Understanding the Components of a Boat Trailer Winch Diagram

When engaging in outdoor activities that involve transportation over land and water, a reliable lifting mechanism becomes essential. This apparatus not only simplifies the process of moving heavy loads but also ensures safety and efficiency. Understanding the various elements that make up this system is crucial for effective operation and maintenance.

The intricacies of this lifting device can be better appreciated by examining its individual elements. Each component plays a vital role in the overall functionality, contributing to the seamless interaction needed for lifting and lowering. Knowledge of these constituents can enhance user experience and prolong the lifespan of the equipment.

As we delve into the specifics, we will explore the essential features, their interconnections, and how they contribute to the performance of the entire system. By familiarizing oneself with these components, one can make informed decisions regarding repairs, upgrades, and safe practices.

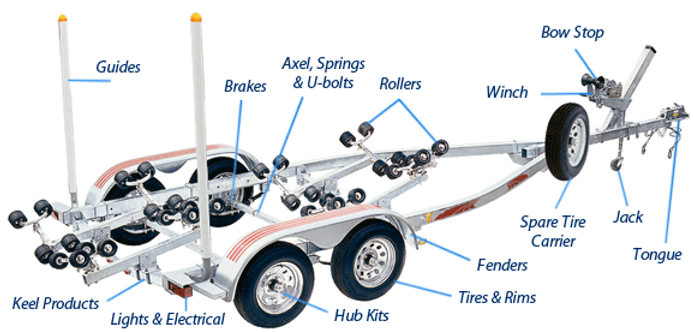

Understanding Boat Trailer Winches

When it comes to transporting watercraft, having the right mechanism to assist in loading and unloading is crucial. This device ensures a smooth operation, allowing for efficient handling of heavy items. Knowing the components and their functions can significantly enhance your experience and safety during these tasks.

The core of this mechanism includes several essential elements that work together seamlessly. Each component plays a vital role, ensuring that the entire system operates effectively and securely. Familiarity with these elements will help you maintain the equipment and troubleshoot any issues that may arise.

| Component | Function |

|---|---|

| Drum | Holds the cable and allows for winding and unwinding. |

| Cable | Connects the item to the drum, enabling movement. |

| Gear system | Provides mechanical advantage for easier lifting. |

| Handle | Allows manual operation of the device. |

| Mounting bracket | Secures the assembly to the support structure. |

Understanding these components will not only improve your proficiency in operating the mechanism but also enhance your confidence in managing your watercraft transport needs.

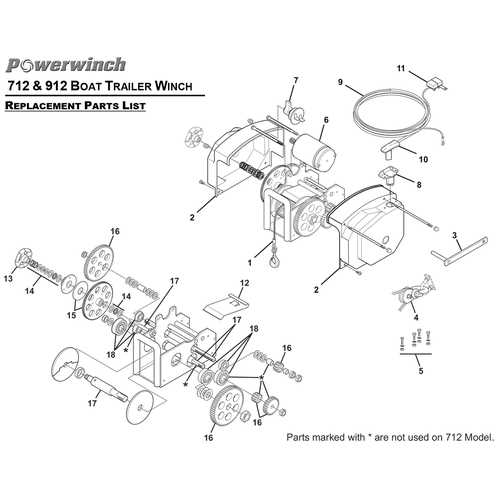

Components of a Winch System

The effectiveness of a pulling mechanism relies on various crucial elements that work together to ensure smooth operation and reliability. Understanding these components is essential for anyone looking to enhance their equipment’s performance or maintain it properly. Each element plays a distinct role in the overall functionality, contributing to the system’s strength and efficiency.

Key Elements

Among the primary components are the drum, which stores the cable, and the motor that powers the retrieval process. The drum is typically made of durable materials to withstand significant tension, while the motor may vary in power and type depending on the application needs. Additionally, a gear system often amplifies the force, allowing for easier handling of heavy loads.

Supporting Features

Another essential aspect includes the mounting bracket, which secures the assembly to its base, providing stability during use. Additionally, a control system allows for precise management of the cable’s movement, enhancing safety and ease of operation. Lastly, a reliable safety mechanism is crucial to prevent accidents and ensure the longevity of the entire setup.

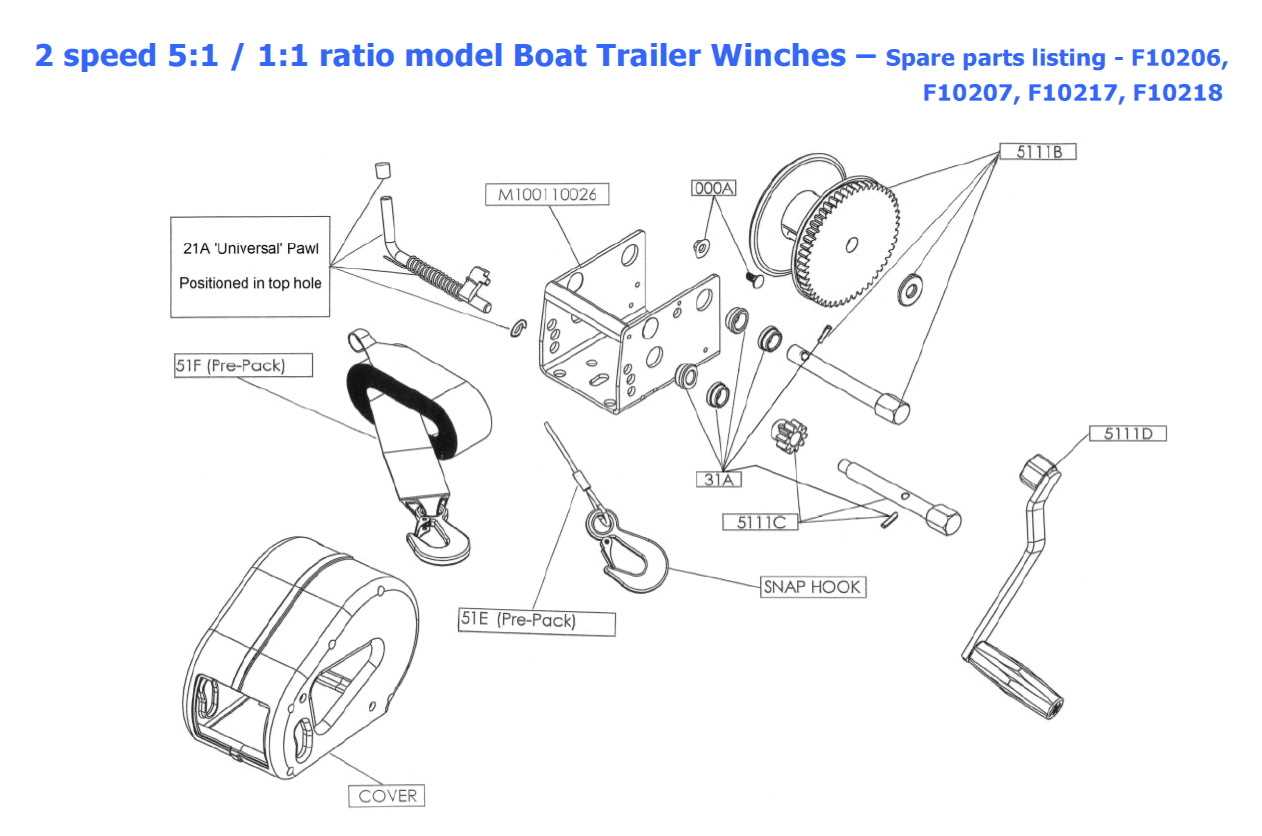

Types of Boat Trailer Winches

Understanding the different types of devices used for hoisting and lowering is essential for anyone involved in marine activities. These tools vary in design, functionality, and application, each offering unique advantages to users. Selecting the right kind can significantly enhance the efficiency and safety of operations on the water.

Manual Devices

Manual mechanisms rely on human effort for operation. They are typically simpler in design and more affordable, making them popular for casual users.

- Hand Crank: Operated by turning a handle, these are straightforward and provide good control.

- Gear-Driven: Utilizing gears to increase lifting power, these models require less physical effort.

Electric Mechanisms

Electric models offer convenience and efficiency, ideal for frequent use or larger loads. These devices often come equipped with advanced features.

- 12V Electric: Powered by a standard battery, suitable for most applications.

- Wireless Remote Control: Allows for operation from a distance, enhancing user safety and convenience.

Choosing the appropriate mechanism depends on specific needs, including load capacity, frequency of use, and personal preference. Each type brings its own set of features to accommodate various demands.

How Winch Mechanisms Function

The operation of mechanical lifting devices relies on a combination of components working in unison to achieve movement and control over heavy loads. Understanding the principles behind these systems can provide insights into their efficiency and reliability in various applications.

Core Components

- Drum: The cylindrical element around which the rope or cable winds.

- Gear System: A series of interlocking gears that amplify torque and control speed.

- Motor: The power source that drives the mechanism, typically electric or hydraulic.

- Rope or Cable: The flexible medium used to connect the load to the drum.

Operating Principles

- The motor activates, turning the drum.

- The rope or cable wraps around the drum as it rotates.

- As the drum turns, it pulls the connected load closer.

- The gear system adjusts the torque to optimize performance for heavy or light loads.

- Control mechanisms allow the operator to manage the speed and direction of the movement.

This combination of parts and functions ensures that the lifting device can handle various tasks, making it an essential tool in many industries.

Safety Features of Winch Systems

When it comes to equipment designed for lifting and pulling, ensuring safety is paramount. Various mechanisms are integrated to minimize risks and enhance user protection. Understanding these features is crucial for anyone operating such machinery, as they significantly contribute to overall safety during use.

One of the primary safety components includes the presence of a reliable brake system. This ensures that loads remain secure during lifting and lowering, preventing accidental slips that could lead to injuries. A well-designed braking mechanism allows for smooth control and immediate response to unexpected situations.

Additionally, the incorporation of safety straps or hooks serves to further secure loads. These components are designed to withstand considerable force, reducing the chances of a load detaching during operation. Regular inspections and maintenance of these items are vital for maintaining their integrity and performance.

Moreover, integrated overload protection is a key feature that prevents the system from lifting weights beyond its capacity. This not only protects the equipment from damage but also safeguards the operator from potential accidents caused by overloading.

Finally, user training and proper operational guidelines play an essential role in safety. Familiarizing operators with the equipment’s features and the correct procedures can significantly mitigate risks associated with mishandling or misuse. A combination of robust design and informed operation lays the foundation for a secure working environment.

Common Issues with Winch Parts

When utilizing a hoisting mechanism, various complications may arise that can hinder its performance. Recognizing and addressing these challenges is crucial for maintaining efficiency and ensuring safety during operations. Below are some prevalent concerns that users often encounter with these essential tools.

Wear and Tear

Continuous use can lead to degradation of components over time. Factors such as exposure to the elements, heavy loads, and friction contribute to the deterioration of cables, gears, and housing. Regular inspections are vital to identify signs of wear early, preventing potential failures that could lead to hazardous situations.

Improper Maintenance

Neglecting routine upkeep can result in malfunctions that impede functionality. Lack of lubrication, accumulation of debris, and failure to check for loose connections can all affect performance. Establishing a consistent maintenance schedule and following manufacturer guidelines can help avoid these pitfalls and prolong the lifespan of the mechanism.

Maintenance Tips for Winch Longevity

Proper care is essential for ensuring the durability and efficient operation of any lifting mechanism. By following a few straightforward maintenance practices, you can significantly extend its lifespan and enhance performance. Regular attention to key components will prevent common issues and ensure smooth functionality, allowing you to rely on your equipment when needed.

Regular Cleaning

Keeping your lifting apparatus clean is crucial. Debris, dirt, and moisture can lead to rust and corrosion, which may compromise structural integrity. After each use, wipe down all surfaces and check for any accumulation of grime. Periodic deep cleaning will help maintain optimal conditions, ensuring that all parts operate smoothly.

Lubrication of Moving Parts

Applying appropriate lubricants to moving elements is vital for reducing friction and wear. Choose a high-quality lubricant designed for mechanical systems. Regularly inspect and apply lubricant to gears, bearings, and cables to maintain efficient operation. This simple step can make a significant difference in performance and longevity.

Choosing the Right Winch Capacity

Selecting the appropriate lifting mechanism capacity is crucial for ensuring safe and efficient operations. The right choice not only facilitates the movement of heavy loads but also minimizes the risk of equipment failure and accidents. Understanding various factors that influence capacity can lead to informed decisions tailored to specific needs.

Factors Influencing Capacity

Several elements must be considered when determining the required capacity. First and foremost, the weight of the load is essential. It is important to account for any additional gear or accessories that may be attached. Environmental conditions, such as slope and surface type, can also affect the necessary lifting power. Always ensure to include a safety margin to accommodate unexpected challenges.

Safety Considerations

Safety should be a primary concern when selecting lifting mechanisms. Overloading can lead to severe consequences, including equipment failure and personal injury. It is advisable to choose a capacity that exceeds the estimated load by at least 25-50%. Regular maintenance and inspections further enhance safety and prolong the lifespan of the equipment.

Installation Guide for Boat Winches

This section provides a comprehensive overview of how to properly install essential hoisting mechanisms for your watercraft. A successful setup ensures not only efficiency but also safety during loading and unloading procedures.

Tools and Materials Needed

- Power drill with appropriate bits

- Wrenches and socket set

- Measuring tape

- Safety goggles

- Mounting hardware (bolts, washers, nuts)

- Lubricant for moving parts

Step-by-Step Installation Process

-

Prepare the Area:

Ensure the installation location is clean and free of obstructions. Measure the space to confirm compatibility with your mechanism.

-

Mount the Mechanism:

Using the drill, create holes in the designated area based on the dimensions of your device. Securely fasten the mechanism with the provided hardware.

-

Attach the Rope or Cable:

Follow the manufacturer’s guidelines to correctly thread the rope or cable through the appropriate slots. Ensure it is tightly wound to prevent slippage.

-

Connect the Handle:

Attach the handle according to the instructions, ensuring it is securely fastened for ease of operation.

-

Test the Setup:

Before regular use, conduct a thorough test to verify that everything operates smoothly and without any unusual noises.

By following this guide, you can ensure that your lifting device is installed correctly, allowing for safe and efficient handling of your watercraft.

Upgrading Winch Components Effectively

Enhancing the elements of your lifting system can significantly improve its performance and reliability. As equipment ages or demands increase, investing in superior components becomes essential. This section explores key strategies for optimizing your setup while ensuring efficiency and safety.

Choosing Quality Materials

When considering upgrades, the choice of materials is paramount. Opting for high-grade alloys and corrosion-resistant finishes can extend the lifespan of your equipment. Durability is not just about initial cost; it impacts long-term functionality and maintenance requirements. Always prioritize reputable manufacturers known for their quality standards.

Integrating Advanced Features

Modern innovations offer features that enhance usability and efficiency. Look for components equipped with automatic braking systems or load indicators. These technologies not only improve safety but also provide real-time feedback on performance, allowing for more informed operation. Evaluating your current setup for compatibility with these advanced features can lead to substantial improvements.

Resources for Winch Diagrams and Parts

When engaging in projects that involve lifting and securing heavy loads, understanding the various components and their configurations is essential. Access to comprehensive resources can enhance knowledge and facilitate the selection of appropriate equipment for specific tasks.

Numerous online platforms provide visual aids and detailed descriptions of the necessary elements, enabling users to grasp the intricacies of each component. These resources often include manuals, instructional videos, and technical guides that are invaluable for both beginners and experienced individuals alike.

In addition to digital content, specialized forums and community groups offer a wealth of shared experiences and recommendations. Engaging with these communities can lead to practical advice and insights that might not be readily available in traditional resources.

For those seeking physical materials, local hardware stores and suppliers often have brochures or display models that illustrate the different components. This hands-on approach can significantly enhance understanding and decision-making when selecting the right tools for specific needs.