John Deere 455 60 Mower Deck Parts Overview

Understanding the essential components of your lawn care machinery is key to maintaining optimal performance. Whether you’re looking to replace a worn-out element or just want to familiarize yourself with the various parts, knowing what to look for can save time and effort. A detailed reference can provide clarity on how each component contributes to the overall function of the system.

In this section, we will break down the critical elements that make up the equipment’s cutting mechanism. This will include a closer look at the various sections and tools involved, providing you with a thorough overview of the layout. Understanding the specific roles of each piece ensures better care and longevity for your machine.

Essential Components of the John Deere 455 Deck

The key to maintaining optimal performance in any grass cutting system lies in understanding the various critical elements involved in its operation. Each component plays a vital role in ensuring smooth functionality, durability, and ease of maintenance. From the primary cutting mechanism to the supporting structure, each part contributes to the overall effectiveness of the equipment.

- Cutting Blades: The primary elements responsible for achieving clean and efficient cuts. These blades are designed for durability and precision, allowing for an even finish on a variety of surfaces.

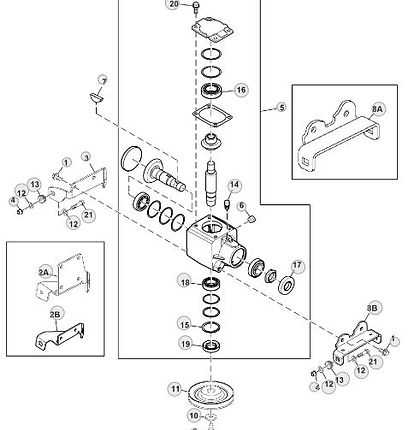

- Spindle Assembly: A crucial part that houses the cutting blades and ensures their rotation. Proper maintenance of this component is necessary to avoid performance issues.

- Drive Pulley: Transfers power from the engine to the cutting blades, allowing them to rotate at the required speed for optimal operation.

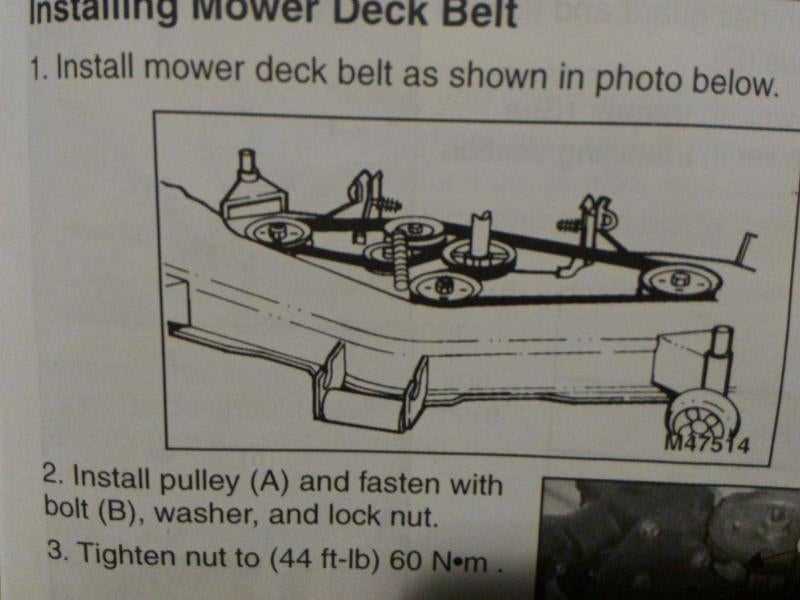

- Belts: These flexible elements connect various moving parts, ensuring that power is distributed efficiently from the engine to the blades and other mechanisms.

- Frame Structure: The backbone of the system, providing stability and housing other components. It ensures the longevity of the entire system by distributing stresses evenly during use.

- Height Adjustment Mechanism: Allows operators to adjust the cutting height for different grass types and conditions, offering versatility in the equipment’s performance.

- Anti-Scalping Wheels: Prevent the cutting mechanism from coming into contact with the ground excessively, thus protecting the surface from damage.

Each of these components must be regularly inspected and maintained to ensure consistent and effective operation. Neglecting any part can lead to decreased performance or even equipment failure. Understanding how they work together is essential for keeping your system running smoothly throughout its lifespan.

Understanding the Mower Deck Assembly

In this section, we will explore the fundamental structure and key components involved in assembling the cutting mechanism of a lawn care machine. The system is designed to facilitate precise grass trimming and ensure optimal performance during operation. Each element plays a crucial role in maintaining the functionality and efficiency of the overall system.

The assembly consists of various interconnected parts that work in harmony to achieve a smooth and even cut. These components include rotating blades, supporting brackets, and the mechanism that drives the rotation. Proper understanding of these elements is essential for effective maintenance and troubleshooting.

By examining the overall assembly, users can gain insights into the optimal alignment and connection of the parts. This knowledge ensures that the machine operates safely and effectively, providing consistent results with every use. Regular inspection and careful handling of these components will help prolong the lifespan of the equipment.

Key Parts for Efficient Mowing

To achieve optimal results in lawn care, having the right components in place is essential. Each element of the equipment plays a crucial role in ensuring smooth performance and precise cutting. Understanding the importance of these key components can enhance efficiency and minimize downtime during operations.

Blades are the core element responsible for delivering a clean and even cut. Their sharpness and durability determine the quality of the finished lawn. Regular maintenance and timely replacement are critical for maintaining performance.

Spindles support the rotation of the blades, making it possible for them to cut the grass effectively. These parts must be robust and well-lubricated to prevent damage during operation.

Bearings play a vital role in reducing friction, ensuring that moving parts function smoothly. Properly maintained bearings extend the life of the entire system and reduce wear and tear on other components.

Belts transfer power from the engine to the cutting mechanism. Regular inspections are necessary to avoid slippage or breakage, which can disrupt operations.

Each of these elements works together to enhance performance. Keeping them in top condition is key to achieving consistent and high-quality results with minimal effort.

Tools Required for Deck Maintenance

Maintaining a lawn care apparatus involves using several essential tools to ensure optimal performance and longevity. Proper upkeep requires specific instruments designed for precision and ease of use during disassembly and cleaning procedures. Having the right equipment on hand can significantly reduce the time spent on repairs and enhance the efficiency of the entire process.

Wrenches are necessary for loosening and tightening bolts securely. They come in various sizes to accommodate different fasteners, ensuring a tight fit and avoiding damage to parts. For more complex tasks, an impact wrench may be used to expedite the process.

For safe handling and removal of components, screwdrivers of various types and sizes will help in accessing smaller fasteners. Additionally, pliers are useful for gripping and pulling parts that may be stuck or difficult to handle.

Cleaning tools such as wire brushes and scrapers are essential for removing debris and buildup from surfaces, ensuring everything runs smoothly and safely. To finish, lubricants and grease should be applied to moving parts to reduce wear and tear.

Replacing Blades and Spindles

Maintaining the cutting elements and support systems of your equipment is crucial for ensuring optimal performance. This section covers the process of replacing key components that directly impact cutting efficiency. Understanding how to properly replace the blades and spindles will extend the lifespan of the machine and improve its overall cutting quality.

Steps for Replacing Blades

When the cutting edges become dull or damaged, it’s essential to replace them promptly to maintain precision and safety. Begin by lifting the machine for easy access to the blades. After removing any covers or protective shields, detach the old blades and install the new ones. Make sure they are securely fastened, as any looseness can cause damage or a reduction in cutting performance.

Steps for Replacing Spindles

The spindles are responsible for rotating the blades. Over time, they may become worn or damaged, resulting in reduced efficiency. To replace the spindles, first, ensure the machine is safely positioned and all necessary safety precautions are followed. After removing the old spindles, install the new ones and make sure they are aligned properly to ensure smooth operation. Tighten the bolts securely to avoid future issues.

| Component | Replacement Procedure | Tools Required |

|---|---|---|

| Blades | Lift the equipment, remove the old blades, and install the new ones securely. | Wrench, socket set |

| Spindles | Detach old spindles, align and attach new ones, then tighten all bolts properly. | Socket wrench, safety gloves |

How to Troubleshoot Deck Issues

When experiencing difficulties with the cutting equipment of your machine, it is essential to identify the root cause and apply the appropriate fixes. Proper troubleshooting helps to avoid unnecessary repairs and ensures the smooth operation of the system. This guide covers common problems and their solutions to get the equipment functioning optimally.

Identify the Problem

Start by thoroughly inspecting the area to identify symptoms that could indicate underlying issues. Look for unusual noises, uneven cuts, or lack of power during operation. It is important to check for the following common factors:

- Blades not spinning correctly

- Uneven cutting pattern

- Unusual vibrations

- Excessive wear on components

Common Solutions

Once the problem is identified, apply the following steps to address it:

- Inspect and Replace Blades: If the blades are dull, bent, or broken, they can cause poor cutting performance. Regularly inspect the condition of the blades and replace them as necessary.

- Check Belt Tension: Loose or broken belts can hinder proper functioning. Ensure belts are tight and in good condition, replacing any damaged ones.

- Clean and Lubricate: Dirt and debris can accumulate, affecting the smooth operation of components. Clean thoroughly and lubricate moving parts to reduce wear.

- Examine Bearings and Spindles: Worn or damaged bearings and spindles can cause unusual vibrations and reduce efficiency. Inspect and replace if necessary.

Step-by-Step Deck Disassembly Guide

In this section, we will explore a structured approach to taking apart your equipment’s cutting mechanism. This guide will help you break down the components carefully and effectively, ensuring that each piece is handled with precision and care. Proper disassembly is crucial for both maintenance and troubleshooting tasks.

1. Preparation: Begin by ensuring that the equipment is turned off, and the engine is cool. Gather the necessary tools, such as wrenches, screwdrivers, and a container to keep small parts organized. Safety is key, so always wear protective gloves and eye protection.

2. Remove the Blade Assembly: Start by detaching the cutting blades. Loosen the bolts securing the blades and gently remove them from the mounting area. Store the blades in a safe location for reassembly or sharpening later.

3. Disconnect the Drive Mechanism: Next, detach the drive system connected to the cutting assembly. This might involve removing a belt or unfastening bolts that secure the drive shaft. Make sure to note how the components are connected for easier reinstallation.

4. Detach the Frame: Once the moving parts are detached, proceed with removing the outer frame that houses the cutting mechanism. This step may require loosening additional bolts or fasteners, so keep track of where each fastener is located.

5. Inspect and Clean: With the main components removed, take this opportunity to inspect all parts for wear or damage. Clean the surfaces and lubricate any moving parts that require maintenance. This will help extend the life of your equipment and ensure smooth operation when reassembled.

By following these steps methodically, you can disassemble the system without causing any damage, preparing it for maintenance or replacement tasks as needed.

Upgrading Your Deck for Better Performance

Improving the efficiency and functionality of your cutting system is essential for achieving superior results. Enhancing the quality of your equipment not only increases performance but also extends the life of your machinery. By upgrading specific components, you can achieve smoother operation and more consistent cutting results, no matter the terrain or conditions.

- Consider installing high-performance blades that offer improved cutting precision.

- Upgrade to reinforced spindles to enhance stability and reduce wear on moving parts.

- Ensure that the belt system is optimized for maximum power transmission efficiency.

- Look into advanced wheel adjustments that provide better ground clearance and maneuverability.

These improvements can help reduce maintenance costs and increase the overall performance of your equipment. Be sure to regularly check the alignment and condition of the upgraded components to maintain their effectiveness over time.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the long-lasting performance of your equipment. Regular attention not only prevents unexpected breakdowns but also helps in maintaining its efficiency over time. Following simple maintenance practices can significantly extend the lifespan of the machine and enhance its operational reliability.

Regular Cleaning

One of the most crucial steps in maintaining your equipment is regular cleaning. Debris such as dirt, grass, and mud can accumulate and cause wear and tear on various components. It is important to thoroughly clean the machine after each use to prevent buildup and potential damage.

Lubrication and Inspection

Ensure all moving parts are properly lubricated to reduce friction and avoid unnecessary wear. Regularly check for signs of rust or corrosion, and replace any worn-out parts promptly. Routine inspections allow you to catch small issues before they develop into costly repairs.

Common Problems with the 455 Deck

The 455 model is known for its robust design, but like any mechanical system, it can face certain issues over time. Regular usage and wear can lead to several common challenges that owners may encounter. These problems often revolve around the functionality of the cutting system, alignment, and the smooth operation of the overall unit.

One frequent issue is uneven cutting, which may result from dull or misaligned blades. This can create an uneven appearance on the lawn and often indicates the need for blade maintenance or adjustment. Another common problem is belt slippage, which can hinder proper operation and reduce performance. This may require checking the tension and condition of the belts to ensure they are functioning optimally.

Owners may also experience difficulty with the height adjustment system, causing inconsistent cutting levels. The components involved in this mechanism can wear out, requiring repairs or replacements to restore the desired functionality. Lastly, vibrations and noise can be signs of loose or damaged parts, indicating the need for routine inspections and tightening of any loose connections.