Comprehensive Guide to Stihl 018 Parts Diagram

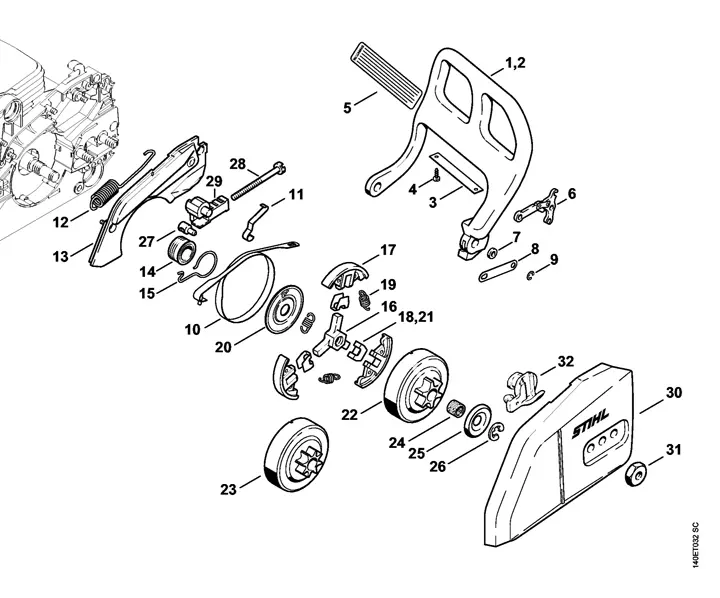

When it comes to maintaining and repairing outdoor power equipment, having a clear understanding of its various elements is crucial. A comprehensive exploration of these components not only facilitates smoother operation but also extends the longevity of the machine. Knowing how each piece functions together allows users to optimize performance and address any issues that may arise.

In this section, we will delve into a visual representation of the key elements that make up a popular model of chain saw. This overview will highlight the ultimate significance of each component, guiding enthusiasts and professionals alike in their maintenance tasks. By familiarizing yourself with these intricate details, you can ensure that your equipment remains in top-notch condition for all your outdoor endeavors.

Overview of Stihl 018 Chainsaw

This section provides a comprehensive look at a popular model in the chainsaw lineup, known for its reliability and efficiency. Designed for both casual users and professionals, this machine offers a blend of power and precision that makes it suitable for various cutting tasks.

The engine is engineered to deliver robust performance while maintaining fuel efficiency, allowing for extended usage without frequent refueling. The lightweight design contributes to ease of handling, reducing user fatigue during prolonged operation.

Key features include an easy-start mechanism, ensuring quick ignition even in challenging conditions. Safety mechanisms, such as a chain brake, enhance user protection, making it a preferred choice for many operators.

With a reputation for durability, this model is equipped with high-quality components that withstand rigorous use. Maintenance is straightforward, with accessible parts designed to facilitate routine servicing and repairs.

In summary, this chainsaw exemplifies a perfect blend of power, safety, and ease of use, making it a reliable tool for anyone looking to tackle outdoor projects effectively.

Importance of Parts Diagrams

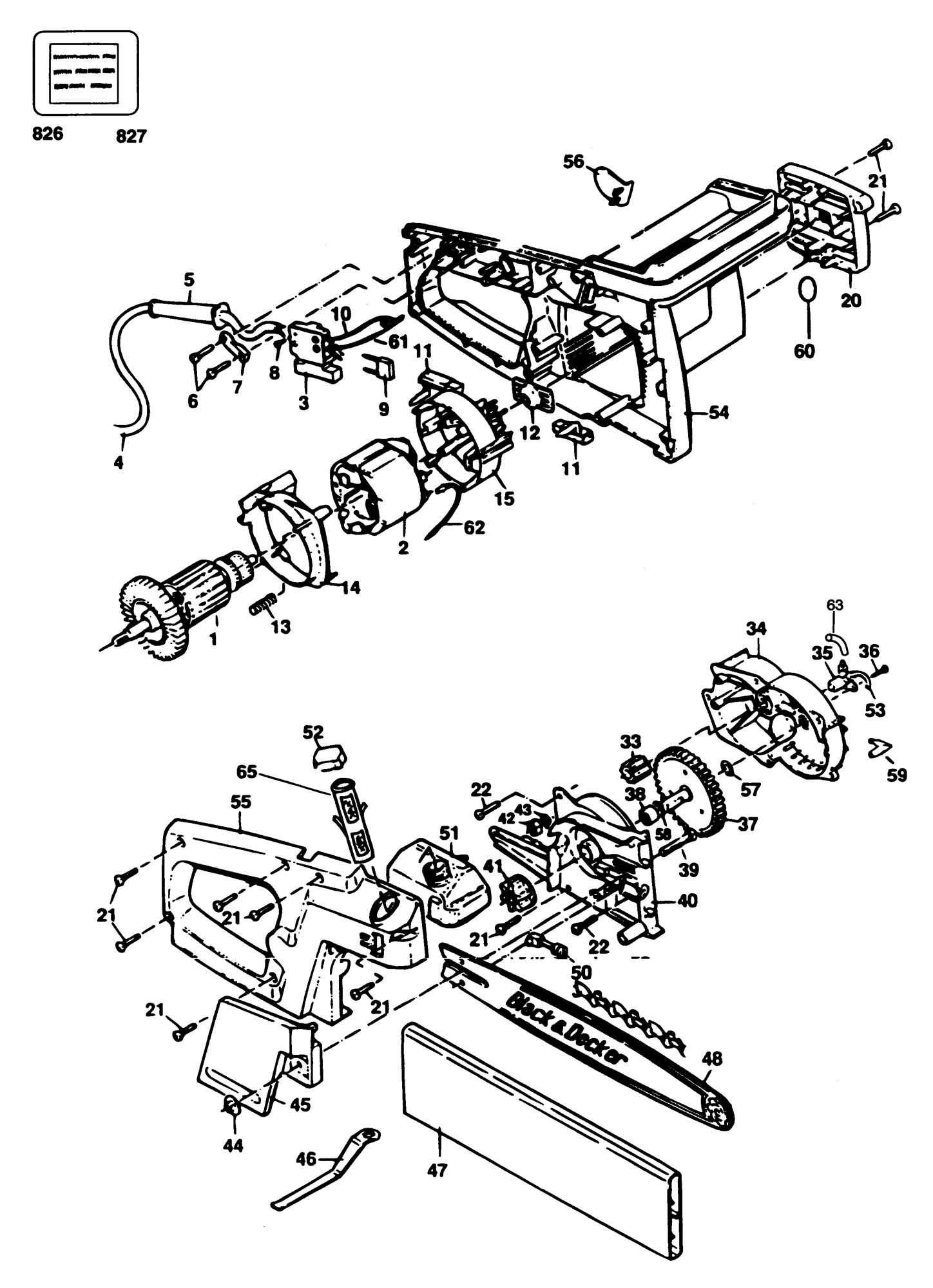

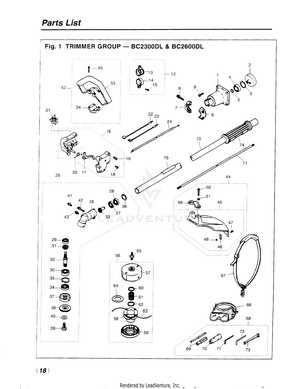

Understanding the intricacies of machinery is crucial for maintenance and repair. Visual representations of components enhance clarity, enabling users to identify and locate specific elements quickly. This knowledge is vital for ensuring optimal performance and longevity of equipment.

Benefits of Visual References

- Facilitates accurate identification of components.

- Simplifies the repair process by providing clear guidance.

- Helps in understanding assembly and disassembly procedures.

- Reduces the likelihood of errors during maintenance.

Enhanced Learning and Efficiency

- Encourages a deeper understanding of machine functionality.

- Promotes efficient troubleshooting techniques.

- Aids in inventory management for replacement items.

- Supports DIY enthusiasts in their repair endeavors.

Identifying Key Components

Understanding the essential elements of a machinery unit is crucial for maintenance and repair. Familiarizing yourself with these components not only enhances efficiency but also aids in troubleshooting issues. Each part plays a specific role, contributing to the overall functionality of the device.

Essential Elements Overview

The primary elements can be categorized based on their functions and importance. Recognizing these categories helps in systematically addressing any problems that may arise.

| Component | Function |

|---|---|

| Engine | Powers the unit, providing necessary energy for operation. |

| Guide Bar | Directs the cutting tool, allowing for precise cuts. |

| Chain | Engages with the guide bar to perform the cutting action. |

| Air Filter | Prevents debris from entering the engine, ensuring optimal performance. |

| Fuel Tank | Stores the fuel needed for operation. |

Importance of Proper Identification

Accurate identification of these components facilitates effective repairs and maintenance. When users know the specific roles of each element, they can make informed decisions about replacement and service, ultimately prolonging the lifespan of the equipment.

Common Replacement Parts

Maintaining outdoor power equipment often requires replacing certain components to ensure optimal performance and longevity. Understanding which elements are prone to wear can help users anticipate needs and minimize downtime.

Essential Components

Among the crucial items frequently replaced are filters, spark plugs, and chains. Regularly changing these components can significantly enhance the efficiency of the equipment and prevent potential malfunctions.

Indicators for Replacement

Signs such as decreased performance, unusual noises, or difficulty starting can indicate the necessity for component renewal. Proactive monitoring of these factors will lead to more effective upkeep and ultimately extend the life of the machinery.

Where to Find Diagrams

Locating detailed illustrations of equipment components can greatly enhance your repair and maintenance efforts. Various resources are available to help you access these valuable visuals.

- Official Manufacturer Websites: Many manufacturers provide downloadable resources directly on their sites.

- Online Retailers: Websites that sell replacement components often include visual guides for reference.

- Forums and Community Groups: Engaging with fellow enthusiasts can lead to shared resources and insights.

- Service Manuals: Printed or digital manuals often contain detailed schematics useful for troubleshooting.

Utilizing these avenues will ensure you have the necessary tools for effective repairs.

Understanding the Assembly Process

Grasping the assembly procedure is crucial for ensuring optimal performance and longevity of machinery. This section outlines the essential steps and considerations involved in the effective assembly of various components.

The following points highlight key aspects to consider:

- Identify all necessary components before starting the assembly.

- Follow the manufacturer’s guidelines to avoid errors.

- Use the appropriate tools to ensure precision and safety.

When assembling, it is beneficial to:

- Organize parts systematically to streamline the process.

- Double-check each connection for stability.

- Test the assembly thoroughly before putting it into operation.

By delving into these aspects, users can achieve the ultimate efficiency and reliability in their equipment.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular attention and care. Proper upkeep not only enhances performance but also minimizes the risk of costly repairs. Following a few essential practices can make a significant difference in the longevity of your tools.

Regular Cleaning

Keeping your machinery clean is crucial. After each use, remove any debris, dirt, or residue that may accumulate. Pay special attention to the air filter and cooling fins, as blockages can lead to overheating and decreased efficiency. Regularly wiping down external surfaces helps prevent rust and wear.

Periodic Inspections

Conducting routine checks on your equipment can identify potential issues before they escalate. Examine key components such as the chain, bar, and spark plug for signs of wear or damage. Replace any worn-out parts promptly to maintain optimal functionality. Additionally, ensure that all fasteners are secure to prevent accidents during operation.

By adopting these maintenance habits, you can significantly enhance the durability and reliability of your tools, ensuring they perform at their best for years to come.

Diagnosing Common Issues

Understanding and resolving frequent problems with your outdoor equipment can greatly enhance its performance and longevity. By familiarizing yourself with typical symptoms and their underlying causes, you can effectively troubleshoot and maintain your tools, ensuring they operate smoothly when needed most.

Common Symptoms and Causes

One of the most prevalent issues users face is difficulty in starting the machine. This can often be attributed to a faulty spark plug, a clogged air filter, or an empty fuel tank. Inspecting these components first can save time and effort in the long run. Another common problem is irregular or poor engine performance, which may result from stale fuel or improper fuel mixture. Regular maintenance and timely replacement of old fuel can mitigate these issues.

Steps for Troubleshooting

To effectively diagnose issues, start by performing a visual inspection of the equipment. Check for any visible damage or loose connections. If the machine won’t start, examine the ignition system and ensure that all safety switches are functioning properly. Cleaning and replacing filters, as well as ensuring that fuel is fresh, can often resolve performance problems. Additionally, consulting a repair manual can provide valuable insights and specifications for your model.

Using OEM vs. Aftermarket Parts

When it comes to maintaining equipment, choosing between original components and third-party alternatives can significantly impact performance and longevity. Each option carries its own set of advantages and disadvantages, influencing everything from compatibility to cost-effectiveness.

Benefits of OEM Components

Original components are designed specifically for the equipment, ensuring optimal fit and performance. They often come with warranties and support, providing peace of mind to users.

Advantages of Aftermarket Options

Third-party alternatives can be more affordable and may offer unique features or enhancements. However, it’s crucial to assess quality and compatibility to avoid potential issues.

| Criteria | OEM Components | Aftermarket Options |

|---|---|---|

| Quality | High | Variable |

| Cost | Higher | Lower |

| Warranty | Often included | Usually limited |

| Performance | Optimal | Can vary |

Exploring Upgrade Options

Enhancing your equipment can lead to improved performance and efficiency. By considering various components, you can tailor your machine to better meet your needs.

Here are some popular upgrade avenues:

- Engine Modifications: Boosting power output or improving fuel efficiency can make a significant difference.

- Cutting Attachments: Upgrading blades or bars can enhance cutting precision and speed.

- Handling Features: Adding ergonomic grips or reducing weight can improve user comfort and control.

- Safety Enhancements: Installing advanced safety features ensures a safer operation.

Each option presents a unique opportunity to delve deeper into your equipment’s capabilities and reach its ultimate potential.

Repair Techniques for Enthusiasts

For those who enjoy working on machinery, understanding repair methods is essential. Whether it’s for maintenance or troubleshooting, having the right techniques can make all the difference in extending the life of your equipment. Below are some effective strategies to enhance your repair skills.

- Familiarize with the Manual: Always start by reading the equipment manual. It provides valuable insights into assembly, disassembly, and maintenance procedures.

- Gather the Right Tools: Investing in quality tools is crucial. Ensure you have a complete set, including wrenches, screwdrivers, and specialty tools specific to your model.

- Systematic Approach: Break down repairs into manageable steps. Document the process with notes or photos to keep track of disassembled parts.

Implementing these techniques not only simplifies repairs but also boosts confidence in handling various issues that may arise.

- Inspect Regularly: Regular inspections can help catch potential problems early. Look for signs of wear and tear, and address them promptly.

- Practice Safety: Always prioritize safety by wearing protective gear and ensuring a clean workspace. Understanding the risks involved will help you work more efficiently.

- Join Community Forums: Engaging with other enthusiasts can provide insights and tips that may not be found in manuals. Sharing experiences can lead to discovering innovative solutions.

By applying these techniques, enthusiasts can develop a deeper understanding of their equipment, ensuring better performance and longevity.

Safety Precautions During Repairs

When performing maintenance on machinery, ensuring personal safety should always be a priority. Proper precautions not only protect the individual conducting the repairs but also prevent potential damage to the equipment. Understanding and implementing safety measures can significantly reduce the risk of accidents and injuries in the workshop.

Essential Safety Gear

Wearing the right protective equipment is crucial during any repair work. This includes items that shield against physical injuries as well as exposure to harmful substances. Below is a table summarizing the essential safety gear:

| Safety Equipment | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and chemicals |

| Gloves | Prevents cuts and exposure to sharp objects |

| Steel-Toed Boots | Protects feet from heavy falling objects |

| Hearing Protection | Reduces noise exposure during operation |

| Respirator Mask | Protects against inhalation of harmful dust and fumes |

Safe Handling and Workspace Practices

In addition to wearing protective gear, maintaining a clean and organized workspace is vital. Clutter can lead to accidents, making it essential to keep tools and materials in their designated places. Always ensure that the equipment is turned off and disconnected from power sources before starting any repair. Furthermore, proper lifting techniques should be employed to avoid strain or injury when moving heavy components.