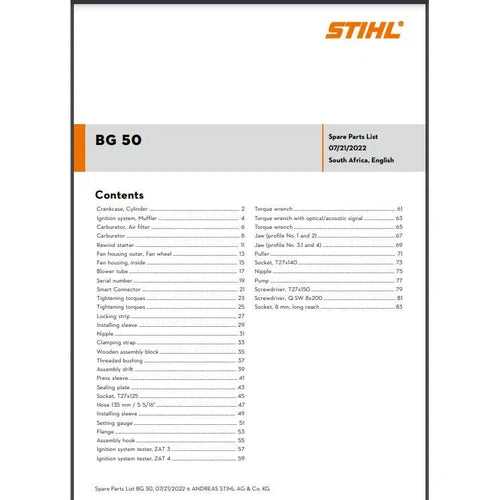

Understanding the Stihl BR 450 C Parts Diagram for Easy Maintenance

In the realm of outdoor machinery, having a clear grasp of how different elements interact is crucial for optimal performance. Whether you’re a professional landscaper or a passionate gardener, knowledge of the intricate makeup of your tools can greatly enhance their longevity and efficiency.

Exploring the various components not only aids in maintenance but also empowers users to troubleshoot effectively. Each part plays a vital role, contributing to the ultimate functionality of the device. By familiarizing yourself with these elements, you can ensure that your equipment operates smoothly, minimizing downtime.

To truly delve into the specifics, it’s beneficial to visualize the arrangement and connection of each component. This understanding paves the way for informed decision-making when it comes to repairs and upgrades, ensuring you get the most out of your investment.

Understanding the Stihl BR 450 C

This section focuses on the key aspects of a powerful tool designed for outdoor maintenance, emphasizing its efficiency and versatility. It caters to users who seek to enhance their gardening experience with a robust and reliable machine.

Key Features

Performance: This device is engineered to provide exceptional power, making it ideal for tackling various tasks in both residential and commercial settings. Its innovative design ensures optimal air flow and reduced operator fatigue.

Maintenance Considerations

Regular upkeep is essential for longevity. Users should familiarize themselves with the essential components and follow the recommended servicing guidelines to maintain peak performance.

Key Features of the BR 450 C

This robust outdoor power tool is designed for high efficiency and ease of use, making it ideal for both professionals and enthusiasts. With its advanced engineering, it delivers exceptional performance in various conditions.

- Powerful Engine: Equipped with a reliable engine that ensures maximum performance and fuel efficiency.

- Ergonomic Design: Features a comfortable grip and adjustable components to reduce fatigue during extended use.

- Low Emissions: Engineered to meet strict environmental standards, minimizing harmful output.

- Easy Maintenance: Designed for quick access to key components, simplifying routine care and upkeep.

- Versatile Applications: Suitable for a wide range of tasks, from residential yard care to commercial landscaping.

These characteristics make it a top choice for anyone looking to achieve ultimate efficiency and performance in their outdoor projects.

Importance of Parts Diagrams

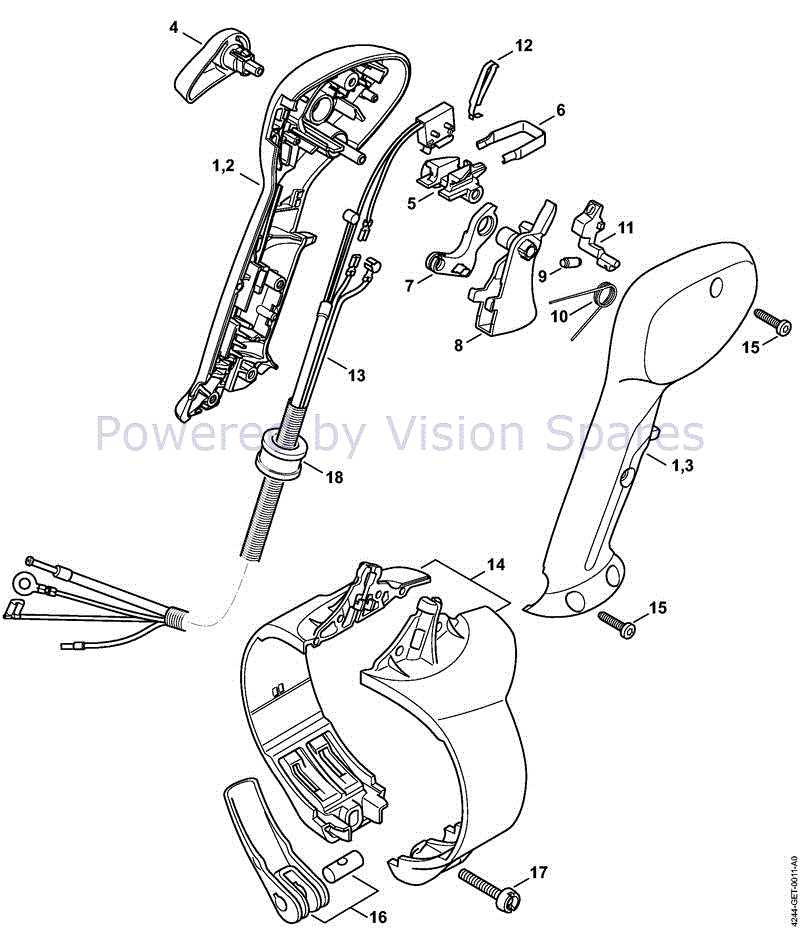

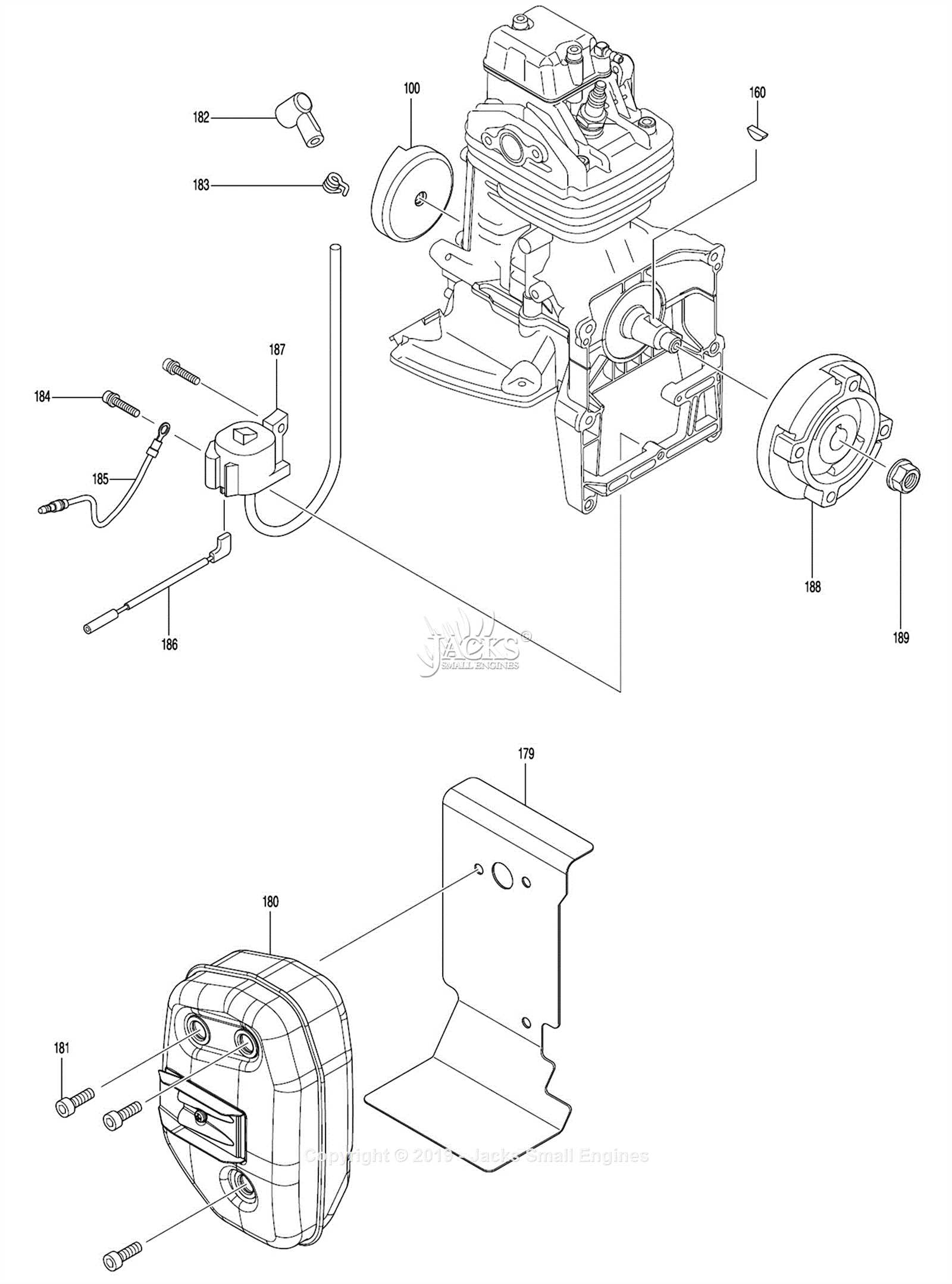

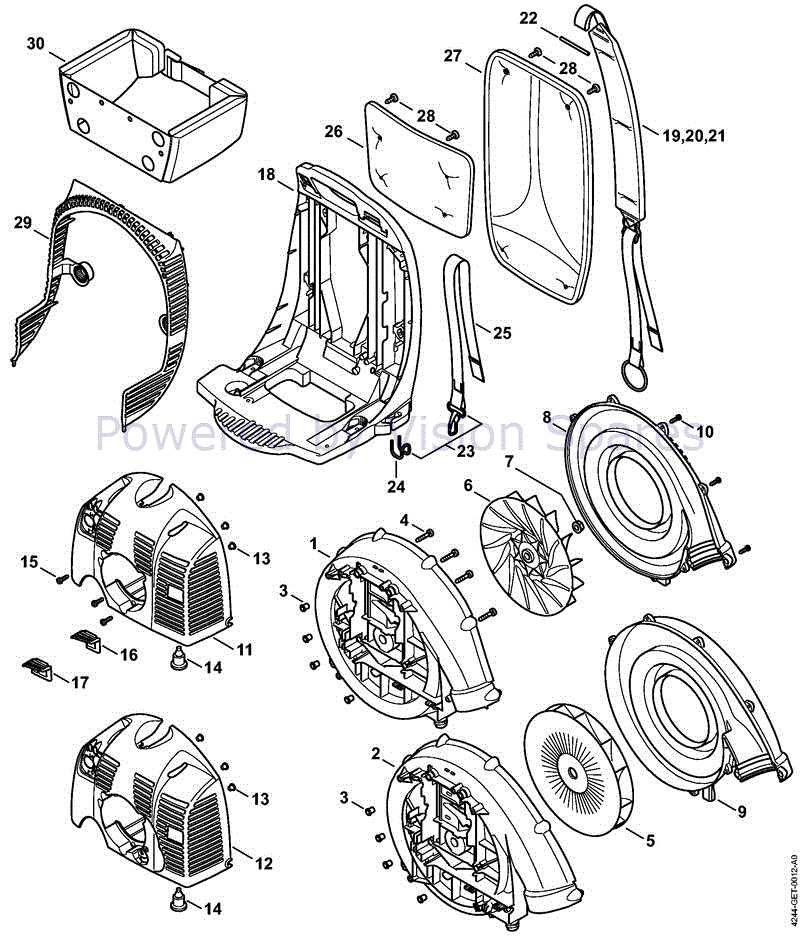

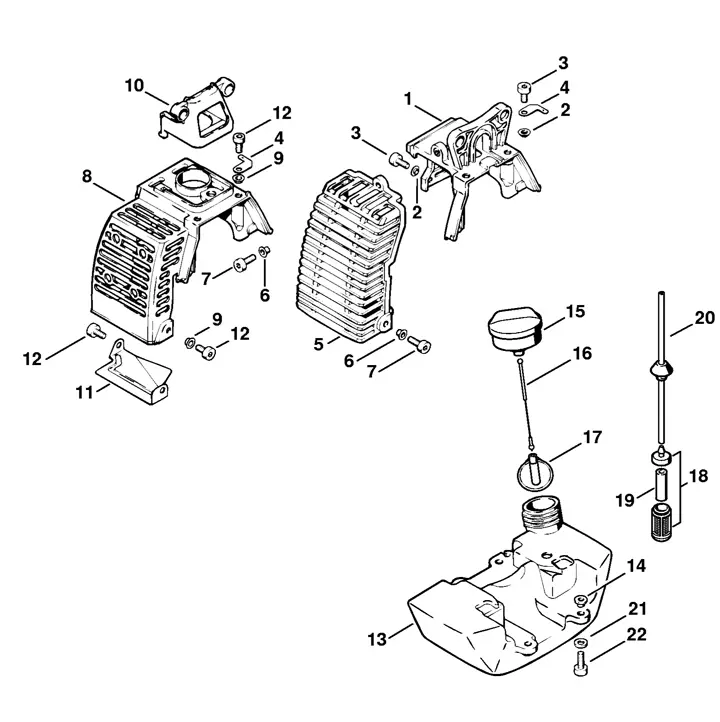

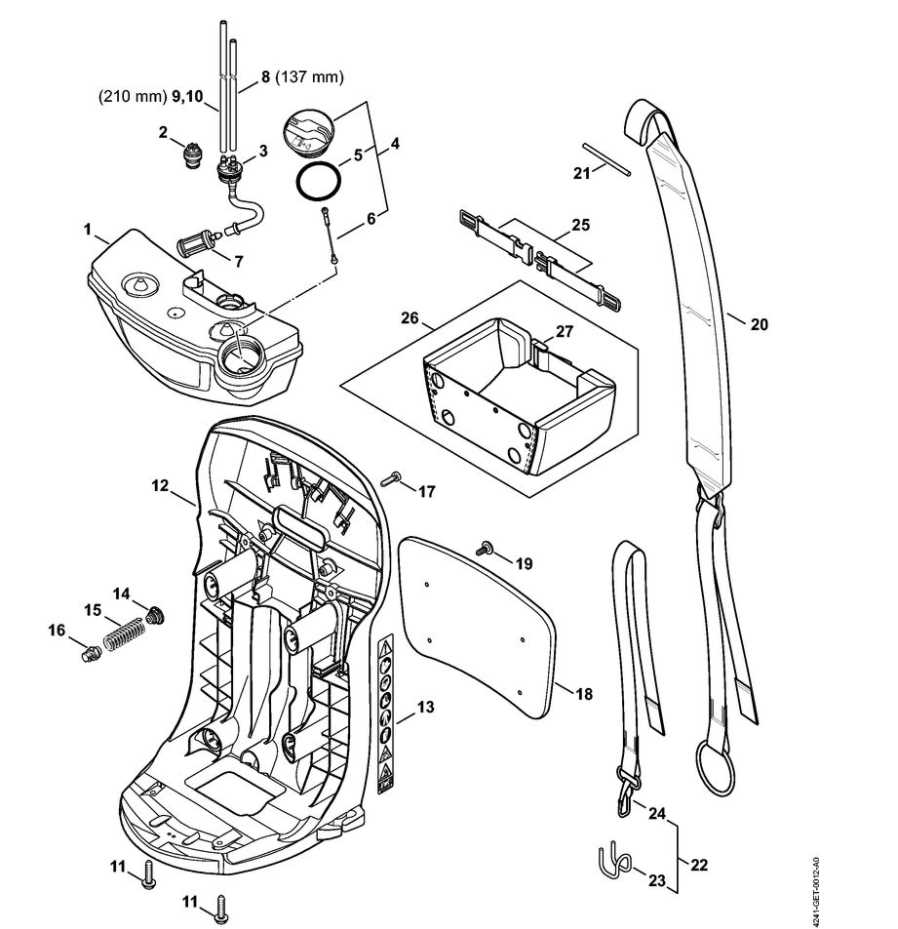

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential guides, allowing users to identify and locate specific elements within a complex assembly. This clarity enhances the overall efficiency of the repair process and minimizes the risk of errors.

Facilitating Repairs

Comprehending each segment through visual aids enables technicians to perform precise repairs. This reduces downtime and ensures that machinery operates optimally. Moreover, having a clear reference helps in troubleshooting issues more effectively.

Enhancing Knowledge

Utilizing visual resources deepens one’s understanding of how various components interact within a system. Familiarity with these interactions fosters a greater appreciation for the engineering behind the equipment, ultimately contributing to more informed operational decisions.

How to Read a Parts Diagram

Understanding an assembly representation is crucial for anyone looking to maintain or repair their equipment. These visual guides provide a clear overview of components and their relationships, making it easier to identify necessary replacements or repairs. Familiarizing yourself with this type of illustration can significantly enhance your troubleshooting skills and efficiency.

Start by examining the layout of the illustration. Typically, components are numbered or labeled, allowing for easy identification. Pay attention to the legend or key, which often explains the symbols or markings used. This will help clarify any unfamiliar notations.

Next, note the orientation of each element. Some representations depict parts from specific angles, which can influence how they fit together. Understanding this perspective is essential for proper assembly and disassembly. Additionally, recognizing groupings or sections within the visual can aid in navigating the complexities of the assembly.

Lastly, always cross-reference with the user manual or service guide when possible. These documents often provide additional insights and context that enhance the information found in the visual guide. By combining both resources, you can achieve a more comprehensive understanding of the equipment and its components.

Common Parts for Stihl BR 450 C

This section highlights essential components commonly found in the specified equipment, providing insight into their functions and importance for optimal performance. Understanding these elements can enhance maintenance practices and ensure longevity.

| Component | Description |

|---|---|

| Fuel Tank | Holds the mixture of fuel and oil necessary for operation. |

| Air Filter | Prevents debris from entering the engine, ensuring efficient combustion. |

| Spark Plug | Ignites the fuel-air mixture, enabling the engine to start and run smoothly. |

| Cylinder | Where the fuel-air mixture is compressed and ignited, generating power. |

| Throttle Control | Regulates engine speed and power output during operation. |

| Exhaust System | Directs gases away from the engine, helping to maintain performance and reduce noise. |

Where to Find Replacement Parts

Locating the necessary components for your equipment can be crucial for maintaining its performance. Various sources provide access to high-quality items, ensuring you keep your machine running efficiently. Whether you’re looking for original manufacturers or aftermarket alternatives, options abound to suit your needs.

| Source Type | Description |

|---|---|

| Authorized Dealers | Official retailers provide genuine components with reliable support. |

| Online Marketplaces | Websites like eBay and Amazon often have a wide variety of components available. |

| Local Hardware Stores | Many local shops carry popular items and can assist with special orders. |

| Manufacturer’s Website | The official website typically lists all available components and where to find them. |

| Specialty Repair Shops | These establishments often have unique items and expert advice. |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By implementing a routine maintenance schedule, you can significantly enhance performance and extend the lifespan of your machinery. Simple practices can make a substantial difference in how well your tools operate over time.

Regular Cleaning

Keeping your equipment clean is essential. Dirt and debris can cause wear and hinder functionality. After each use, wipe down surfaces, and periodically check for buildup in critical areas to prevent clogs and overheating.

Inspect and Replace Worn Components

Regularly examine all parts for signs of wear or damage. Timely replacement of worn elements can prevent larger issues down the line. Always refer to the manufacturer’s recommendations for replacement intervals and suitable materials.

Identifying Issues with Your Equipment

Understanding the common problems that can arise with your machinery is crucial for maintaining optimal performance. Regular inspections can help you detect issues before they escalate, saving you time and money. It’s essential to recognize the signs that indicate something may be wrong, ensuring your tool operates effectively.

Listen for Unusual Noises: Strange sounds can be a clear indication of underlying issues. Pay attention to any grinding or rattling noises that may suggest wear or damage.

Check for Vibrations: Excessive vibration can signal a misalignment or imbalance in the equipment. If you notice a change in how your tool feels during operation, investigate further.

Monitor Performance: A decrease in efficiency or power can indicate a need for maintenance. If your equipment struggles to perform its tasks, it may be time to examine key components.

Inspect for Leaks: Fluid leaks can point to seal or hose failures. Regularly checking for any signs of leaking can help prevent more serious damage.

Review the Maintenance Schedule: Adhering to a consistent maintenance routine can mitigate many common issues. Always refer to your manufacturer’s guidelines to ensure longevity.

By staying vigilant and proactive, you can ensure your machinery remains in top condition, ultimately enhancing its lifespan and effectiveness.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor equipment, having the right instruments is essential for ensuring efficient and effective repairs. A well-equipped toolkit not only simplifies the process but also enhances safety and precision. Understanding which tools are necessary can make a significant difference in achieving optimal performance.

Essential Hand Tools

Basic hand tools such as screwdrivers, wrenches, and pliers are fundamental for any repair task. These items allow for adjustments, replacements, and maintenance without the need for complicated machinery. Ensuring these tools are in good condition will facilitate smoother operations during the repair process.

Power Tools and Accessories

In addition to hand tools, power tools can greatly expedite the repair process. Drills, saws, and other powered instruments can handle tougher tasks with ease. Moreover, having the appropriate accessories, like drill bits and blades, is crucial for tackling various challenges effectively.

Assembly Process Explained

The assembly process is a crucial aspect of ensuring that machinery operates effectively and efficiently. This stage involves a series of systematic steps that lead to the proper configuration of components, which are vital for optimal performance. Understanding this sequence not only aids in effective assembly but also contributes to longevity and reliability of the equipment.

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools required for assembly. |

| 2 | Carefully examine each part for defects or damages before starting. |

| 3 | Follow the specific order of assembly as outlined in the manual. |

| 4 | Secure components tightly to prevent any operational issues. |

| 5 | Test the assembled unit to ensure everything functions as intended. |

Cost Considerations for Replacement Parts

When it comes to maintaining outdoor power equipment, budgeting for components is crucial. Understanding the expenses associated with replacements can significantly impact overall operational costs. Various factors influence pricing, including quality, brand reputation, and sourcing options.

Factors Influencing Costs

Numerous elements contribute to the final price of components. The choice between original equipment and aftermarket options often presents a cost dilemma. Additionally, the complexity of the part, availability, and market demand can also affect pricing.

Cost Comparison Table

| Type | Average Cost | Longevity |

|---|---|---|

| OEM Components | $100 – $300 | 5 – 10 years |

| Aftermarket Components | $50 – $200 | 2 – 5 years |

| Used Components | $20 – $100 | 1 – 3 years |

Safety Precautions During Repairs

Engaging in maintenance and repair activities requires a careful approach to ensure personal safety and the proper functioning of equipment. By adhering to specific guidelines, individuals can minimize the risks associated with handling tools and machinery. Understanding these precautions is essential for a successful and safe repair process.

Always wear appropriate personal protective equipment. This includes gloves, goggles, and sturdy footwear to shield against potential hazards. Such gear significantly reduces the risk of injury from sharp components or flying debris during disassembly and reassembly.

Ensure the equipment is powered down and disconnected from any power source before beginning any repair tasks. This step is crucial to prevent accidental activation, which could lead to serious injuries. Additionally, allow any hot components to cool down adequately to avoid burns.

Maintain a clean and organized workspace. Clutter can lead to accidents and make it difficult to locate essential tools or parts. Keeping everything in order also allows for a more efficient workflow, enabling repairs to be completed in a timely manner.

Lastly, familiarize yourself with the equipment’s manual. Understanding the specific assembly and disassembly processes is vital for safety and efficacy. If uncertain about any step, consulting the manual or seeking professional assistance is highly advisable.