Keg Tap Parts Diagram Explained for Better Understanding

The functionality of a beverage dispensing system hinges on a variety of crucial elements that work in unison to ensure a seamless experience for users. Each component plays a significant role in delivering drinks efficiently while maintaining optimal flavor and freshness. A comprehensive grasp of these elements is essential for both enthusiasts and professionals in the industry.

In this section, we will explore the various sections of these systems, highlighting their specific functions and interconnections. By breaking down the anatomy of these mechanisms, readers will gain insight into how each segment contributes to the overall process. Understanding these intricacies can enhance both maintenance and performance, leading to improved outcomes.

Whether you are looking to troubleshoot a specific issue or simply wish to deepen your knowledge, familiarizing yourself with the essential features of these systems is invaluable. From valves to regulators, each piece is designed to optimize the flow and quality of the beverage, ensuring that every pour is as delightful as intended.

Keg Tap Parts Overview

This section provides an in-depth exploration of the essential components involved in dispensing beverages from a container. Understanding these elements is crucial for both enthusiasts and professionals, as they play a significant role in the overall functionality and efficiency of the system.

Essential Components

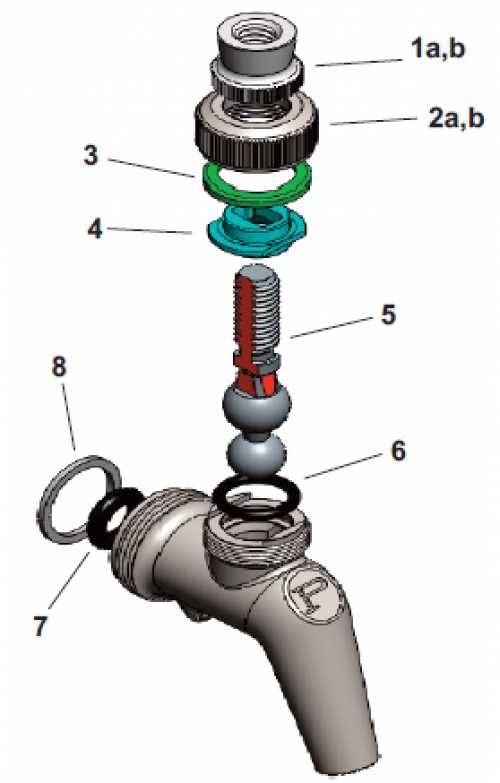

- Fitting: Connects the device to the beverage container.

- Lever: Operates the release mechanism for the liquid.

- Seal: Ensures a tight closure to maintain pressure.

- Body: Houses the internal mechanisms that facilitate dispensing.

- Spout: Directs the flow of the beverage into the glass.

Functionality and Maintenance

Each element has a distinct function that contributes to the overall performance of the system. Regular maintenance of these components is essential to prevent leaks and ensure a seamless pouring experience. Proper cleaning and occasional replacement of worn parts can enhance durability and effectiveness.

- Inspect seals regularly to avoid leaks.

- Clean the spout to prevent contamination.

- Check the fitting for secure connections.

Understanding Keg Tap Functionality

In the world of beverage dispensing, the mechanism that facilitates the release of liquid from a sealed container plays a crucial role. This system not only ensures the preservation of the contents but also allows for efficient service. Understanding how this device operates can enhance both the experience of the consumer and the efficiency of the provider.

Key components work in harmony to control the flow of liquid. When activated, these elements create a pathway for the beverage to flow while maintaining the necessary pressure within the container. This pressure is vital for ensuring that the drink remains carbonated and fresh until served.

The interaction between different mechanical parts is essential for optimal performance. A well-designed system minimizes waste and maximizes efficiency, allowing for precise pouring. Understanding these mechanics not only aids in proper usage but also in troubleshooting potential issues that may arise during operation.

Moreover, regular maintenance of these components is crucial. Ensuring that all parts are clean and functioning correctly can prevent unwanted flavors and maintain the overall quality of the beverage. This attention to detail is what distinguishes a great serving experience from a mediocre one.

Essential Components of Keg Taps

Understanding the fundamental elements involved in the dispensing system is crucial for achieving optimal performance and efficiency. Each component plays a specific role, ensuring a smooth flow and maintaining the quality of the beverage being served.

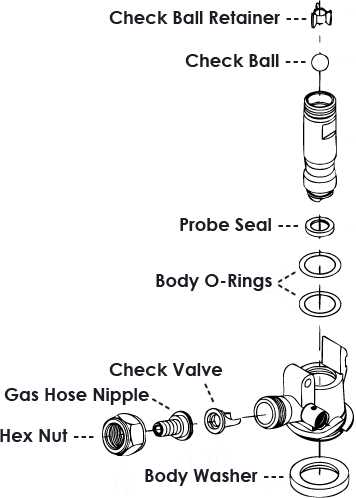

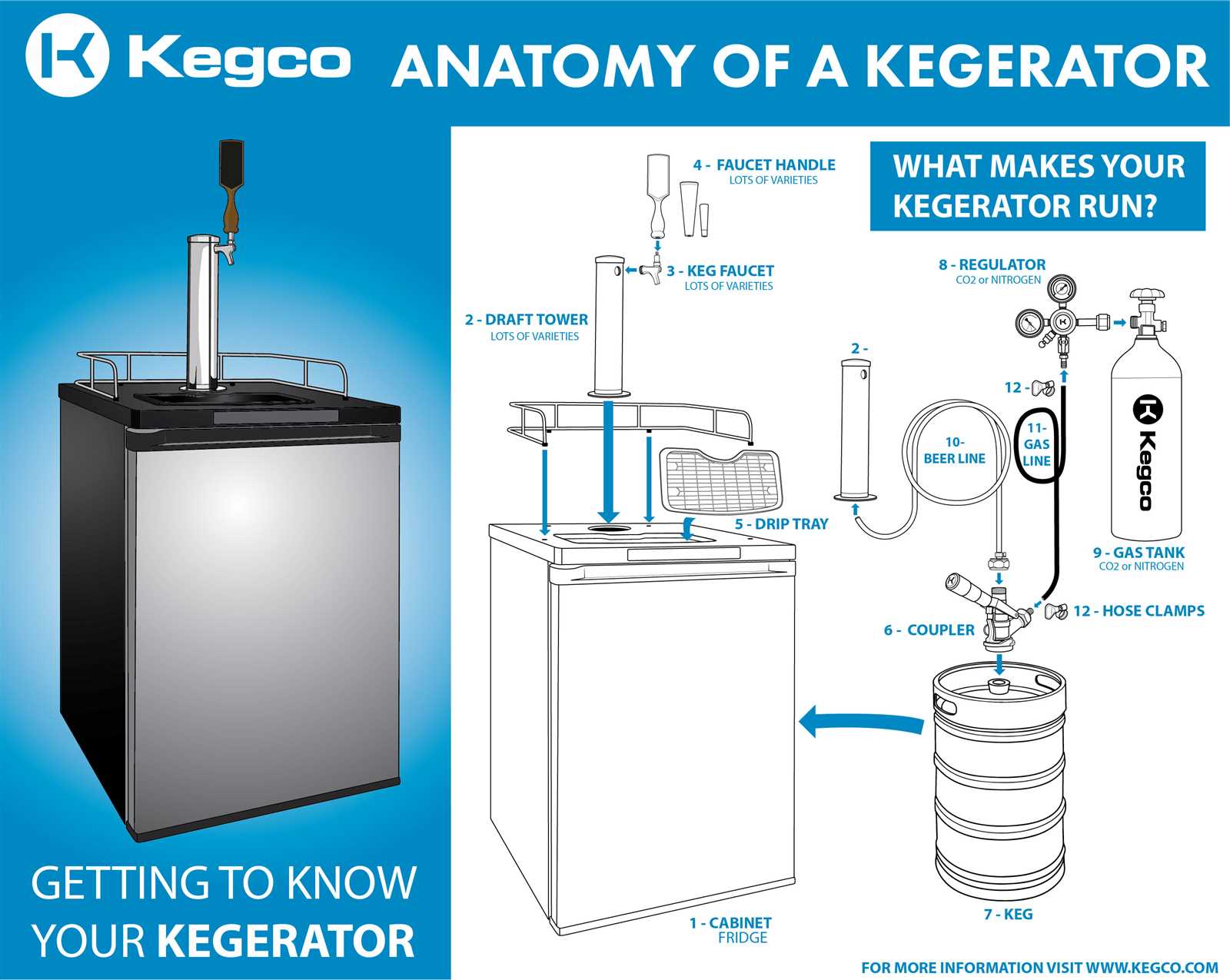

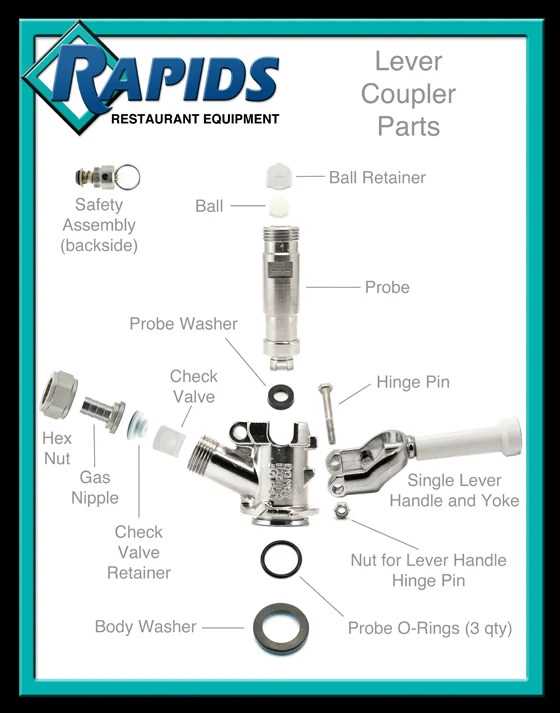

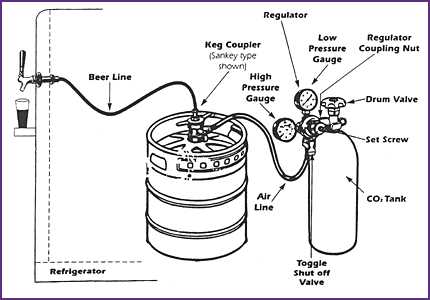

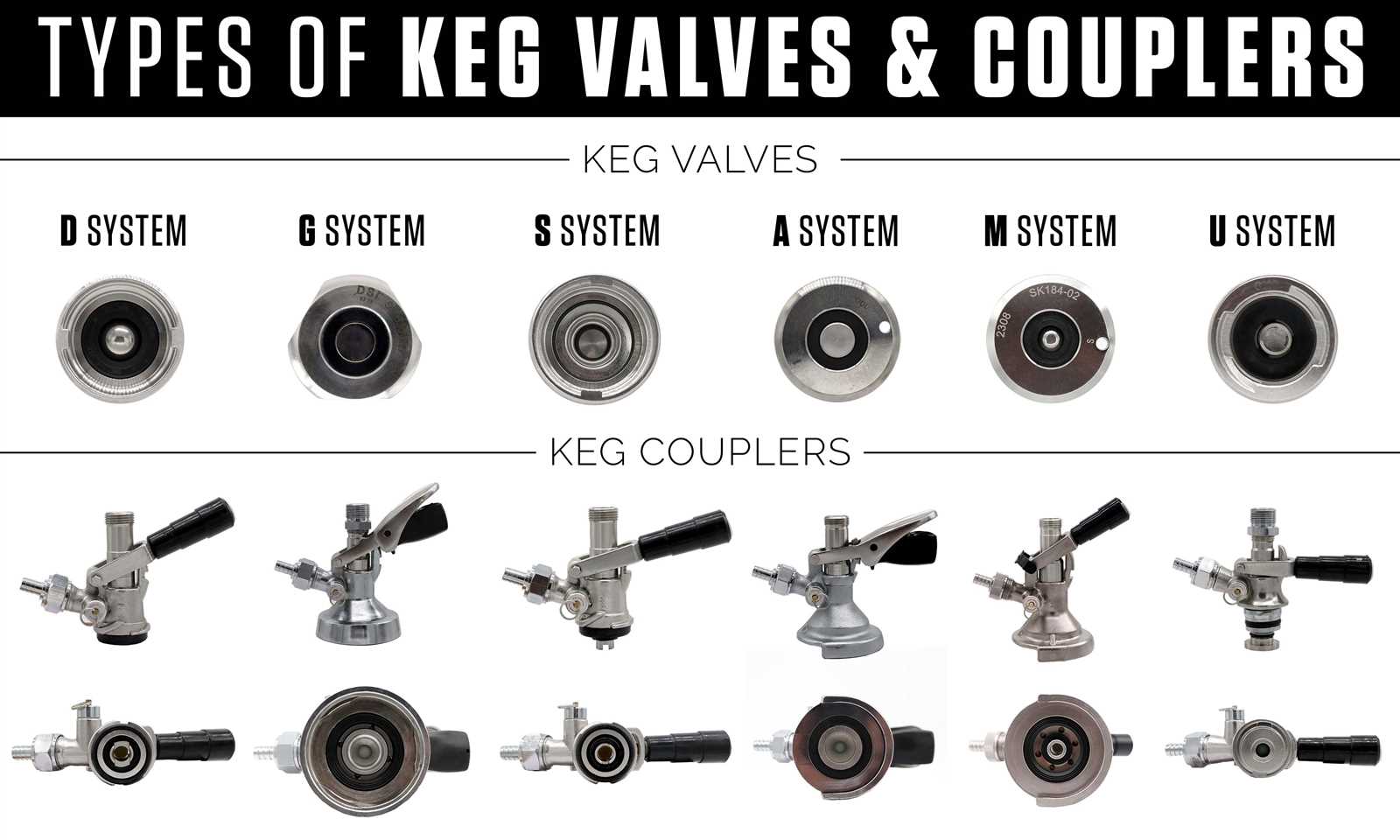

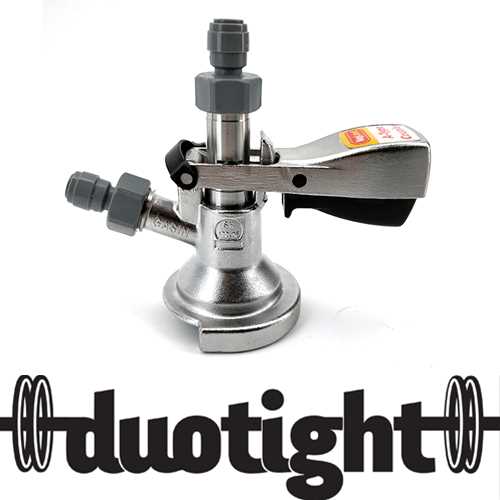

- Coupler: This device connects to the container and allows for the release of the liquid. Different types are designed for various container systems.

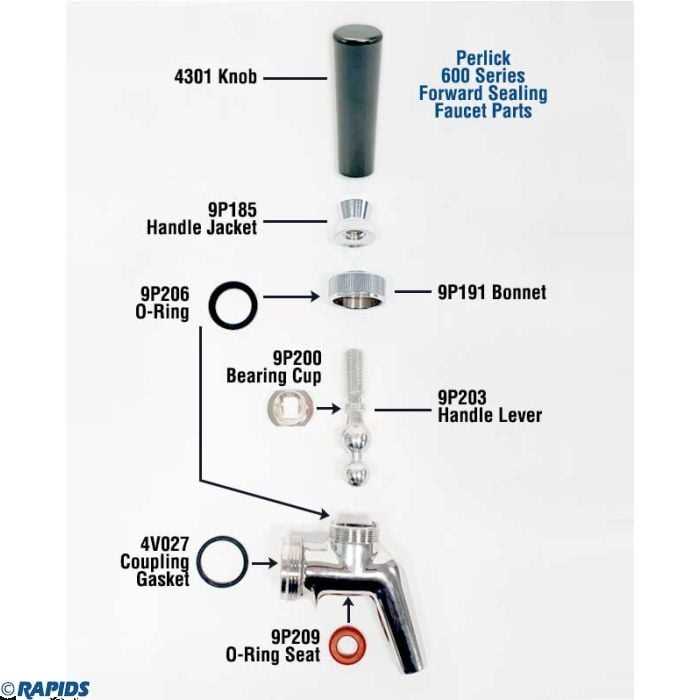

- Faucet: This element controls the flow of the beverage, providing an easy way to dispense it while preventing spills.

- Shank: A vital connector between the faucet and the beer line, ensuring a secure passage for the liquid.

- Beer line: The tubing that transports the beverage from the container to the dispensing mechanism. Proper maintenance is essential for hygiene and flavor preservation.

- CO2 Regulator: This device manages the pressure of the gas used to propel the liquid, allowing for consistent pouring.

Each of these components contributes to the overall functionality and user experience, making knowledge of their operation indispensable for any enthusiast or professional in the beverage service industry.

Different Types of Keg Taps

When it comes to serving beverages from large containers, various mechanisms are utilized to ensure an efficient and enjoyable experience. Each design offers unique features suited for specific needs, contributing to the overall functionality and ease of use.

Ball Lock Couplers are popular in home brewing, designed for quick connections and disconnections. These mechanisms feature a simple push-and-twist operation, making them user-friendly and efficient.

Pin Lock Couplers operate similarly but utilize a pin-based system for secure attachment. This type is favored in many commercial settings, offering reliable performance and compatibility with various container types.

Lever-Handle Couplers provide a classic approach, with a lever that engages and disengages the connection. Their robust construction makes them ideal for high-volume environments where durability is essential.

Homebrew Couplers cater to enthusiasts, featuring adaptable designs that can accommodate multiple types of containers. These often include interchangeable components, allowing users to customize their setup according to personal preferences.

Each style of dispensing mechanism plays a crucial role in the overall process, ensuring that beverages are served fresh and with minimal effort. Understanding these differences helps in selecting the most suitable option for any occasion.

Common Issues with Keg Taps

When serving beverages from a pressurized container, various challenges can arise that may affect performance and user experience. Understanding these common problems can help ensure smooth operation and optimal enjoyment of the drinks.

Frequent Problems Encountered

- Inadequate Flow: Insufficient liquid may indicate a blockage or incorrect pressure settings.

- Leaking Connections: Seals or fittings may deteriorate, leading to unwanted spills.

- Temperature Control: Improper cooling can spoil the flavor of the beverage.

- Excessive Foam: This can result from over-carbonation or incorrect pouring techniques.

Troubleshooting Tips

- Check for Blockages: Inspect hoses and connectors for any debris that could hinder flow.

- Inspect Seals: Regularly examine all connections and replace any worn components.

- Monitor Pressure: Ensure the pressure is set according to the beverage type being served.

- Maintain Temperature: Use appropriate cooling systems to keep the beverage at the desired serving temperature.

Maintenance Tips for Keg Equipment

Regular upkeep of your beverage dispensing setup is essential for optimal performance and longevity. Proper maintenance not only ensures consistent quality in your beverages but also prevents costly repairs down the line. Here are some key practices to keep your system in excellent condition.

Cleaning and Sanitizing

Frequent cleaning is crucial for maintaining the integrity of your system. Residue buildup can lead to off-flavors and contamination. Make it a routine to disassemble components and clean them using appropriate sanitizing solutions. Pay special attention to areas where liquid can accumulate, as these are prone to mold and bacteria growth.

Regular Inspections

Conduct thorough inspections of all components regularly. Look for signs of wear, leaks, or corrosion. Check seals and gaskets for proper function and replace them as necessary. Maintaining an eye on these details can help you catch issues before they escalate, ensuring smooth operation and enhancing the lifespan of your equipment.

How to Assemble a Keg Tap

Assembling the essential components for dispensing beverages can be a straightforward yet rewarding task. Understanding the various elements involved ensures proper functionality and enhances the overall experience. This guide will walk you through the necessary steps to put together this system effectively.

Gather Your Components

Begin by collecting all the necessary elements for your assembly. This typically includes a dispensing handle, a connector, and a pressure regulator. Ensure that each piece is compatible with your setup to avoid any complications during assembly.

Step-by-Step Assembly Process

Start by attaching the connector to the appropriate inlet, ensuring a tight seal to prevent leaks. Next, secure the pressure regulator to maintain the desired flow of liquid. Finally, fasten the dispensing handle, checking that it operates smoothly. It’s crucial to verify that all connections are secure before proceeding to use the setup.

Once assembled, perform a quick test to confirm functionality. If all components work seamlessly together, you’re ready to enjoy your perfectly dispensed beverages!

Identifying Parts on a Diagram

Understanding the components represented in a schematic is essential for effective assembly and maintenance. Each symbol or label corresponds to a specific element, making it easier to visualize the overall system. By familiarizing yourself with these representations, you can enhance your troubleshooting skills and ensure proper functionality.

Common Symbols and Their Functions

Each icon in a schematic serves a distinct purpose, allowing for a clearer understanding of the mechanisms at play. Below is a brief overview of frequently encountered symbols:

| Symbol | Description |

|---|---|

| Valve | Controls the flow of liquids, often depicted as a circle with a line. |

| Connector | Links two or more components, usually represented by a simple dot or line. |

| Pressure Regulator | Maintains consistent pressure, commonly shown as a triangle within a circle. |

| Outlet | Indicates where the fluid exits, often depicted with an arrow. |

Tips for Interpretation

When examining a schematic, start by identifying the primary functions of each symbol. Pay attention to the layout, as it can reveal the flow direction and relationship between elements. Cross-referencing with a glossary or guide can further assist in clarifying any uncertainties you may encounter.

Upgrading Your Keg Tap System

Enhancing your beverage dispensing setup can significantly improve both efficiency and user experience. Whether you’re a casual host or a professional, modernizing your equipment will lead to better performance and satisfaction. This section explores various methods to elevate your system, focusing on components, technology, and overall design.

Key Considerations for Improvement

Before diving into upgrades, it’s crucial to assess your current configuration. Consider factors such as capacity, ease of use, and maintenance needs. Here are some important aspects to keep in mind:

| Aspect | Recommendation |

|---|---|

| Material Quality | Opt for durable materials like stainless steel to enhance longevity. |

| Pressure Regulation | Invest in reliable regulators for consistent flow and optimal serving temperature. |

| Cleaning System | Integrate a self-cleaning mechanism to ensure hygiene with minimal effort. |

| Customization | Explore interchangeable faucets to accommodate various beverage types. |

Benefits of Modernization

Upgrading your system not only boosts functionality but also enhances the overall aesthetic appeal. A well-designed setup can attract more attention at events and create a more enjoyable atmosphere. Improved technology can lead to more precise pouring and less waste, ensuring every drop counts. By investing in quality components, you’ll create a reliable system that meets your needs for years to come.

Safety Precautions When Using Keg Taps

Ensuring safety during the handling of beverage dispensing equipment is crucial. Proper awareness and adherence to guidelines can prevent accidents and injuries while enhancing the overall experience. This section outlines essential precautions to consider when using such systems.

General Safety Guidelines

Before operating the dispensing mechanism, it is important to familiarize yourself with the equipment and its functions. Always ensure that the area is clear of obstacles and that all necessary tools are within reach. Here are some fundamental precautions:

| Precaution | Description |

|---|---|

| Inspect Equipment | Check for any signs of wear or damage before use. |

| Wear Protective Gear | Use gloves and goggles to protect against spills and splashes. |

| Follow Manufacturer Instructions | Adhere to the operating manual for safe and effective use. |

| Maintain Cleanliness | Ensure that all surfaces are clean to prevent contamination. |

Handling and Storage Recommendations

Proper handling and storage of the equipment can significantly reduce risks. Always handle with care and store in designated areas away from heat sources. Consider the following tips:

| Recommendation | Description |

|---|---|

| Secure Connections | Ensure all connections are tight to prevent leaks. |

| Store in Upright Position | Keep the containers stored upright to avoid spills. |

| Check for Pressure | Monitor pressure levels to prevent hazardous situations. |

| Use Appropriate Tools | Utilize the right tools for installation and maintenance. |

Where to Buy Keg Tap Parts

Finding the necessary components for your beverage dispensing system can enhance your brewing experience and ensure optimal performance. Whether you’re a casual enthusiast or a serious aficionado, knowing where to source these essential items is crucial.

Online Retailers

- Specialty Brewing Websites: Many online stores focus on brewing supplies and offer a wide range of components for your setup.

- General E-commerce Platforms: Websites like Amazon and eBay provide a vast selection and user reviews to guide your choices.

- Manufacturer Websites: Direct purchases from the producers often guarantee authenticity and quality.

Local Suppliers

- Homebrew Shops: Local stores dedicated to home brewing often carry essential equipment and accessories.

- Restaurant Supply Stores: These retailers may have components designed for commercial use that can be suitable for home setups.

- Hardware Stores: Some larger hardware retailers stock basic items that can be repurposed for beverage systems.