Comprehensive Guide to Honda GX670 Parts Diagram

Understanding the inner workings of an engine is crucial for ensuring its optimal performance and longevity. By familiarizing yourself with the various mechanisms and how they interact, you can better maintain and troubleshoot your equipment, ensuring that it continues to run smoothly.

This guide offers an in-depth look at the various elements that make up a robust motor system. From critical mechanisms to support functions, each part plays a key role in delivering the power and efficiency needed for demanding tasks. By exploring each section, you will gain valuable insight into how the different sections work together to keep everything running seamlessly.

Whether you’re looking to improve your understanding or carry out specific maintenance tasks, this detailed overview provides essential information about the structure and function of various components. The following sections will walk you through every aspect, giving you the knowledge to addres

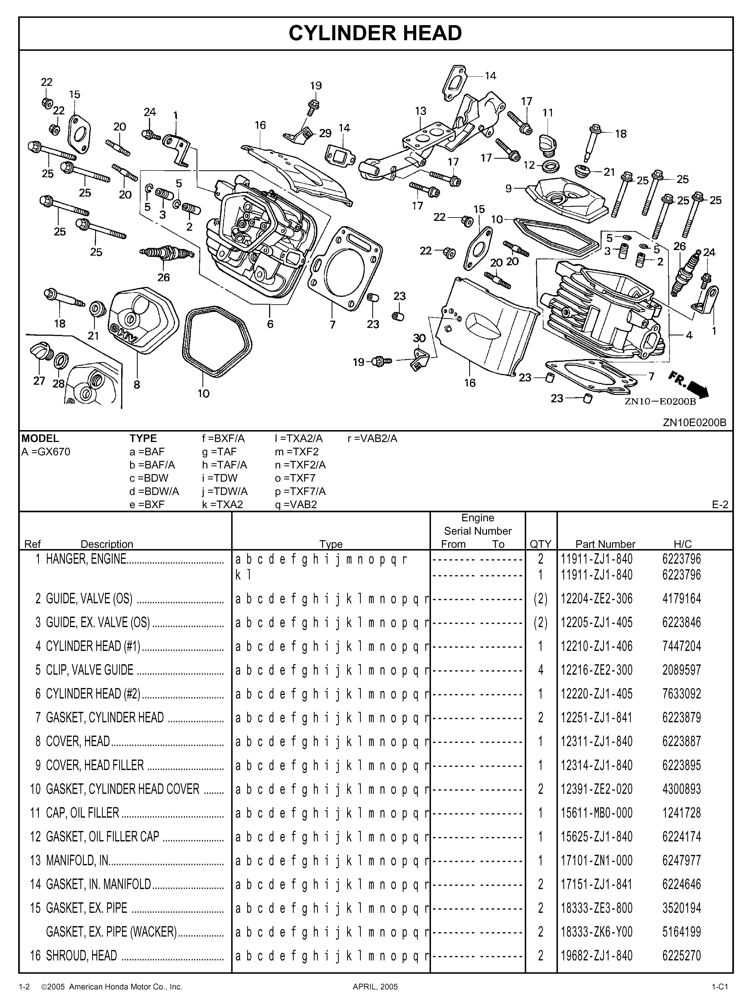

Understanding the Layout of Honda GX670 Components

The arrangement of components within this engine model is designed to ensure efficient performance and ease of maintenance. Each section is meticulously organized to optimize the internal structure, making it easy for users to locate and work with key elements during repairs or servicing. Familiarizing yourself with how these components are positioned will help in understanding how they function together.

From the placement of the fuel system to the alignment of moving parts, every detail contributes to the smooth operation of the engine. By recognizing the role of each element, it becomes easier to identify potential issues, as well as to perform regular checks or replacements when necessary. This clear arrangement of elements not only simplifies troubleshooting but also extends the life of the engine when properly maintained.

Key Features of the Engine

The engine is designed to provide high performance and durability, making it suitable for various demanding applications. Its thoughtful construction and components contribute to efficiency and reliability over extended use.

- Efficient Cooling System: An advanced cooling mechanism ensures optimal temperature management, allowing the engine to maintain consistent performance even under heavy loads.

- High-Performance Power Output: The engine generates substantial power, making it ideal for both industrial and commercial use where consistent strength is required.

- Durable Design: The robust construction includes high-quality materials and components that extend the lifespan and reduce the need for frequent maintenance.

- Fuel Efficiency: Designed to consume less fuel while delivering maximum power, the engine promotes cost-effectiveness and environmental consciousness.

- Low Vibration and Noise Levels: A smooth o

Detailed Breakdown of Engine Parts

Understanding the intricate components of a combustion engine is essential for proper maintenance and troubleshooting. Each element plays a critical role in ensuring the engine functions efficiently and delivers optimal performance. In this section, we will explore the key components and their specific functions.

- Cylinder Block: The foundation of the engine, housing various crucial elements such as pistons and crankshaft.

- Pistons: Responsible for converting fuel into mechanical energy through compression and expansion.

- Crankshaft: Transforms the reciprocating motion of the pistons into rotational force, driving other mechanical systems.

- Camshaft: Coordinates the opening and closing of intake and exhaust valves to regulate airflow in the combustion chamber.

- Fuel Tank: The main reservoir that stores fuel before it enters the system.

- Fuel Pump: A component that transfers fuel from the tank to the combustion chamber, ensuring steady pressure and flow.

- Fuel Filter: Protects the system by removing impurities and particles from the fuel before it reaches the engine.

- Fuel Injectors: Responsible for injecting the right amount of fuel into the engine’s combustion chamber for optimal performance

Cooling Mechanisms in the Honda GX670

Effective cooling is essential to ensure the longevity and performance of engines, especially in environments where they are subjected to high temperatures. Keeping internal components at an optimal temperature prevents overheating and minimizes wear, contributing to overall engine efficiency. This section explores the specific methods used to manage temperature, ensuring steady operation and reliable performance even under demanding conditions.

Air Cooling System Overview

One of the primary methods for managing engine temperature involves an air-based system. Air is circulated over the external components, drawing heat away from critical areas. This simple yet effective system ensures that excess heat is dissipated quickly, preventing thermal damage. The design of the airflow pathways is carefully considered to maximize cooling efficiency while maintaining smooth operation.

Additional Cooling Features

Beyond air-based systems, additional features have been integrated to enhance heat management. These

Exhaust System Overview and Parts

The exhaust system is a crucial component in ensuring optimal engine performance and efficiency. It is responsible for directing harmful gases away from the engine, while also helping to reduce noise and manage temperature. This system is made up of several key elements that work together to ensure smooth operation and longevity of the engine.

Key Components of the Exhaust System

At the heart of the exhaust setup are the manifold, which collects gases from the engine’s cylinders, and the muffler, designed to minimize sound. The exhaust pipe links these components, directing gases safely away. Additionally, other parts such as the catalytic converter serve to reduce emissions, making the entire system more eco-friendly and compliant with regulations.

Maintenance Considerations

Regular inspection and maintenance of the exhaust system are essential for preserving engine health and performance. Over time, components such as gaskets, seals, and pipes may wear out, leading to leaks or reduced efficiency. Prompt replacement of these worn-out parts can help avoid more severe issues that may affect overall engine functionality.

Ignition System: Parts and Their Roles

The ignition mechanism in an engine relies on several components working together to initiate the combustion process. These elements ensure the spark is generated at the correct moment, allowing the fuel to ignite and drive the engine’s performance. Each component plays a vital role in the smooth operation of the ignition cycle.

Key Elements of the Ignition Mechanism

The key elements that contribute to the ignition process include a spark-generating unit, a power distributor, and a voltage regulator. The spark plug is responsible for creating the necessary spark that ignites the air-fuel mixture. Meanwhile, the coil provides the high voltage needed for the spark plug to work effectively. The distributor ensures the spark is sent to the right cylinder at the right time, while the voltage regulator maintains a consistent power supply to these components.

How Each Component Contributes to Engine Efficiency

Every part in the ignition assembly has a distinct function that contributes to the engine’s overall efficiency. The timing of the spark is crucial; a delay or early spark can lead to misfires, poor fuel efficiency, or engine damage. Proper synchronization between the spark plug, coil, and distributor allows for optimal engine performance, reducing emissions and enhancing fuel consumption.

Crankshaft and Connecting Rod Assembly

The crankshaft and connecting rod assembly is a crucial component in any internal combustion engine, responsible for transferring the energy produced by the combustion process to mechanical motion. This assembly converts the up-and-down movement of the pistons into rotational power, enabling the engine to function efficiently. Proper alignment and balance of these parts are essential for optimal engine performance and durability.

Function and Design

The crankshaft serves as the primary rotational force generator in the engine, while the connecting rod links the crankshaft to the piston, allowing the piston’s linear movement to be converted into rotational energy. Both parts must be precisely engineered to withstand the immense forces generated during operation. The crankshaft typically features counterweights to reduce vibrations, while the connecting rod is designed for strength, ensuring the smooth transmission of power.

Maintenance and Care

Regular inspection and maintenance of the crankshaft and connecting rod assembly are vital to ensure long-term engine performance. Proper lubrication helps reduce friction and prevent wear, while keeping the parts free from dirt and debris is essential to avoid damage. Any signs of cracks, wear, or deformation should be addressed immediately to avoid costly repairs or engine failure. Additionally, ensuring the correct torque specifications when reassembling these parts will maintain their integrity and functionality.

Honda GX670 Carburetor Components Explained

The carburetor is a crucial component in the engine’s fuel delivery system, ensuring the proper mix of air and fuel for combustion. It consists of various parts that work together to regulate engine performance, from starting to running at optimal efficiency. Understanding these components is essential for troubleshooting and maintenance.

Throttle Valve: The throttle valve controls the amount of air and fuel entering the engine. When the throttle is opened, it allows more fuel and air to flow, increasing engine speed and power. A malfunctioning throttle valve can lead to poor acceleration or stalling.

Needle Valve: The needle valve regulates the fuel flow to the carburetor’s float chamber. It ensures that the correct amount of fuel is available for the air-fuel mixture. If it gets clogged or wears out, fuel delivery can become inconsistent, affecting engine performance.

Float Chamber: The float chamber maintains a constant level of fuel within the carburetor. The float inside rises as the fuel level increases, closing the needle valve when the correct fuel level is reached. This prevents overfilling and ensures stable operation.

Jets: Jets are small, precisely calibrated nozzles that meter the fuel flow into the air stream. There are typically different jets for idle, low, and high-speed operation. Clogged jets can disrupt fuel flow, causing rough idling or poor throttle response.

Choke: The choke is used to enrich the air-fuel mixture during engine startup, especially in colder conditions. It temporarily limits the air intake, allowing the engine to run smoother at low temperatures. Improper choke function can result in hard starting or

Electrical System: Wiring and Connections

The electrical system of any small engine is crucial for its operation, ensuring power is delivered efficiently to all necessary components. Proper wiring and secure connections are vital for maintaining the functionality of the engine, preventing malfunctions and ensuring long-term reliability. This section will explore the essential aspects of the electrical network, focusing on the distribution of power and key wiring components.

Key Components of the Electrical Network

The primary components of the electrical network include the ignition system, starter motor, battery, and various sensors. Each part must be properly connected to ensure smooth operation. Faulty connections or wear and tear on wires can lead to performance issues such as starting problems or power loss.

Wiring Tips and Best Practices

When working with the electrical network, it’s important to use high-quality cables that can withstand vibrations and environmental factors. Proper insulation is crucial for safety, and ensuring secure connections is key to avoiding shorts or power interruptions. Always check for signs of corrosion or fraying that may compromise the system’s integrity.

Valve Train: Key Parts and Maintenance

The valve train is a critical component in any engine, responsible for managing the intake and exhaust valves. It ensures proper engine performance by controlling the timing of valve openings and closings. Regular maintenance of this system is vital for optimal engine efficiency and longevity, preventing issues that could lead to costly repairs.

Essential Components of the Valve Train

The valve train consists of several key components, each playing a specific role in the operation of the engine. These include the camshaft, push rods, rocker arms, valves, and springs. The camshaft is responsible for opening and closing the valves at precise intervals, while the rocker arms help transfer motion from the camshaft to the valves. Springs control the closing force of the valves, ensuring they return to their seat after being opened.

Maintenance Tips for Valve Train Efficiency

Maintaining the valve train involves regular inspection and lubrication of its parts. The camshaft and rocker arms should be checked for wear and tear, as these parts are subject to significant stress. Ensuring that the valve springs are functioning properly is also crucial, as worn springs can lead to improper valve seating, resulting in poor engine performance. Regular oil changes and using high-quality engine oil can prevent premature wear of these components.

Air Filtration System and Its Components

The air filtration system plays a crucial role in ensuring the optimal performance of internal combustion engines. It serves as a protective barrier, preventing harmful particles and debris from entering the engine. A well-designed filtration system is essential for maintaining engine efficiency, prolonging its lifespan, and reducing the risk of damage caused by contaminants in the air intake.

Key Elements of the Filtration System

At the heart of the air filtration system lies the filter element, which traps dust, dirt, and other foreign particles. The filter is typically housed in a protective casing that helps secure it in place while allowing air to pass through efficiently. An air filter element can come in different forms, such as paper, foam, or cotton, each with its own advantages in terms of filtration efficiency and durability.

Supporting Components and Maintenance

Supporting components such as the air intake housing, sealants, and pre-filters are critical to the system’s overall functionality. The intake housing ensures that clean air is directed into the system, while the sealants prevent air leakage that could reduce filtration efficiency. Regular maintenance, including cleaning and replacing the filter, is necessary to keep the system working at peak performance.

Fuel System Components and Functions

The fuel system plays a critical role in delivering energy to the engine. It ensures efficient operation by controlling the flow and mixture of fuel required for combustion. This section will cover the main elements that make up the system and their individual roles in maintaining a balanced and smooth performance.

Key Elements of the System