Understanding the Stihl MS341 Parts Diagram for Efficient Maintenance

When it comes to maintaining and repairing your cutting tool, a clear visualization of its internal structure is essential. Knowing the arrangement and functionality of each element not only simplifies the repair process but also enhances the overall performance of the machine. A comprehensive guide that illustrates these components can be invaluable for both novice and experienced users alike.

Every component plays a critical role in the effective operation of your equipment. From the engine to the bar and chain, understanding how these parts interact can lead to better maintenance practices. With the right knowledge, users can quickly identify issues and replace worn or damaged elements, ensuring their tool remains in peak condition.

Moreover, having access to an illustrative resource allows enthusiasts and professionals to appreciate the intricate design of their tools. This understanding fosters a deeper connection with the equipment, promoting a more informed approach to its care. Whether you are troubleshooting a problem or simply performing routine upkeep, familiarity with the layout of your chainsaw’s components is crucial for optimal functionality.

Understanding the Stihl MS341 Chainsaw

This powerful cutting tool is designed for both professionals and enthusiasts who require efficiency and reliability in their work. With its robust engine and well-thought-out design, it stands out as a go-to option for various tasks, from tree felling to pruning. Understanding its components and functionality is crucial for anyone looking to maximize performance and longevity.

The engine, featuring advanced technology, ensures that the tool delivers impressive cutting speed while maintaining fuel efficiency. Coupled with a lightweight structure, it offers excellent maneuverability, making it ideal for extended use without causing fatigue. The balance between power and weight is meticulously engineered, allowing users to tackle tough jobs with ease.

Regular maintenance plays a vital role in ensuring optimal performance. Familiarizing oneself with the various components and their functions can aid in troubleshooting and repairs. For instance, knowing how the ignition system and fuel delivery mechanisms work together can prevent common issues that might arise during operation.

In summary, understanding the intricacies of this chainsaw not only enhances the user experience but also promotes safety and efficiency. Proper knowledge empowers users to maintain their equipment effectively, ensuring it serves them well for years to come.

Overview of Stihl MS341 Features

This section provides a comprehensive look at the key attributes of a specific model designed for efficient performance and reliability. It highlights the essential aspects that contribute to its functionality and user experience, ensuring that both casual users and professionals can achieve their tasks with ease.

Power and Efficiency

The engine of this machine is engineered for optimal power output, allowing for swift cutting and handling of various materials. Its fuel efficiency means longer operational periods without frequent refueling, making it a valuable tool for extended work sessions.

Ergonomic Design

The thoughtful design ensures comfort during use, reducing fatigue. The lightweight construction, combined with well-placed controls, enhances maneuverability, allowing for precise handling in diverse environments. Safety features integrated into the design further provide peace of mind, ensuring that users can focus on their tasks without unnecessary worry.

Importance of Parts Diagrams

Understanding the intricate layout of components within machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for both professionals and enthusiasts, offering a clear insight into how different elements interact and function together. These illustrations facilitate a comprehensive understanding of equipment, making it easier to identify, troubleshoot, and replace necessary components.

Enhanced Clarity: Visual aids simplify complex structures, allowing users to pinpoint specific sections effortlessly. This clarity is vital for accurate assessments and timely repairs, ultimately leading to improved performance and longevity of the equipment.

Efficient Troubleshooting: When issues arise, having access to a visual guide enables quick identification of potential problem areas. Users can systematically approach repairs, reducing downtime and ensuring that the machinery is back in operation as soon as possible.

Streamlined Ordering Process: For those needing replacements, clear illustrations can significantly expedite the ordering process. Knowing exactly which parts are required helps prevent errors and ensures that the correct components are obtained without unnecessary delays.

Educational Value: For newcomers, these visual references provide an invaluable learning resource. By studying how different pieces fit and work together, users can gain a deeper understanding of machinery mechanics, enhancing their skills and confidence in handling repairs.

In summary, visual representations of equipment components are indispensable in the realms of maintenance and repair. They not only streamline processes but also empower users with knowledge, ultimately leading to more efficient and effective machinery management.

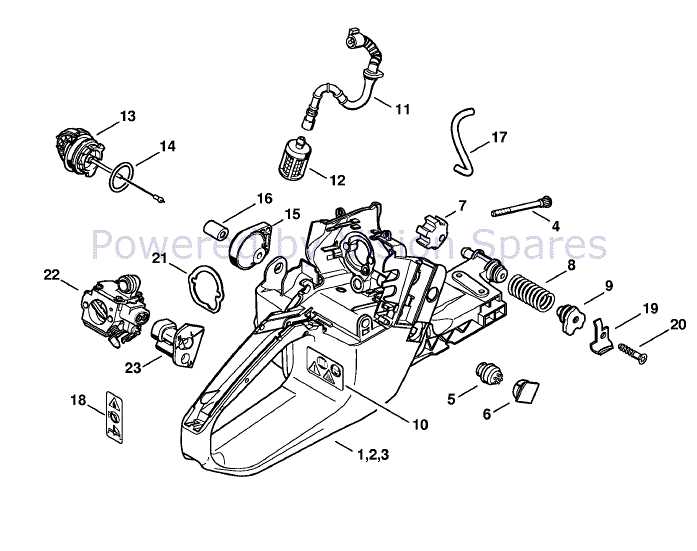

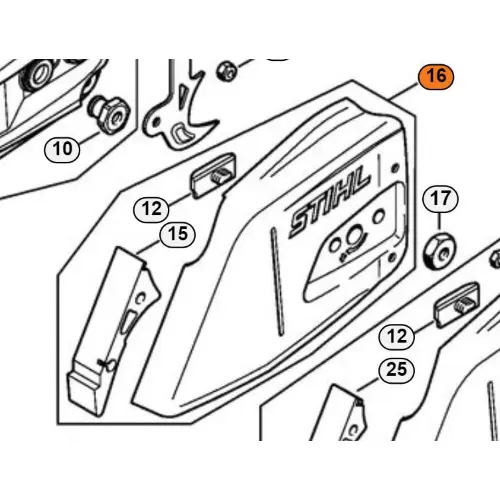

How to Read a Parts Diagram

Understanding an assembly layout is essential for anyone looking to maintain or repair equipment. These visual representations serve as a guide to help identify components and their relationships, making it easier to locate and replace parts as needed. Familiarizing yourself with these illustrations can streamline the repair process and enhance overall efficiency.

Identifying Components

Begin by observing the labels and numbers associated with each element in the illustration. These identifiers correspond to a parts list, which typically provides additional details such as specifications and quantities. Take note of any symbols or color codes that may indicate specific features or functions, as these can be crucial for proper assembly and maintenance.

Understanding Relationships

Next, analyze how the components connect and interact with one another. Pay attention to arrows or lines that indicate movement or assembly order. Recognizing these relationships is vital for accurate disassembly and reassembly, ensuring that everything fits together correctly and functions as intended.

Common Components of MS341

Understanding the essential elements of this cutting tool is crucial for effective maintenance and operation. Each part plays a vital role in ensuring optimal performance, reliability, and safety. This section will explore the key components that contribute to the functionality of the machine, highlighting their importance and interrelation.

Engine Assembly

The engine assembly serves as the heart of the equipment, providing the necessary power for cutting tasks. It typically includes various parts such as the cylinder, piston, and ignition system. A well-maintained engine ensures smooth operation and enhances overall efficiency, making regular inspections and servicing essential.

Cutting Mechanism

The cutting mechanism consists of elements that directly interact with the material being cut. This includes the chain, guide bar, and sprocket. These components work together to deliver precise cuts and maintain the tool’s effectiveness. Proper tension and lubrication are critical for the longevity and performance of the cutting assembly.

Replacement Parts for Stihl MS341

Maintaining outdoor power equipment is crucial for optimal performance and longevity. When components wear out or become damaged, finding the right substitutes ensures that your machine operates smoothly. This section explores essential replacements that enhance functionality and reliability.

Common Components for Replacement

Several key elements are often subject to wear, requiring periodic attention. Identifying these components helps users keep their machinery in top condition.

| Component | Description | Importance |

|---|---|---|

| Cylinder | Houses the piston and is crucial for compression. | Essential for engine efficiency. |

| Piston | Moves within the cylinder to create power. | Vital for converting fuel into motion. |

| Air Filter | Prevents debris from entering the engine. | Protects engine components and maintains airflow. |

| Fuel Lines | Transport fuel from the tank to the engine. | Critical for proper fuel delivery. |

Choosing Quality Alternatives

When selecting replacements, opting for high-quality substitutes is essential. Quality components not only enhance performance but also prolong the lifespan of your machinery. Always ensure compatibility with your specific model to achieve the best results.

Where to Find Genuine Parts

Finding authentic components for your equipment is crucial for maintaining its performance and longevity. High-quality replacements ensure that your machine operates efficiently and safely, reducing the risk of breakdowns and enhancing overall functionality.

Authorized Dealers

One of the most reliable sources for genuine components is authorized retailers. These dealers have direct access to manufacturer stock and can provide:

- Original equipment manufacturer (OEM) items

- Expert advice on compatibility and installation

- Warranty options for added peace of mind

Online Marketplaces

Reputable online platforms also offer a wide selection of original items. When shopping online, consider the following:

- Check seller ratings and reviews for credibility.

- Ensure the website provides a secure payment method.

- Look for clear return policies in case of issues.

Utilizing these sources can help you find the right components that meet the standards required for optimal performance.

Tips for Maintaining Your Chainsaw

Regular upkeep is essential for ensuring the longevity and efficiency of your cutting tool. Proper maintenance not only enhances performance but also guarantees safety during use. Following a consistent care routine can prevent common issues and keep your equipment in optimal condition.

Routine Checks

Performing frequent inspections can help identify potential problems before they escalate. Here are some critical components to monitor:

| Component | What to Check | Frequency |

|---|---|---|

| Chain | Sharpening and tension | After every use |

| Bar | Wear and lubrication | Every few uses |

| Air Filter | Clogging and cleanliness | Weekly |

| Fuel System | Leaks and contamination | Monthly |

Seasonal Maintenance

In addition to routine checks, seasonal upkeep is vital. Before and after heavy usage periods, conduct a thorough assessment of your equipment. Replace worn parts, clean the exterior, and ensure that all moving components are adequately lubricated. Following these steps will prolong the life of your cutting tool and ensure it operates smoothly when needed.

Identifying Wear and Tear

Recognizing signs of deterioration in machinery is crucial for maintaining optimal performance and ensuring safety. Over time, components can experience various forms of damage that may affect functionality. Understanding the common indicators of wear can help in timely maintenance and replacements.

Common Signs of Deterioration

- Visual Damage: Look for cracks, chips, or deformities on parts that can indicate structural failure.

- Surface Wear: Check for discoloration or roughness, which often signifies abrasion or corrosion.

- Unusual Noises: Listen for grinding or rattling sounds during operation; these can point to internal wear.

- Performance Issues: Noticeable drops in efficiency or power can suggest that components are no longer functioning properly.

Regular Inspection Practices

- Schedule routine checks to assess components regularly.

- Keep a maintenance log to track any repairs or replacements.

- Consult the manufacturer’s guidelines for specific wear benchmarks.

- Engage a professional for thorough inspections if significant wear is suspected.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right tools is essential for effective and efficient repairs. This section will outline the various instruments that are necessary for a successful maintenance job, ensuring that your equipment runs smoothly and lasts longer.

Essential Tools

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for removing and securing components.

- Wrenches: Adjustable wrenches and socket sets help in loosening and tightening bolts and nuts.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- File Set: Used for smoothing edges and surfaces after repairs.

Safety Equipment

- Safety Glasses: Protect your eyes from debris during repairs.

- Gloves: Wear durable gloves to safeguard your hands from sharp edges and chemicals.

- Ear Protection: Use earplugs or earmuffs to protect against loud noises while operating machinery.

Equipping yourself with these tools and safety gear will not only enhance your repair capabilities but also contribute to a safer working environment. Always prioritize using quality instruments for the best results.

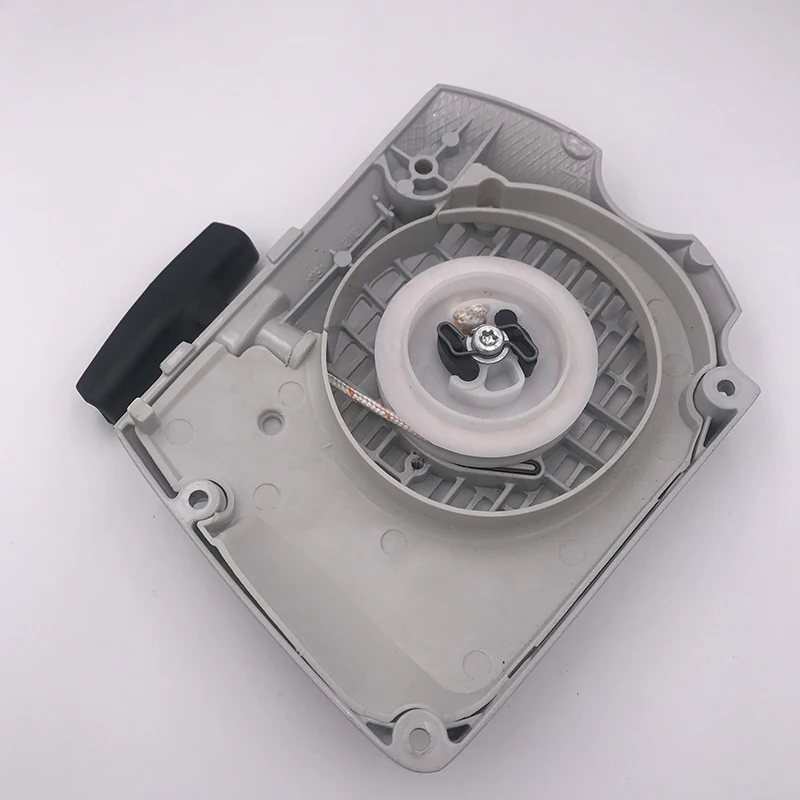

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing issues that may arise with your equipment. By following a structured process, you can identify problems effectively and implement the necessary repairs to restore functionality.

Identification of Issues

Begin by assessing the symptoms your machine is exhibiting. Common indicators may include unusual noises, decreased performance, or complete failure to start. Document each symptom thoroughly to help pinpoint the underlying problem.

Disassembly and Inspection

Once the issues are identified, carefully disassemble the unit, taking care to note the arrangement of each component. Inspect parts for wear and tear, looking for any damage that could contribute to the malfunction. Keep a clean workspace and organize the components to facilitate reassembly.

Safety Precautions During Maintenance

Ensuring safety during maintenance tasks is crucial for preventing accidents and injuries. Proper precautions not only protect the individual performing the upkeep but also preserve the integrity of the equipment. Following recommended safety measures can significantly reduce risks associated with maintenance activities.

- Always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and ear protection.

- Disconnect power sources before starting any maintenance work to prevent accidental activation.

- Work in a well-ventilated area to avoid inhalation of harmful fumes and particles.

- Use tools that are specifically designed for the tasks at hand to ensure efficiency and safety.

- Keep the work area clean and organized to minimize tripping hazards and distractions.

Regularly inspecting tools and equipment for wear and damage is essential. This practice not only enhances safety but also promotes optimal performance.

- Check all electrical components for fraying or exposed wires.

- Inspect cutting tools for sharpness and integrity.

- Ensure that safety guards and covers are in place and functioning properly.

By adhering to these guidelines, individuals can create a safer maintenance environment, reducing the likelihood of accidents and ensuring a more effective maintenance process.

Upgrading Parts for Better Performance

Enhancing the functionality of your outdoor power equipment can lead to significant improvements in efficiency and effectiveness. By selecting high-quality components, you can unlock greater capabilities and ensure that your machinery operates at its best. This approach not only extends the lifespan of the equipment but also optimizes its performance for demanding tasks.

One of the primary upgrades to consider is the ignition system. A more advanced ignition module can lead to quicker starts and smoother operation, resulting in less downtime during your projects. Additionally, upgrading the air filter and intake can improve airflow, allowing for better combustion and increased power output.

Another vital area for enhancement is the fuel system. Utilizing premium fuel lines and a high-performance carburetor can greatly influence fuel efficiency and throttle response. Coupled with a suitable muffler, these modifications can reduce noise levels and emissions, making your work environment more pleasant.

Don’t overlook the importance of the cutting attachments. Opting for sharper, more durable blades or chains can significantly improve cutting speed and precision. Regular maintenance and timely replacement of these components are crucial for maintaining peak performance.

Investing in quality upgrades not only improves the functionality of your equipment but also enhances your overall experience. With the right modifications, you can transform your tools into more powerful allies for any task at hand.