Understanding Kubota BX25 Parts Diagram for Efficient Maintenance

Understanding the organization of critical components within a machine is essential for efficient maintenance and repair. In this guide, we will explore how various essential elements are structured and how they interact to keep the system running smoothly.

We’ll break down the main sections, highlighting the most important elements to ensure you have a comprehensive understanding of how they fit together. Whether you are looking to perform routine upkeep or address specific issues, this information will provide valuable insights into the core workings of the equipment.

Familiarizing yourself with the layout will also help in identifying potential problem areas and anticipating any necessary replacements or adjustments over time. This approach ensures a long-lasting and reliable performance from the machine.

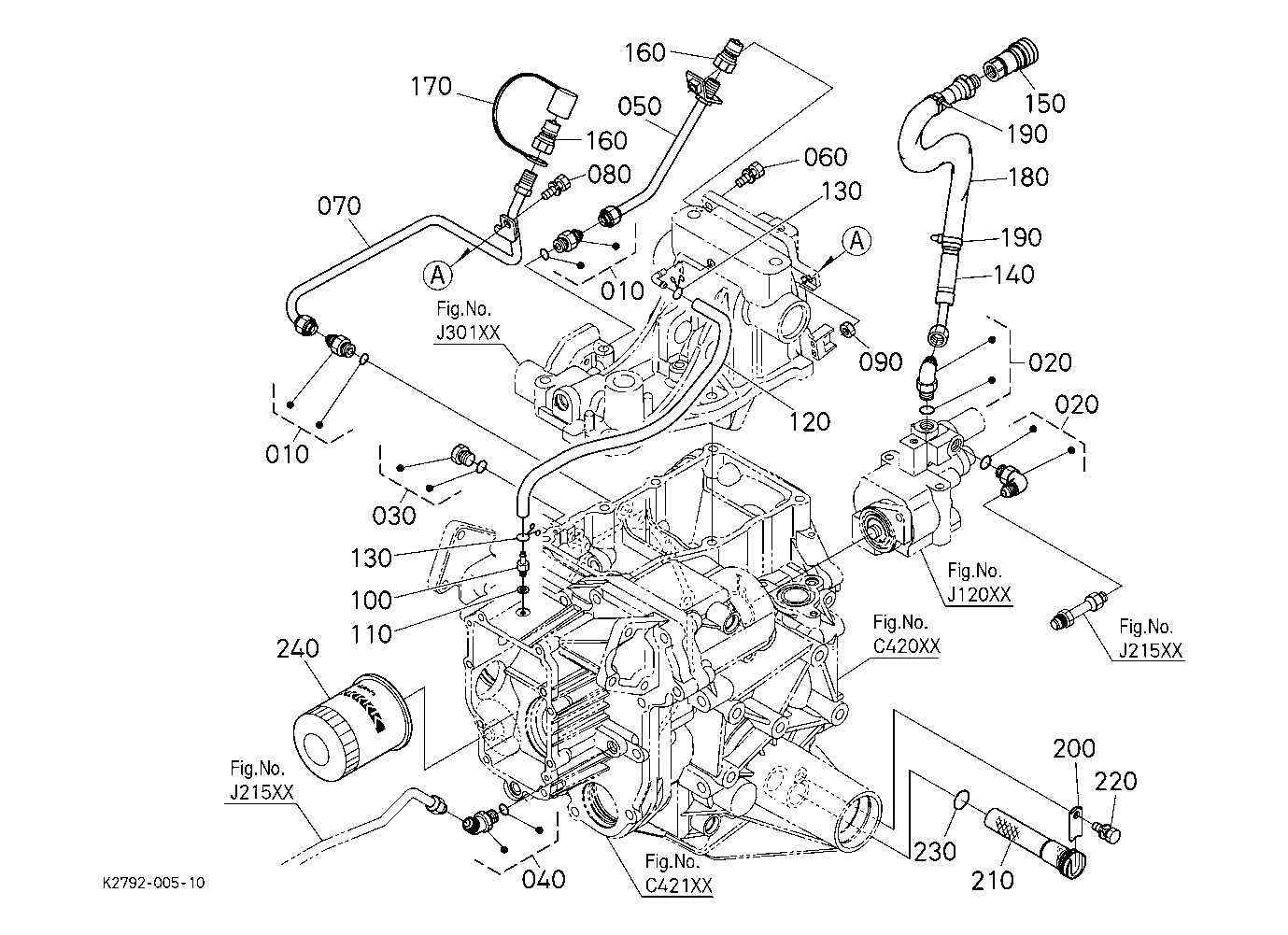

Engine Component Overview

The power unit of this compact equipment model is a complex system of interconnected parts designed for optimal performance. Each element works in harmony, ensuring efficiency and durability. In this overview, we’ll explore the key sections of the motor setup and how they contribute to the machine’s overall functionality.

Cylinder Block: This core structure houses the critical moving components, providing the foundation for the engine’s internal mechanics. It ensures stability and supports various functions essential for operation.

Cooling System: A vital aspect of preventing overheating, the cooling assembly maintains the temperature, protecting the core mechanisms from damage during heavy use. The system is designed to ensure the longevity of the equipment.

Fuel System: Responsible for delivering the necessary energy, this section ensures that the engine receives an efficient and consistent flow of fuel. Proper distribution helps maintain steady power output.

Lubrication System

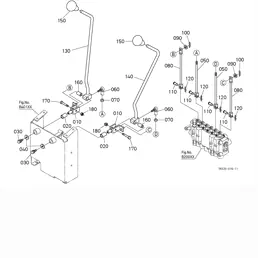

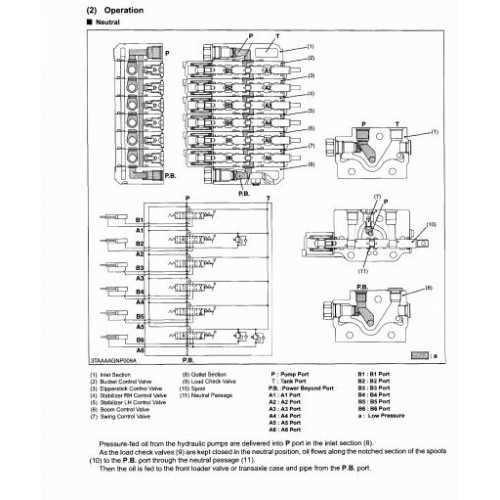

Understanding the Hydraulics System

The hydraulic system is a crucial component of many machines, responsible for transferring power efficiently through fluid. It plays a key role in the operation, allowing various mechanical tasks to be performed with ease. This section will cover the basic principles, how the system works, and why it is essential for functionality.

Main Components

- Pump: The heart of the system, pushing fluid through the entire circuit.

- Reservoir: Stores the hydraulic fluid, ensuring there is enough supply for smooth operation.

- Valves: Control the flow of fluid, managing the pressure and direction.

- Cylinders: Convert the fluid power into mechanical force, moving parts of the machine.

How It Works

In simple terms, the hydraulic system operates by pressurizing a liquid, which then creates motion or force. The fluid is pumped from the reservoir through hoses and valves to different parts, where it applies force to the cylinders, moving the mechanical co

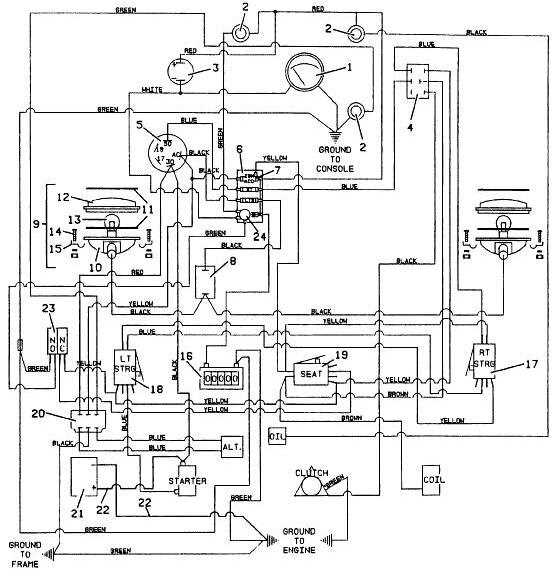

Identifying Electrical System Components

The electrical system in any machinery is essential for ensuring proper functionality and safety. Understanding the various components involved helps maintain, troubleshoot, and improve the overall performance. This section will guide you through recognizing the main elements without requiring advanced technical expertise.

Main Components Overview

Several key elements make up the core of the electrical system. Each serves a unique purpose in powering and controlling different functions. Below is a breakdown of the most significant components you may encounter.

- Battery: Provides the necessary energy to start and run various electronic elements.

- Alternator: Responsible for generating electrical power to recharge the battery and supply energy to other components while in operation.

- Wiring Harness: A collection of wires that transmit electrical signals between different parts of the system.

Additional Key Elements

Beyond the main components, there are additional elements that help regulate and ensure the efficiency of the electrical system.

- Fuse Box: Protects the system by interrupting the circuit in case of overloads or short circuits.

- Relays: Switches that control high-current circuits using low-current signals, ensuring safe and efficient ope

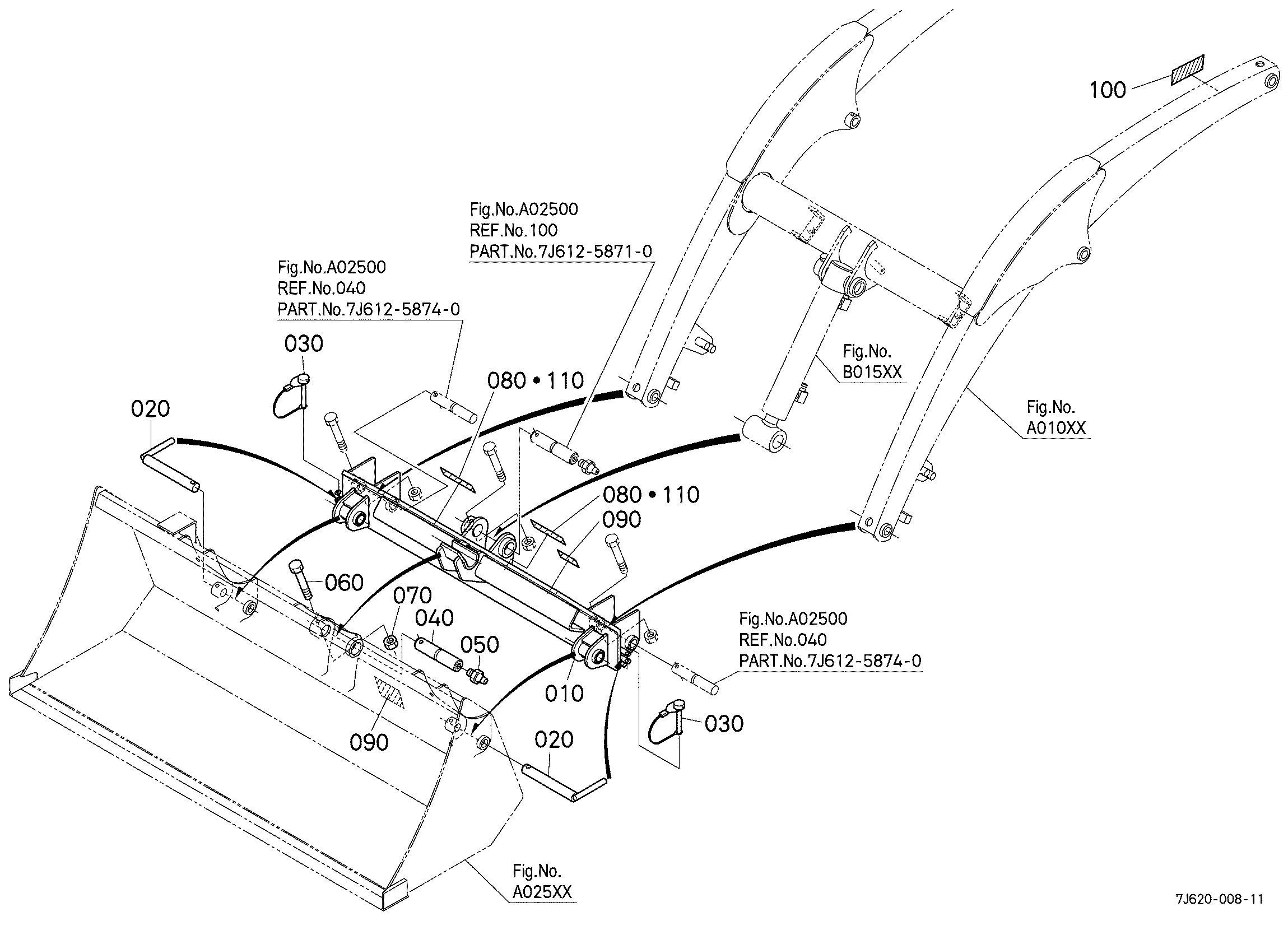

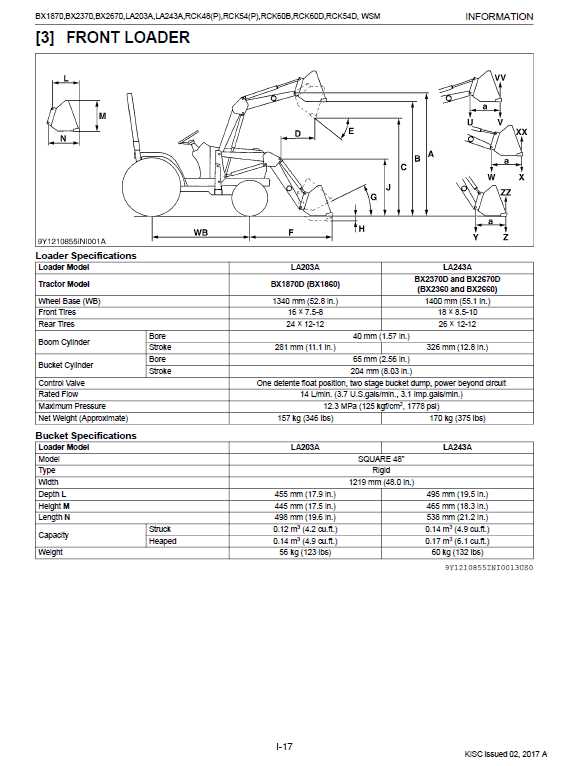

Guide to Front Loader Mechanism

The front loader mechanism is a vital component for many compact machines, offering essential functionality for lifting and moving materials. This section provides an overview of how the system operates, detailing the core processes and elements involved in its efficient use. Understanding the key components will allow users to better manage and maintain the mechanism for improved performance.

- Hydraulic System: Central to the front loader’s function, the hydraulic system powers the lifting and tilting motions. This system relies on fluid pressure to enable smooth and controlled movements.

- Control Levers: Located within easy reach, these levers allow the operator to adjust the loader’s position. Precise control is essential for handling various materials and ensuring stability during operation.

- Bucket and Arms: The loader’s arms are connected to a bucket, which can be raised, lowered, or tilted to scoop and dump materials. The bucket’s capacity and design affect its efficiency for different tasks.

By mastering the interaction between these elements, operators can use the front loader mechanism more effectively, optimizing its performance for a range of applications, from light lifting to more demanding tasks.

Transmission Parts and Their Functions

The transmission system plays a crucial role in the operation of any vehicle, ensuring that power is efficiently transferred from the engine to the wheels. Understanding the key components involved in this process allows for better maintenance and troubleshooting. Each element within this system has a specific task that contributes to the overall performance of the vehicle’s drive mechanism.

Main Components of the Transmission System

One of the most important elements is the gearbox, which adjusts the speed and torque based on the driving conditions. This mechanism allows the vehicle to smoothly transition between different speeds and ensures optimal power usage. Another vital component is the clutch, responsible for engaging and disengaging the engine from the drivetrain, allowing for seamless shifting between gears.

Supporting Components

The drive shaft transfers the rotational power from the gearbox to the wheels, ensuring movement. Additionally, the differential distributes this power between the wheels, enabling them to rotate at different speeds, particularly during turns, enhancing control and st

Exploring the Rear Hitch Assembly

The rear hitch assembly serves as a critical component for various attachments, enhancing the versatility of the machine. This assembly allows for the seamless connection of implements, enabling users to perform a wide range of tasks efficiently. Understanding its structure and function can significantly improve operational effectiveness and ease of maintenance.

Key elements of the rear hitch assembly include several integral components that work together to provide stability and functionality. Below is a detailed overview of these components:

Component Description Hitch Plate The main mounting surface that connects to the rear of the vehicle and secures various attachments. Pins Metal rods used to secure attachments to the hitch plate, ensuring they remain firmly in place during operation. Brackets Support structures that reinforce the hitch assembly, providing additional stability for attached implements. Links Connecting rods that allow for the movement and flexibility of attached equipment while maintaining a secure connection. Adjustment Mechanism A system that enables the operator to modify the height and angle of the hitch for optimal performance with different implements. Understanding the configuration and interplay of these components is essential for effective usage and maintenance. Regular inspection and timely repairs will ensure the rear hitch assembly remains in optimal condition, facilitating a broad spectrum of agricultural and landscaping tasks.

Detailed View of Steering Components

The steering mechanism plays a crucial role in maneuvering equipment, providing the operator with the ability to navigate through various terrains. Understanding the individual elements that comprise this system is essential for effective maintenance and repair.

Key Elements of the Steering System

- Steering Wheel: The primary interface for the operator, allowing for directional control.

- Steering Column: Connects the wheel to the steering mechanism, providing support and housing for controls.

- Linkage Assembly: Transmits the motion from the steering wheel to the wheels, enabling precise movements.

- Rack and Pinion: A type of gear mechanism that converts rotational motion into linear motion, enhancing responsiveness.

- Control Arms: Attach the wheels to the chassis, allowing for stability during steering.

Maintenance Tips

- Regularly check for any signs of wear and tear in the components.

- Ensure that the steering fluid levels are adequate and that there are no leaks.

- Inspect the linkage for any looseness or play, which may affect steering precision.

- Lubricate moving parts as recommended by the manufacturer to maintain optimal performance.

Brake System Structure and Parts

The braking mechanism is a crucial component in any machinery, ensuring safe operation and control. Understanding its structure and the elements involved can enhance maintenance and troubleshooting efforts.

The braking system primarily consists of the following components:

- Brake Pedal: The interface for the operator, initiating the braking action.

- Master Cylinder: Converts the force from the brake pedal into hydraulic pressure.

- Brake Lines: Tubes that transport the hydraulic fluid from the master cylinder to the braking units.

- Brake Calipers: Mechanisms that press the brake pads against the rotor to create friction.

- Brake Pads: Friction materials that engage with the rotor to slow down or stop the vehicle.

- Rotors: Disc components that the brake pads clamp down on to generate stopping power.

Proper functioning of each element is essential for the overall effectiveness of the braking system. Regular inspections can help identify wear and potential failures, ensuring that the machinery operates safely and efficiently.

Fuel System Breakdown for BX25

The fuel system is a vital component of any engine, ensuring that the necessary energy is supplied for optimal performance. Understanding its structure and functions can significantly enhance maintenance and troubleshooting efforts.

Key Elements: The fuel system typically consists of several integral parts, including the tank, pump, filter, and injectors. Each of these elements plays a crucial role in delivering fuel efficiently and effectively to the engine.

Fuel Tank: The reservoir stores the liquid energy, ensuring an adequate supply during operation. Proper inspection and cleaning of the tank are essential to prevent contaminants from entering the system.

Fuel Pump: This component is responsible for transporting fuel from the tank to the engine. It must maintain the correct pressure to facilitate smooth operation.

Fuel Filter: A vital component, it removes impurities and particulates from the fuel, protecting the engine from damage. Regular replacement of the filter is recommended to ensure optimal performance.

Injectors: These precision devices atomize the fuel, allowing for better combustion and efficiency. They should be inspected periodically to prevent clogging and ensure they function correctly.

Understanding the individual components of the fuel system aids in identifying issues and performing effective maintenance, ultimately leading to a more reliable and efficient operation.

Maintenance Tips for Kubota BX25 Parts

Regular upkeep is essential for ensuring the longevity and performance of your equipment. Implementing proper maintenance practices can help prevent unexpected breakdowns and enhance the efficiency of various components. By staying proactive, you can maximize the lifespan of your machinery and maintain optimal functionality.

Routine Inspections

Conduct frequent inspections of all vital components. Check for signs of wear, leaks, and any irregularities. Early detection of issues allows for timely repairs, which can save time and money in the long run. Additionally, ensure that all moving parts are adequately lubricated to reduce friction and prevent premature deterioration.

Cleaning and Debris Removal

Keep your equipment clean by regularly removing dirt, dust, and debris. This helps prevent clogging and maintains airflow, which is crucial for optimal performance. Use appropriate cleaning agents that won’t damage surfaces, and pay special attention to areas that are prone to accumulation.

By following these maintenance tips, you can ensure that your machinery operates smoothly and remains in excellent condition for years to come.

Cooling System Components Explained

The cooling mechanism of a machinery system plays a crucial role in maintaining optimal operating temperatures, thereby ensuring efficiency and longevity. Understanding the key elements of this system is essential for effective maintenance and troubleshooting. Each component contributes uniquely to the overall functionality, working in harmony to manage heat produced during operation.

Key Components of the Cooling System

The primary elements that make up the cooling mechanism include the radiator, coolant, water pump, and thermostat. Each part serves a distinct purpose, and together they create a seamless flow that dissipates heat effectively. Regular inspection and maintenance of these components can prevent overheating and improve performance.

Component Description Radiator This part dissipates heat from the coolant as it passes through, allowing for temperature regulation. Coolant A fluid that absorbs heat from the engine and transfers it to the radiator for cooling. Water Pump Circulates coolant throughout the system, ensuring consistent flow and heat exchange. Thermostat Regulates the temperature by controlling the flow of coolant to maintain optimal operating conditions. Importance of Regular Maintenance

Routine checks and maintenance of the cooling system are vital for preventing overheating and ensuring the longevity of the machinery. Monitoring the condition of each component and replacing any worn parts will enhance performance and reliability, making it essential for operators to stay vigilant.

Tire and Wheel Specifications

The selection of appropriate tires and wheels is crucial for optimal performance and stability in various terrains. These components play a vital role in supporting the vehicle’s weight, enhancing traction, and ensuring maneuverability. Understanding the specifications allows for informed decisions when it comes to replacements or upgrades.

Tire Dimensions: It is essential to know the correct dimensions of the tires to ensure a proper fit. This includes the width, aspect ratio, and diameter, which collectively affect the overall handling and ride comfort. A well-matched tire size improves efficiency and reduces wear.

Load Capacity: Each tire has a designated load capacity that must be adhered to in order to prevent damage and ensure safety. This specification indicates the maximum weight each tire can support, which is critical when transporting heavy loads or operating in challenging conditions.

Tread Pattern: The tread pattern significantly influences traction and performance on different surfaces. Options range from aggressive treads for off-road applications to smoother patterns for improved road performance. Choosing the right tread design enhances control and stability during operation.

Wheel Material: Wheels can be made from various materials, each offering distinct advantages. Steel wheels are known for their durability and resistance to impact, while aluminum wheels provide a lightweight option that can improve handling. Selecting the appropriate material contributes to the overall performance and longevity of the vehicle.

Offset and Backspacing: Understanding wheel offset and backspacing is essential for proper fitment. Offset refers to the distance from the wheel’s centerline to the mounting surface, while backspacing is the distance from the mounting surface to the back edge of the wheel. These measurements affect handling, clearance, and suspension geometry.