Stihl TS350 Super Parts Diagram Guide

For anyone engaged in the maintenance and operation of cutting equipment, a comprehensive grasp of the machinery’s components is essential. This knowledge not only enhances efficiency but also extends the lifespan of the tools in use. By familiarizing oneself with the intricate assembly of these devices, users can diagnose issues and perform repairs with greater confidence.

In this section, we will explore the various elements that constitute these powerful machines. Each component plays a vital role in the overall functionality, and recognizing their specific functions can significantly improve troubleshooting efforts. From the power source to the cutting mechanism, every piece has its importance.

Moreover, having access to visual representations of these elements aids in understanding how they interconnect and operate as a cohesive unit. This guide will provide detailed insights, ensuring that users are well-equipped to handle their machinery effectively and efficiently. Knowledge is the key to successful operation and maintenance.

Overview of Stihl TS350 Super

This section provides a comprehensive understanding of a high-performance cutting tool designed for heavy-duty applications. Renowned for its durability and efficiency, this machine is favored by professionals in construction and masonry. Its robust design and advanced features facilitate precision cutting, making it a reliable choice for various tasks.

Equipped with a powerful engine, this model ensures optimal performance even in challenging conditions. The user-friendly interface allows for seamless operation, enhancing productivity on job sites. Additionally, its lightweight construction contributes to reduced fatigue during extended use.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke engine for high power output |

| Weight | Lightweight design for ease of handling |

| Cutting Depth | Adjustable cutting depth for versatile applications |

| Fuel Efficiency | Optimized fuel consumption for longer operation |

| Safety Features | Equipped with advanced safety mechanisms |

This tool stands out in its category, combining power, versatility, and safety, making it an essential asset for professionals seeking reliability and performance in their equipment.

Key Features of the TS350 Model

This model is designed to deliver exceptional performance and durability, making it a preferred choice for professionals in various industries. Its advanced engineering and robust construction ensure reliability and efficiency during operation.

Power and Efficiency

- High-performance engine for rapid cutting.

- Optimized fuel consumption for longer operational periods.

- Enhanced torque to tackle tough materials effortlessly.

User-Friendly Design

- Lightweight construction for improved maneuverability.

- Ergonomic handle for comfortable use over extended periods.

- Quick-release features for easy maintenance and blade changes.

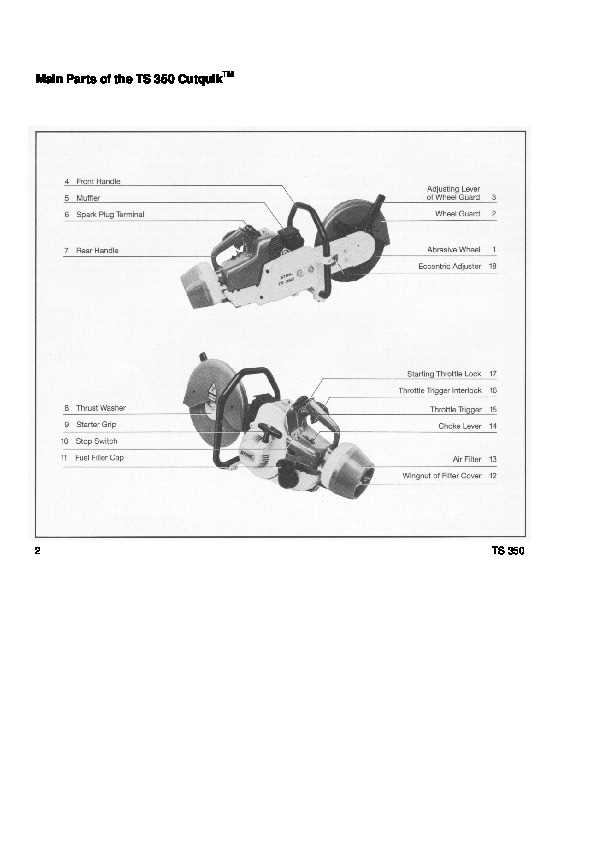

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of machinery. They provide an ultimate guide for users to identify individual elements, facilitating effective repairs and maintenance.

Clear organization of information helps users quickly locate specific parts, enhancing efficiency during troubleshooting. This not only saves time but also reduces the likelihood of errors, ultimately ensuring that machinery operates at peak performance.

Moreover, these visuals serve as a valuable resource for both novices and seasoned professionals, allowing them to delve deeper into the intricacies of the equipment. Understanding each component’s role fosters a greater appreciation for the overall system, promoting more informed decisions regarding upgrades and replacements.

Understanding Component Functions

In any machinery, each element plays a crucial role in ensuring optimal performance and efficiency. By exploring the individual functions of these components, users can gain insights into how the overall system operates and how to maintain it effectively.

Core Elements and Their Roles

Every apparatus comprises key elements that contribute to its functionality. For instance, the engine is the powerhouse, generating the energy needed for operation, while the cooling system prevents overheating, ensuring longevity. Understanding these core roles allows for better troubleshooting and enhancements.

Maintenance and Longevity

Regular inspection of each component is vital for preserving the machine’s integrity. Identifying wear and tear can prevent minor issues from escalating into significant problems. By prioritizing maintenance, operators can enhance performance and extend the lifespan of the equipment, leading to ultimate efficiency.

Common Repairs for the TS350

Regular maintenance and timely repairs are essential for the longevity and performance of power tools. Users often encounter specific issues that require attention, and understanding these common problems can help in addressing them efficiently. From fuel system adjustments to blade replacements, being familiar with these repairs ensures optimal functionality and safety.

1. Fuel System Issues

One of the most frequent challenges involves the fuel delivery system. Clogs in the fuel filter or issues with the carburetor can hinder performance. Cleaning or replacing these components can restore proper operation and prevent future complications.

2. Blade Wear and Tear

Blades are critical to the effectiveness of any cutting tool. Over time, they may dull or become damaged. Regular inspection and sharpening are vital, and in some cases, complete replacement may be necessary to maintain cutting efficiency.

3. Air Filter Maintenance

The air filter plays a crucial role in engine performance. A clogged or dirty filter can lead to reduced power and efficiency. Cleaning or replacing the air filter regularly will ensure that the engine receives adequate airflow, contributing to better performance.

4. Electrical System Troubles

Issues with the ignition system, such as faulty spark plugs or wires, can prevent the engine from starting. Routine checks and replacements of these components can help avoid frustrating start-up failures.

5. Vibration and Noise Issues

Excessive vibration or unusual noises can indicate loose or worn parts. Tightening screws, checking mounts, and replacing worn components can enhance safety and comfort during operation.

Essential Tools for Maintenance

Proper upkeep of equipment requires a set of fundamental instruments that ensure efficiency and longevity. These tools enable users to perform necessary inspections, adjustments, and repairs, ultimately contributing to optimal performance.

Key Instruments

- Wrenches: Ideal for tightening and loosening bolts.

- Screwdrivers: Essential for handling various screws.

- Filters: Crucial for maintaining clean airflow and fluid.

- Protective Gear: Necessary for safety during maintenance tasks.

Additional Supplies

- Lubricants: Helps reduce friction and wear.

- Cleaning Solutions: Keeps parts free from debris and grime.

- Measuring Tools: Ensures precise adjustments and calibrations.

How to Interpret Diagrams

Understanding technical illustrations is crucial for effectively maintaining and repairing equipment. These visual aids provide a wealth of information, helping users to identify components and comprehend their functions. Proper interpretation can lead to enhanced efficiency in troubleshooting and assembling machinery.

Familiarizing Yourself with Symbols

Each illustration features unique symbols and notations that convey specific meanings. It is essential to familiarize yourself with these representations to avoid confusion. Key elements often include part numbers, connection types, and various annotations that indicate how components interact. Take time to study the legend or key, if provided, as it serves as a guide for understanding the visual content.

Following the Flow

Many illustrations depict a logical flow of assembly or operation. By following the sequential arrangement of elements, you can gain insights into how each component fits into the larger system. Pay attention to directional arrows and grouping of parts, as they indicate relationships and processes. This systematic approach will aid in comprehending the overall structure and functionality of the machinery.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is crucial for optimal performance and longevity. Fortunately, there are several avenues to explore for obtaining high-quality replacements. Whether you’re looking for genuine items or compatible alternatives, knowing where to look can save you time and effort.

Authorized Dealers

Visiting an authorized dealer is one of the most reliable options. These establishments typically carry a comprehensive selection of original components, ensuring that you receive items that meet the manufacturer’s standards. Additionally, the staff at these locations are often knowledgeable and can assist with finding the correct components for your specific model.

Online Marketplaces

The internet offers a plethora of options for acquiring spare components. Reputable online platforms provide a wide range of choices, including original and aftermarket items. When purchasing online, it’s essential to check reviews and ratings to ensure that you’re buying from a trustworthy source. Always verify that the components are compatible with your equipment to avoid issues down the line.

Remember to compare prices and options to find the best deals, and don’t hesitate to reach out to customer support if you have any questions about your purchase.

Safety Considerations When Repairing

When undertaking maintenance on equipment, prioritizing safety is crucial to ensure a secure working environment. Proper precautions can prevent accidents and injuries, allowing for efficient repairs.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and hearing protection.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Disconnect the power source before starting any disassembly to prevent unexpected operation.

- Keep your workspace organized to minimize hazards and easily locate tools.

By adhering to these guidelines, you can significantly reduce risks and ensure a safer repair process.

Tips for Efficient Troubleshooting

Troubleshooting machinery can often feel overwhelming, but with a systematic approach, you can quickly identify and resolve issues. This section will provide valuable strategies to enhance your efficiency while diagnosing problems, ensuring minimal downtime and effective repairs.

Understand Common Symptoms

Familiarize yourself with typical signs of malfunction. Recognizing these indicators can guide your investigation and help pinpoint the root cause swiftly. Take note of unusual noises, performance drops, or unexpected behavior during operation.

Utilize Diagnostic Tools

Leverage various diagnostic tools to streamline the process. Instruments such as multimeters, pressure gauges, and visual inspection aids can provide critical insights. Documenting findings as you delve into each aspect of the equipment will help in pinpointing the ultimate solution.