Understanding the Components of a Jeep 4.0 Engine

In the realm of automotive mechanics, comprehending the intricate layout and functionality of a power unit is essential for both enthusiasts and professionals. This section delves into the various elements that constitute this crucial system, shedding light on their roles and interrelationships. By grasping how these components work together, one can gain deeper insights into the overall performance and maintenance of the vehicle.

Familiarity with the individual sections of the power unit is vital for effective troubleshooting and enhancements. Each segment plays a specific role, contributing to the efficiency and reliability of the vehicle. Whether it involves identifying wear and tear or planning for upgrades, having a comprehensive understanding of these features facilitates informed decisions.

Moreover, knowledge of the layout can enhance one’s ability to perform repairs or modifications with confidence. This expertise not only aids in resolving issues but also empowers vehicle owners to engage more fully with their machines, leading to a greater appreciation of their engineering marvels. Exploring the relationships between these vital components opens the door to improved functionality and longevity.

This section explores the essential elements that contribute to the overall functionality of the power unit. Understanding these crucial components is vital for anyone interested in performance, maintenance, and troubleshooting.

Primary Parts

- Block: The main structure housing various internal components.

- Cylinder Head: Covers the top of the cylinders and contains essential mechanisms.

- Pistons: Move up and down within the cylinders to convert fuel into motion.

- Crankshaft: Transforms linear motion from the pistons into rotational motion.

- Camshaft: Regulates the timing of the opening and closing of valves.

Supporting Components

- Oil Pan: Holds lubricating fluid to reduce friction between moving parts.

- Timing Belt: Ensures synchronized movement of the camshaft and crankshaft.

- Fuel Injectors: Deliver fuel to the combustion chamber at precise intervals.

- Intake Manifold: Distributes air and fuel mixture to each cylinder.

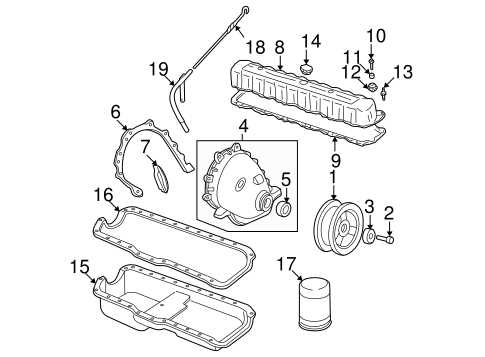

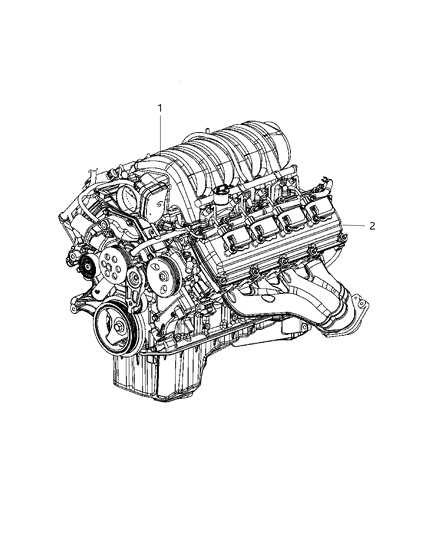

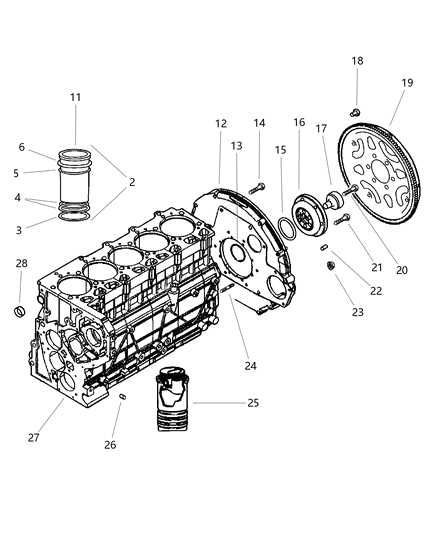

Understanding the Engine Assembly

The assembly of a power unit is a critical component of any vehicle’s performance. It consists of various interconnected elements that work harmoniously to generate motion and efficiency. A thorough comprehension of this assembly not only aids in maintenance but also enhances overall understanding of how these components interact to deliver optimal functionality.

Key Components of the Power Unit

Every power unit consists of several key elements, each playing a vital role in its operation. Below are some of the essential components:

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders where combustion occurs. |

| Piston | A moving element within the cylinder that converts combustion energy into mechanical energy. |

| Crankshaft | A rotating shaft that translates linear motion from the pistons into rotational energy. |

| Camshaft | Controls the opening and closing of intake and exhaust valves. |

Importance of Proper Assembly

Proper assembly of these components ensures the smooth operation of the entire system. Misalignment or improper installation can lead to decreased performance and potential damage. Regular inspections and maintenance can help identify issues early, promoting longevity and reliability.

Functionality of Major Parts

This section explores the essential components of a specific mechanical system and their crucial roles in ensuring optimal performance. Understanding how these elements work together provides valuable insights into the overall operation and efficiency of the machinery.

Core Components

The fundamental elements within the system contribute significantly to its functionality. Each component has a designated purpose, whether it is to facilitate movement, regulate temperature, or manage fuel flow. Their harmonious interaction is vital for achieving peak performance and reliability.

Supportive Mechanisms

In addition to the core components, several supportive mechanisms enhance the system’s efficiency. These may include systems for lubricating moving parts, managing airflow, or filtering impurities. Their roles, while often overlooked, are essential for maintaining longevity and preventing breakdowns.

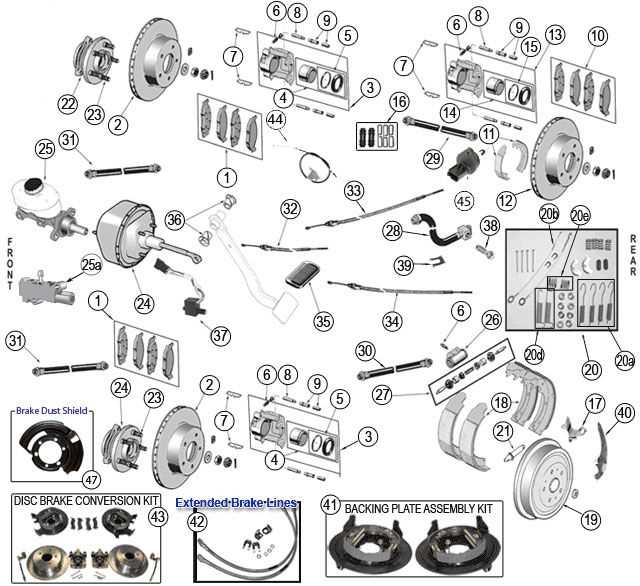

Common Issues in Engine Parts

Various challenges can arise with internal components of a vehicle’s power source, impacting overall performance and reliability. Recognizing these common difficulties is essential for effective maintenance and optimal functioning.

Frequent Challenges

- Overheating: Insufficient cooling can lead to excessive temperatures, causing damage to vital elements.

- Oil Leaks: Deterioration of seals and gaskets may result in oil escaping, which can affect lubrication.

- Wear and Tear: Continuous use can cause significant degradation of moving components, leading to reduced efficiency.

- Misalignment: Improper installation or adjustment can lead to vibrations and abnormal functioning.

Preventive Measures

- Regular inspections of components to identify early signs of issues.

- Timely replacement of worn-out seals and gaskets to prevent leaks.

- Ensuring proper lubrication to minimize friction and heat.

- Following manufacturer guidelines for installation and adjustments.

Maintenance Tips for Engine Longevity

Ensuring the durability of your vehicle’s power source requires consistent care and attention. By following a few essential practices, you can significantly enhance the lifespan and performance of this critical component. Regular maintenance not only prevents costly repairs but also improves efficiency, ensuring a smooth driving experience.

Regular Fluid Checks

Monitoring the levels and condition of various fluids is vital for optimal functionality. Here are some key fluids to inspect:

| Fluid Type | Frequency of Check | Importance |

|---|---|---|

| Oil | Every 3,000-5,000 miles | Reduces friction and wear |

| Coolant | Every 6 months | Prevents overheating |

| Transmission Fluid | Every 30,000 miles | Ensures smooth shifting |

Scheduled Inspections

Periodic assessments by a qualified technician can catch potential issues before they escalate. These evaluations typically include checks on belts, hoses, and filters, ensuring all components operate efficiently.

Comparing Engine Parts with Other Models

Understanding the differences among various components in automotive machinery is essential for enthusiasts and professionals alike. This section explores how certain mechanical elements vary when juxtaposed with those found in different models. By examining these distinctions, we can gain insights into performance characteristics, durability, and overall design philosophies across various vehicles.

| Component | Model A | Model B | Model C |

|---|---|---|---|

| Crankshaft | Forged steel, high torque | Cast iron, standard torque | Aluminum, lightweight |

| Cylinder Head | Multi-valve, aluminum | Single-valve, cast iron | Dual-valve, magnesium |

| Piston | High compression, coated | Standard compression, uncoated | Low compression, reinforced |

| Intake Manifold | Performance-oriented, optimized flow | Standard design, moderate flow | Variable geometry, adjustable |

| Exhaust System | High-flow, stainless steel | Standard, mild steel | Turbocharged, integrated |

Aftermarket Parts and Upgrades

Enhancing performance and durability is a common goal for many vehicle enthusiasts. By incorporating alternative components, owners can achieve improved functionality and tailor their machines to meet specific needs. This section explores the benefits and options available for those looking to modify their rides.

Benefits of Upgrades

Utilizing alternative components can lead to significant improvements in various aspects of performance. These modifications often result in better power delivery, enhanced fuel efficiency, and increased longevity of the overall system. Additionally, aftermarket enhancements can contribute to a more personalized driving experience, allowing owners to achieve the desired performance metrics.

Popular Modifications

There are numerous modifications available, each serving different purposes. Here are some popular alternatives:

| Modification Type | Description |

|---|---|

| Exhaust System | Upgraded exhaust systems can improve airflow and increase horsepower. |

| Cold Air Intake | Enhances engine efficiency by increasing airflow and reducing intake temperatures. |

| ECU Tune | Reprogramming the engine control unit can optimize fuel maps for better performance. |

| Suspension Kits | Improves handling and ride quality, providing better stability on and off-road. |

| Performance Tires | Upgrading to specialized tires can enhance grip and control in various conditions. |

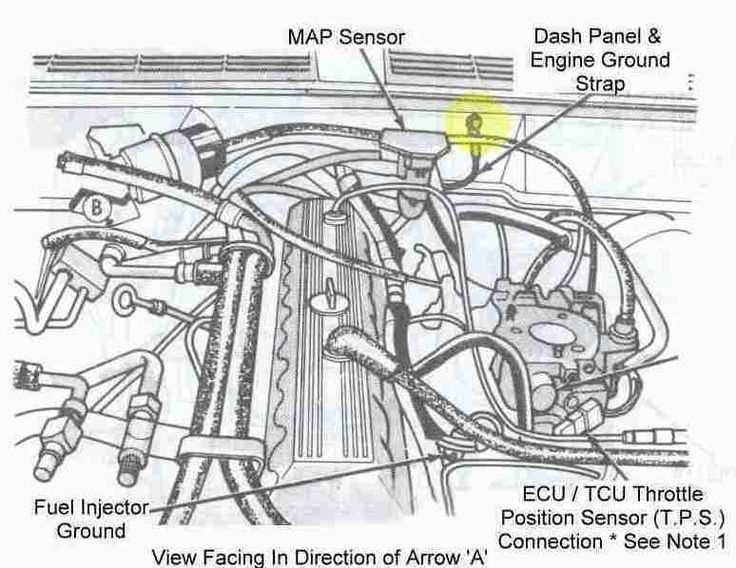

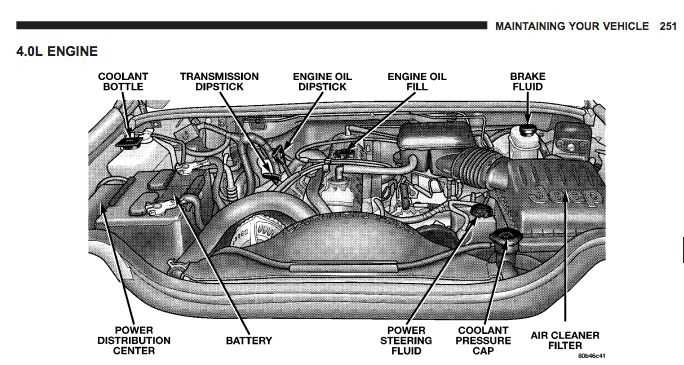

Visual Guide to Engine Layout

This section aims to provide a comprehensive overview of the arrangement of components within the power unit. Understanding the layout is crucial for both enthusiasts and professionals, as it enhances the ability to diagnose issues and perform maintenance effectively.

Key Components Overview

Familiarizing yourself with the essential elements of the assembly can simplify repairs and upgrades. Below are the primary constituents:

- Block: The main structure housing various elements.

- Cylinder Head: Encloses the top of the cylinders, playing a vital role in combustion.

- Piston: Moves up and down within the cylinder, converting fuel energy into mechanical motion.

- Crankshaft: Transforms linear motion from the pistons into rotational energy.

- Valves: Control the intake of air and fuel as well as the exhaust of gases.

Understanding the Layout

Recognizing how these components interact is key to a thorough comprehension of the entire system:

- Power Generation: The process begins with the combustion of fuel within the cylinders.

- Motion Transfer: The pistons push down, turning the crankshaft, which then drives the wheels.

- Exhaust Management: Gases are expelled through the valves, ensuring the system remains efficient.

Importance of Genuine Parts

Utilizing authentic components in any mechanical system is crucial for optimal functionality and longevity. These original items are designed specifically for compatibility, ensuring that all elements work together seamlessly. Their quality is generally higher than that of aftermarket alternatives, which can lead to better performance and reliability.

When a system is assembled with genuine items, it often results in fewer operational issues and a more efficient performance. Authentic components typically undergo rigorous testing to meet specific standards, providing peace of mind to the user. Additionally, using original items can help maintain the overall value of the machinery, making it a wise investment in the long run.

Furthermore, manufacturers often provide warranties and support for systems that utilize authentic components, offering an added layer of security for the owner. This ensures that any potential issues can be addressed swiftly and effectively, minimizing downtime and enhancing the user experience.

Resources for Jeep Enthusiasts

For those passionate about off-road vehicles, having access to reliable information and tools is essential for enhancing the ownership experience. Numerous resources cater to this community, providing valuable insights, tips, and parts for maintenance and upgrades.

Here are some helpful resources that can assist enthusiasts in their journey:

- Online Forums: Engage with fellow enthusiasts to share experiences and advice.

- DIY Websites: Explore step-by-step guides and tutorials for repairs and modifications.

- Social Media Groups: Join dedicated groups on platforms like Facebook for real-time discussions and support.

- Local Clubs: Connect with like-minded individuals for events, trail rides, and meet-ups.

- Parts Suppliers: Find reputable vendors that offer a wide range of components for upgrades and replacements.

These resources can help owners stay informed, connected, and empowered, ensuring a fulfilling journey with their beloved vehicles.