Comprehensive Guide to Briggs and Stratton P2200 Parts Diagram

In the realm of portable energy solutions, having a comprehensive grasp of the individual elements that contribute to functionality is crucial. A thorough exploration of these components not only enhances the efficiency of the device but also aids in effective troubleshooting and maintenance. Recognizing the role each part plays allows users to maximize the potential of their equipment.

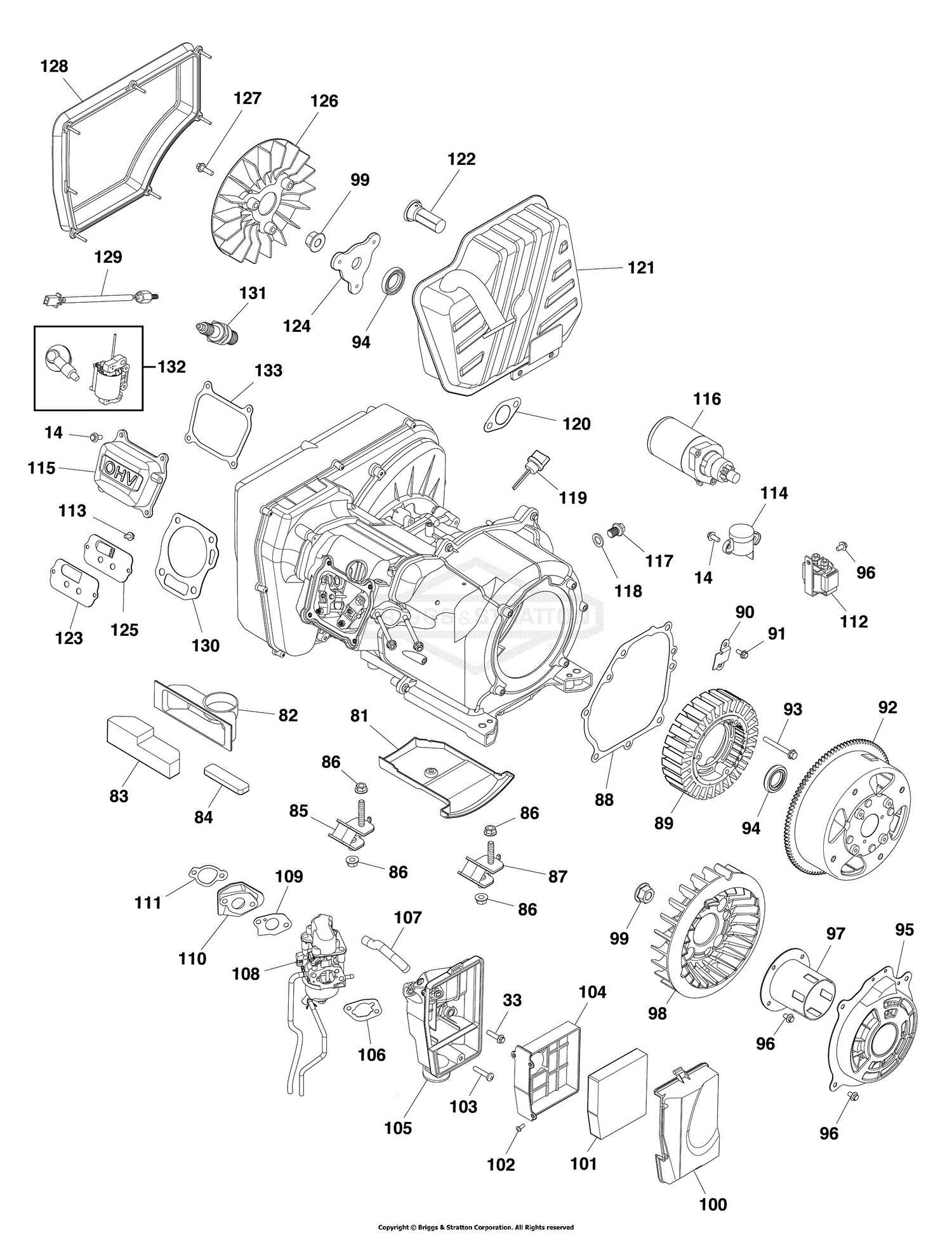

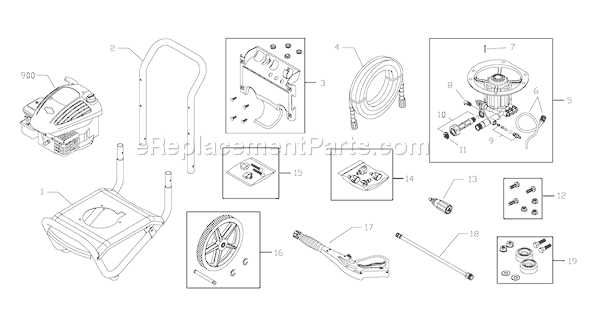

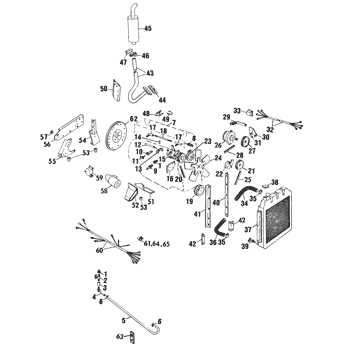

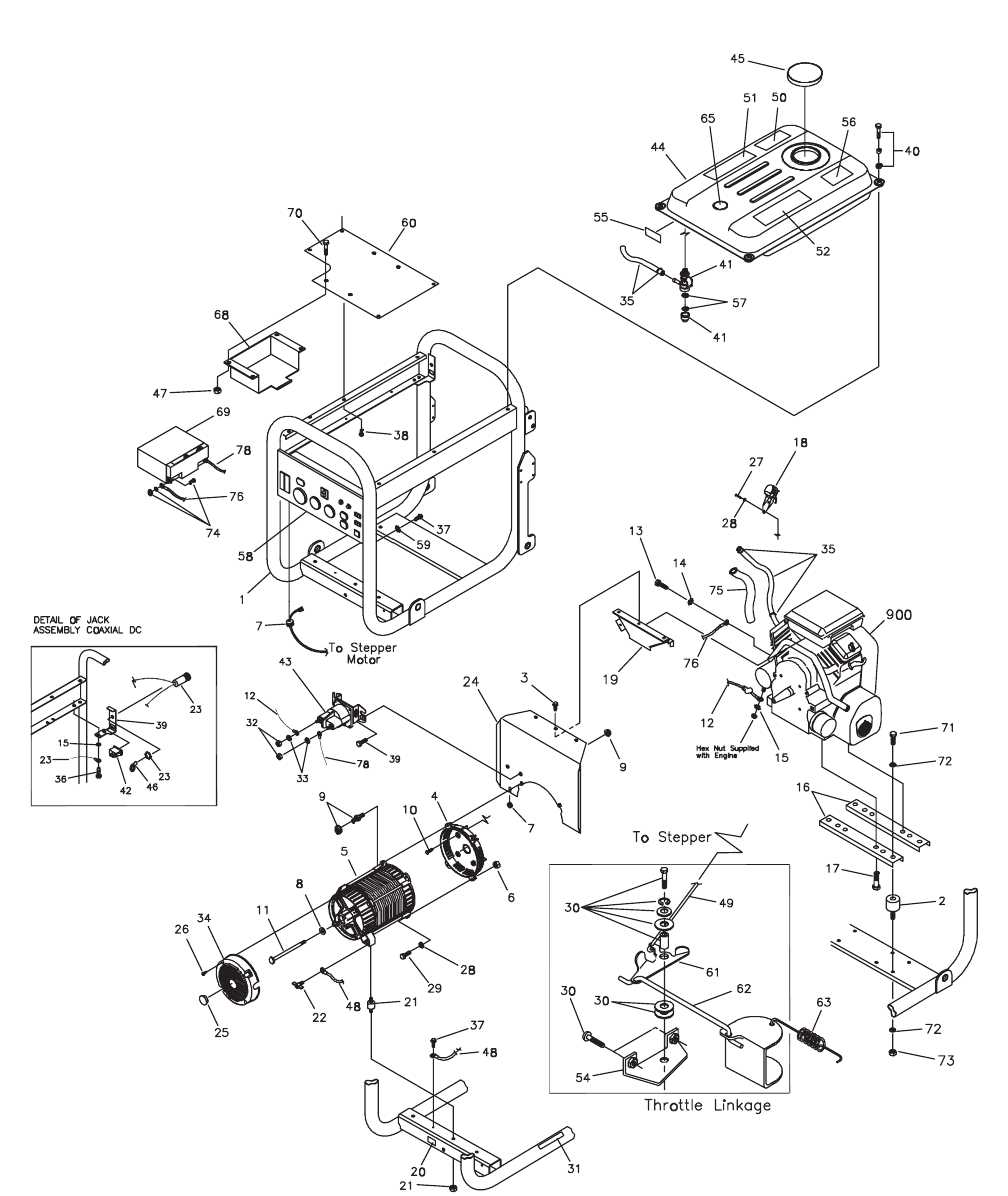

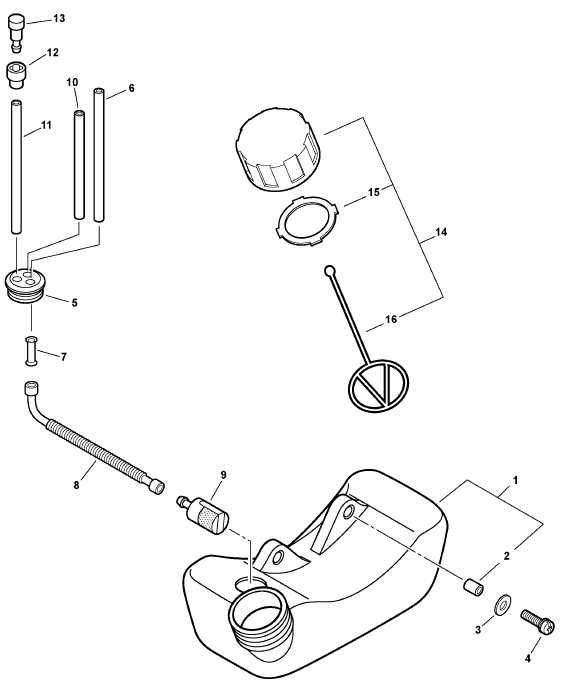

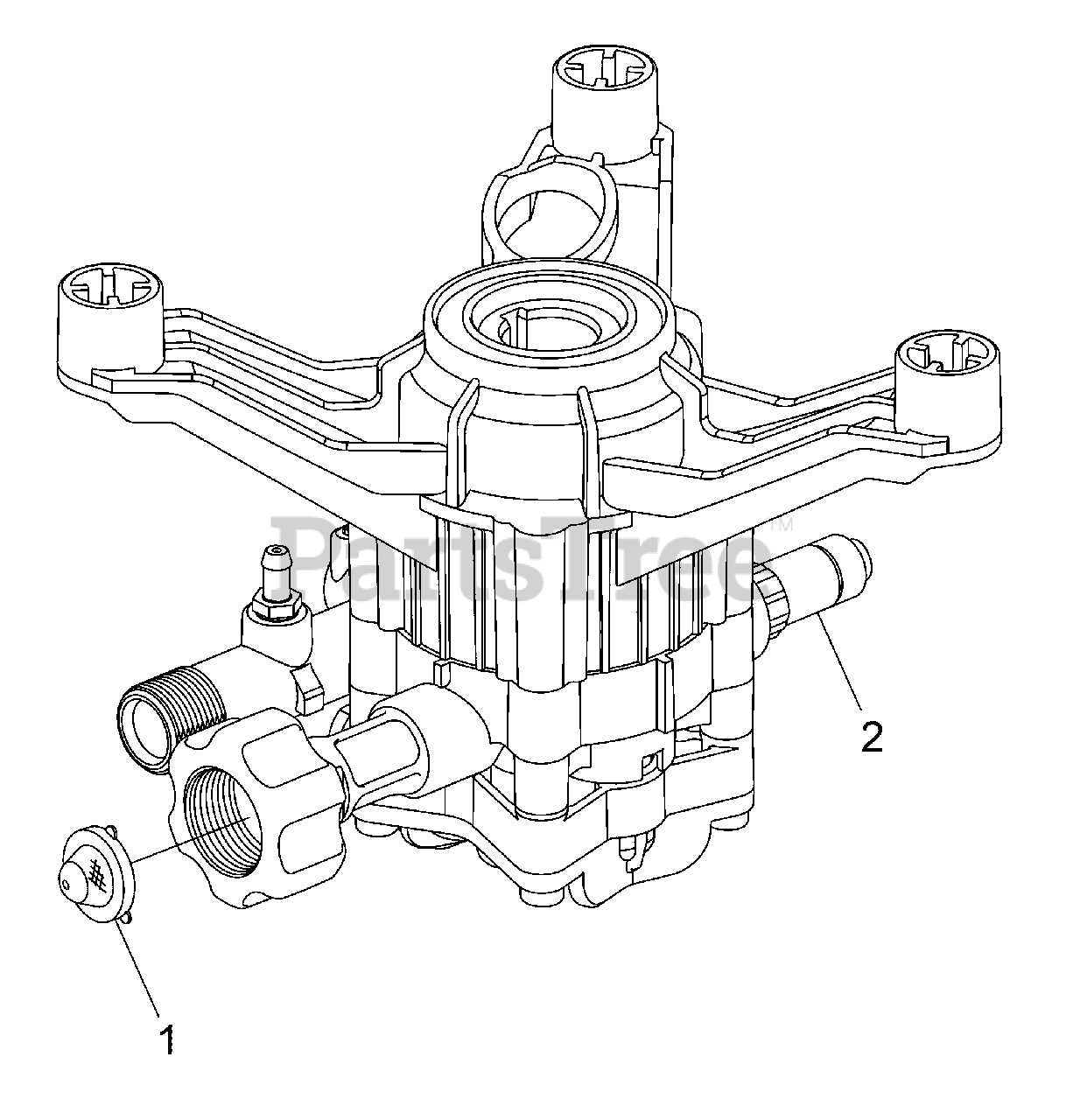

Detailed schematics serve as invaluable tools for both novice and experienced users alike. They provide a clear visual representation of how various elements interact, facilitating easier repairs and replacements. By delving into these illustrations, individuals can gain insights into the assembly and operation of their power sources.

Moreover, familiarity with the layout of components can lead to informed decisions when it comes to purchasing replacements. Understanding which pieces are essential for optimal performance empowers users to select the right options, ensuring longevity and reliability in their portable power systems. This knowledge ultimately translates to a more satisfying and efficient user experience.

Understanding the Briggs and Stratton P2200

This section explores the features and components of a popular generator model designed for versatility and efficiency. Knowing the intricacies of this device can enhance its operation and maintenance, ensuring it serves well in various applications.

One of the key aspects to consider is its power output. The generator is built to provide a reliable energy source for both recreational and professional use. Users can expect:

- Quiet operation suitable for residential areas.

- Portability for easy transportation to different locations.

- Fuel efficiency for extended runtime without frequent refueling.

Moreover, understanding the fundamental components can aid in troubleshooting and repairs. Key elements include:

- Engine: The heart of the unit, responsible for power generation.

- Fuel system: Ensures proper delivery of gasoline for optimal performance.

- Electrical system: Facilitates the output of electricity to connected devices.

In addition to these features, regular maintenance practices can significantly prolong the life of the equipment. This includes:

- Regular oil changes to keep the engine running smoothly.

- Air filter checks to maintain airflow and efficiency.

- Inspection of spark plugs to ensure proper ignition.

Ultimately, familiarizing oneself with this generator model not only enhances operational efficiency but also empowers users to address minor issues independently, promoting a better overall experience.

Key Features of P2200 Generator

This compact power source is designed for efficiency and convenience, making it an ideal choice for various applications. Its combination of performance and portability allows users to tackle outdoor activities or emergency situations with ease.

Portability and Design

The lightweight construction coupled with an ergonomic handle facilitates effortless transportation. Whether you need power for a camping trip or to back up essential appliances during a power outage, its design ensures you can take it wherever you go.

Power Output and Efficiency

Featuring a robust output, this generator provides sufficient energy for multiple devices. Its innovative engineering maximizes fuel efficiency, allowing for extended run times without frequent refueling. This balance of power and economy makes it a reliable option for both recreational and emergency use.

In summary, the generator stands out with its unique blend of portability, efficiency, and reliable performance, catering to a variety of user needs.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as valuable tools, allowing users to identify individual elements and their relationships within a system. This clarity aids in troubleshooting and ensures that any necessary replacements are accurately sourced.

Enhanced Troubleshooting

Visual aids significantly streamline the diagnostic process. By providing a clear overview of each component, users can quickly pinpoint issues, reducing the time spent on repairs. This organized approach minimizes frustration and enhances the efficiency of maintenance tasks.

Accurate Replacement and Maintenance

Having a detailed reference allows for precise identification of required items during replacements. This not only ensures compatibility but also contributes to the longevity and optimal performance of equipment. Knowing the exact specifications helps prevent costly mistakes and unnecessary downtime.

Common Components in P2200 Models

The variety of features found in these power generators contributes to their reliability and performance. Understanding the key elements that make up these machines can enhance maintenance practices and extend their lifespan. Below are some of the essential components typically seen in these models.

Key Parts

- Engine: The heart of the generator, responsible for converting fuel into mechanical energy.

- Fuel Tank: Stores the necessary fuel for operation, ensuring adequate supply during use.

- Air Filter: Prevents debris from entering the engine, promoting efficient combustion.

- Oil Filter: Maintains engine health by filtering contaminants from the lubricating oil.

- Starter System: Allows for easy ignition of the engine, often using a recoil or electric starter.

Additional Components

- Voltage Regulator: Ensures stable output voltage, protecting connected devices.

- Control Panel: Provides user interface for monitoring performance and managing settings.

- Exhaust System: Directs harmful gases away from the engine and reduces noise levels.

- Chassis: The framework that houses all components, providing stability and portability.

How to Read Parts Diagrams

Understanding visual representations of components is essential for anyone involved in maintenance or repair tasks. These illustrations provide a clear overview of each element and its relationship to the overall assembly, allowing for effective troubleshooting and part replacement.

Familiarize Yourself with the Symbols

Every illustration uses specific symbols to denote different types of components. Familiarizing yourself with these icons is crucial, as it helps in identifying what each part does. For example, a circle may represent a fastener, while a rectangle might indicate a housing unit. Reviewing the accompanying legend will enhance your comprehension.

Study the Layout

Pay attention to how the components are arranged. Typically, parts are displayed in a way that reflects their assembly order. By understanding the layout, you can gain insights into how each element interacts with others. Additionally, noting any numbers associated with the components can guide you in finding replacements efficiently.

In conclusion, mastering the skill of interpreting these visual aids can significantly improve your repair proficiency, making your tasks more manageable and effective.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for maintaining optimal performance and longevity. Reliable sources ensure that you receive high-quality items that fit perfectly and meet manufacturer specifications. Here are some recommended avenues to explore when searching for original replacements.

| Source | Description |

|---|---|

| Manufacturer’s Website | The most dependable place to find authentic items is directly from the manufacturer’s online store. This guarantees the authenticity of the products. |

| Authorized Dealers | Visiting certified retailers can provide access to genuine components, often with the added benefit of expert advice and service. |

| Local Repair Shops | Local mechanics and repair shops may stock or order original items, offering personalized service and installation assistance. |

| Online Marketplaces | Reputable e-commerce platforms can be a convenient option, but it’s crucial to verify the seller’s credibility to ensure quality. |

| Community Forums | Engaging with online communities can provide recommendations and insights on where to find reliable components. |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any equipment. Regular attention not only enhances performance but also prevents unexpected breakdowns. Following a systematic maintenance routine can significantly improve reliability and efficiency.

Here are some practical guidelines to help ensure your machine remains in optimal condition:

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dirt and debris from the exterior and engine components to prevent overheating and corrosion. |

| Oil Changes | Replace the oil as recommended to maintain engine lubrication and reduce wear on moving parts. |

| Air Filter Maintenance | Inspect and clean or replace the air filter regularly to ensure proper airflow and engine efficiency. |

| Spark Plug Inspection | Check the spark plug for wear and replace it if necessary to ensure smooth starting and combustion. |

| Fuel Quality | Use fresh fuel and consider adding stabilizers to prevent degradation, which can lead to engine problems. |

| Storage Care | During off-seasons, store the equipment in a dry place and follow proper storage procedures to prevent damage. |

Implementing these practices can significantly enhance the durability and functionality of your equipment, ensuring it serves you well for many years to come.

Troubleshooting Common Issues

When dealing with small engines, understanding how to identify and resolve frequent problems can save time and enhance performance. Various symptoms may arise during operation, and recognizing these issues early can prevent further complications. This section will guide you through common challenges and their potential solutions.

Engine Won’t Start: One of the most frequent problems is the engine failing to ignite. This may result from a depleted fuel tank, a clogged air filter, or a faulty spark plug. Check the fuel level and ensure the fuel is fresh. If the air filter is dirty, replace it to promote adequate airflow. Inspect the spark plug for wear or damage; cleaning or replacing it might be necessary.

Excessive Vibrations: If the machine shakes more than usual, it could indicate an imbalance. Loose or damaged components, such as blades or mounting screws, should be examined. Tightening any loose parts or replacing worn ones can help restore stability.

Overheating: Overheating can lead to severe damage. Ensure that the cooling fins are free of debris and that oil levels are appropriate. Running the engine with insufficient oil can cause overheating, so regular checks are crucial for proper maintenance.

Loss of Power: If you notice a decrease in performance, it could be due to fuel issues, air intake problems, or even internal engine wear. Ensure the fuel system is clear and that there are no blockages in the air filter. Regular maintenance and timely oil changes can also mitigate power loss.

By addressing these common issues promptly, users can ensure their engines run smoothly and efficiently, prolonging their lifespan and enhancing overall reliability.

Upgrading Your P2200 Parts

Enhancing the components of your generator can significantly improve its efficiency and longevity. By selecting higher-quality replacements or additional accessories, you can achieve better performance and reliability in various applications. Understanding the available options is essential for making informed decisions regarding upgrades.

When considering enhancements, focus on key areas such as fuel efficiency, noise reduction, and overall durability. Options like advanced air filters or improved spark plugs can lead to more effective combustion, which translates to enhanced power output. Additionally, investing in sound-dampening technology may create a more pleasant user experience, especially in residential settings.

Moreover, regular maintenance plays a crucial role in keeping your generator running smoothly. Upgrading routine maintenance items, such as oil filters and hoses, can prevent unexpected breakdowns. It’s advisable to consult user manuals or manufacturer guidelines to ensure compatibility with upgraded components.

Lastly, seek advice from fellow users or online forums for recommendations on trusted brands and products. With the right upgrades, you can transform your generator into a more powerful and efficient machine, ready to tackle any task with ease.

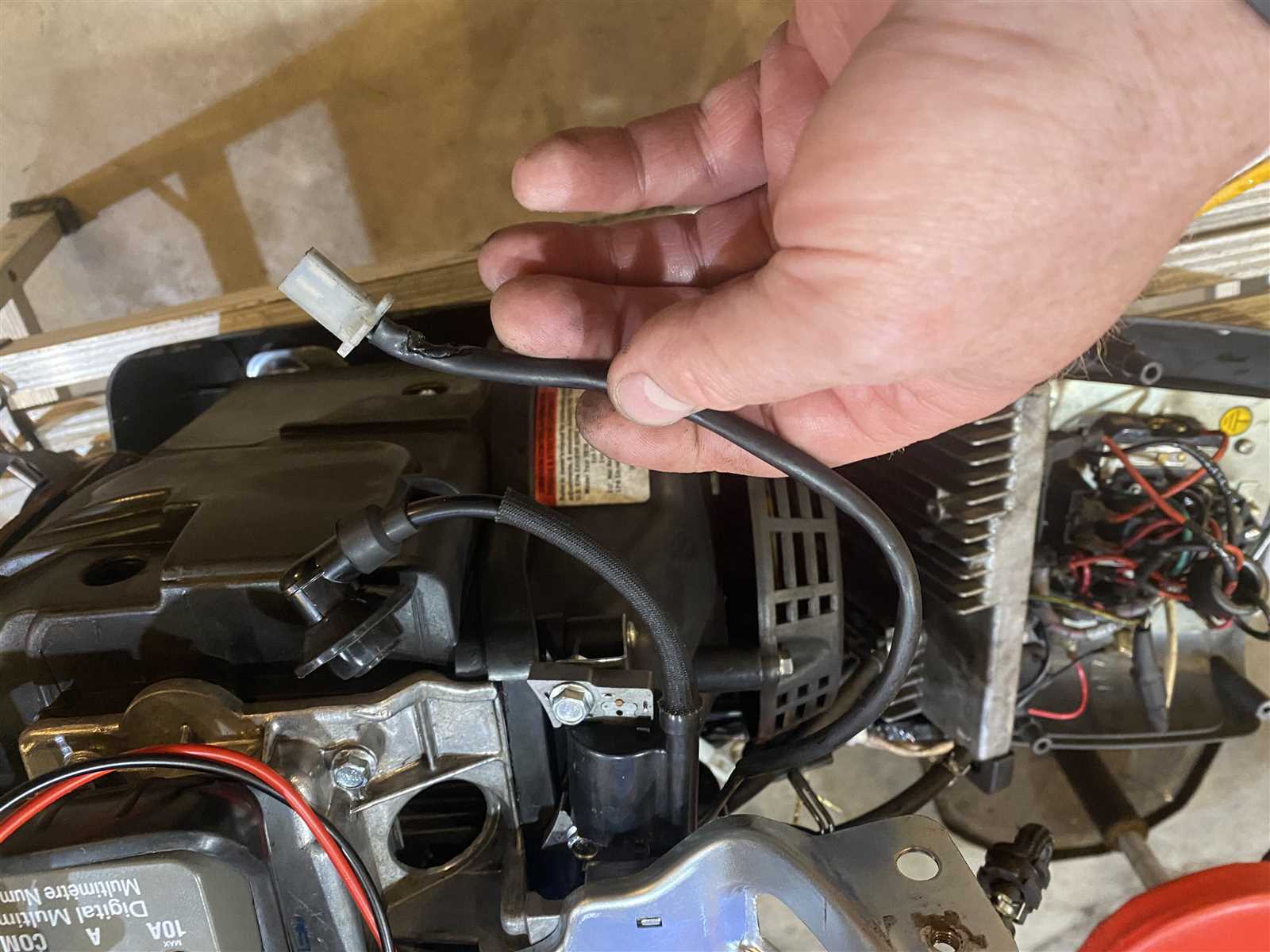

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, creating a secure environment for both the individual and the equipment involved.

Here are essential safety measures to follow during repairs:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Disconnect the power source before starting any repair work to eliminate the risk of accidental activation.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust particles.

- Keep the workspace organized and free of clutter to minimize hazards and trip risks.

Additionally, consider these guidelines:

- Read the manufacturer’s manual to understand specific safety instructions related to the equipment.

- Use tools that are in good condition and appropriate for the task to avoid unnecessary strain or accidents.

- Involve a second person if the task requires heavy lifting or handling of large components.

- After completing repairs, double-check that all tools and parts are properly secured before re-energizing the equipment.

Following these precautions will significantly reduce the likelihood of incidents and contribute to a safer repair process.

Comparing P2200 to Other Models

This section explores the differences and similarities between the specified generator and its counterparts in the market. Understanding these distinctions can help users make informed decisions based on their specific needs, whether for power output, fuel efficiency, or overall design features.

Power Output and Efficiency

When evaluating various generators, one key aspect is the power output they provide. Some models may offer higher wattage, catering to more demanding applications, while others focus on fuel efficiency, allowing for longer operation times on a single tank. Users should consider what their primary power needs are and how often they will use the generator to determine the best fit.

Design and Portability

Another critical factor is the design and portability of the units. Some generators are lightweight and compact, making them ideal for camping or outdoor events. Others may prioritize durability and robustness, suitable for industrial applications. Assessing the environments in which the generator will be used can guide users toward the model that best suits their lifestyle.

Resources for Further Research

Expanding your knowledge on small engine maintenance can be invaluable for ensuring optimal performance. Numerous sources are available that provide detailed information, including manuals, forums, and instructional videos. Engaging with these resources will enhance your understanding and facilitate effective repairs and upkeep.

Online Manuals and Guides

- Manufacturer’s official website

- Third-party manual websites

- Online retailers with product listings

Community Forums and Discussion Boards

- Dedicated small engine repair forums

- Social media groups focused on outdoor equipment

- YouTube channels specializing in maintenance tutorials

Utilizing these resources can significantly aid in troubleshooting and enhance your hands-on skills in engine care.