Comprehensive Guide to Outboard Engine Parts Diagram

The intricate world of watercraft propulsion systems is essential for anyone seeking to enhance their knowledge of marine mechanics. A clear comprehension of the various elements involved can significantly improve maintenance and troubleshooting efforts. This guide will illuminate the structure and function of each crucial component, paving the way for more efficient operation and repair.

Whether you are a seasoned technician or a passionate hobbyist, familiarity with the assembly of these mechanical systems is invaluable. From power generation to the transmission of thrust, each segment plays a vital role in ensuring smooth navigation on the water. By breaking down these mechanisms into their fundamental units, we can gain insights into their performance and interrelations.

Exploring the arrangement and functionality of these components not only deepens our understanding but also empowers us to make informed decisions regarding upgrades and repairs. As we delve into the specifics, it becomes evident how these parts collaborate to create a seamless experience on the waves.

Understanding Outboard Engine Components

Gaining insight into the various elements of a marine propulsion system is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring smooth operation and reliability on the water. By familiarizing oneself with these essential features, users can enhance their overall experience and troubleshoot potential issues effectively.

Key Elements of Marine Propulsion Systems

Among the primary components are the fuel delivery systems, which ensure that the right mixture reaches the combustion chamber. Additionally, the cooling apparatus is pivotal in preventing overheating, while the drive mechanism transfers power efficiently to the propeller, propelling the vessel forward. Understanding these functions helps in appreciating the complexity of marine technology.

Maintenance and Care

Regular upkeep of these critical components not only prolongs their lifespan but also enhances performance. Identifying wear and tear early can prevent more significant problems down the line. A proactive approach to maintenance guarantees that each element operates at its ultimate capacity, providing a safe and enjoyable maritime experience.

Essential Parts of Outboard Motors

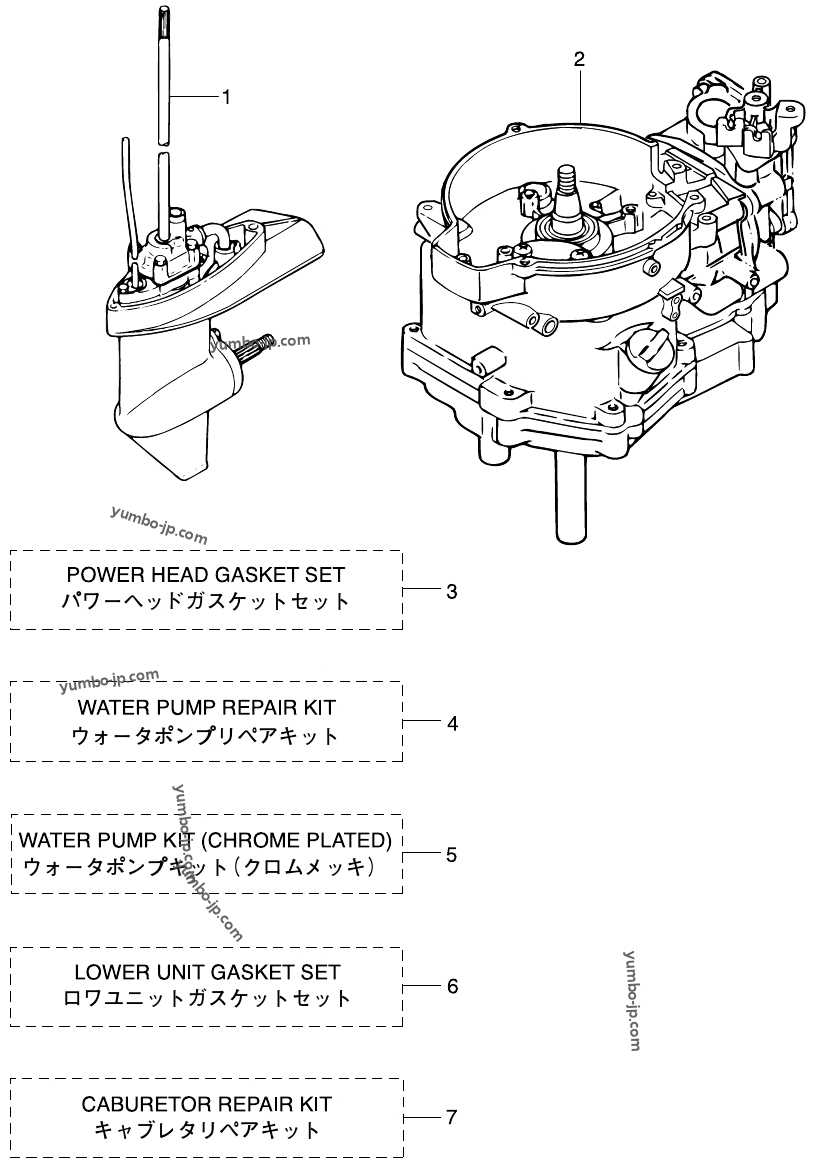

Understanding the key components of marine propulsion systems is crucial for optimal performance and maintenance. These crucial elements work in harmony to ensure smooth operation on the water, enabling boats to navigate effectively.

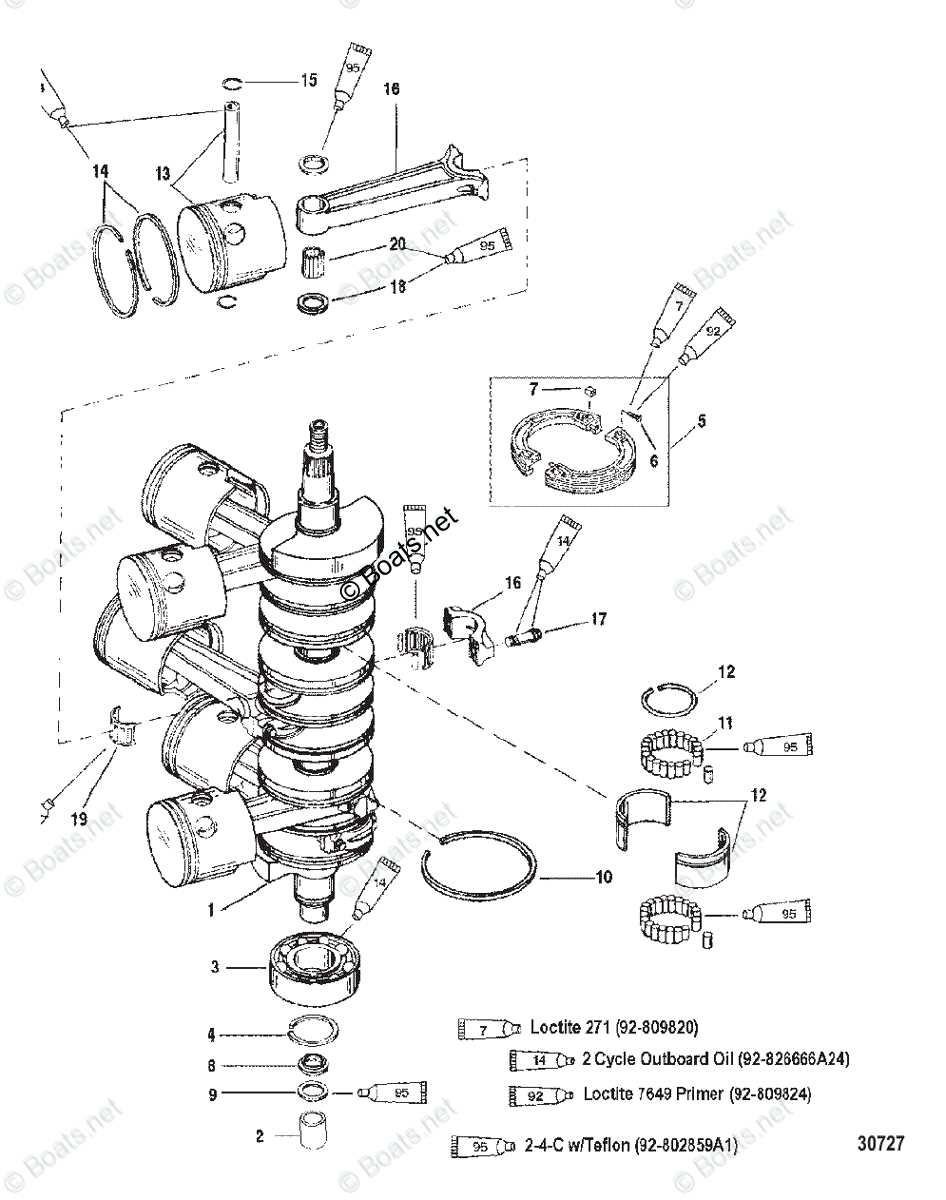

Powerhead: This is the powerhouse of the system, housing the combustion chamber and various mechanisms that convert fuel into motion.

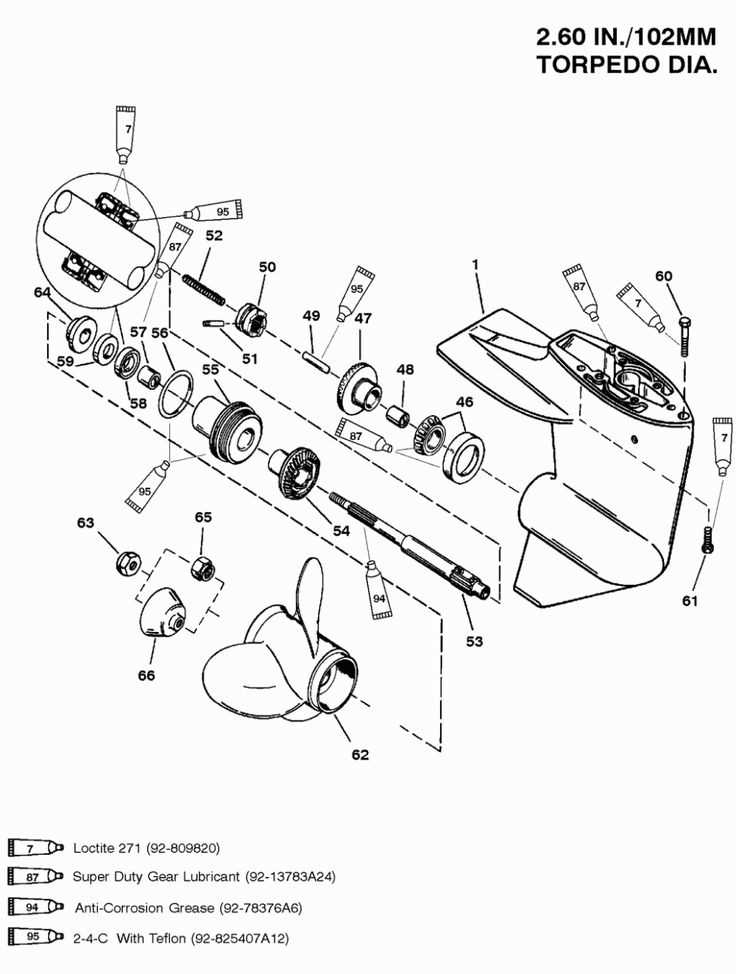

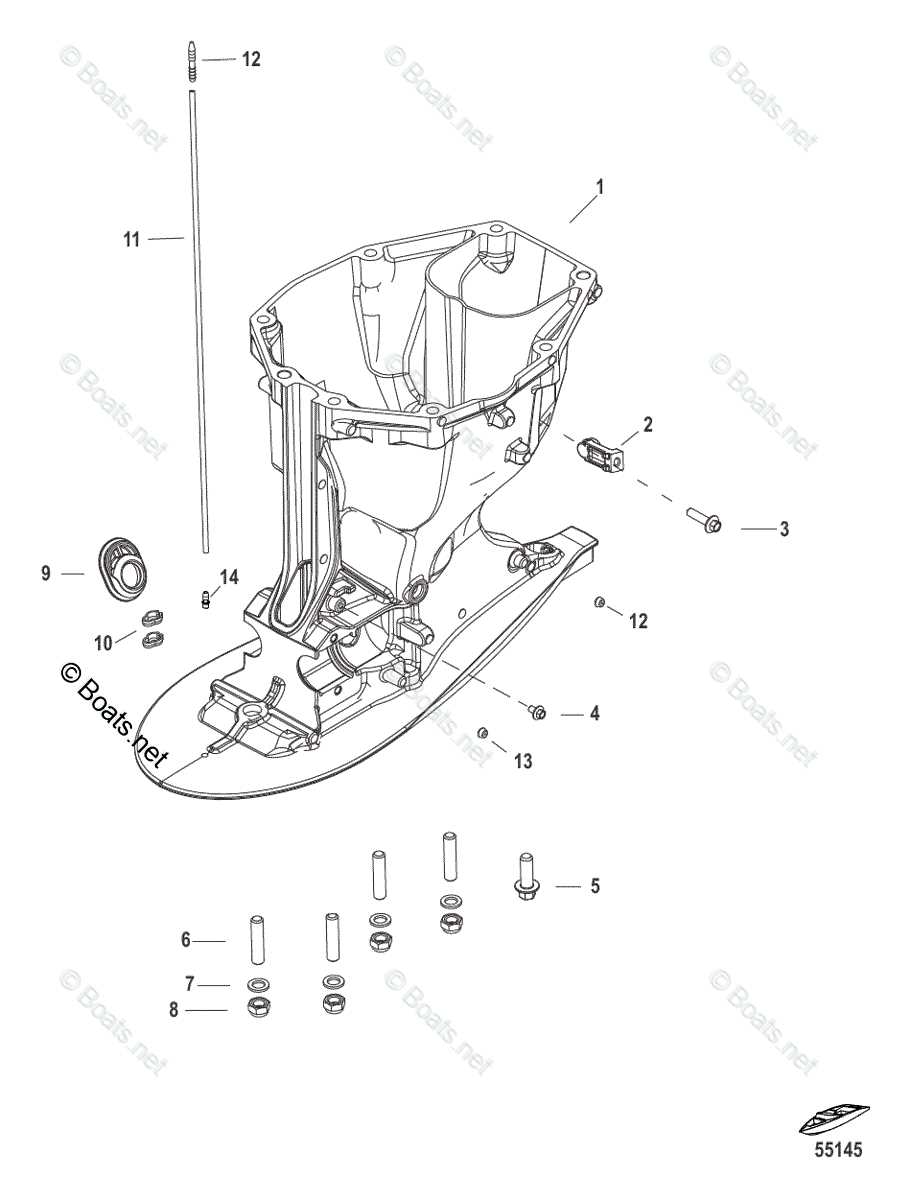

Lower Unit: This section includes the gearcase and driveshaft, facilitating the transfer of power from the engine to the propeller, ultimately propelling the vessel forward.

Propeller: Serving as the primary thrust provider, the propeller transforms rotational energy into movement, allowing for various speeds and maneuverability.

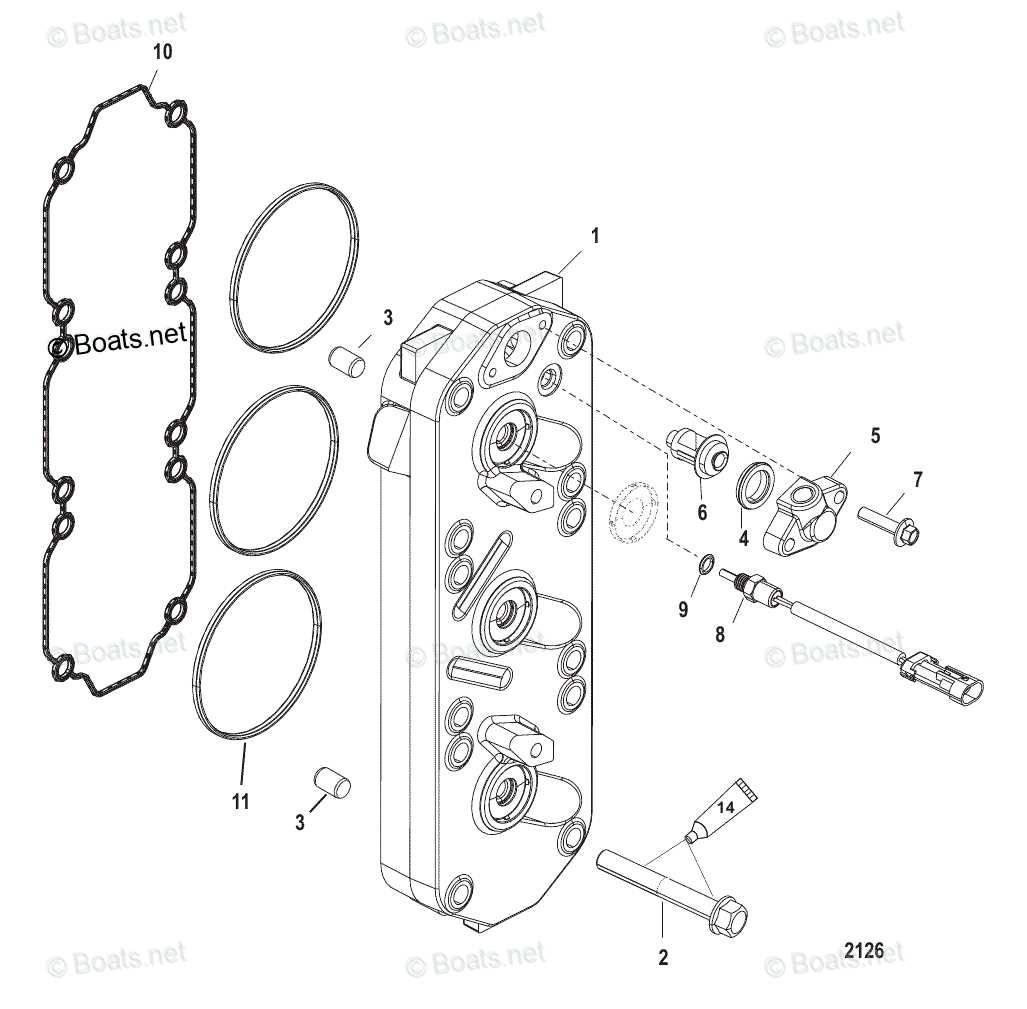

Cooling System: Essential for regulating temperature, this system prevents overheating by circulating water around vital components, ensuring longevity and reliability.

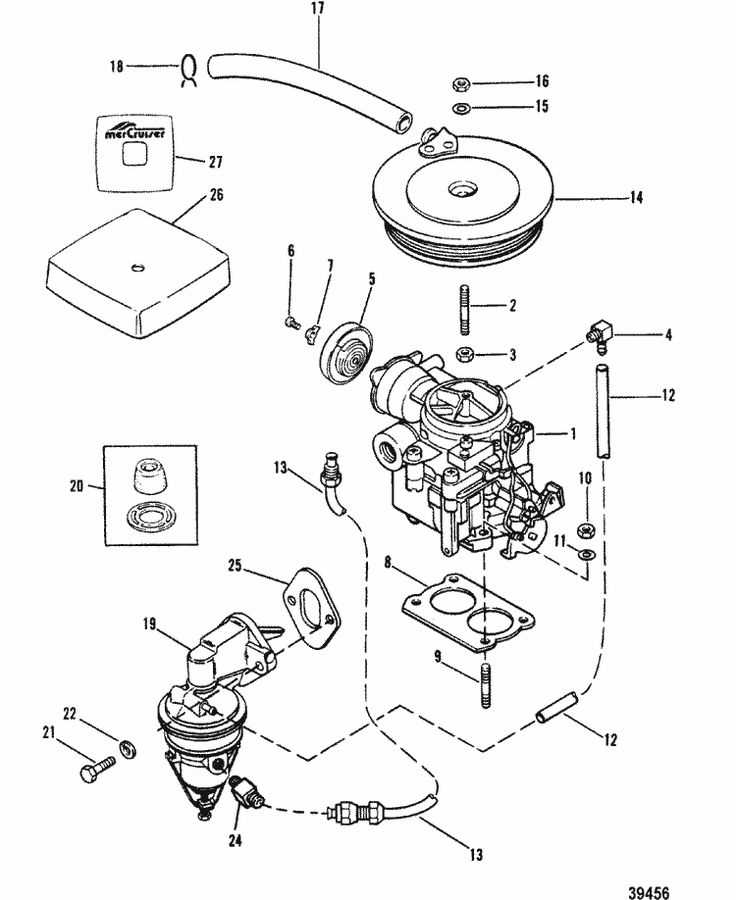

Fuel System: This component manages the intake and delivery of fuel to the combustion chamber, ensuring efficient operation and performance.

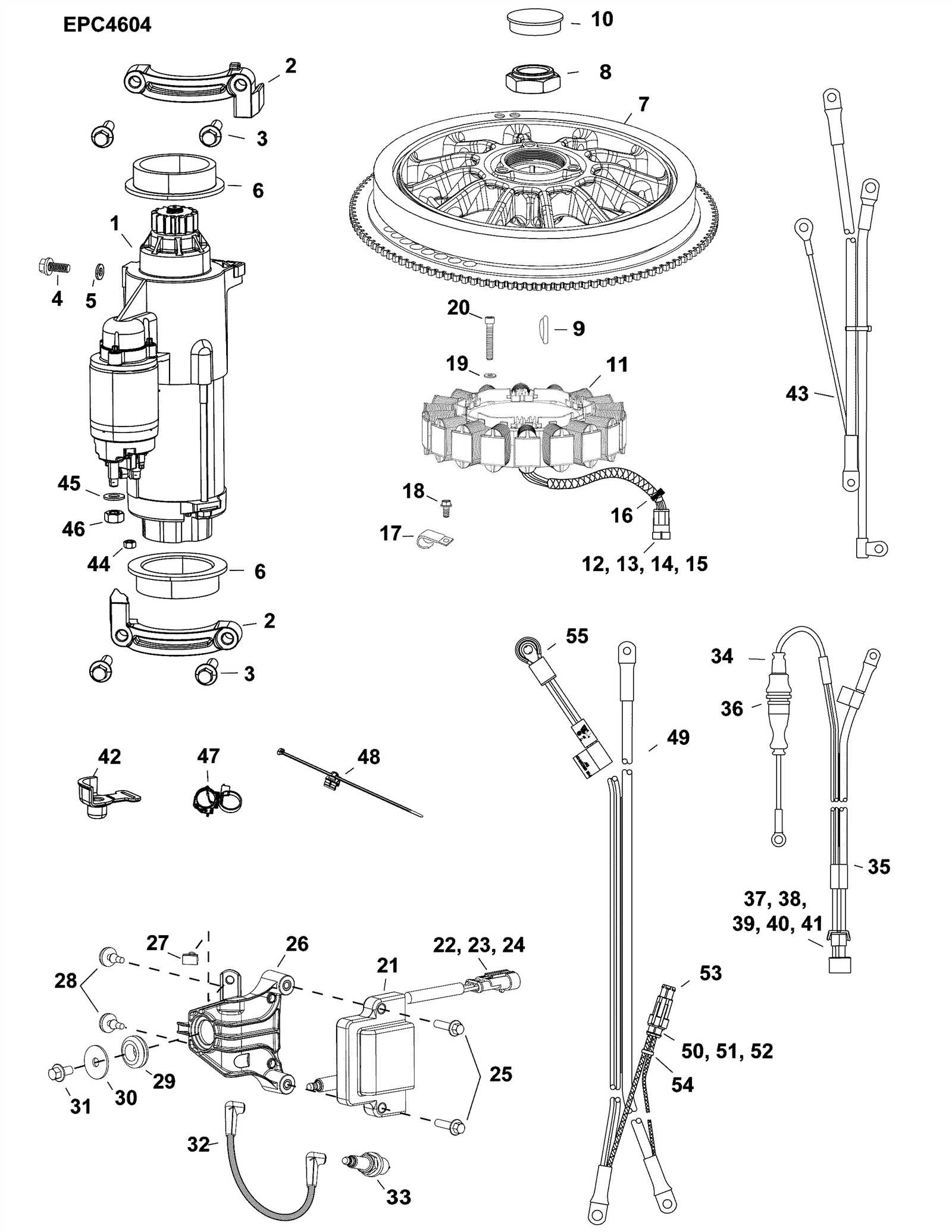

Electrical System: This network powers various functionalities, from starting mechanisms to navigation lights, making it an integral part of the entire setup.

By comprehensively understanding these components, operators can better maintain and troubleshoot their marine systems, leading to enhanced performance and durability.

Functionality of Each Engine Component

This section delves into the essential roles played by various elements within the mechanical system, emphasizing their importance in ensuring optimal performance and efficiency. Each component contributes uniquely to the overall functionality, enabling the machinery to operate smoothly and reliably.

- Power Generation: The primary function is to convert fuel into mechanical energy, which drives the entire system.

- Fuel Delivery: This component ensures a steady supply of fuel to the combustion chamber, facilitating efficient burning.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring longevity.

- Lubrication: Reduces friction between moving parts, minimizing wear and tear while enhancing performance.

- Ignition: Responsible for initiating combustion, ensuring that the fuel mixture ignites at the correct moment.

- Exhaust Management: Safely expels combustion byproducts, contributing to cleaner operation and compliance with environmental standards.

Each of these components works in harmony, highlighting the intricate design and engineering that underpins high-performance machinery.

Common Outboard Engine Repair Issues

Maintenance and repair are essential for the longevity of any marine propulsion system. Understanding frequent malfunctions can help users address problems before they escalate. This section explores typical challenges encountered by boat enthusiasts.

1. Fuel System Problems

Issues within the fuel system can lead to performance inefficiencies. Clogs and leaks often stem from debris or degraded components, impacting overall functionality.

2. Electrical Failures

Electrical components are critical for operation. Faulty wiring, corroded connections, or dead batteries frequently disrupt performance and require prompt attention.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Fuel Leak | Visible leakage, poor acceleration | Inspect hoses, replace damaged fittings |

| Hard Starting | Long cranking time, stalling | Check battery, inspect spark plugs |

| Overheating | Warning alarms, steam | Clean cooling passages, check thermostat |

Maintenance Tips for Engine Longevity

Proper upkeep is essential for ensuring a long lifespan and optimal performance of your machinery. Implementing regular maintenance practices can help prevent unexpected breakdowns and costly repairs.

- Regularly check fluid levels to ensure they are clean and adequate.

- Inspect and replace filters as necessary to maintain efficiency.

- Keep all external components clean to prevent corrosion and wear.

- Schedule routine inspections to catch potential issues early.

- Utilize quality fuel to minimize deposits and enhance performance.

By following these guidelines, you can significantly extend the operational life of your equipment and enhance its reliability.

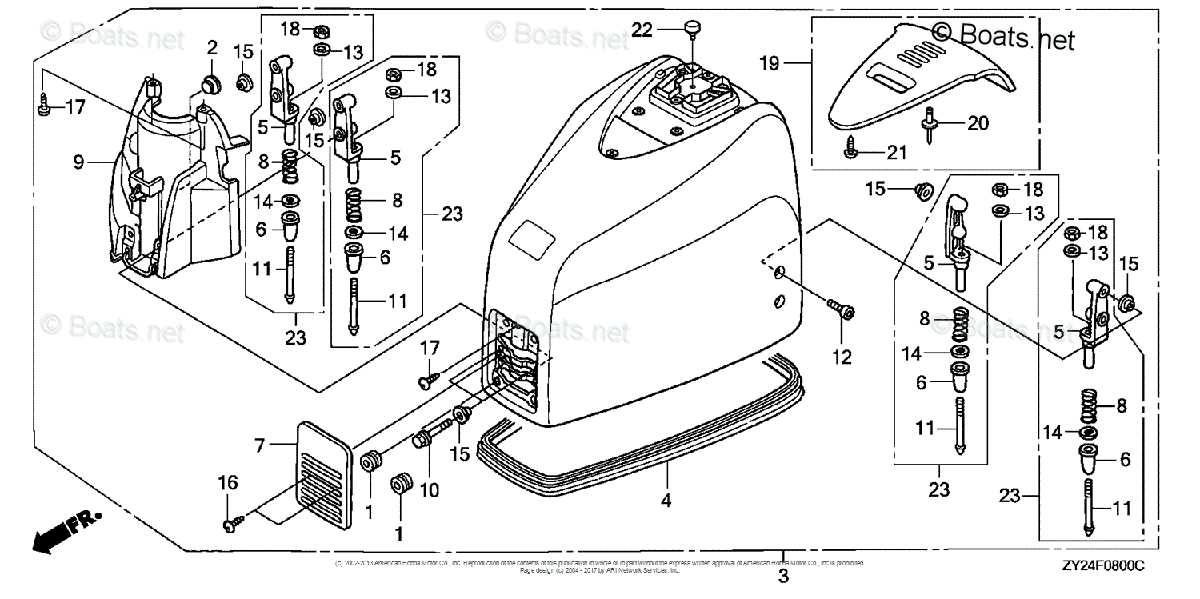

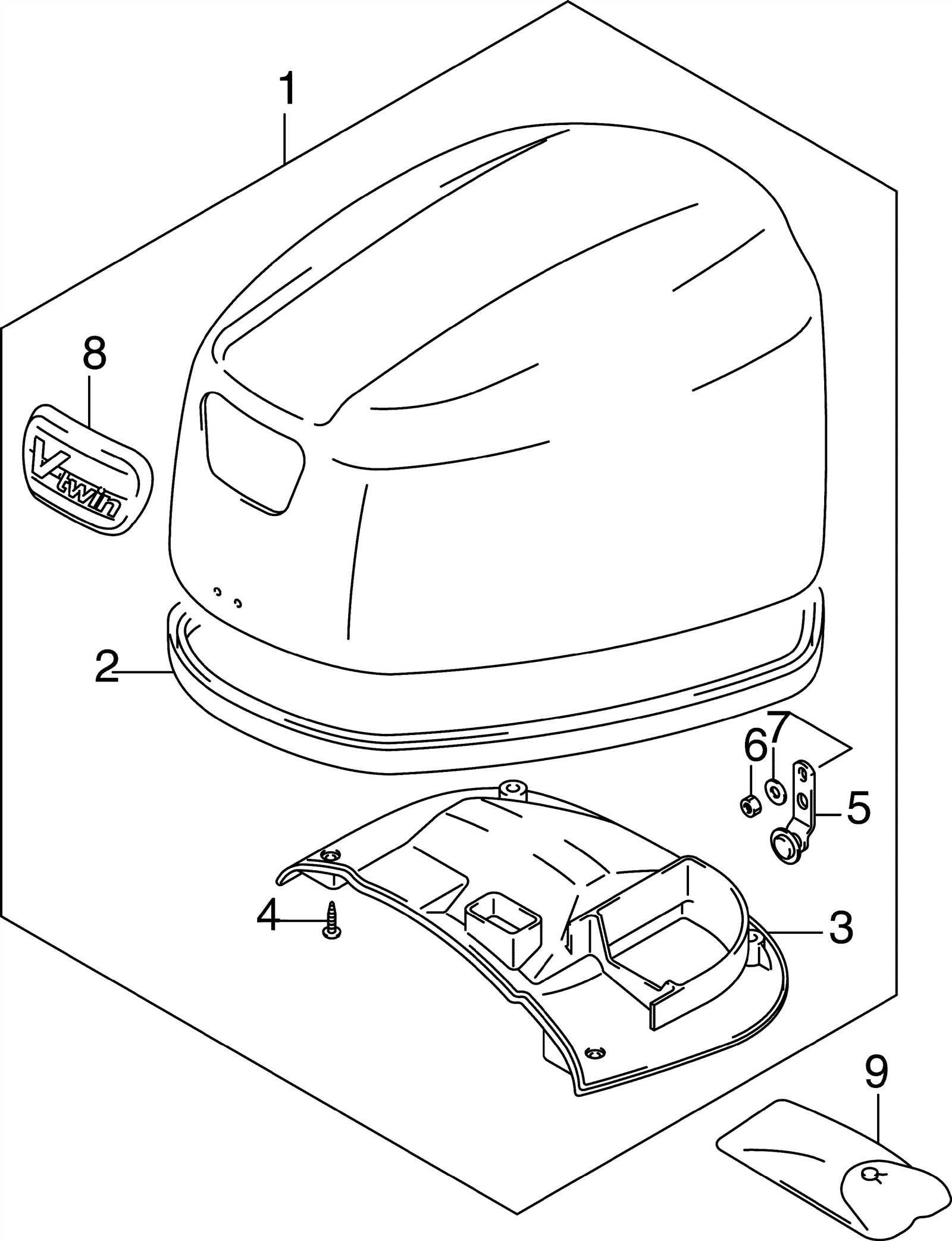

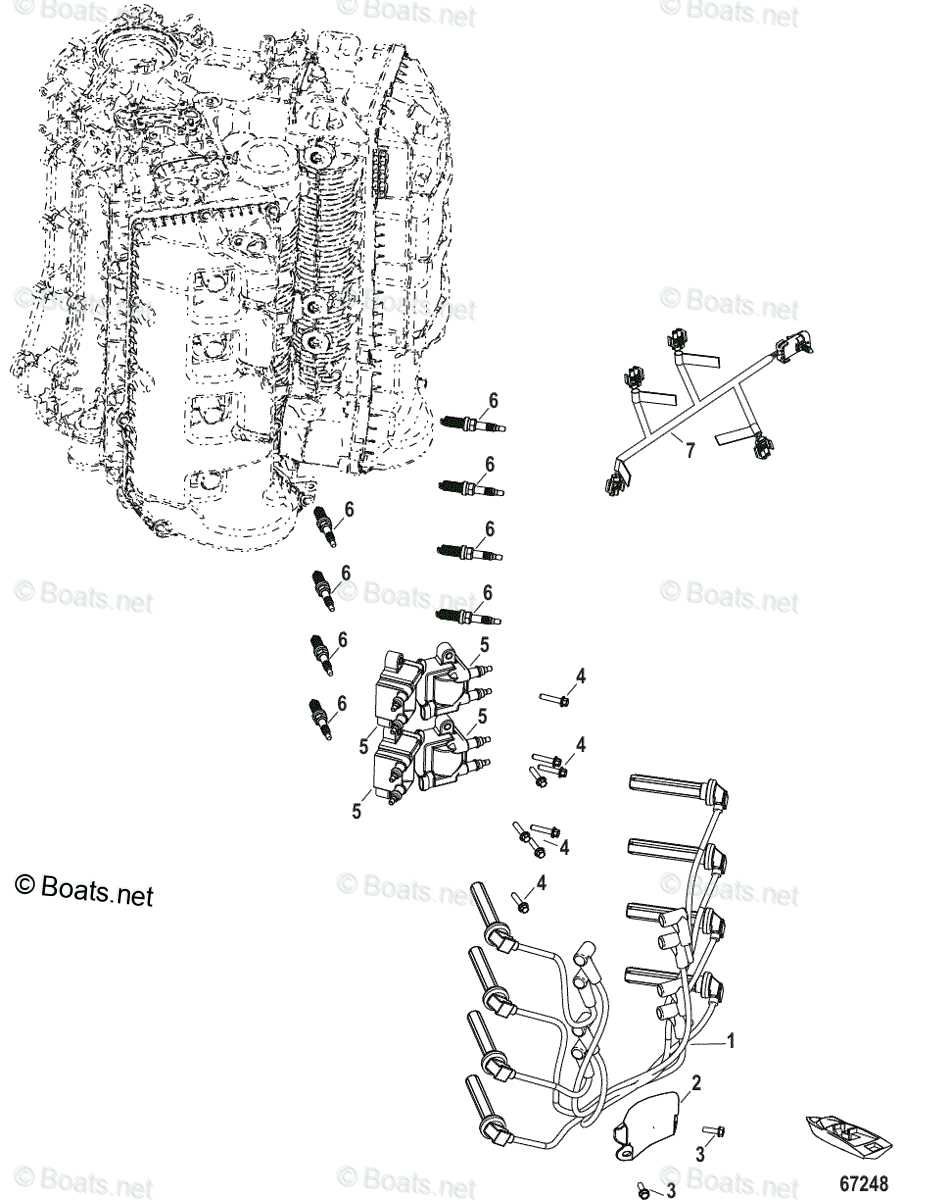

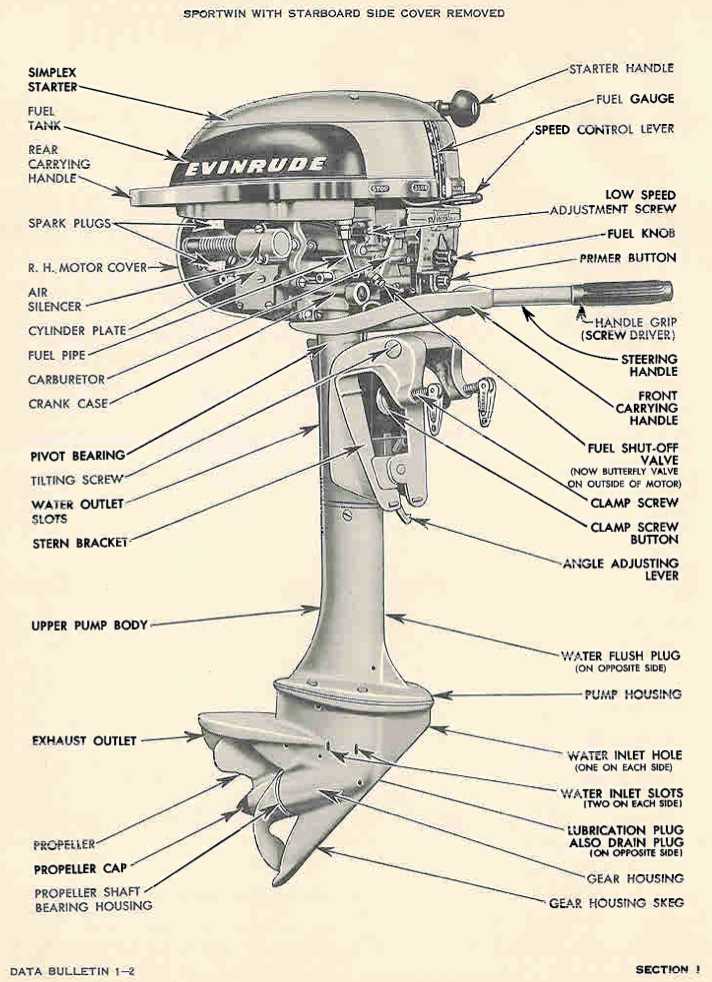

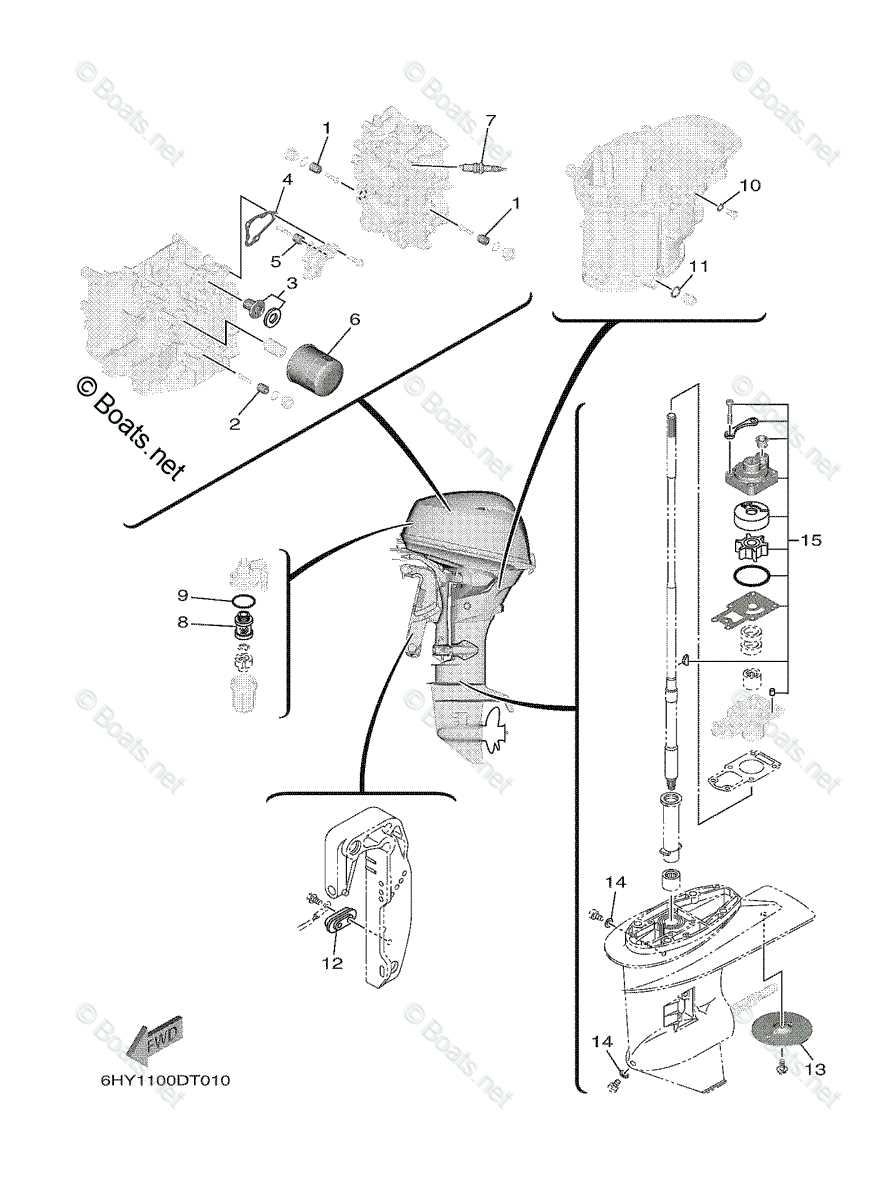

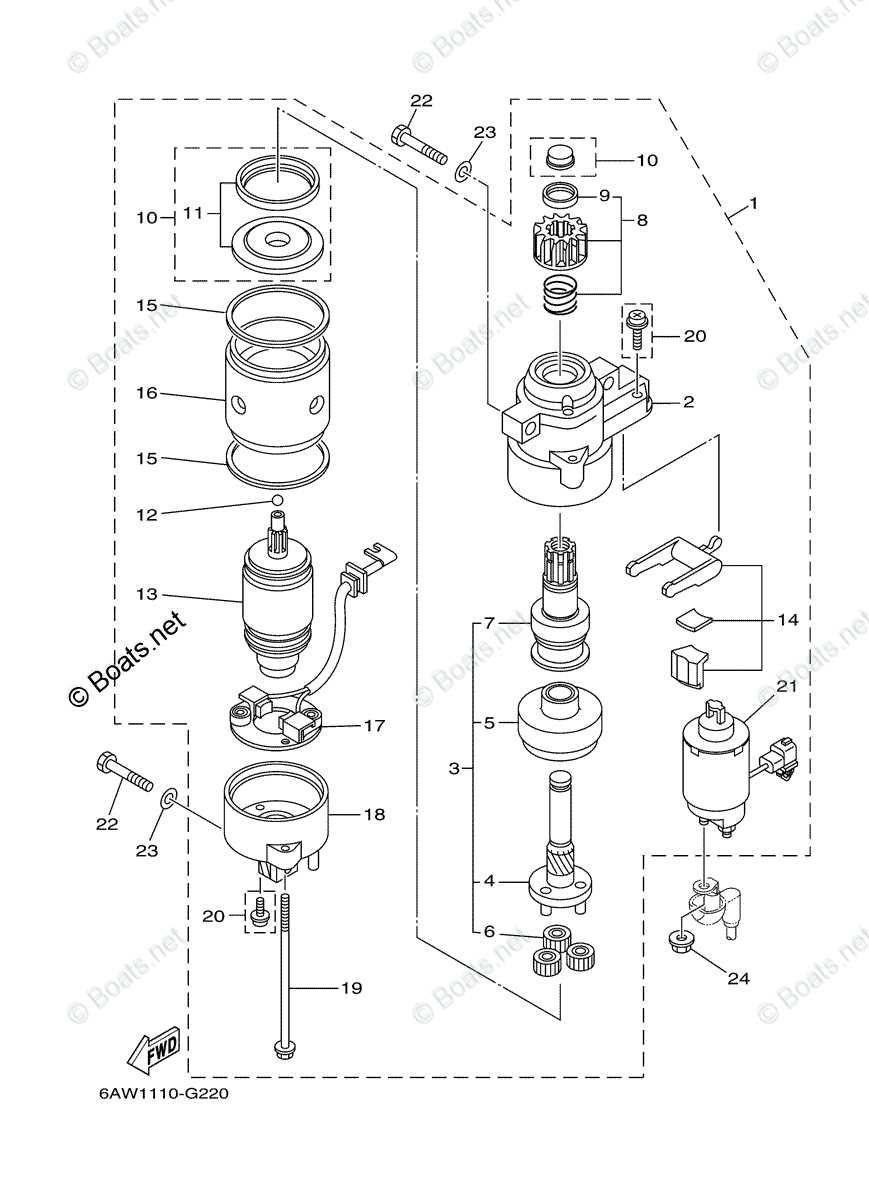

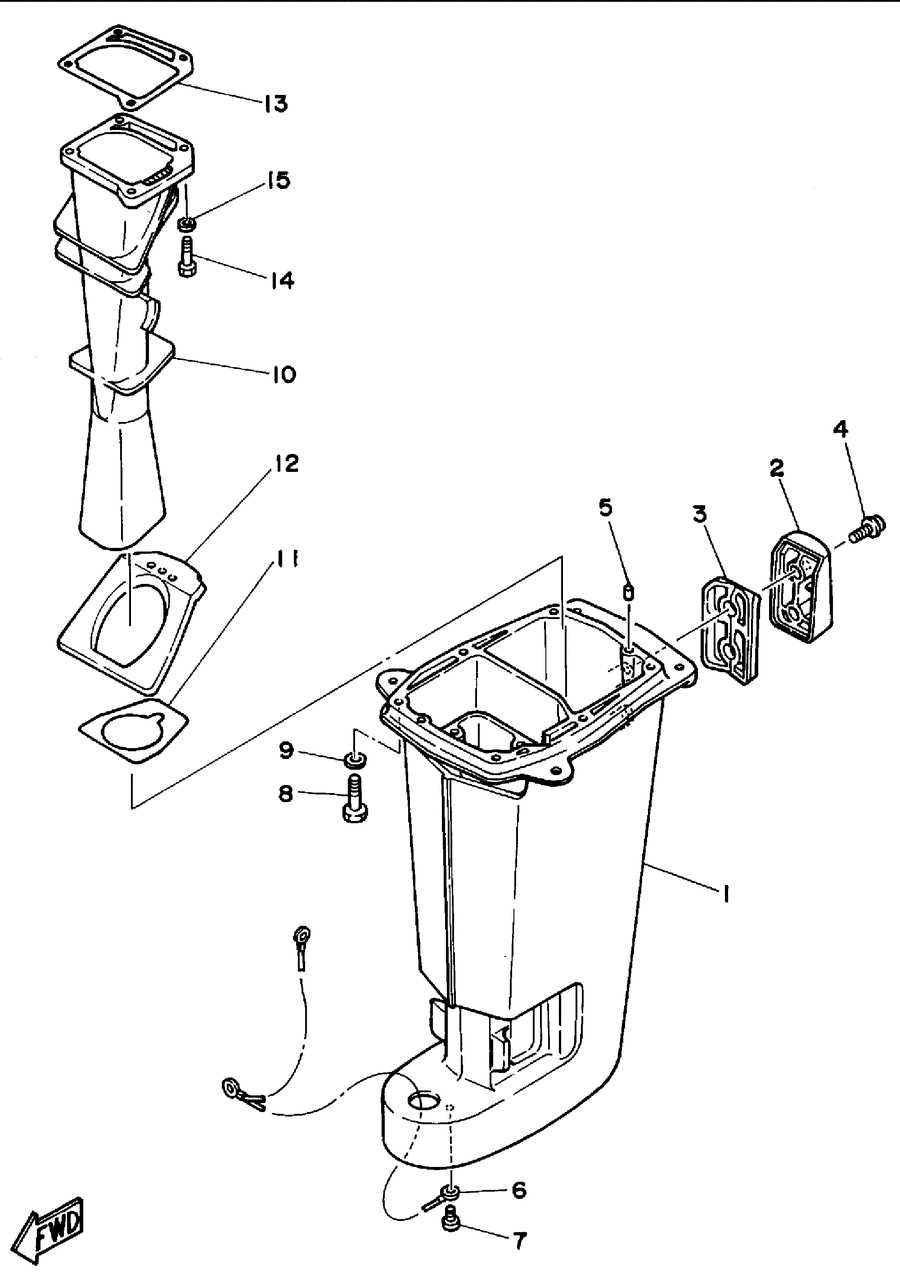

Identifying Parts in Diagrams

Understanding the components illustrated in technical representations is crucial for effective maintenance and repair. These visual aids serve as a roadmap, guiding users through the intricate systems involved. Recognizing each element and its function empowers individuals to troubleshoot issues with confidence.

Typically, these visuals are annotated with labels and symbols that provide essential information. Familiarizing yourself with common terminologies and representations is key to interpreting these schematics accurately. For instance, various shapes may denote specific functionalities, while connecting lines can indicate relationships between elements.

Moreover, paying attention to scale and proportions can reveal how components interact within the overall structure. Being mindful of these details enhances comprehension and facilitates effective assembly or disassembly tasks. Ultimately, mastering the art of identification can significantly streamline the repair process, ensuring optimal performance.

Choosing Quality Replacement Parts

Selecting high-quality components for your machinery is essential to ensure optimal performance and longevity. With countless options available, it’s vital to understand how to discern quality replacements from subpar alternatives, as this can significantly affect reliability and safety.

Key Factors to Consider

When evaluating options, focus on the material, compatibility, and manufacturer reputation. High-grade materials often translate to better durability and efficiency. Ensuring that the replacement fits seamlessly with existing mechanisms is crucial for preventing issues down the line. Lastly, consider products from established brands known for their commitment to quality.

Comparison of Quality Indicators

| Indicator | High Quality | Low Quality |

|---|---|---|

| Material | Corrosion-resistant, durable | Cheap, prone to wear |

| Compatibility | Perfect fit, tested | Loose fit, untested |

| Brand Reputation | Well-reviewed, trusted | Little feedback, unknown |

Investing time in research and considering these indicators will ultimately lead you to the best choices for reliable replacements, enhancing your overall experience.

Importance of Proper Engine Setup

Ensuring an optimal arrangement of your propulsion system is crucial for achieving peak performance and longevity. A well-executed setup not only enhances efficiency but also contributes to safety on the water. Proper configuration minimizes wear and tear, leading to a smoother experience and reduced maintenance costs.

Benefits of a Correct Configuration

- Improved Fuel Efficiency: A finely tuned system maximizes fuel usage, saving money in the long run.

- Enhanced Performance: Achieving the right balance leads to better speed and responsiveness.

- Extended Lifespan: Reducing unnecessary strain on components prevents premature failure.

- Increased Safety: A properly arranged mechanism ensures reliable operation, reducing the risk of accidents.

Key Considerations for Setup

- Alignment: Ensure that all components are correctly aligned to prevent vibration and damage.

- Calibration: Regularly check settings and make adjustments to maintain optimal performance.

- Maintenance: Routine inspections can identify issues early, allowing for timely repairs.

- Installation: Follow manufacturer guidelines to ensure every part is positioned as intended.

Taking the time to focus on a meticulous arrangement pays off significantly, ensuring a reliable and enjoyable experience on the water.

Common Myths About Outboard Engines

In the world of marine propulsion, misconceptions abound, often leading to confusion and misinformation. Understanding these fallacies can enhance both performance and safety.

- Myth 1: Larger models are always better.

- Myth 2: Fuel efficiency is not a concern for recreational use.

- Myth 3: Maintenance is only necessary when issues arise.

- Myth 4: Only professional technicians can perform repairs.

- Myth 5: They are too complicated for novice users.

Dispelling these myths can lead to a more informed approach to marine machinery, ultimately enhancing the experience on the water.

Upgrading Outboard Engine Performance

Enhancing the performance of your watercraft can lead to a more thrilling experience on the water. This process involves a combination of optimizing various components and making thoughtful modifications. Whether you’re looking to increase speed, improve fuel efficiency, or boost overall handling, understanding the key areas for improvement is essential.

Key Areas for Improvement

- Propulsion System: Choosing the right propeller can significantly impact your vessel’s speed and efficiency.

- Fuel Delivery: Upgrading to a high-performance fuel system can enhance power output and throttle response.

- Intake and Exhaust: Modifying these systems can improve airflow and exhaust flow, resulting in better combustion.

- Weight Reduction: Removing unnecessary items or replacing heavy components with lighter alternatives can enhance overall performance.

Performance Modification Options

- Upgrade the propeller for optimal performance based on your specific requirements.

- Install a performance chip to enhance fuel mapping and increase power.

- Consider aftermarket intake systems for improved airflow.

- Evaluate the benefits of a high-performance exhaust system.

Implementing these upgrades not only maximizes your craft’s capabilities but also elevates your enjoyment on the water. Proper planning and execution are key to achieving the desired results.

Resources for Further Learning

Expanding your knowledge in this field can significantly enhance your understanding and skills. Below are some valuable resources to explore.

- Online Courses:

- Coursera – Offers courses on marine technology.

- Udemy – Features practical classes related to maintenance and repair.

- Books:

- “Marine Engineering” by A. D. W. Smith – A comprehensive guide.

- “Understanding Marine Machinery” by H. J. Stevens – A useful reference.

- Websites:

- MarineLink – Provides articles and news in the maritime industry.

- BoatUS – Offers resources and advice for boat owners.

- YouTube Channels:

- Marine Tech – Focuses on repair techniques and tutorials.

- Boating Tips – Covers various aspects of vessel upkeep.

Utilizing these materials can help you delve deeper into the subject and gain the ultimate expertise in your endeavors.