Understanding Stihl HS 45 Parts Diagrams for Efficient Maintenance

Maintaining outdoor power equipment requires a solid understanding of its internal mechanisms. Familiarity with the various elements that comprise a trimmer is essential for ensuring optimal performance and longevity. This guide aims to provide a comprehensive overview of how these components work together, facilitating smoother maintenance and troubleshooting processes.

In the realm of landscaping tools, recognizing the intricate relationships between individual parts can significantly enhance your ability to diagnose issues. Each element plays a crucial role in the functionality of the machine, and having a clear visual reference can simplify repairs and replacements. This resource serves as a valuable reference for enthusiasts and professionals alike, promoting a more efficient approach to equipment upkeep.

Whether you’re a seasoned user or a novice, understanding the layout and functionality of each section can empower you to tackle repairs with confidence. By delving into the specific configurations, you’ll be better equipped to handle maintenance tasks, ensuring your equipment remains in peak condition for all your outdoor endeavors.

Understanding Stihl HS 45 Components

In any gardening tool, a comprehensive understanding of its various elements is essential for optimal performance and maintenance. Each component plays a specific role, contributing to the overall efficiency and functionality of the equipment. By familiarizing oneself with these parts, users can enhance their experience and ensure longevity.

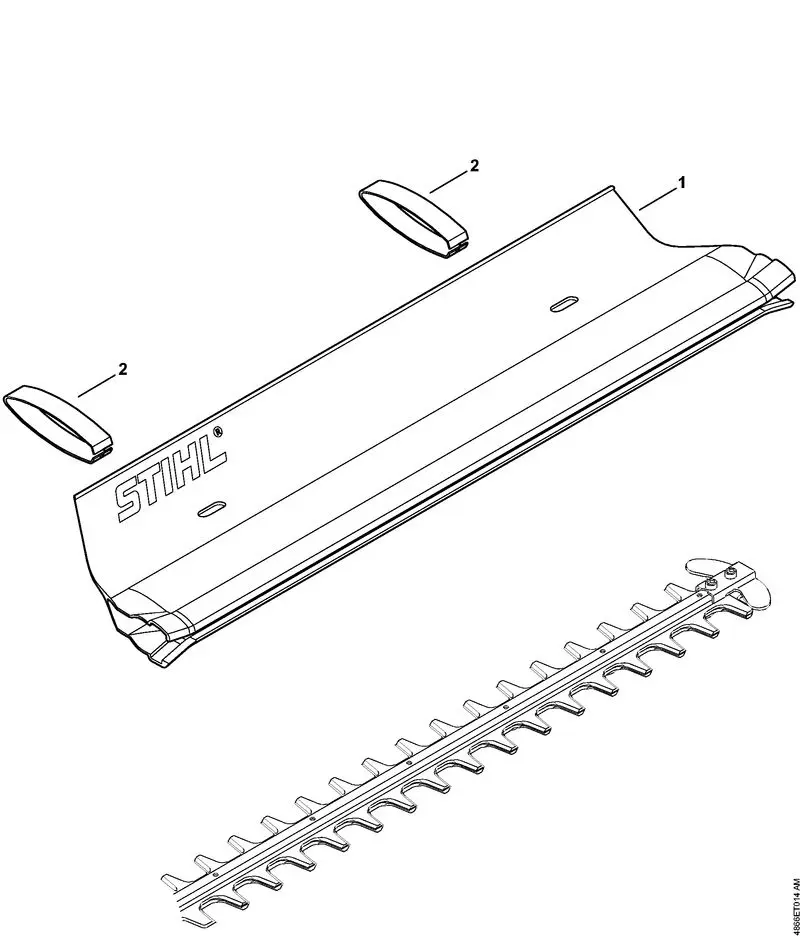

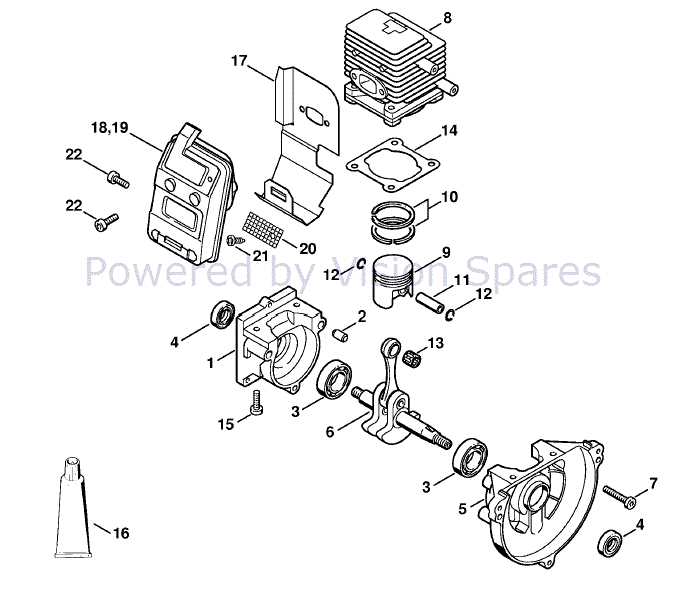

The engine serves as the heart of the device, providing the necessary power for operation. Understanding its mechanics can aid in troubleshooting issues that may arise during use. Additionally, the blades are crucial for achieving precise cuts; keeping them sharp and well-maintained is vital for achieving the desired results.

Other significant elements include the handle, which ensures user comfort and control, and the fuel system, responsible for efficient power delivery. Recognizing how these parts interact can help users identify potential problems early, ensuring a smoother and more effective gardening experience.

Ultimately, grasping the function and importance of each component not only improves operation but also empowers users to perform necessary maintenance tasks, contributing to the overall longevity of the tool.

Key Features of Stihl HS 45

The model in question stands out due to its exceptional design and performance characteristics, making it a reliable choice for various landscaping tasks. Its robust construction ensures durability, while user-friendly features enhance ease of use, appealing to both professionals and gardening enthusiasts alike.

Performance and Efficiency

Equipped with a powerful engine, this equipment delivers impressive cutting power. It allows users to tackle thick hedges and dense shrubs with ease, ensuring a clean and precise finish. Additionally, its fuel efficiency contributes to longer operational times without frequent refueling.

Safety Features

Safety is paramount, and this model incorporates multiple features designed to protect the user during operation. The well-placed handles offer a secure grip, while the integrated safety mechanisms minimize the risk of accidental starts, ensuring a safer working environment.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke engine for efficient power output |

| Blade Length | 24 inches, ideal for various trimming tasks |

| Weight | Lightweight design for improved maneuverability |

| Handle Design | Ergonomic handles for enhanced comfort |

Benefits of Using Genuine Parts

Utilizing authentic components in your equipment offers numerous advantages that enhance performance and longevity. These original elements are designed specifically for compatibility, ensuring seamless operation and reliability throughout their lifespan.

Durability is a key factor when choosing original components. They are crafted with superior materials that withstand wear and tear, reducing the need for frequent replacements. This not only saves time but also minimizes overall maintenance costs.

Furthermore, using genuine elements contributes to optimal performance. Each component is engineered to meet the exact specifications required for your equipment, allowing it to function at its best. This precision leads to enhanced efficiency and effectiveness during use.

Another significant advantage is warranty protection. Many manufacturers provide guarantees when authentic components are used, offering peace of mind and financial security against potential failures. This coverage can be invaluable in case of unexpected issues.

Additionally, choosing original parts supports safety. Authentic components undergo rigorous testing to ensure they meet safety standards, reducing the risk of malfunctions that could pose hazards during operation.

In summary, opting for genuine components not only ensures compatibility and reliability but also promotes long-term savings and safety. Investing in these high-quality items is a decision that pays off in both performance and peace of mind.

Common Issues with HS 45 Units

Many users encounter various challenges with their cutting tools, often stemming from wear and tear, improper maintenance, or operational errors. Understanding these frequent problems can help ensure better performance and longevity of the equipment.

One prevalent issue is starting difficulties. This can result from stale fuel, a clogged air filter, or problems with the ignition system. Regularly checking these components can significantly enhance starting reliability.

Another common concern is poor cutting performance. Dull blades or improper tension can lead to ineffective trimming. Keeping the blades sharp and adjusting their tension according to the manufacturer’s recommendations is crucial for optimal results.

Vibration is also a frequent complaint. Excessive vibration can cause discomfort and may indicate that components are loose or damaged. Regular inspections and tightening of bolts can mitigate this issue.

Finally, fuel leakage can occur if seals or gaskets are worn out. Addressing leaks promptly not only prevents fuel wastage but also ensures safe operation.

By being aware of these common challenges, users can take proactive steps to maintain their equipment and enjoy efficient performance.

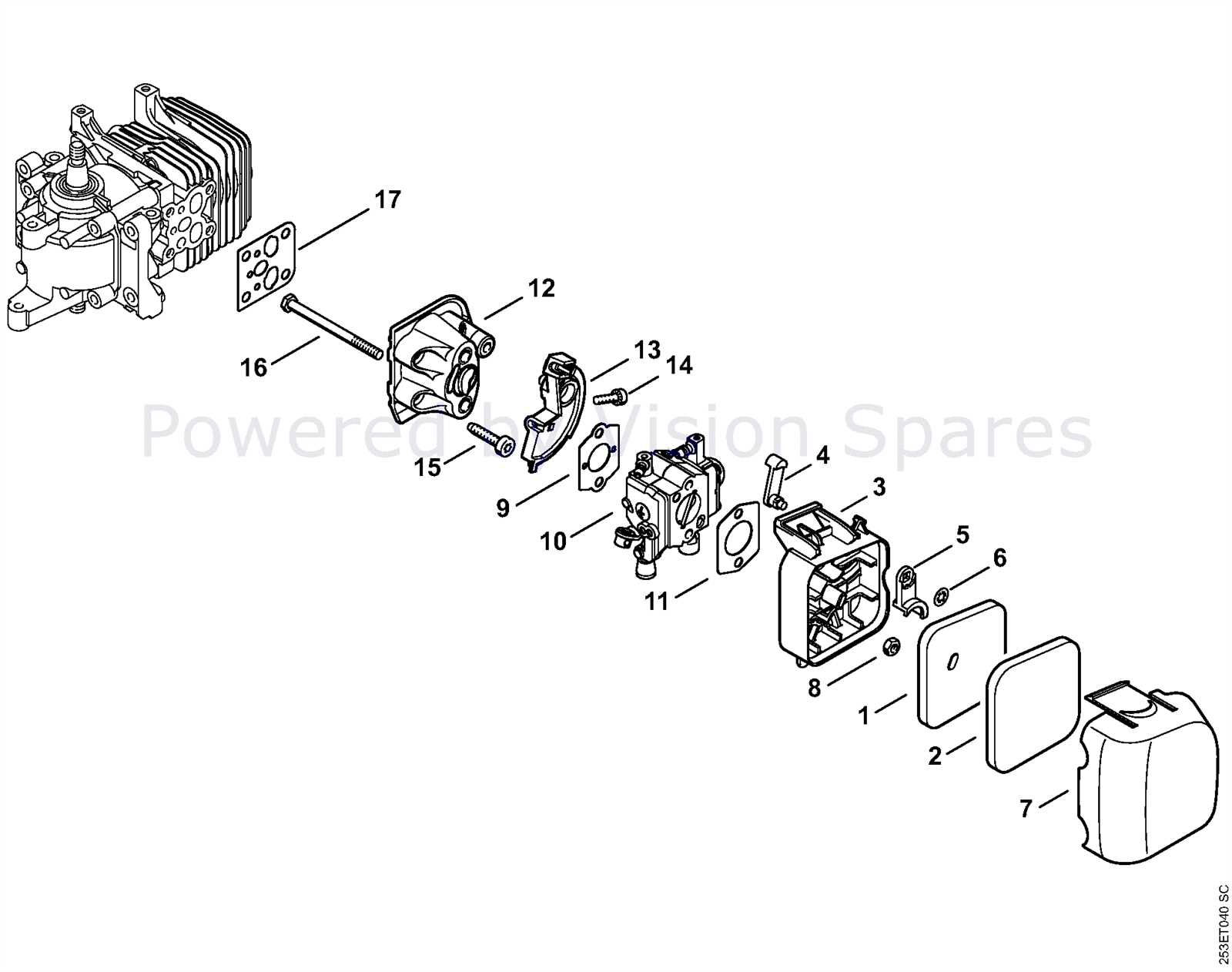

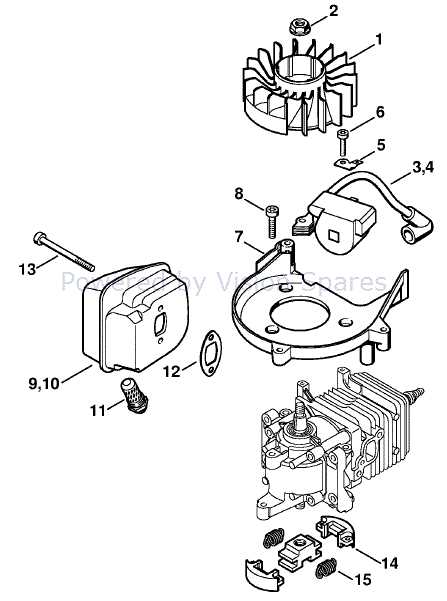

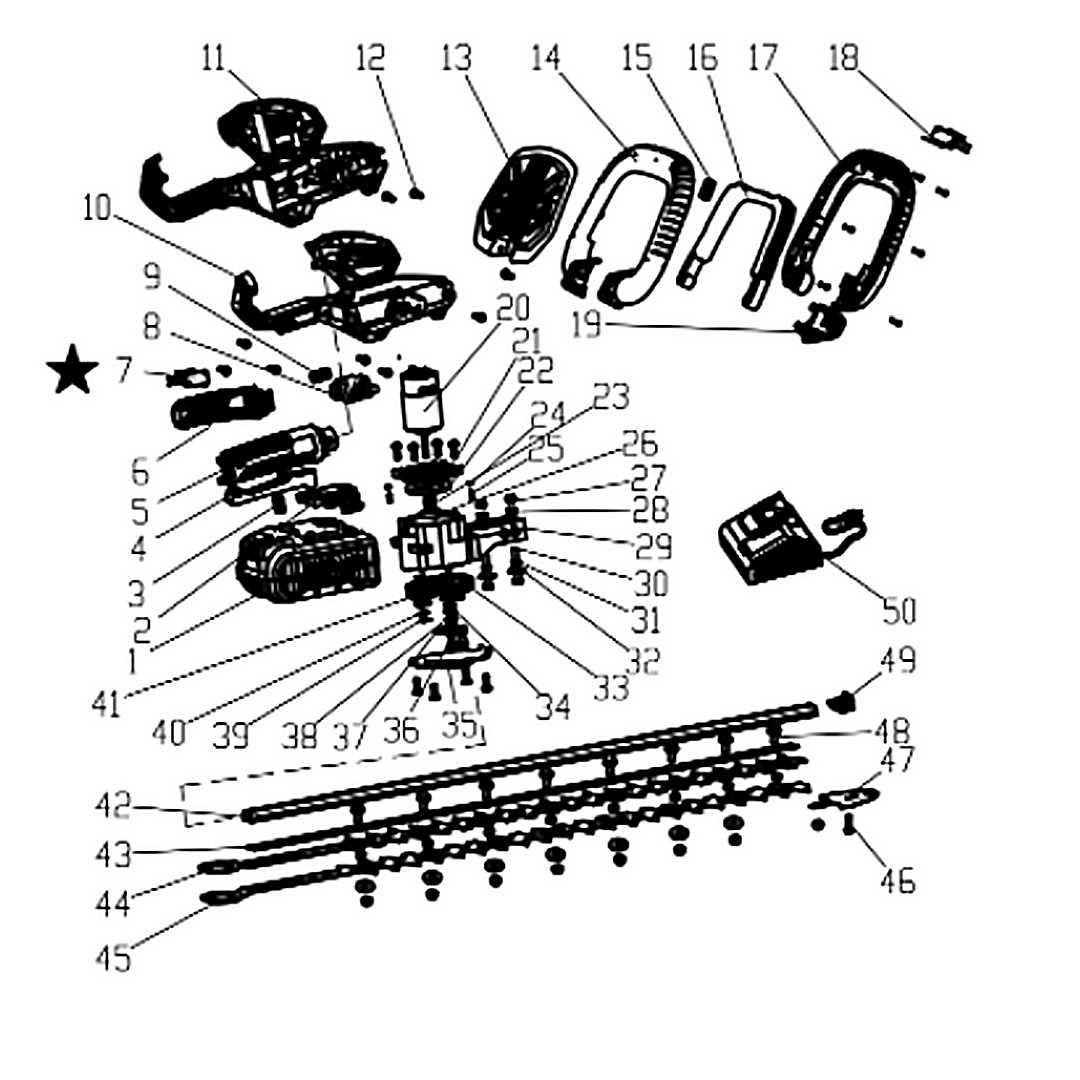

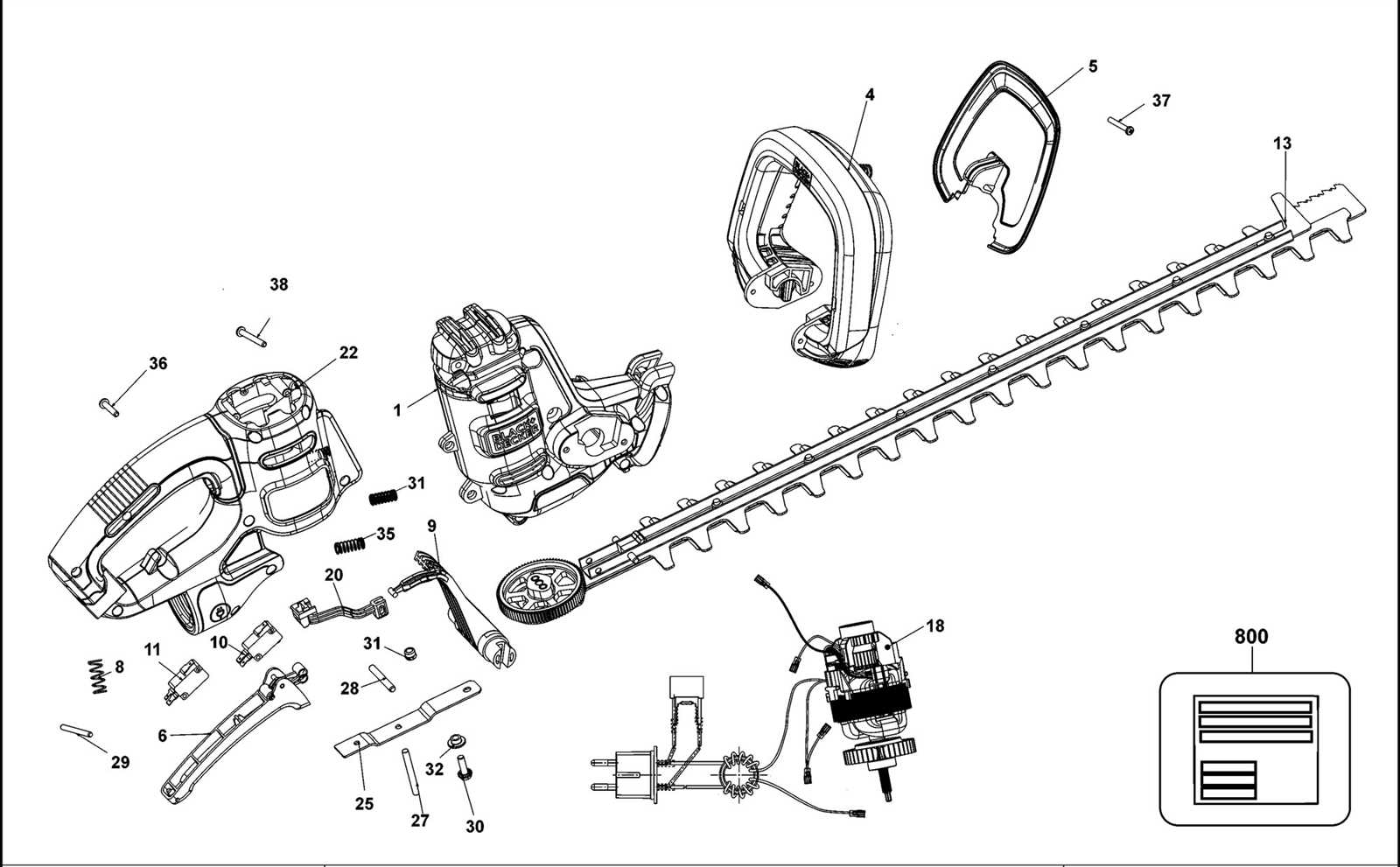

How to Interpret Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear overview of individual elements, their functions, and how they interact within a larger system. By mastering the interpretation of these visuals, you can streamline your approach to troubleshooting and ensure your equipment operates efficiently.

Key Components of Visual Representations

When examining a visual representation, focus on the following aspects to enhance your comprehension:

| Aspect | Description |

|---|---|

| Labels | Each element is often accompanied by a label that specifies its name or part number. |

| Connections | Lines or arrows may indicate how different elements are linked or how they function together. |

| Numbering | Sequential numbers can help you identify the order of assembly or specific sections to focus on. |

| Legend | A key may explain symbols or color codes used within the illustration for easier understanding. |

Tips for Effective Interpretation

To maximize your understanding, consider these strategies:

- Compare the visual with your actual equipment to locate components accurately.

- Take notes on any unfamiliar elements for further research.

- Consult accompanying documentation for additional context on functionality.

Essential Maintenance for HS 45

Regular upkeep of your equipment is crucial to ensure optimal performance and longevity. By adhering to a maintenance schedule, you can prevent unexpected breakdowns and maintain efficiency. This guide outlines key practices to keep your unit in top condition.

Key Maintenance Tasks

- Cleaning: Regularly clean the cutting blades and housing to prevent debris buildup, which can affect performance.

- Blade Sharpening: Keep the blades sharp for clean cuts. Dull blades can strain the engine and lead to uneven trimming.

- Fuel System Inspection: Check for fuel leaks and ensure the fuel is fresh. Stale fuel can cause starting issues and decreased efficiency.

Periodic Checks

- Inspect the spark plug for wear and replace if necessary.

- Examine the air filter and clean or replace it to ensure proper airflow.

- Check all screws and fasteners to ensure they are tight and secure.

By following these essential maintenance tips, you will enhance the performance and lifespan of your equipment, ensuring it operates smoothly whenever you need it.

Finding Replacement Parts Online

Locating suitable components for your equipment has never been easier, thanks to the vast array of online resources available. Whether you are looking for specific pieces or general accessories, the internet offers numerous platforms to assist in your search.

Here are some effective strategies to streamline your quest:

- Utilize Manufacturer Websites: Many brands provide a dedicated section for their products, featuring lists of compatible items.

- Explore Online Marketplaces: Platforms like Amazon and eBay often have a wide selection of components at competitive prices.

- Join Online Forums: Communities focused on your equipment type can offer valuable insights and recommendations for sourcing parts.

- Consult Local Dealers: Many retailers have online catalogs, allowing you to check availability before visiting in person.

When searching, ensure you have the model information handy, as this will help you identify the right components more efficiently. Additionally, reviews and ratings can guide you in selecting high-quality items from reputable sellers.

By leveraging these resources, you can easily find what you need to keep your machinery running smoothly.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks on garden equipment, having the right tools is essential for achieving successful outcomes. The appropriate instruments not only facilitate the repair process but also ensure safety and efficiency, allowing for precise adjustments and replacements. Below, we outline the necessary tools to consider when engaging in such tasks.

Basic Hand Tools

Every toolkit should include a variety of hand tools to tackle different aspects of repair work. Common items such as screwdrivers, wrenches, and pliers are fundamental for loosening or tightening various components. It’s advisable to have both flathead and Phillips screwdrivers in multiple sizes to accommodate different fasteners. Additionally, a set of metric and imperial wrenches will provide the versatility needed for various applications.

Specialized Equipment

In addition to basic tools, certain specialized equipment can greatly enhance your repair efforts. Torque wrenches ensure that bolts are tightened to the correct specifications, preventing damage or malfunction. Furthermore, a reliable multimeter can help diagnose electrical issues, while a cleaning kit ensures that components remain free of debris and contaminants. Investing in quality tools will lead to better results and extend the lifespan of your equipment.

DIY Repair Tips for Gardeners

Maintaining gardening tools can significantly enhance your gardening experience and prolong the lifespan of your equipment. By acquiring some basic repair skills, you can tackle common issues and save both time and money. This section offers practical advice for gardeners looking to perform simple fixes themselves.

1. Regular Maintenance: Keep your tools in top condition by cleaning them after each use. Remove dirt and debris to prevent rust and deterioration. Lubricate moving parts periodically to ensure smooth operation.

2. Identify Common Issues: Familiarize yourself with frequent problems, such as dull blades or faulty spark plugs. Recognizing these issues early allows for timely intervention, preventing further damage.

3. Use the Right Tools: Invest in basic repair tools like screwdrivers, wrenches, and pliers. Having the right equipment makes repairs easier and more efficient, allowing you to tackle a variety of tasks with confidence.

4. Refer to Manuals: Always consult the manufacturer’s manual for specific instructions related to your equipment. Manuals often provide valuable troubleshooting tips and diagrams that can guide you through the repair process.

5. Safety First: Always prioritize safety when performing repairs. Use protective gear and ensure tools are unplugged or disconnected from power sources before starting any work.

6. Seek Online Resources: Utilize online forums, video tutorials, and community groups dedicated to gardening. These platforms can offer insights and support from fellow enthusiasts who have faced similar challenges.

By implementing these simple strategies, gardeners can effectively manage tool maintenance and repairs, ensuring their equipment remains reliable throughout the gardening season.

Safety Precautions During Maintenance

Ensuring safety during maintenance tasks is crucial for both the user and the equipment. Proper precautions can help prevent accidents and prolong the lifespan of the machinery. By following specific guidelines, one can perform necessary upkeep without risking personal injury or damaging the device.

Always wear protective gear such as gloves, goggles, and ear protection. These items shield against potential hazards like sharp edges, flying debris, and loud noises. It is essential to maintain personal safety while handling tools and equipment.

Before starting any maintenance work, ensure that the machine is turned off and disconnected from any power source. This precaution prevents accidental starts, which can lead to serious injuries. Additionally, let the device cool down if it has been in use, as hot components can cause burns.

Maintain a clean workspace to avoid trips and falls. Remove any unnecessary tools or materials that could obstruct movement. A tidy area not only enhances safety but also improves efficiency during maintenance tasks.

Lastly, always refer to the manufacturer’s guidelines for specific safety instructions related to the equipment. Following recommended procedures and using the correct tools ensures that maintenance is performed safely and effectively.

Comparing HS 45 to Other Models

When assessing the capabilities of different hedge trimming machines, it’s essential to recognize the distinctive features and performance metrics that set each model apart. The HS 45, known for its reliability and ease of use, presents certain advantages when juxtaposed with its counterparts. This comparison highlights the nuances that potential users should consider when selecting the right equipment for their needs.

Key Features Comparison

Examining the primary characteristics of various models provides insight into their suitability for specific tasks. Below is a comparative table showcasing essential attributes of the HS 45 alongside other popular machines in the market.

| Model | Engine Power (cc) | Cutting Length (cm) | Weight (kg) | Fuel Efficiency (L/h) |

|---|---|---|---|---|

| HS 45 | 27.2 | 60 | 4.4 | 0.6 |

| Model A | 25.4 | 55 | 5.0 | 0.5 |

| Model B | 30.1 | 65 | 4.9 | 0.7 |

Performance and Usability

While the HS 45 excels in user-friendliness and maneuverability, its competitors may offer enhanced power or longer cutting lengths. It is crucial to weigh these performance metrics against the specific tasks at hand, whether it be residential trimming or larger commercial jobs. Ultimately, understanding the strengths and weaknesses of each model empowers users to make informed choices tailored to their landscaping requirements.

Understanding Warranty and Support Options

When purchasing equipment, it’s essential to comprehend the protections and assistance available to ensure your investment remains secure. This section delves into the various warranty frameworks and support avenues offered, allowing users to maintain optimal performance and longevity of their tools.

Warranties typically cover defects in materials and workmanship, providing peace of mind for buyers. Understanding the specific terms and duration of coverage is crucial, as this can vary significantly between models. Additionally, knowing what steps to take in case of an issue can streamline the process of getting support.

| Warranty Type | Coverage Duration | Key Benefits |

|---|---|---|

| Limited Warranty | 1-2 years | Defects in materials and workmanship |

| Extended Warranty | Up to 3 years | Longer protection period |

| Service Plans | Varies | Regular maintenance and repairs |

Additionally, manufacturers often provide various support options to assist users. These can include customer service hotlines, online resources, and authorized service centers. Familiarizing yourself with these channels can enhance your overall experience and ensure that any concerns are addressed promptly.

Upgrading Your Stihl HS 45

Enhancing your gardening tool can significantly improve its performance and longevity. By investing in quality upgrades, you can achieve better efficiency and a smoother operation. This process not only revitalizes your equipment but also elevates your overall gardening experience.

One of the most effective ways to boost performance is by replacing older components with high-quality alternatives. Upgraded blades, for instance, can provide a cleaner cut and reduce the time spent on maintenance. Additionally, ensuring that the motor is in optimal condition can lead to improved power output, making your tasks easier and more efficient.

Consider enhancing the ergonomic features as well. Handles that offer better grip and control can minimize fatigue during extended use. This small adjustment can make a substantial difference in comfort and handling, allowing you to work longer without discomfort.

Lastly, regular maintenance and timely upgrades of essential elements can prevent common issues and extend the lifespan of your equipment. Investing in these enhancements is a smart way to ensure your tool remains reliable and efficient for years to come.