Understanding the Husqvarna ST 224 Parts Diagram for Efficient Maintenance

For those who rely on their snow-clearing equipment during winter months, knowing the intricate details of its construction is essential. Each piece plays a vital role in ensuring optimal performance, and having a clear visual representation can aid in both maintenance and repairs. A comprehensive overview of these elements not only enhances your understanding but also empowers you to address issues effectively.

In this section, we delve into the various segments that make up a reliable snow-clearing machine. From the powerful engine to the adjustable chute, every component has its significance. Familiarizing yourself with these parts can lead to better upkeep, extended longevity, and enhanced efficiency in clearing snow from your driveway or walkway.

Furthermore, grasping the layout of these elements can facilitate smoother repairs when the need arises. Whether you’re replacing a worn-out component or simply performing routine checks, having a visual guide will help you navigate the intricacies of your machinery. Let’s explore these essential features in detail to ensure your equipment is always ready for the winter challenges ahead.

Understanding Husqvarna ST 224 Parts

Grasping the components of a snow-clearing machine is essential for optimal performance and maintenance. Each element plays a critical role in ensuring efficiency during operation. A comprehensive understanding of these components not only aids in troubleshooting but also facilitates timely replacements and repairs, enhancing the longevity of the equipment.

Key Components Overview

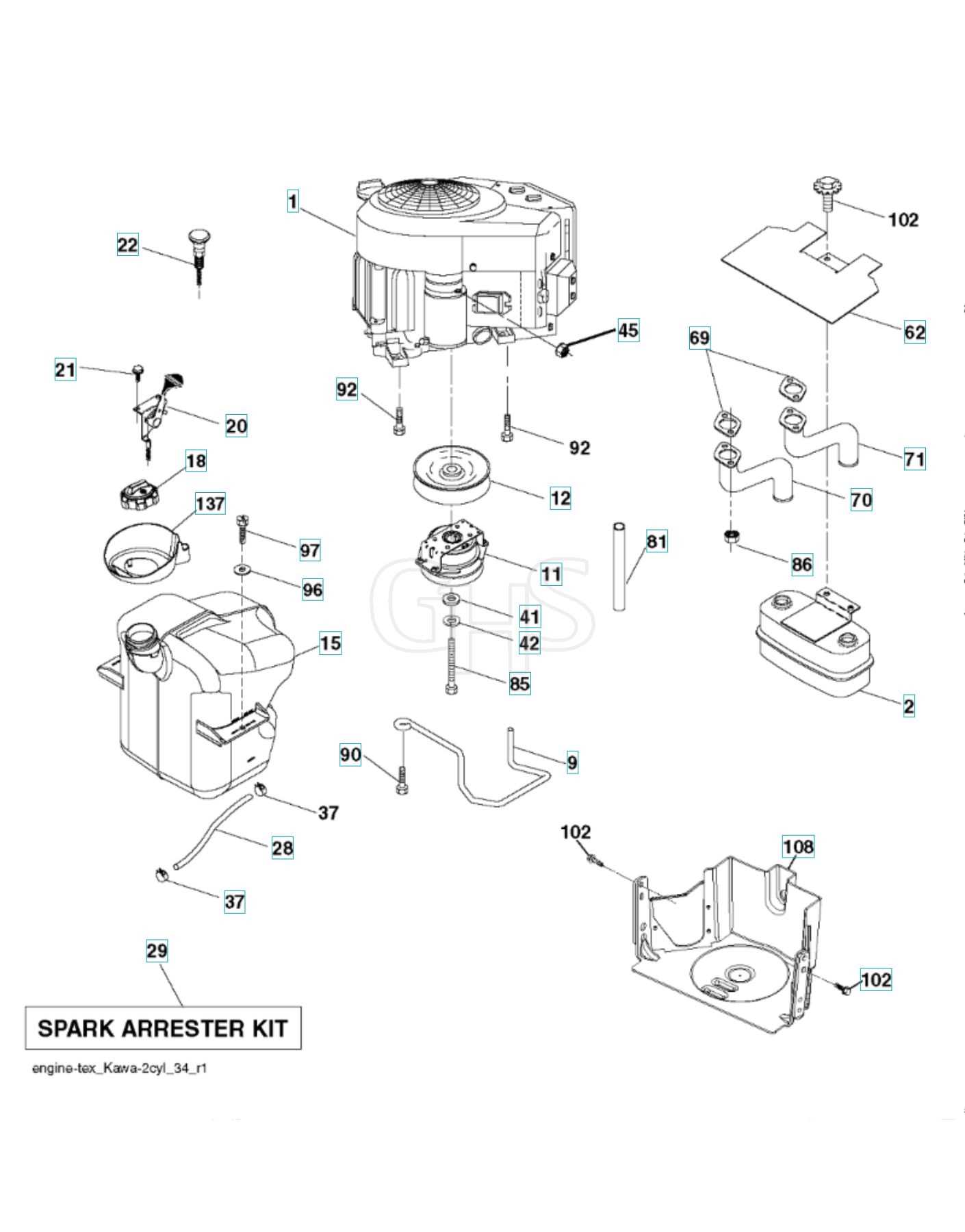

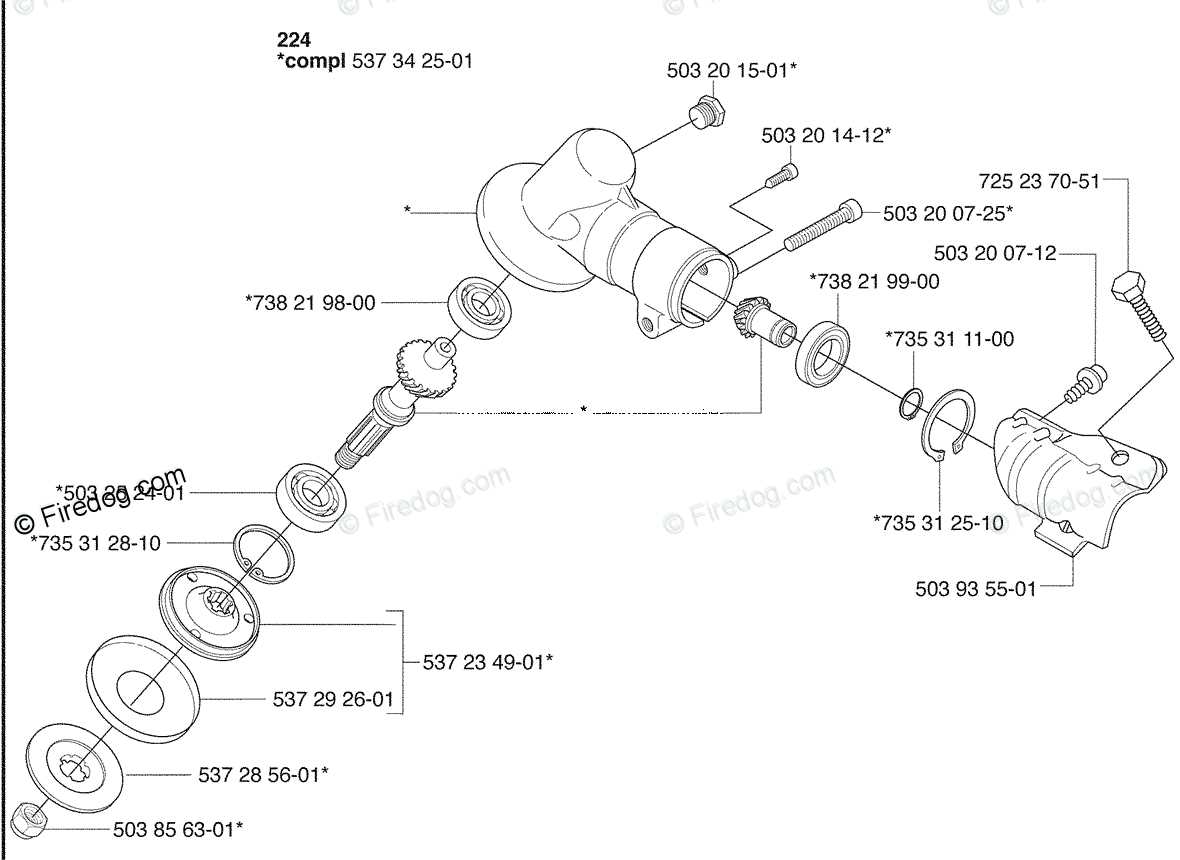

The primary elements of a snow blower include the engine, auger, impeller, and chute. The engine powers the unit, driving the auger and impeller, which work together to collect and discharge snow effectively. The chute directs the snow, allowing for customizable throwing angles. Familiarity with these vital sections can significantly improve operational effectiveness.

Maintenance and Replacement Insights

Regular upkeep is crucial for any machinery. Checking and replacing worn or damaged components can prevent major issues down the line. It’s advisable to refer to specific manuals for guidance on which components require periodic attention and how to execute replacements properly. This proactive approach ensures reliable performance during winter conditions.

Overview of the Snowblower Model

This section provides a comprehensive look at a popular snow-clearing machine, designed to tackle winter challenges effectively. The model combines durability with efficient performance, ensuring that snow removal is both swift and straightforward.

Key Features

Among its notable characteristics are a powerful engine, a robust housing structure, and user-friendly controls. These elements work together to enhance usability and ensure a reliable operation in various snow conditions.

Specifications

| Feature | Details |

|---|---|

| Engine Type | 4-cycle, gas-powered |

| Clearing Width | 24 inches |

| Throwing Distance | Up to 30 feet |

| Weight | Approximately 150 lbs |

| Starter | Electric and recoil |

Overall, this snow-clearing device is engineered to meet the demands of winter, making it an ideal choice for homeowners and businesses alike.

Key Components of the ST 224

Understanding the essential elements of this snow-clearing machine is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance and durability, contributing to a seamless experience during winter months.

The engine serves as the powerhouse, providing the necessary energy for the entire unit. Coupled with the auger system, it effectively breaks up and gathers snow, allowing for efficient removal. The chute directs the cleared snow, enabling the user to control where it lands.

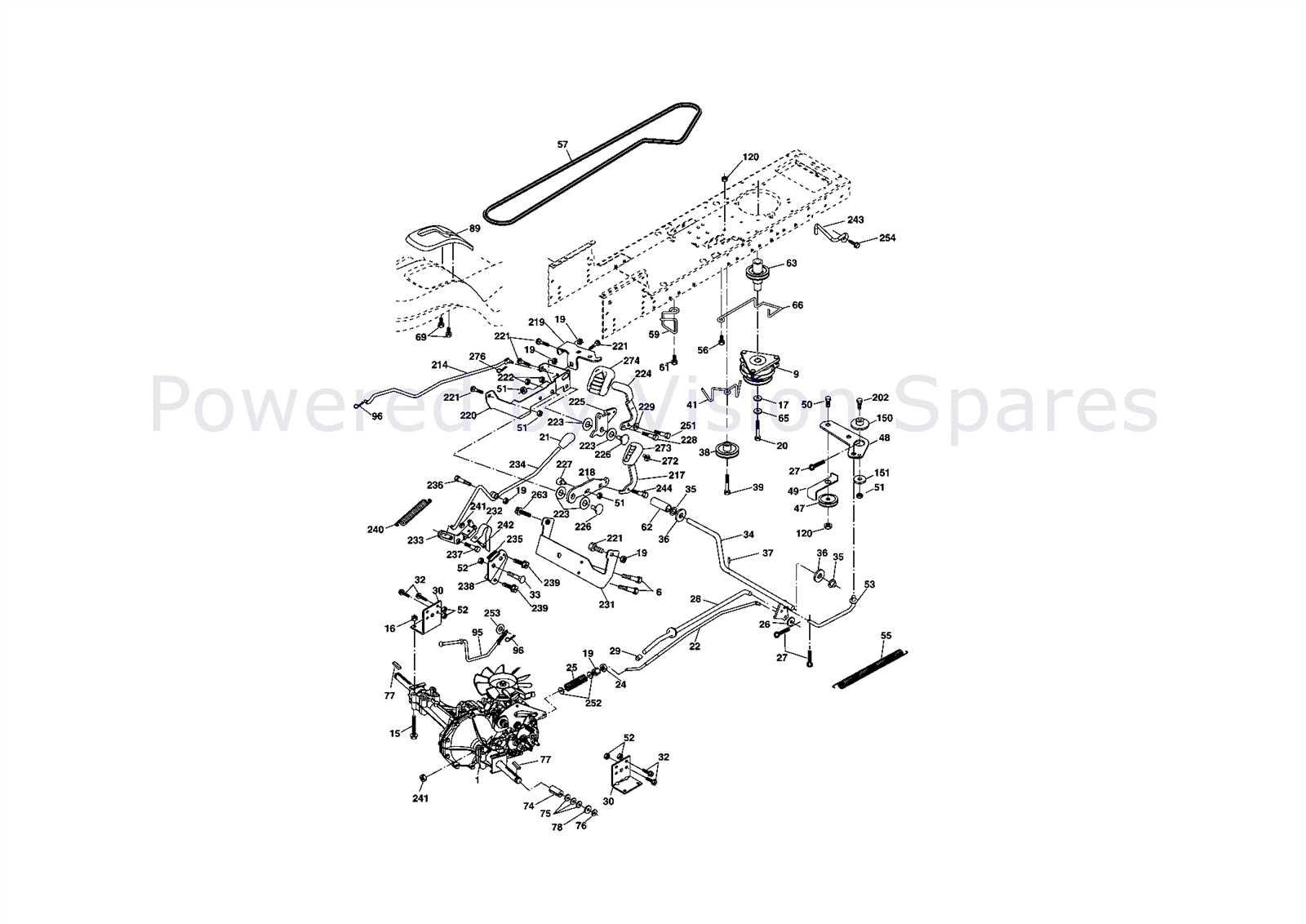

Additionally, the drive system is essential for maneuverability, ensuring that the machine can navigate various terrains with ease. A sturdy frame provides structural integrity, supporting all moving parts while withstanding harsh conditions. Lastly, the control panel allows for user interaction, providing various settings for customized operation.

Importance of Parts Diagrams

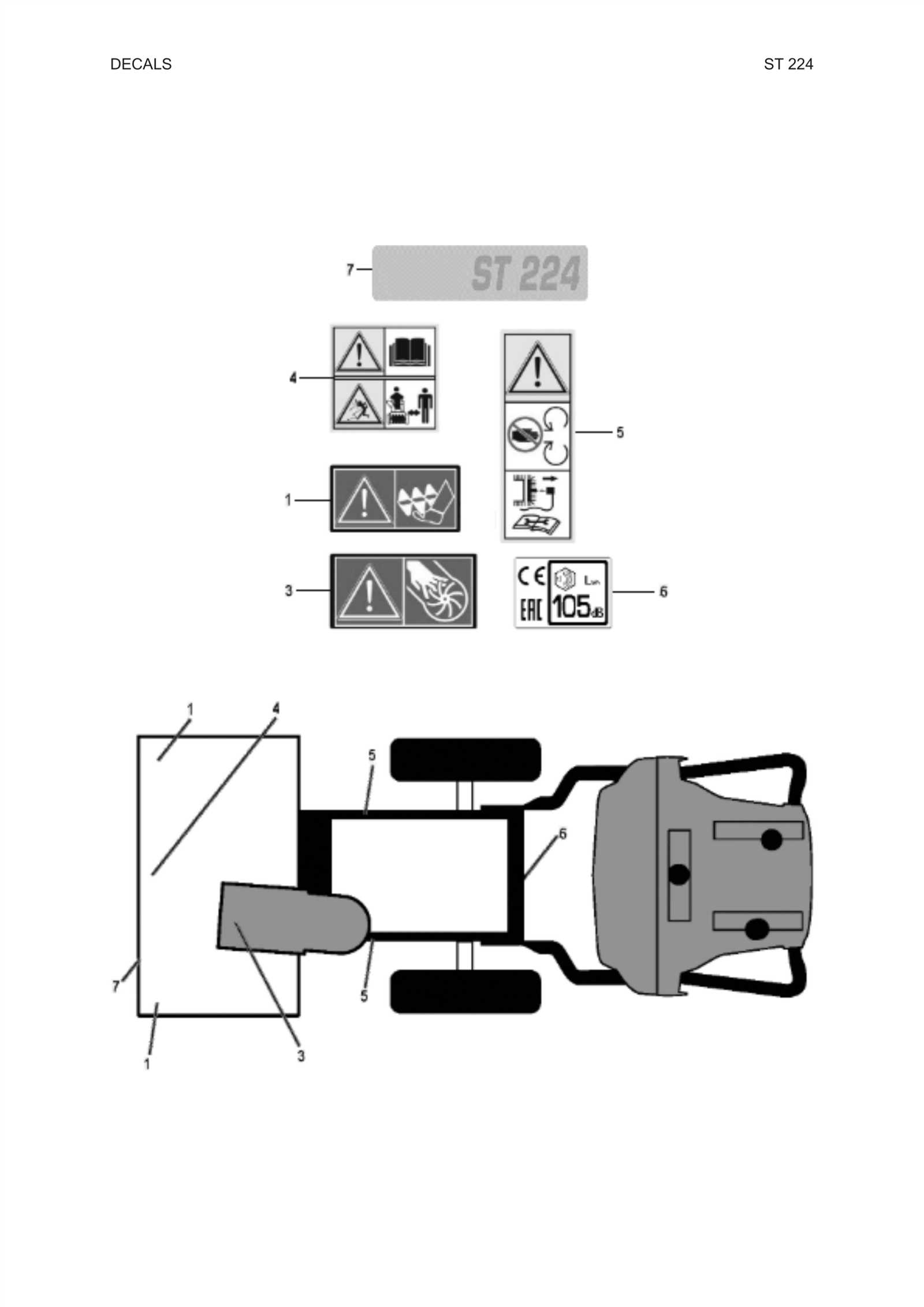

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations that illustrate the components and their interconnections play a crucial role in this process. They serve as a valuable resource for both seasoned technicians and DIY enthusiasts, ensuring that repairs are conducted efficiently and accurately.

These visual aids simplify the identification of individual elements, allowing for easier troubleshooting and replacement. Moreover, they foster a clearer comprehension of how each component contributes to the overall functionality of the equipment. This clarity can prevent costly mistakes and enhance the longevity of the machine.

| Benefits | Description |

|---|---|

| Clarity | Visual representations provide a clear overview of components and their arrangements. |

| Efficiency | Facilitates quicker identification and replacement of malfunctioning elements. |

| Prevention | Helps avoid errors during repairs, leading to reduced maintenance costs. |

| Learning | Enhances understanding of machinery, benefiting users with varying experience levels. |

In summary, these visual tools are indispensable for anyone involved in the upkeep of mechanical devices, offering both practical and educational advantages that streamline the repair process and enhance overall efficiency.

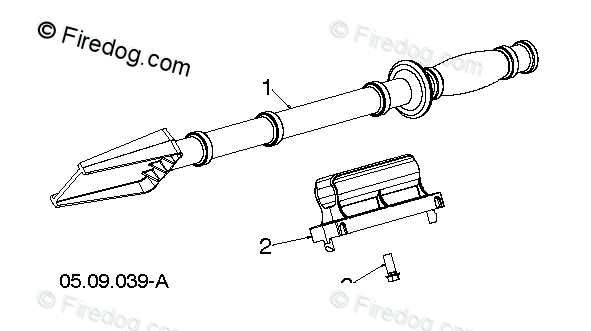

How to Read the Diagram

Understanding a visual representation of components can greatly enhance your ability to assemble and maintain equipment effectively. This guide will help you navigate the essential elements found within these illustrations, allowing you to pinpoint each part’s role and interconnections.

Familiarize yourself with the layout: Start by identifying the orientation of the image. Often, diagrams are arranged in a logical sequence, showcasing the assembly from top to bottom or left to right.

Identify key symbols: Different shapes and lines indicate specific functions or connections. For instance, solid lines may represent direct links, while dashed lines could signify optional parts.

Refer to the legend: Many visual guides include a legend or key that clarifies symbols and numbering. Use this resource to ensure accurate interpretation of the components.

Cross-reference with documentation: To achieve the ultimate understanding, align your findings with manuals or guides that provide detailed explanations about each item and its function.

By mastering these techniques, you’ll be well-equipped to tackle repairs and upgrades with confidence.

Common Issues and Solutions

When operating a snow-clearing machine, users may encounter a variety of challenges that can hinder performance. Understanding these common problems and their respective remedies is essential for maintaining efficiency and prolonging the lifespan of the equipment. This section outlines frequent issues faced by operators and offers practical solutions to address them effectively.

Engine Difficulties

One of the most prevalent concerns involves engine troubles, which can manifest as difficulty starting or irregular running. Possible causes include stale fuel, clogged filters, or spark plug issues. To resolve these problems, ensure that fresh fuel is used, clean or replace any filters, and check the spark plug for wear or deposits. Regular maintenance checks can help prevent these issues from arising.

Drive System Malfunctions

Another common issue pertains to the drive mechanism, which may experience slippage or failure to engage. This can often result from worn belts or improper tension. To address this, inspect the belts for signs of wear and adjust the tension as needed. If belts are frayed or damaged, replacing them promptly will restore proper function and ensure reliable operation during use.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular upkeep and careful attention. By following some essential maintenance practices, you can enhance performance and extend the lifespan of your machinery. This not only saves you money in the long run but also ensures reliable operation throughout the seasons.

Regular Inspections

Conducting routine checks on various components is crucial. Look for signs of wear and tear, such as frayed belts or loose screws. Regularly cleaning the filters and checking fluid levels can prevent minor issues from escalating into major problems.

Proper Storage

Storing your equipment properly when not in use is essential. Keep it in a dry, sheltered place to protect it from the elements. Covering the machinery can also prevent dust accumulation, which can interfere with its operation. Additionally, consider performing a thorough cleaning before storage to remove debris and grime.

Where to Find Replacement Parts

Locating the necessary components for your outdoor equipment can greatly enhance its performance and longevity. Fortunately, there are numerous avenues to explore when searching for these essential elements. From official retailers to online marketplaces, options abound for those in need of specific items.

Below is a table summarizing various sources where you can find suitable components:

| Source | Description | Advantages |

|---|---|---|

| Official Dealers | Authorized sellers that provide genuine components. | Quality assurance and reliable customer support. |

| Online Retailers | Websites specializing in outdoor equipment supplies. | Convenience and a wide range of options. |

| Local Repair Shops | Neighborhood services that offer repairs and sales. | Personalized assistance and quick service. |

| Second-Hand Markets | Platforms for buying used items. | Cost-effective solutions for budget-conscious buyers. |

| Manufacturer Websites | Direct online portals of equipment producers. | Access to the latest updates and original components. |

Each of these options presents unique benefits, making it easier to find what you need to maintain and repair your machinery effectively.

Aftermarket vs. Original Parts

When it comes to maintaining outdoor equipment, the choice between genuine components and alternatives can significantly impact performance and longevity. Each option presents its own set of advantages and drawbacks, influencing both functionality and cost-effectiveness.

Original components are typically designed by the manufacturer, ensuring compatibility and adherence to specific quality standards. This often results in superior durability and reliability, making them a preferred choice for those seeking optimal performance.

On the other hand, aftermarket alternatives can provide a more budget-friendly solution, often appealing to cost-conscious users. While some may offer decent quality, variability in production can lead to inconsistencies in performance and fit.

Ultimately, the decision hinges on balancing quality, budget, and personal preferences, making it essential to delve into the specifics of each option before committing.

Tools Needed for Assembly

Assembling machinery requires a set of essential implements to ensure the process is efficient and effective. Having the right tools not only streamlines the assembly but also enhances the quality and durability of the final product. Below is a list of the necessary items to facilitate a successful construction.

1. Wrenches: A variety of wrenches, including adjustable and socket types, are crucial for securing bolts and nuts. They provide the leverage needed to achieve the appropriate tightness without damaging components.

2. Screwdrivers: Both flathead and Phillips screwdrivers are essential for fastening and loosening screws. A set with varying sizes ensures compatibility with different fasteners encountered during assembly.

3. Pliers: Pliers are invaluable for gripping, twisting, and cutting wires. Needle-nose pliers can reach tight spots, while larger ones provide better leverage for heavy-duty tasks.

4. Torque Wrench: This tool is vital for applying a specific torque to bolts, ensuring that they are not under- or over-tightened. Proper torque is critical to maintain the integrity of the assembled machinery.

5. Hammer: A reliable hammer is necessary for driving in nails or adjusting parts into place. Opt for a rubber mallet to prevent damage to sensitive components.

6. Safety Gear: Never underestimate the importance of personal protective equipment such as gloves, goggles, and ear protection. These items ensure safety throughout the assembly process.

Having these tools on hand will significantly contribute to a smooth and efficient assembly experience, allowing for a well-constructed and reliable machine.

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing common issues with your snow-clearing equipment. Following these guidelines will help you efficiently identify and address any malfunction, ensuring optimal performance.

Tools You Will Need

- Wrench set

- Screwdriver set

- Replacement components

- Grease and oil

- Cleaning cloth

- Safety gloves

Repair Steps

- Prepare Your Workspace: Clear the area around your equipment and ensure you have adequate lighting.

- Safety First: Disconnect the power source and wear protective gear before starting any repairs.

- Inspect the Equipment: Look for visible signs of wear or damage. Pay attention to belts, blades, and other moving parts.

- Disassemble as Needed: Use the appropriate tools to carefully remove any components that require attention.

- Replace Damaged Parts: Install new or refurbished components where necessary. Ensure a snug fit and proper alignment.

- Lubricate Moving Parts: Apply grease or oil to all necessary areas to reduce friction and prevent wear.

- Reassemble the Equipment: Follow your disassembly steps in reverse to put everything back together securely.

- Test for Functionality: Reconnect the power source and run the equipment briefly to check for any remaining issues.

By following these steps, you can effectively maintain and repair your snow-clearing machine, ensuring it operates smoothly when you need it most.

Safety Precautions During Repairs

Engaging in maintenance activities can be rewarding but also poses risks if proper measures are not taken. Ensuring safety should be the utmost priority before, during, and after any repair tasks. Following guidelines can prevent accidents and injuries, creating a safer working environment.

Personal Protective Equipment

Wearing the appropriate personal protective gear is essential. This includes safety goggles to protect your eyes, gloves to shield your hands, and sturdy footwear to prevent slips and injuries. Each piece of equipment plays a crucial role in minimizing risk during repairs.

Workspace Safety

Maintain a clean and organized workspace to reduce hazards. Ensure tools are in good condition and stored properly when not in use. Adequate lighting is also vital, as it enhances visibility and helps you identify potential dangers quickly. Always have a first aid kit accessible for emergencies.

Customer Support and Resources

When it comes to maintaining and troubleshooting outdoor equipment, having access to reliable support and informative resources is crucial. Whether you are seeking assistance with repairs, looking for user manuals, or exploring maintenance tips, a variety of options are available to ensure you can keep your machinery in optimal condition.

Contact Information

If you require direct assistance, reaching out to the customer support team can provide you with personalized guidance. Various contact methods are typically available, including phone support, email inquiries, and live chat options. Below is a table summarizing common contact details:

| Support Method | Details |

|---|---|

| Phone | 1-800-XXX-XXXX |

| [email protected] | |

| Live Chat | Available on website |

Additional Resources

For those who prefer self-service options, numerous resources are accessible online. These include user manuals, troubleshooting guides, and instructional videos, all designed to empower you with the knowledge needed to address common issues. Visiting the official website can lead you to a wealth of information tailored to your specific model.