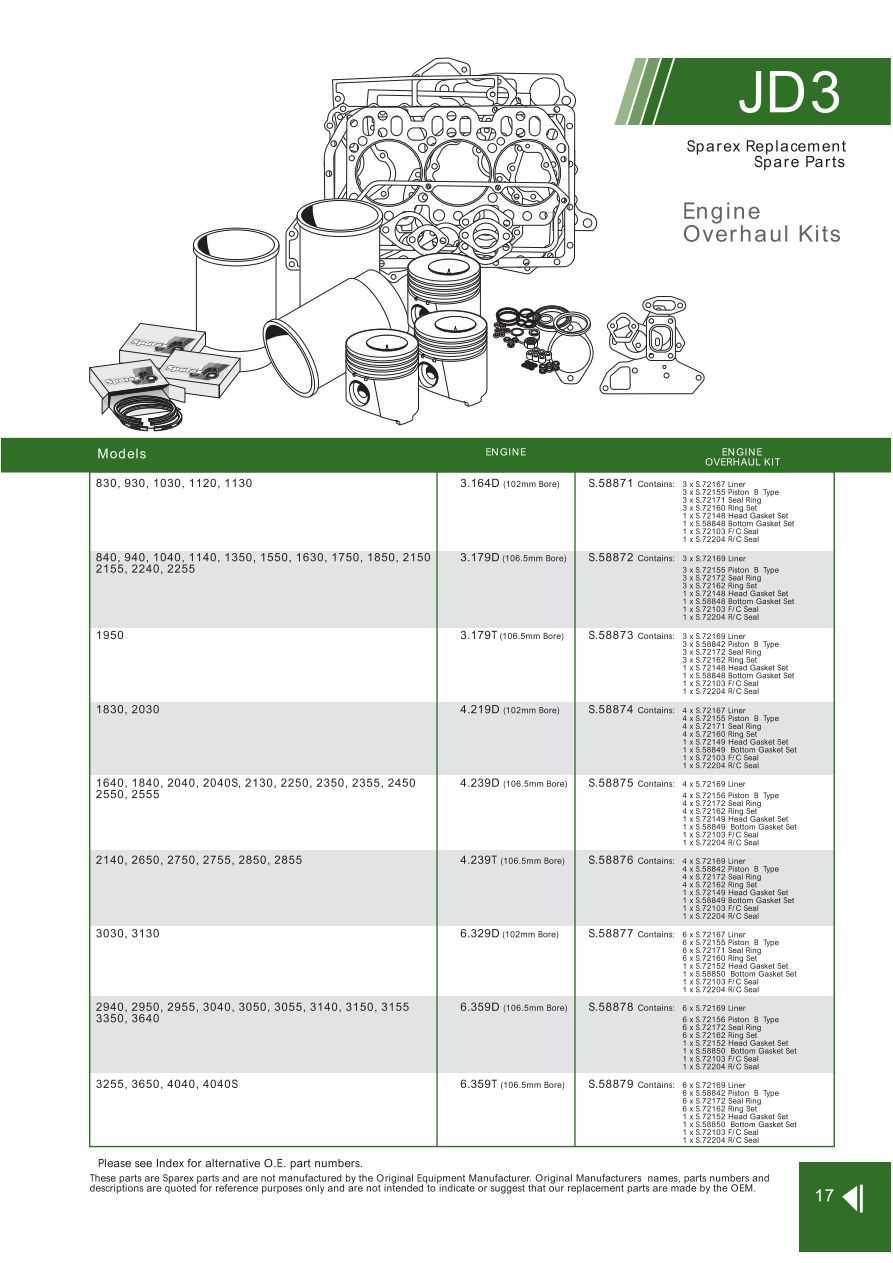

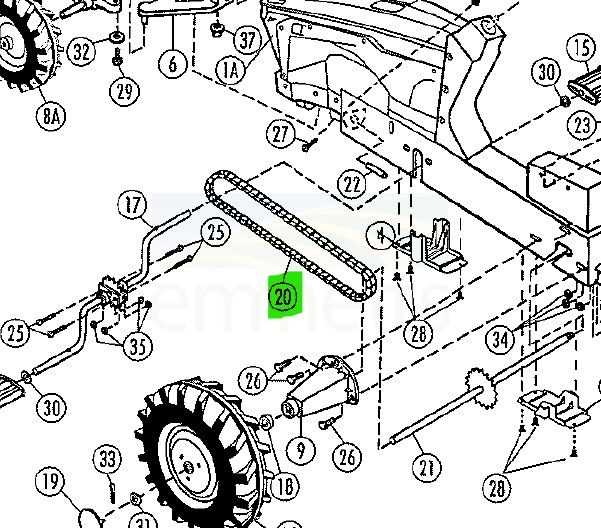

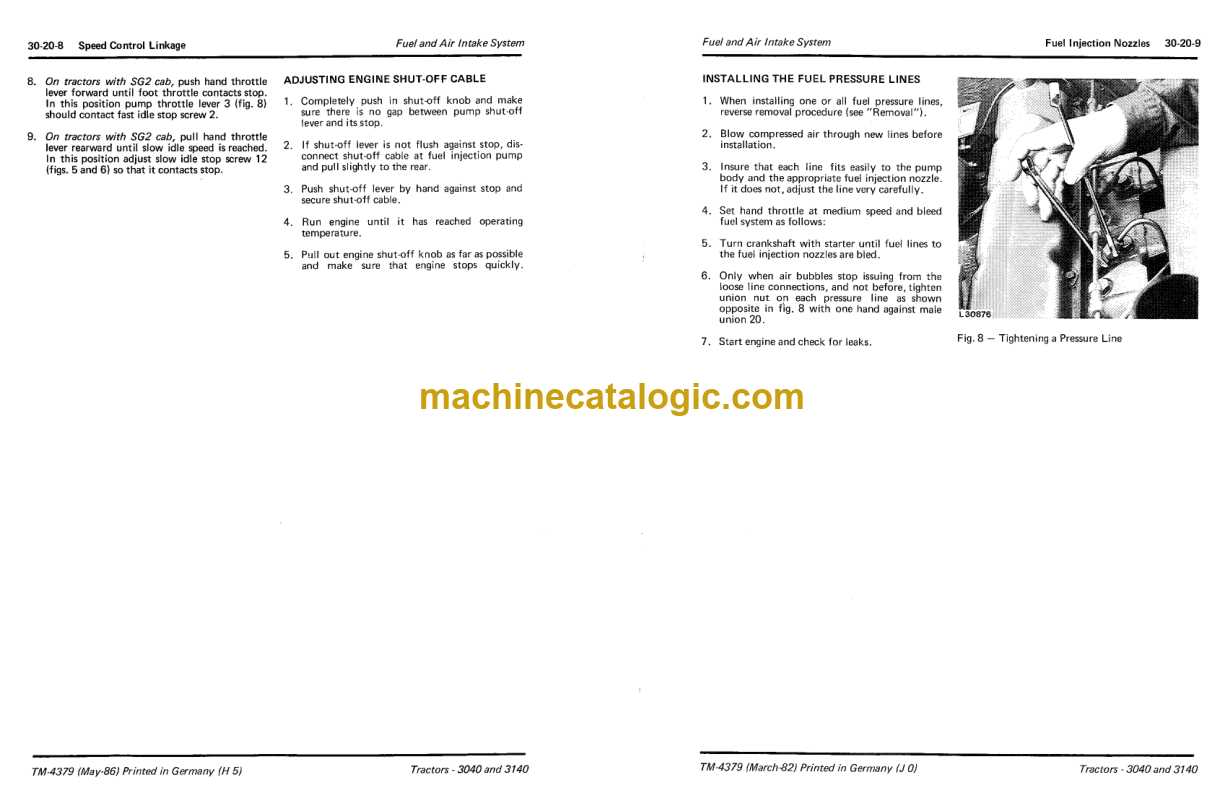

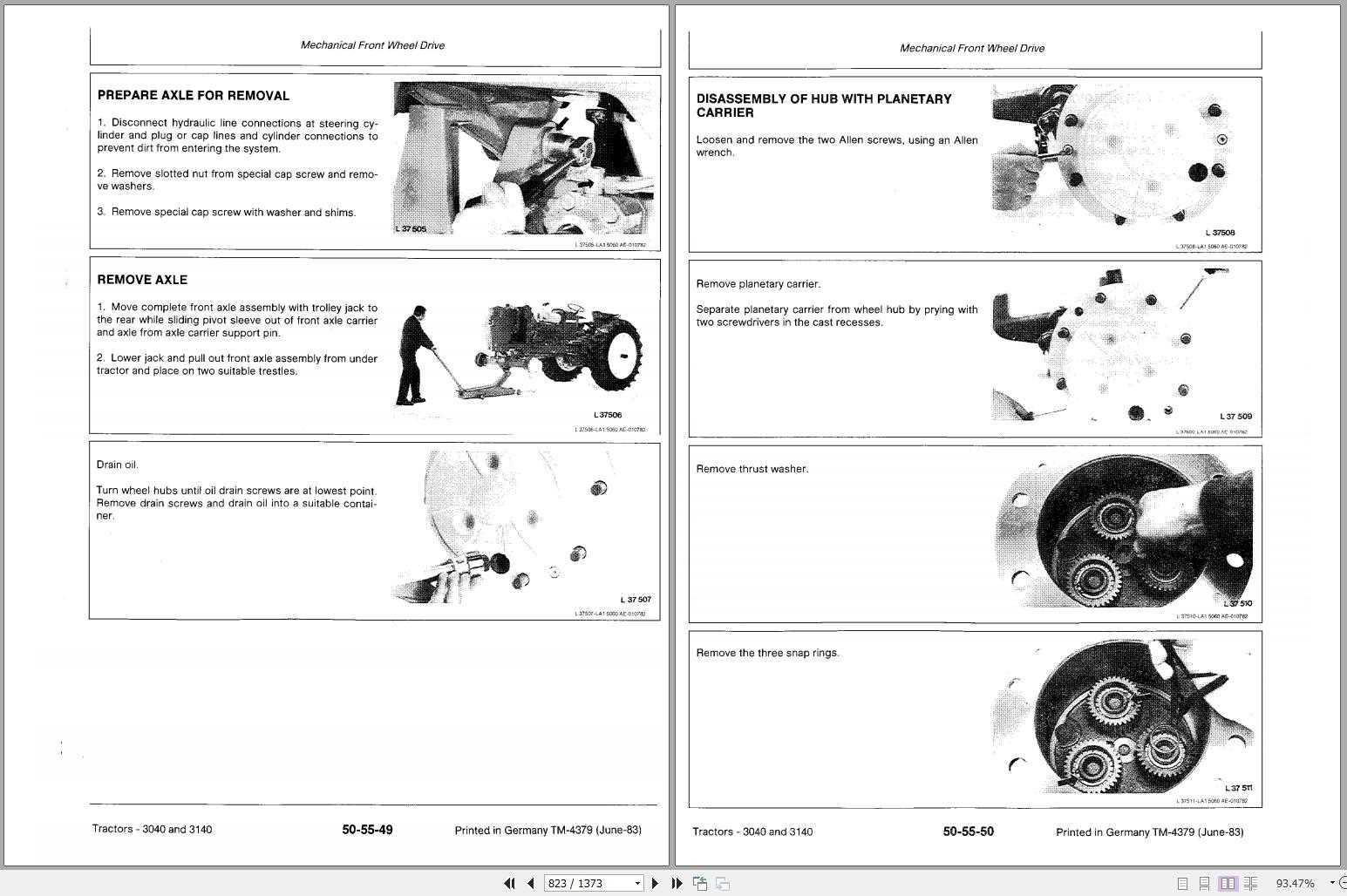

Visual aids play a significant role in grasping the intricate connections and functions within these vehicles. By examining detailed illustrations, operators can delve into the specifics of each segment, enhancing their ability to troubleshoot and replace items when necessary.

Ultimately, this exploration not only fosters a deeper appreciation for the engineering involved but also empowers users to maintain their equipment efficiently, reducing downtime and maximizing productivity.

Overview of John Deere 3140

This section provides a comprehensive insight into a specific agricultural machine renowned for its reliability and efficiency. Designed to meet diverse farming needs, it combines robust engineering with user-friendly features, making it a favorite among operators.

| Feature | Description |

|---|---|

| Engine | Powerful and efficient, ensuring optimal performance for various tasks. |

| Transmission | Smooth gear shifting for enhanced maneuverability in different terrains. |

| Hydraulics | Advanced hydraulic system for effective operation of attachments. |

| Comfort | Designed with ergonomic controls to enhance user experience during operation. |

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for maintenance and repair. Visual representations offer clarity, helping technicians identify each element efficiently.

- Facilitates quick troubleshooting

- Enhances communication among team members

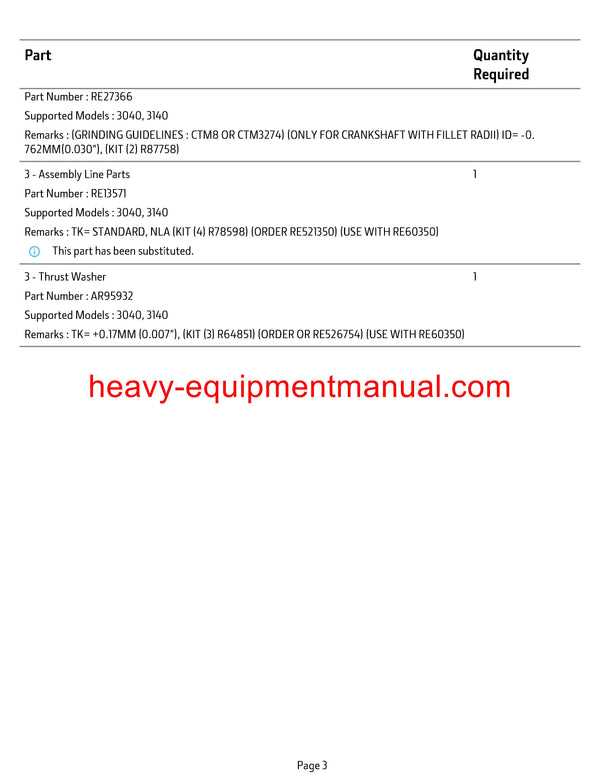

- Supports accurate ordering of components

- Reduces downtime during repairs

- Increases overall equipment longevity

Ultimately, these visual aids are essential for ensuring operational efficiency and reliability in machinery management.

Key Components of John Deere 3140

Understanding the essential elements of this agricultural machine is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and reliability in the field.

Engine: The heart of the machine, delivering power and efficiency. A well-maintained engine guarantees high productivity and longevity.

Transmission: This system allows for smooth shifting and control over speed and torque, critical for various tasks.

Hydraulics: Vital for lifting and powering attachments, the hydraulic system enhances versatility and functionality.

Chassis: The framework that supports all components, providing stability and durability during operation.

Electrical System: Ensures the functionality of lights, gauges, and starting mechanisms, playing an essential role in the overall operation.

By delving into these components, operators can ensure their machine operates at its ultimate efficiency.

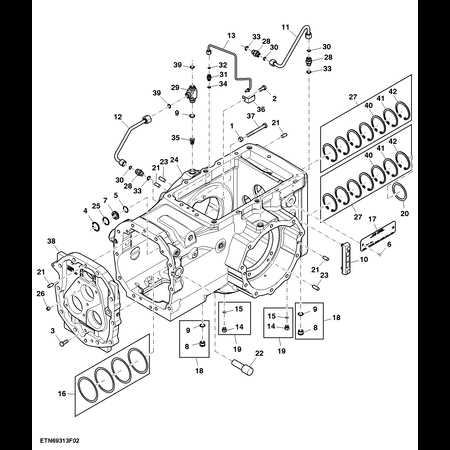

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These illustrations provide a visual guide, helping users identify various elements and their relationships within a machine. Familiarizing yourself with the layout and symbols used in these visuals can significantly enhance your repair efficiency.

Here are key steps to effectively interpret these visuals:

- Familiarize Yourself with Symbols:

- Identify common symbols representing different components.

- Learn the meaning of various lines and connections.

- Understand the Layout:

- Recognize the general organization, such as grouping similar items together.

- Notice how larger assemblies are displayed alongside individual parts.

- Reference the Key:

- Consult any accompanying legend or key that explains the symbols used.

- Use the key to clarify any uncertain components.

- Follow Connections:

- Trace lines to understand how parts are connected or interact.

- Pay attention to arrows that indicate movement or flow.

By mastering these techniques, you’ll gain confidence in navigating technical illustrations, making your repair tasks more straightforward and effective.

Common Issues with 3140 Parts

When working with agricultural machinery, several frequent challenges may arise concerning their components. Understanding these common issues is crucial for effective maintenance and longevity of the equipment. Proper identification and resolution can prevent costly downtimes and ensure optimal performance.

One prevalent problem involves wear and tear of critical elements, which can lead to decreased efficiency. Regular inspections are essential to detect early signs of fatigue. Additionally, improper alignment or installation of components often results in mechanical failures, emphasizing the importance of accurate assembly procedures.

Another issue is the availability of replacement items. Some components may become scarce over time, making repairs difficult. This highlights the necessity of planning ahead and sourcing parts from reliable suppliers to avoid operational disruptions.

Lastly, corrosion and rust can severely impact the functionality of various elements, particularly in harsh environments. Implementing protective measures and routine cleaning can mitigate these risks and prolong the life of the machinery.

Where to Find Replacement Parts

Locating suitable components for agricultural machinery can be a daunting task. Understanding where to source quality replacements is essential for maintaining optimal performance and longevity of your equipment.

Online Retailers

Many online platforms specialize in providing a wide array of components. Here are some popular options:

- Dedicated agricultural equipment websites

- Major e-commerce platforms

- Manufacturer’s official online stores

Local Dealerships and Suppliers

Visiting nearby dealerships can yield immediate results. Consider these sources:

- Authorized local dealers for brand-specific support

- Independent suppliers with a focus on agricultural machinery

- Parts salvage yards that offer used components

Exploring these avenues will enhance your chances of finding the right components quickly and efficiently.

Understanding Tractor Maintenance Needs

Regular upkeep is essential for the longevity and efficiency of agricultural machinery. Proper maintenance ensures that equipment operates at peak performance and minimizes unexpected breakdowns.

Key aspects of effective maintenance include:

- Routine inspections to identify wear and tear.

- Regular fluid changes, including oil and coolant.

- Checking and replacing filters as needed.

- Maintaining tire pressure and tread depth.

By adhering to a structured maintenance schedule, operators can:

- Enhance the lifespan of their machinery.

- Improve fuel efficiency.

- Reduce repair costs over time.

Understanding these maintenance needs is the ultimate step towards reliable and effective operation in the field.

Tools for Parts Replacement

When it comes to maintaining and restoring machinery, having the right tools is essential for efficient and effective component swaps. The following equipment can streamline the process, ensuring that each task is completed accurately and safely.

- Wrenches: Essential for loosening and tightening fasteners, these tools come in various sizes to accommodate different bolts and nuts.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is necessary for dealing with various screws found in machinery.

- Pliers: These are useful for gripping, twisting, and cutting wires or other materials that may need to be adjusted during the replacement process.

In addition to basic hand tools, there are specialized instruments that can enhance the efficiency of the operation:

- Socket Sets: Ideal for reaching fasteners in tight spaces, socket sets allow for quicker and more efficient removal and installation.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Diagnostic Tools: These devices help identify issues within the machinery, guiding you on which components may need attention.

Using the appropriate tools not only speeds up the replacement process but also reduces the risk of errors, ultimately prolonging the lifespan of the equipment. Investing in quality instruments will pay off in the long run, making maintenance tasks easier and more reliable.

Safety Tips During Repairs

When undertaking maintenance tasks on machinery, prioritizing safety is essential. Proper precautions can prevent accidents and ensure a smooth repair process.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the equipment is turned off and properly secured before starting any work.

- Keep your workspace clean and free of unnecessary tools and debris to minimize hazards.

In addition to personal safety, consider the following:

- Read the user manual thoroughly before attempting repairs.

- Have a first aid kit readily available in case of emergencies.

- Never rush through repairs; take your time to avoid mistakes.

By adhering to these guidelines, you can create a safer environment for yourself and others during maintenance activities.

Customer Reviews on 3140 Parts

This section explores feedback from users regarding components for the model in question. Insights shared by customers provide valuable information on performance, durability, and overall satisfaction.

Many reviews highlight the following key points:

- Quality of materials used

- Ease of installation

- Availability of replacement options

- Customer service experiences

Overall, users appreciate the reliability of these components, often noting:

- Longevity under various working conditions

- Cost-effectiveness compared to competitors

- Support from online communities

Such evaluations assist potential buyers in making informed decisions, enhancing their experience with machinery maintenance and repair.

Comparison with Other John Deere Models

This section explores the nuances and similarities among various models from the renowned manufacturer. Each variant brings unique features and specifications, catering to different operational needs and preferences.

Performance: While certain models excel in power and efficiency, others may focus on versatility or compact design. Understanding these distinctions is crucial for selecting the right machine for specific tasks.

Technology: Advanced technology integration varies across the lineup, with some models offering enhanced precision farming capabilities, while others may have simpler, more traditional controls.

Maintenance: Comparing maintenance requirements is essential for long-term ownership. Some machines may boast easier accessibility to components, reducing downtime and service costs.

Ultimately, the choice between these models depends on the intended use, budget, and personal preference, making it vital to delve into their unique attributes.

Upgrading Components for Better Performance

Enhancing machinery efficiency often involves upgrading specific components to achieve superior functionality and longevity. By selecting high-quality replacements and modern enhancements, operators can optimize their equipment’s capabilities and minimize downtime.

Key Areas for Upgrades

- Engine Modifications

- Transmission Improvements

- Hydraulic System Enhancements

Benefits of Upgrading

- Increased Power Output

- Improved Fuel Efficiency

- Enhanced Durability

Investing in these upgrades can ultimately lead to greater productivity and lower operational costs, making it a wise choice for any serious operator.