Comprehensive Guide to Stihl MS 270 Parts Diagram

When working with a powerful cutting tool, comprehending its internal structure is crucial for efficient operation and maintenance. Every element within the machinery plays a vital role in ensuring optimal performance and safety. By delving into the assembly of this equipment, users can enhance their knowledge and skills, ultimately leading to better care and longevity of the tool.

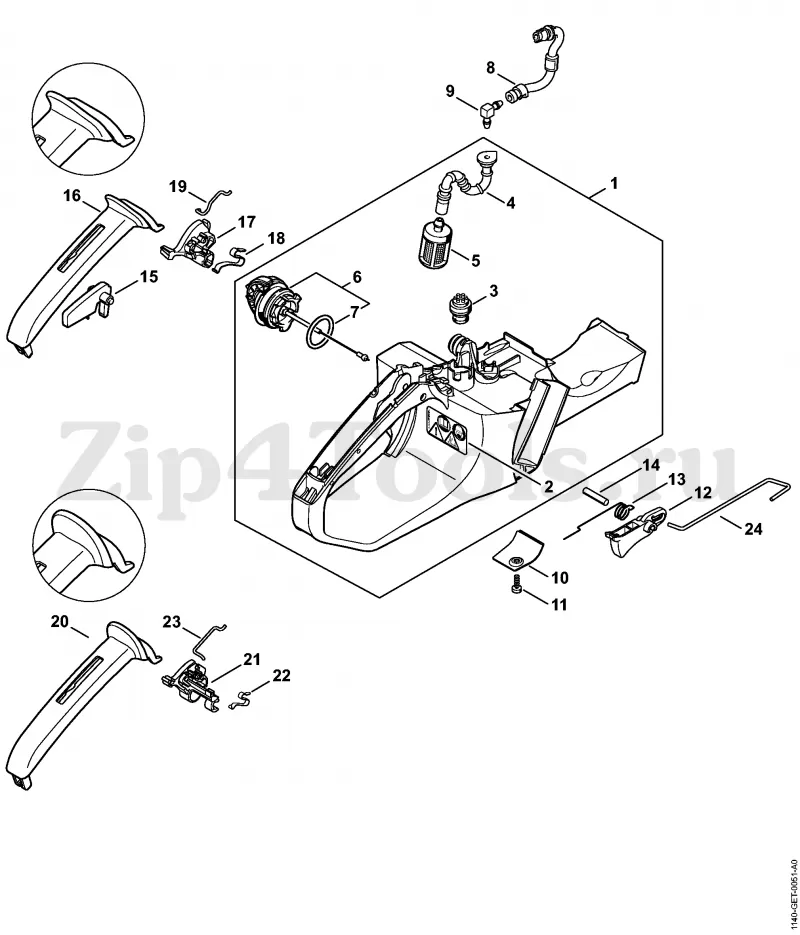

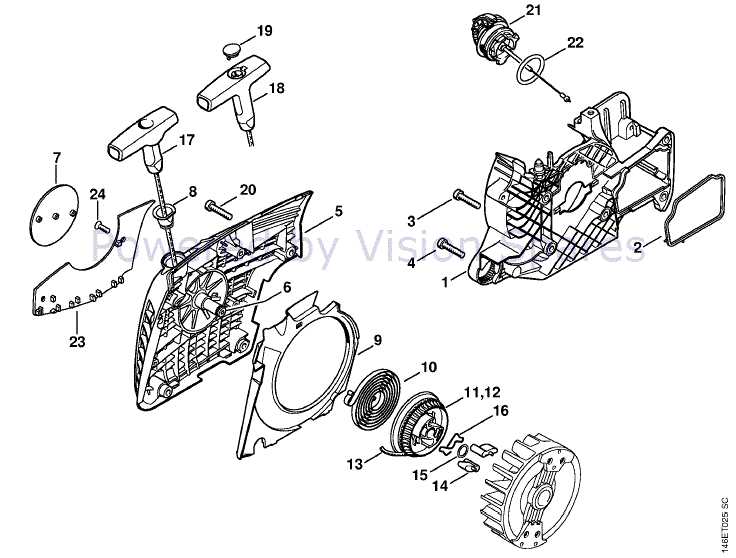

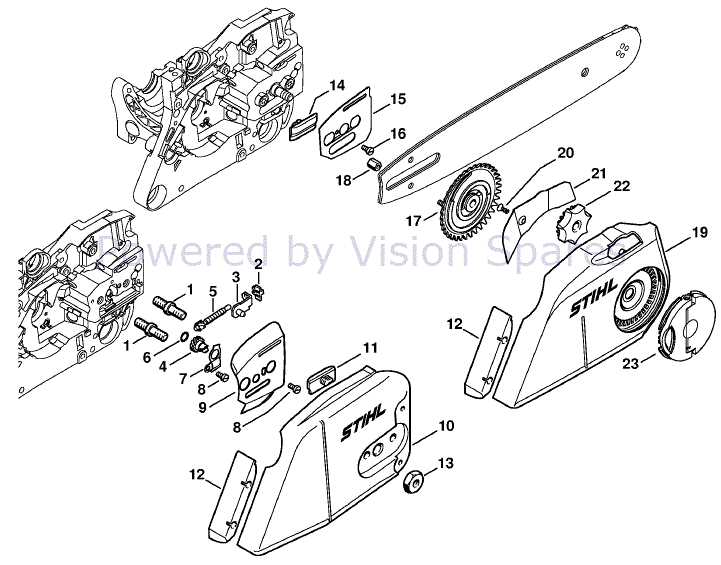

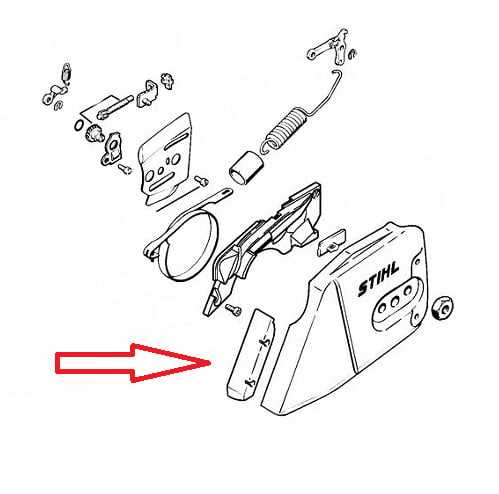

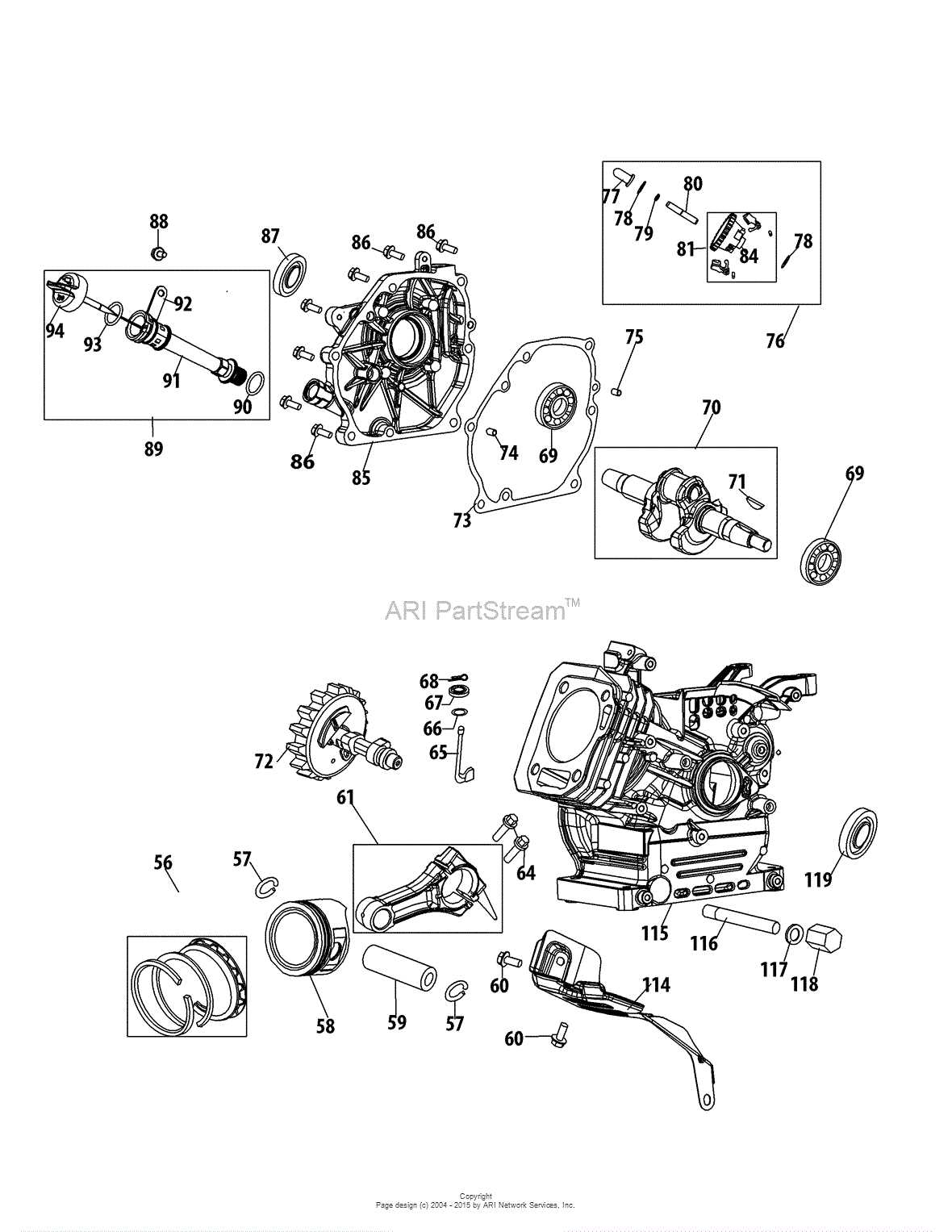

Visual representations of the various elements offer a clear understanding of how each piece interacts with others. This insight not only aids in identifying potential issues but also simplifies the process of repairs and replacements. Familiarity with these components empowers users to tackle challenges confidently and effectively.

Moreover, knowing the specifics of each section encourages a proactive approach to maintenance. Regular inspections and timely interventions can prevent minor problems from escalating into significant failures. By grasping the intricacies of the machinery, operators can ensure their tools remain reliable and efficient for all their cutting tasks.

Understanding the Stihl MS 270 Components

When exploring the intricacies of a high-performance cutting tool, it is essential to familiarize oneself with its various elements. Each component plays a crucial role in ensuring optimal functionality and longevity. This section delves into the key constituents that make up this remarkable machine.

- Engine: The powerhouse of the tool, responsible for converting fuel into mechanical energy.

- Guide Bar: The metal bar that supports the cutting chain, providing stability and precision during operation.

- Chain: The serrated loop that performs the cutting action, essential for effective wood processing.

- Fuel System: Comprising the tank, lines, and filter, this system ensures a steady supply of fuel to the engine.

- Air Filter: A protective element that prevents debris from entering the engine, promoting efficient performance.

- Starter Mechanism: The assembly that initiates the engine’s operation, allowing for quick starts.

Understanding these fundamental elements not only enhances your ability to maintain the tool but also improves safety and operational efficiency. Regular checks and replacements of these components can significantly impact performance and reliability.

- Identify each component and its function.

- Perform regular maintenance checks.

- Replace worn or damaged elements promptly.

By mastering the components, users can ensure their cutting tool remains in peak condition, ready to tackle any challenge with ease.

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear overview of various elements, their arrangements, and connections, aiding users in identifying and locating specific items needed for their tasks.

To interpret these illustrations effectively, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout. The visual will usually show the assembly in a logical order, helping you understand how parts fit together. |

| 2 | Look for reference numbers. Each component is typically marked with a unique identifier that corresponds to a list of items, making it easier to find what you need. |

| 3 | Examine the connections. Pay attention to how different pieces connect, as this can be crucial for disassembly and reassembly. |

| 4 | Consult the accompanying list. This often provides detailed descriptions, including specifications and compatibility information. |

| 5 | Keep a reference handy. Having a printed copy or digital version can assist you during the repair process, allowing for quick cross-referencing. |

By following these steps, you can efficiently navigate the visual guide, ensuring that you successfully complete your maintenance tasks with confidence.

Common Issues with MS 270 Parts

When working with any type of machinery, it’s essential to recognize potential challenges that can arise from its components. Understanding these common difficulties can lead to more efficient maintenance and better overall performance. This section explores frequent problems encountered with various elements of a specific model, providing insights for troubleshooting and prevention.

Wear and Tear

Over time, certain components may experience significant wear and tear due to constant use. This degradation can lead to decreased efficiency and performance issues. Regular inspections and timely replacements can help mitigate these effects, ensuring the equipment operates smoothly.

Fuel System Problems

Issues with the fuel system are among the most prevalent concerns for users. Clogs in the fuel lines or carburetor can hinder performance, resulting in starting difficulties or inconsistent operation. Routine cleaning and maintenance of the fuel components are vital for optimal functioning.

Where to Buy Replacement Parts

Finding the right components for your equipment is essential for maintaining optimal performance and longevity. Whether you’re looking for specific pieces for repairs or upgrades, knowing where to source high-quality replacements can save time and ensure reliability.

Authorized Dealers

One of the most reliable options is to purchase from authorized dealers. These establishments often carry a comprehensive inventory of original components, ensuring compatibility and quality. Additionally, they can provide expert advice on installation and maintenance.

Online Retailers

Another convenient choice is online retailers, which offer a vast selection of products at competitive prices. When shopping online, make sure to check customer reviews and ratings to gauge the reliability of the seller. Many websites also provide detailed descriptions and compatibility guides to help you find the right match.

Maintenance Tips for Stihl MS 270

Regular upkeep of your equipment is essential for optimal performance and longevity. Adopting a routine maintenance schedule not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some valuable recommendations to keep your machine running smoothly.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Chain Sharpening | After every 2-3 uses | Keep the cutting chain sharp for cleaner cuts and reduced wear. |

| Air Filter Cleaning | Every 10 hours | Remove debris and dirt from the air filter to ensure proper airflow. |

| Fuel System Inspection | Monthly | Check fuel lines and replace old fuel to prevent engine issues. |

| Bar and Chain Lubrication | Before each use | Ensure proper lubrication to prevent overheating and wear. |

| General Cleaning | After each use | Remove sawdust and debris to keep the equipment in good condition. |

By following these straightforward maintenance tasks, you can ensure that your equipment remains reliable and efficient, allowing you to tackle any job with confidence.

Identifying OEM vs. Aftermarket Parts

Understanding the difference between original and alternative components is crucial for anyone involved in maintenance or repair tasks. Each type of component has its own set of advantages and disadvantages, influencing performance, longevity, and cost. Knowing how to distinguish between them can lead to more informed decisions and better outcomes in your projects.

Characteristics of Original Equipment Components

Original equipment components are designed specifically for a particular machine, ensuring compatibility and optimal performance. These parts are typically manufactured by the same company that produced the equipment, providing peace of mind regarding quality and reliability.

Traits of Alternative Components

Alternative components, on the other hand, are produced by third-party manufacturers. While they can offer cost savings, the quality and compatibility can vary significantly. It’s essential to evaluate these options carefully, considering both the potential risks and benefits.

| Feature | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Consistent and reliable | Variable, dependent on manufacturer |

| Cost | Generally higher | Usually lower |

| Warranty | Often includes warranty | May vary by manufacturer |

| Availability | Limited to authorized dealers | Widely available from various sources |

Step-by-Step Parts Replacement Guide

This section provides a comprehensive approach to replacing components in your equipment, ensuring optimal performance and longevity. Following these instructions will help you navigate the process with ease and confidence.

-

Gather Necessary Tools:

Before starting, make sure you have the following tools ready:

- Screwdriver set

- Wrench

- Replacement components

- Safety gloves

-

Ensure Safety:

Before working on the equipment, disconnect it from any power source to prevent accidents.

-

Remove the Existing Component:

Carefully unscrew or unfasten the part that needs replacement. Keep track of any screws or fasteners for reinstallation.

-

Inspect Surrounding Areas:

Check for any signs of wear or damage in nearby components that may require attention.

-

Install the New Component:

Align the new part correctly and secure it in place with the screws or fasteners you removed earlier.

-

Test the Equipment:

Once everything is reassembled, reconnect the power source and test the equipment to ensure it operates smoothly.

Following these steps will help maintain the efficiency and safety of your machinery. Regular checks and timely replacements contribute to a longer service life.

Safety Precautions When Working on Chainsaws

Operating a cutting tool requires careful attention to safety measures to prevent accidents and injuries. Familiarity with safety practices is essential for anyone handling these powerful machines. This section highlights critical precautions to ensure a safe working environment when using these devices.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as helmets, goggles, gloves, and cut-resistant clothing to minimize the risk of injury. |

| Inspect the Equipment | Before starting, check the tool for any signs of damage or wear. Ensure that all components are securely fastened and functioning properly. |

| Maintain a Clear Work Area | Keep the workspace free of obstacles and debris to prevent trips and falls while operating the tool. |

| Proper Handling Techniques | Always use both hands when operating the tool and maintain a firm grip to ensure control during use. |

| Awareness of Surroundings | Stay alert to your environment, including the presence of bystanders, and be aware of potential hazards such as overhead branches. |

| Follow Manufacturer Guidelines | Adhere to the manufacturer’s instructions regarding operation, maintenance, and troubleshooting to ensure safe usage. |

By implementing these safety measures, operators can significantly reduce the likelihood of accidents and injuries, creating a safer work environment for themselves and others.

Tools Needed for Parts Replacement

When undertaking the task of replacing components in outdoor equipment, having the right tools is essential for a smooth and efficient process. Proper preparation ensures that the job is completed safely and effectively, minimizing the risk of damage to the machine.

Here’s a list of essential tools to consider:

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing and securing screws.

- Wrenches: A set of adjustable or fixed wrenches will help in loosening and tightening bolts.

- Socket Set: A socket set allows for quick and efficient removal of nuts and bolts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing over-tightening.

- Pliers: Needle-nose and regular pliers are useful for gripping and pulling small components.

- Cleaning Supplies: Rags and brushes are important for cleaning parts and maintaining the equipment’s condition.

- Safety Gear: Gloves and goggles protect against injury during the replacement process.

By equipping yourself with these tools, you will be well-prepared to handle any component replacement task efficiently and effectively.

Benefits of Using Genuine Stihl Parts

When it comes to maintaining outdoor power equipment, choosing authentic components is crucial for ensuring optimal performance and longevity. Using original items designed specifically for your machine can significantly enhance its efficiency and reliability.

Quality Assurance

Authenticity guarantees that each component is manufactured to exact specifications. This precision not only improves functionality but also reduces the risk of breakdowns. Genuine components undergo rigorous testing, ensuring they meet high standards for durability and performance.

Optimal Performance

Employing original replacements allows your equipment to operate at its best. Compatibility with the rest of the machine’s design means you experience fewer issues, leading to smoother operation and less downtime. Furthermore, using non-genuine items can lead to costly repairs down the line, as they may not work harmoniously with your equipment.

Upgrading Your Stihl MS 270 Performance

Enhancing the efficiency of your power tool can significantly improve its functionality and longevity. By implementing a few strategic modifications, you can elevate its performance, making it more effective for various tasks. This section outlines several practical upgrades that can contribute to better operation and greater overall satisfaction.

- Air Filter Improvement: Upgrading to a high-flow air filter can enhance airflow, allowing for a more efficient combustion process.

- Exhaust Modifications: Installing a performance exhaust system can reduce back pressure, improving engine efficiency and power output.

- Fuel System Optimization: Consider using a higher-quality fuel or an octane booster to maximize engine performance and responsiveness.

- Chain and Bar Selection: Upgrading to a more suitable chain and bar can enhance cutting efficiency and reduce wear on the engine.

These enhancements can provide a noticeable boost in performance, enabling you to tackle more demanding tasks with ease. Regular maintenance and thoughtful upgrades will ensure your tool remains in peak condition, ultimately prolonging its lifespan and effectiveness.