Comprehensive Guide to Stihl Parts Diagrams

When dealing with complex machinery, it is essential to have a clear understanding of how each individual element connects and functions within the entire system. Knowing the specific arrangement of various mechanisms can make repairs and maintenance much more efficient. By visualizing the structural blueprint of these components, users can easily identify what needs attention and how to proceed with necessary adjustments.

Each machine, regardless of its complexity, has a detailed structure where every piece plays a critical role. Whether it’s addressing performance issues or simply replacing worn-out elements, understanding how everything fits together allows for smoother operation and extended equipment life. This section will guide you through the intricate assembly, offering clarity on how everything is organized to work seamlessly.

Comprehensive Overview of Equipment Components

Understanding the various elements that make up mechanical tools is crucial for both maintenance and repairs. Each device consists of an array of interconnected pieces, all working together to ensure optimal performance and longevity. Recognizing how these elements interact provides a solid foundation for troubleshooting and enhancing functionality.

Below is a detailed breakdown of essential components commonly found in equipment, along with their respective roles:

| Component | Description | Function | ||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power Source | The primary element that provides energy for the device to operate. | Supplies the necessary force to drive all other mechanisms. | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Drive Mechanism | A system responsible for transferring energy from the source to the working parts. | Converts energy into motion to perform the intended tasks. | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Component | Description | Function | ||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Block | The main body of the machine where energy is generated. | Converts fuel into mechanical power. | ||||||||||||||||||||||||||||||||||||||

| Drive Mechanism | A system of gears and shafts responsible for motion. | Transmits power from the engine to other moving parts. | ||||||||||||||||||||||||||||||||||||||

| Control Lever | A manual interface used to regulate machine operations. | Adjusts speed, direction, or function of the equipment. | ||||||||||||||||||||||||||||||||||||||

| Cutting Tool |

| Component | Common Symptoms | Recommended Solutions |

|---|---|---|

| Ignition Module | Difficulty starting, irregular engine operation | Check connections; replace if damaged |

| Fuel Filter | Reduced power, stalling | Clean or replace to ensure proper fuel flow |

| Chain Brake | Chain does not stop, excessive vibration | Inspect for wear; adjust or replace as needed |

| Air Filter | Loss of power, poor acceleration | Clean regularly; replace if severely clogged |

| Clutch | Slipping, unusual noise during operation | Inspect for wear; replace if necessary |

Insights into Mechanical Structure for Repairs

Understanding the intricate design of machinery is crucial for effective maintenance and troubleshooting. This knowledge allows technicians to identify components and their relationships within a system, facilitating quicker and more efficient repairs. An in-depth exploration of the mechanical architecture can reveal potential issues before they escalate, ensuring optimal performance and longevity of the equipment.

Key Components and Their Functions

Each element within a mechanical assembly plays a specific role in the overall operation. Recognizing these functions aids in diagnosing faults and streamlining repair processes. The following table summarizes common elements and their purposes:

| Component | Function |

|---|---|

| Engine | Generates power for operation |

| Fuel System | Supplies the necessary fuel to the engine |

| Ignition System | Starts the combustion process |

| Cooling System | Prevents overheating of the engine |

| Lubrication System | Reduces friction between moving parts |

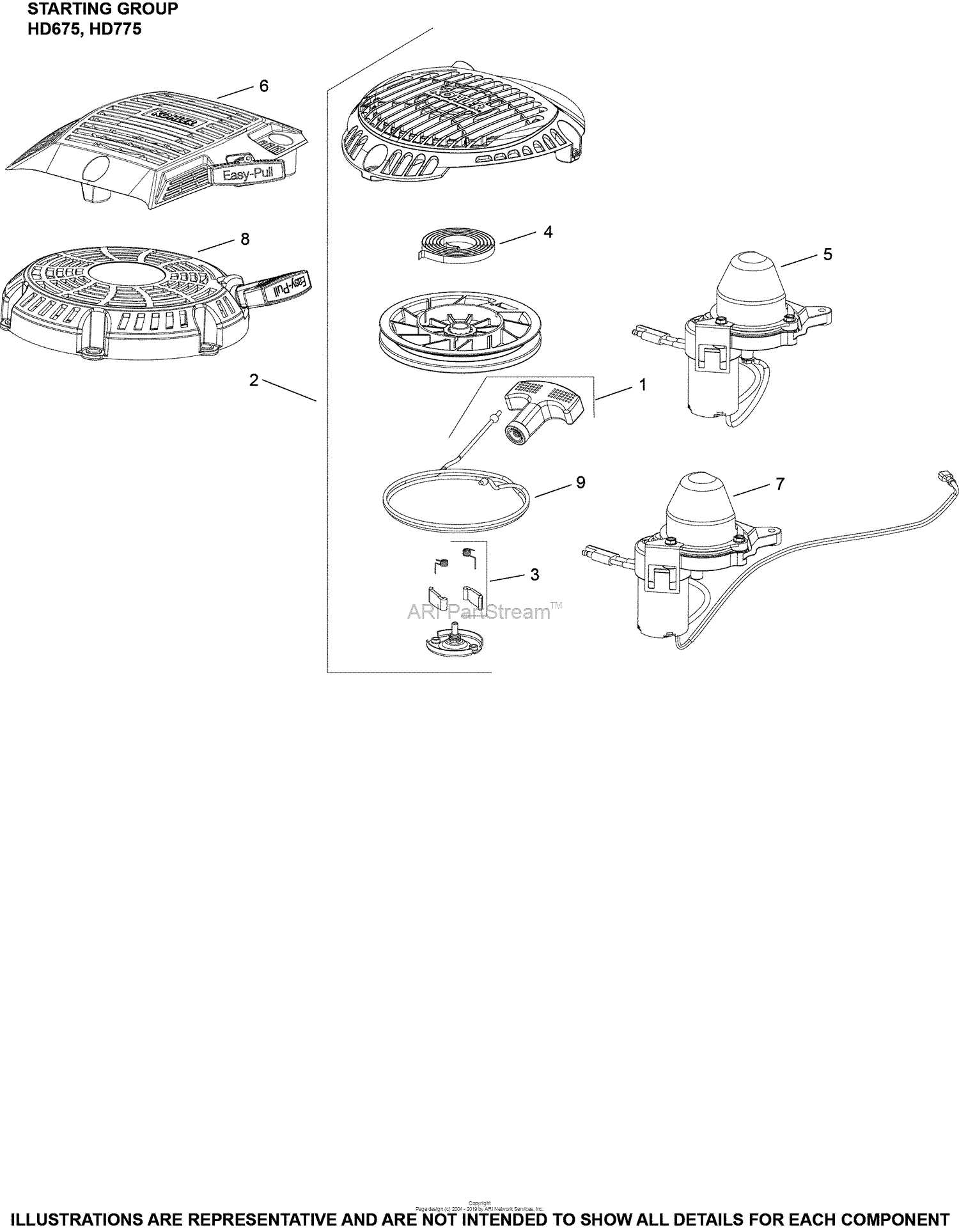

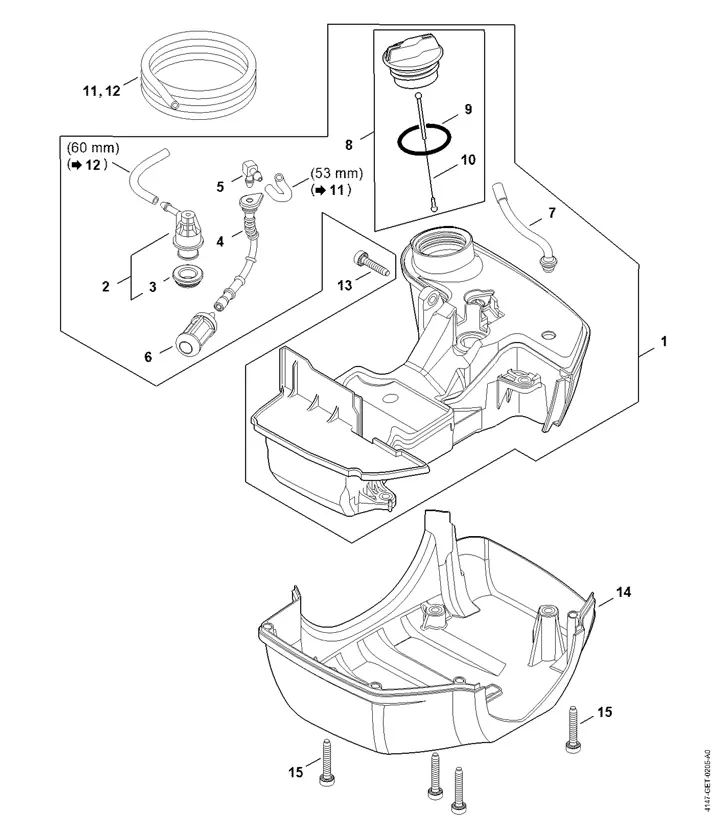

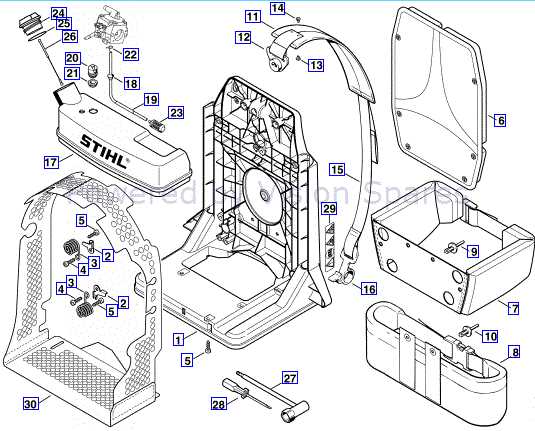

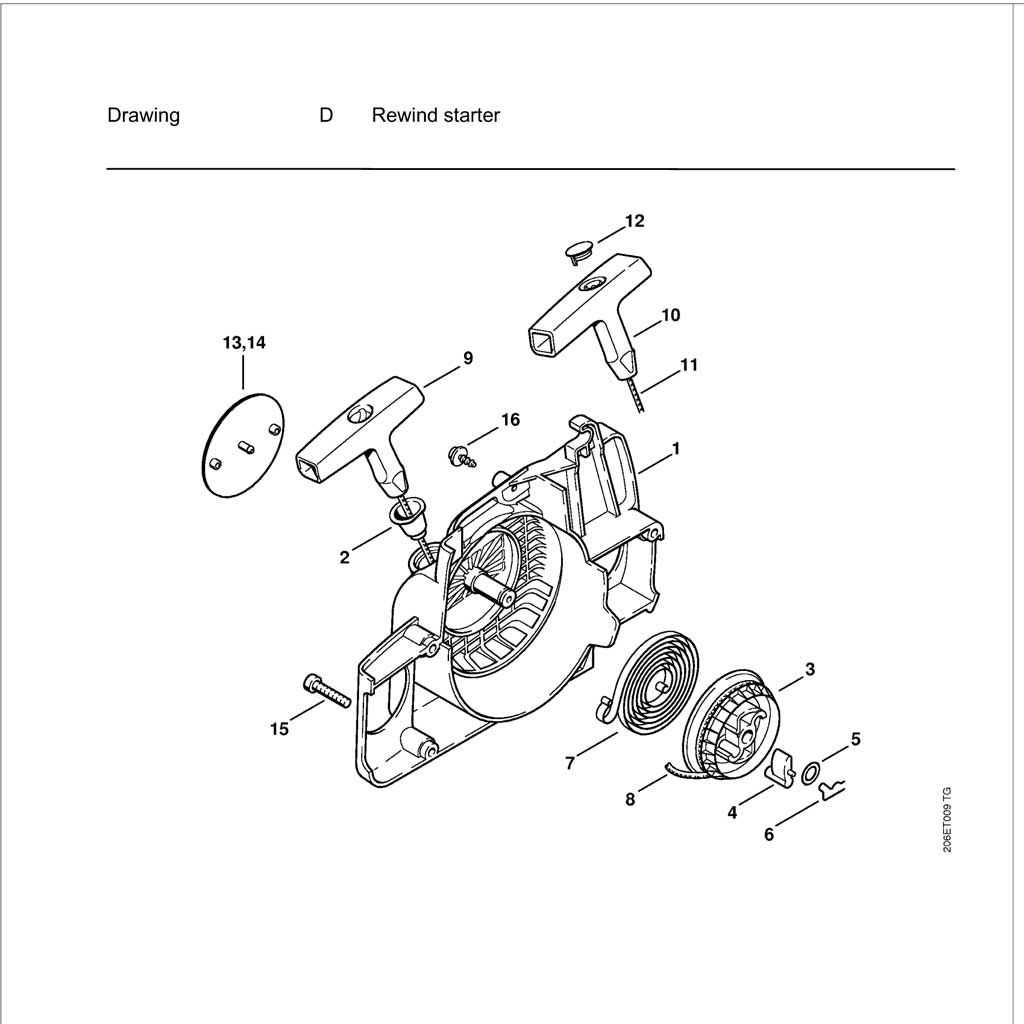

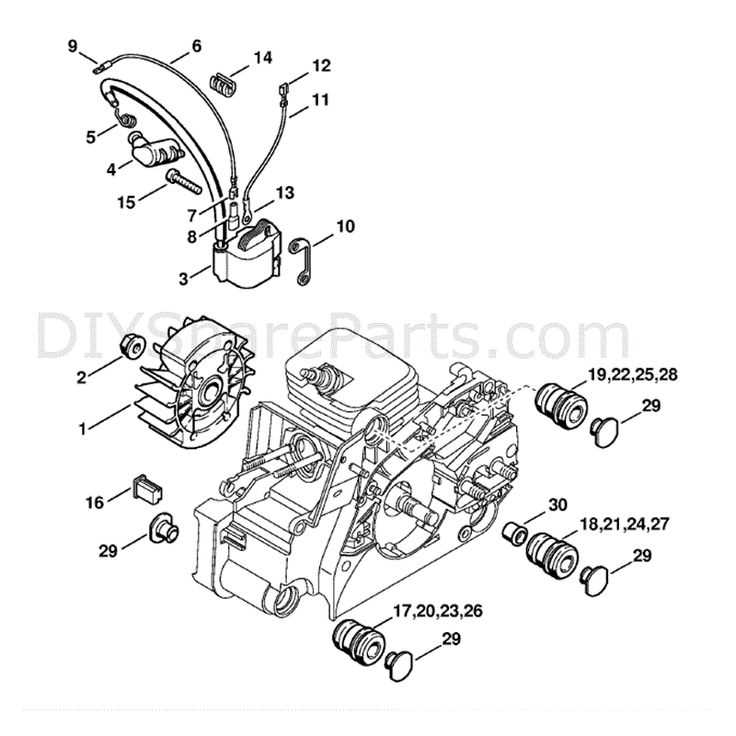

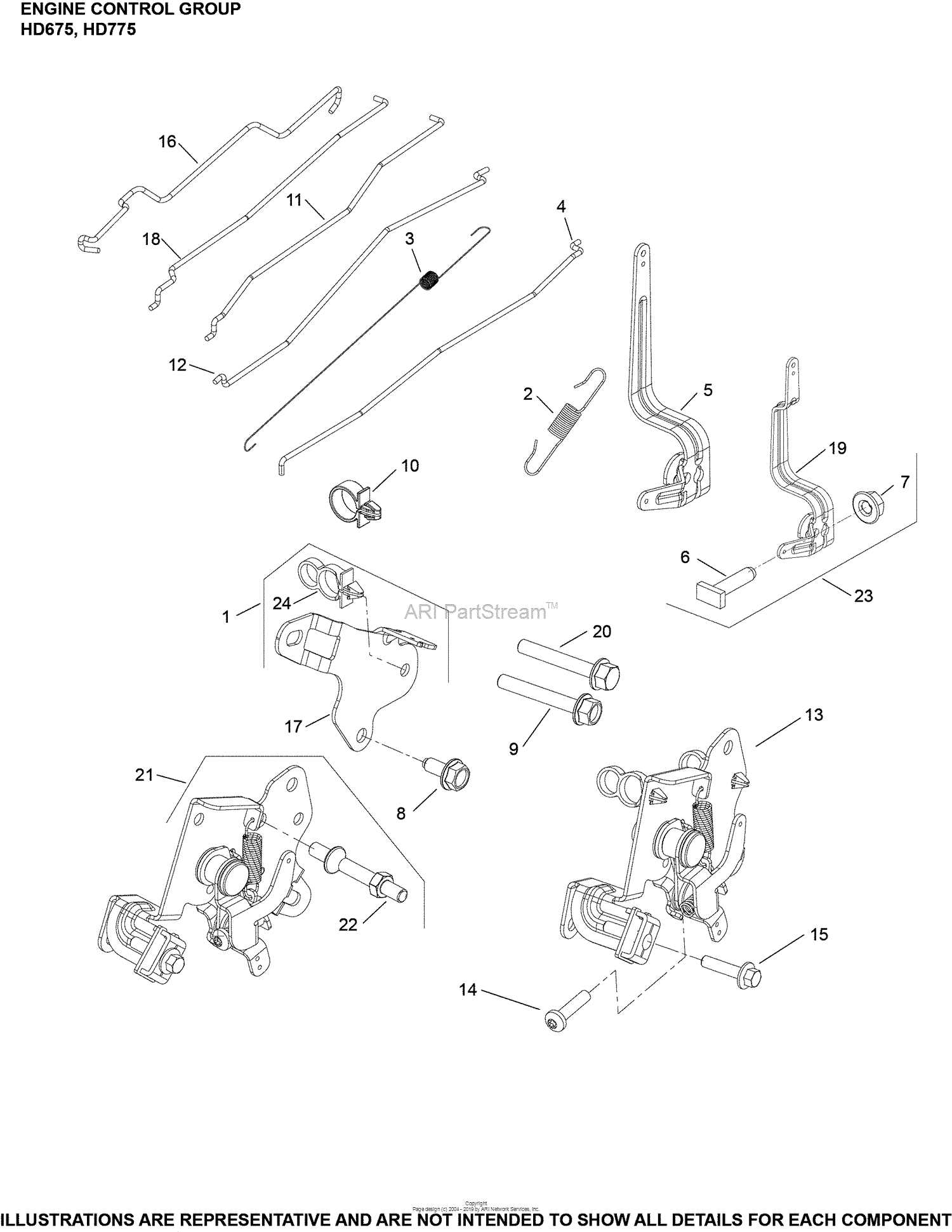

Understanding Assembly Layouts

Familiarity with assembly layouts enables technicians to navigate complex structures with ease. Each layout presents a visual representation of how components interact, making it easier to pinpoint areas requiring attention. By analyzing these arrangements, one can approach repairs methodically, ensuring that all necessary adjustments are made without overlooking critical aspects.

Replacing and Upgrading Individual Parts

Maintaining the efficiency and longevity of your equipment often involves replacing or enhancing specific components. This process not only ensures optimal performance but can also introduce new features or improved functionality. Understanding the steps involved in this task is essential for achieving successful outcomes.

Identifying Components for Replacement

Begin by assessing the current condition of each component. Look for signs of wear and tear, damage, or inefficiency. Common elements to consider include:

- Blades or cutting tools

- Filters and air intakes

- Fuel lines and hoses

- Electrical connectors and switches

Steps for Replacement and Upgrade

- Gather Necessary Tools: Ensure you have the required tools on hand for disassembly and assembly.

- Consult the Manual: Refer to the manufacturer’s manual for specific instructions on removing and installing each component.

- Carefully Disassemble: Take your time when removing the existing components to avoid damaging surrounding areas.

- Install New Components: Follow the instructions meticulously to ensure correct placement and secure fit.

- Test the Equipment: After reassembly, conduct a thorough test to confirm proper functionality.

Tips for Using Diagrams in Troubleshooting

Utilizing visual representations can significantly enhance the process of diagnosing issues in machinery and equipment. These illustrations serve as valuable tools for understanding complex systems and identifying potential failures. Here are some effective strategies to maximize the benefits of these resources during troubleshooting.

Firstly, familiarize yourself with the symbols and notations used in the visuals. Each illustration may employ unique markings, which can convey critical information regarding the components and their interconnections. Understanding these elements will enable you to navigate the visual guide more efficiently.

Secondly, take a systematic approach to analysis. Begin by examining the overall layout before zooming in on specific areas of interest. This helps in maintaining a comprehensive perspective while identifying localized problems.

| Strategy | Description |

|---|---|

| Familiarize with Symbols | Understand the unique markings and notations used in the visuals. |

| Systematic Approach | Examine the overall layout before focusing on specific areas. |

| Cross-Reference with Manuals | Use accompanying documentation for additional context and clarification. |

| Consult Online Resources | Look for forums or tutorials that provide insights into common issues and solutions. |

Lastly, consider engaging with online communities or forums where enthusiasts share their experiences. These platforms can provide additional insights and alternative solutions that may not be covered in the visual materials.

Enhancing Equipment Lifespan through Proper Care

Maintaining the functionality and longevity of your machinery is essential for optimal performance. By adopting routine maintenance practices, you can prevent unexpected breakdowns and enhance the efficiency of your tools. Proper care not only extends the life of your equipment but also ensures that it operates safely and reliably, providing you with peace of mind during use.

Regular Maintenance Practices

Implementing a consistent maintenance schedule is crucial. This includes checking fluid levels, cleaning filters, and inspecting components for wear and tear. Regularly replacing worn parts and addressing minor issues before they escalate can significantly reduce the risk of costly repairs. Following the manufacturer’s guidelines for maintenance intervals is also vital in preserving the integrity of your equipment.

Safe Storage and Usage

In addition to regular upkeep, storing your tools properly when not in use is essential for prolonging their lifespan. Keep equipment in a dry, protected environment to prevent rust and corrosion. Utilizing appropriate protective gear during operation not only safeguards the user but also minimizes the likelihood of damage to the machinery. Adopting these practices will ensure that your tools remain in optimal condition for years to come.

Choosing the Right Replacement Parts for Performance

Selecting appropriate components for machinery is essential to ensure optimal functionality and longevity. The performance of equipment can significantly depend on the quality and compatibility of these elements. Understanding the specific requirements of your machinery and the role of each component is vital in making informed decisions.

Understanding Compatibility and Quality

When seeking new components, it’s crucial to consider their compatibility with your existing machinery. High-quality replacements that meet the original specifications can enhance performance and reduce the risk of malfunctions. Look for reputable brands that offer detailed information on their products to ensure a reliable match.

Assessing Your Needs

Evaluate the specific demands of your equipment and the conditions under which it operates. Identifying the right components based on these factors can lead to improved efficiency and reduced wear. Conduct thorough research and consult with experts if necessary to make choices that align with your performance goals.