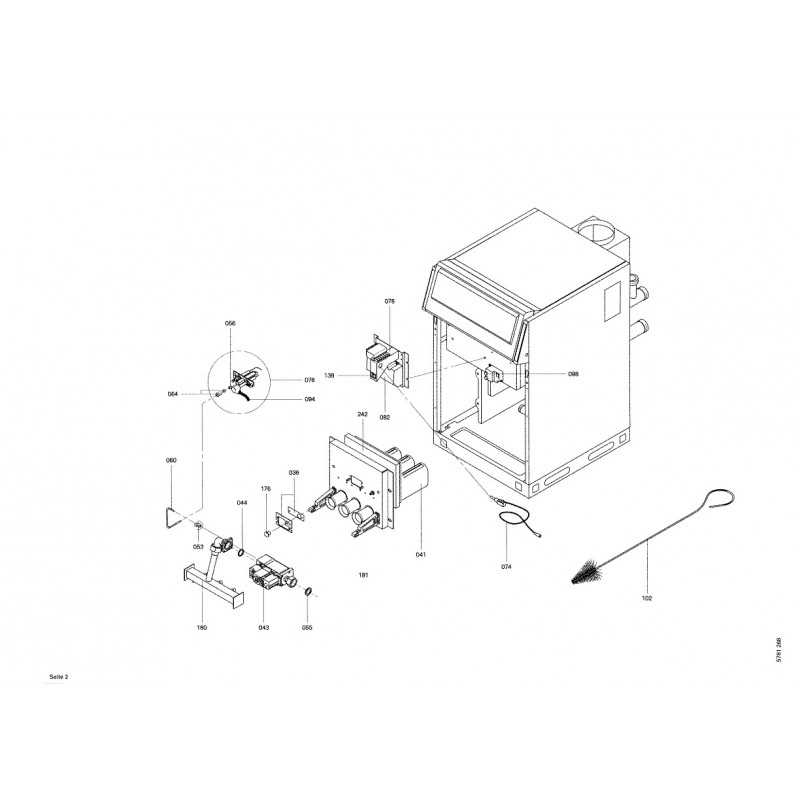

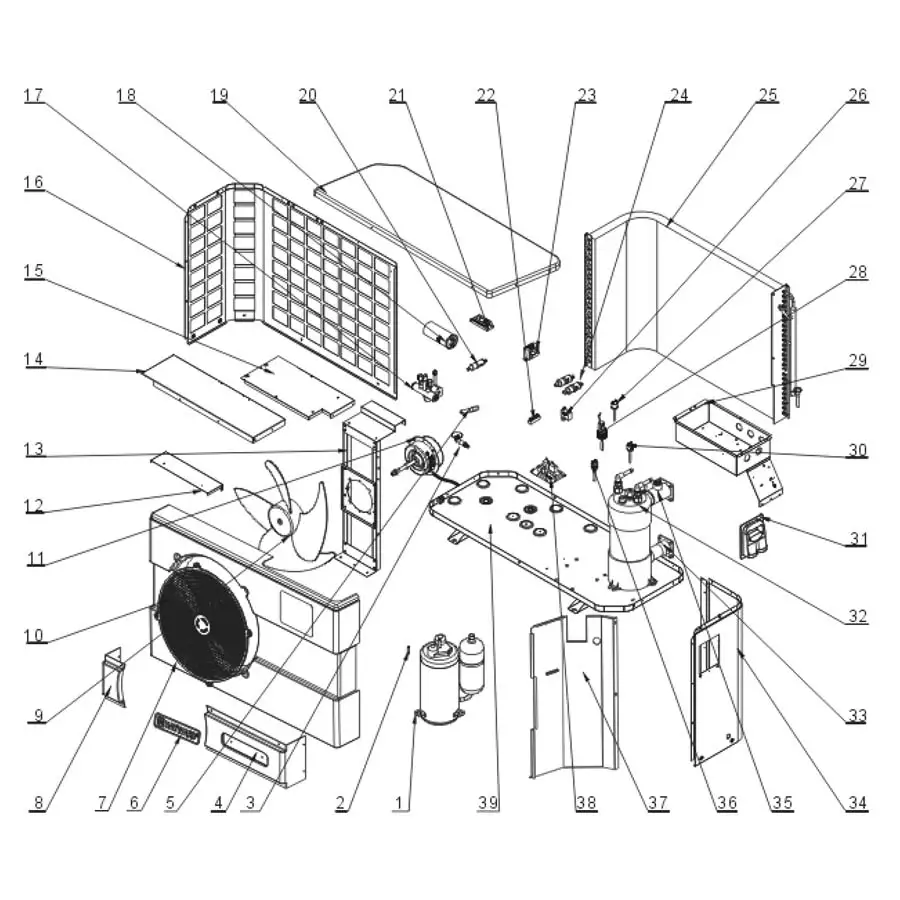

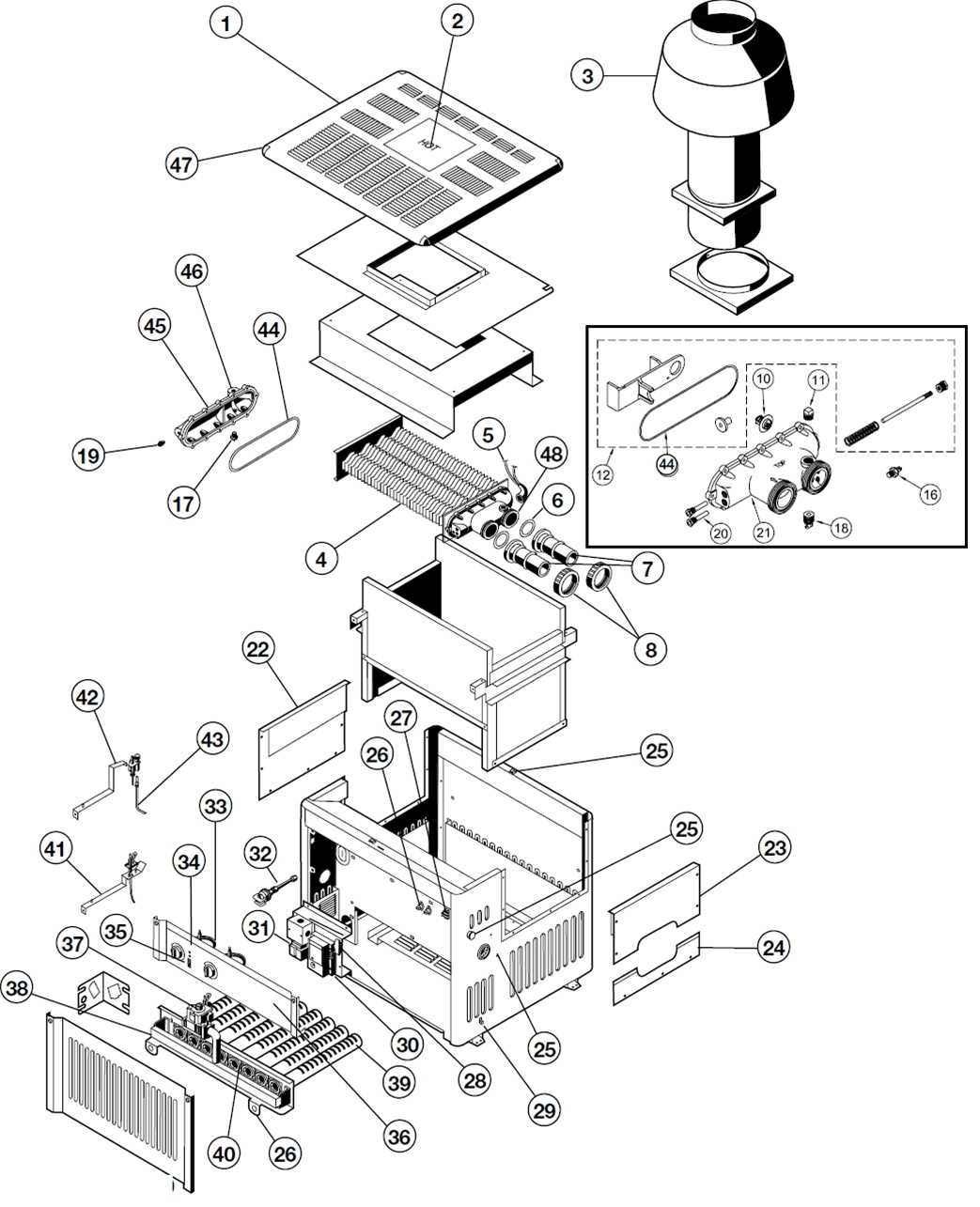

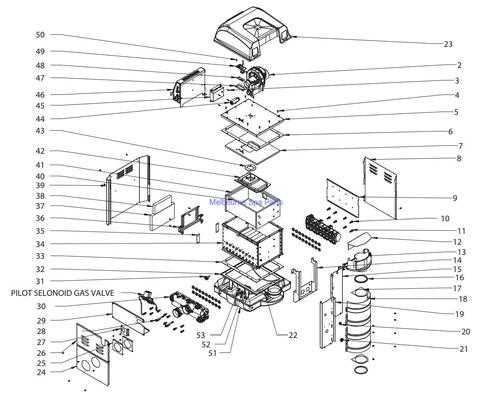

Hayward H200 Pool Heater Parts Diagram

Efficient operation of a heating mechanism is crucial for maintaining optimal conditions in outdoor environments. Knowing the layout and function of individual components can significantly enhance troubleshooting and maintenance. This section provides a comprehensive overview of essential elements involved in the functioning of such systems.

Each element plays a pivotal role in ensuring that the entire system operates seamlessly. Understanding how these components interact allows users to identify potential issues, perform necessary repairs, and ensure longevity. Moreover, familiarizing oneself with these components is beneficial for anyone seeking to optimize their system’s performance.

By exploring the various elements that contribute to the overall functionality, users can gain valuable insights into the intricacies of the setup. This knowledge empowers individuals to make informed decisions regarding maintenance, upgrades, and replacements, ultimately leading to improved efficiency and reliability.

Understanding Hayward H200 Pool Heater

The subject of efficient temperature management for outdoor water environments has gained significant attention. A robust and reliable solution can enhance the enjoyment and usability of such areas throughout the year. Familiarity with the components and functions of these systems is essential for optimal performance and longevity.

Components play a crucial role in ensuring the effective operation of these systems. Each element works in harmony to regulate temperature, circulate water, and maintain desired conditions. Understanding how these components interact can lead to improved efficiency and reduced operational costs.

Maintenance is equally important. Regular checks and servicing can prevent unexpected breakdowns and extend the lifespan of the system. Identifying common issues early on allows for timely interventions, minimizing inconvenience for users.

Overall, a comprehensive grasp of how these systems function contributes to a better experience, ensuring that users can enjoy their water features at the ideal temperature, regardless of external conditions.

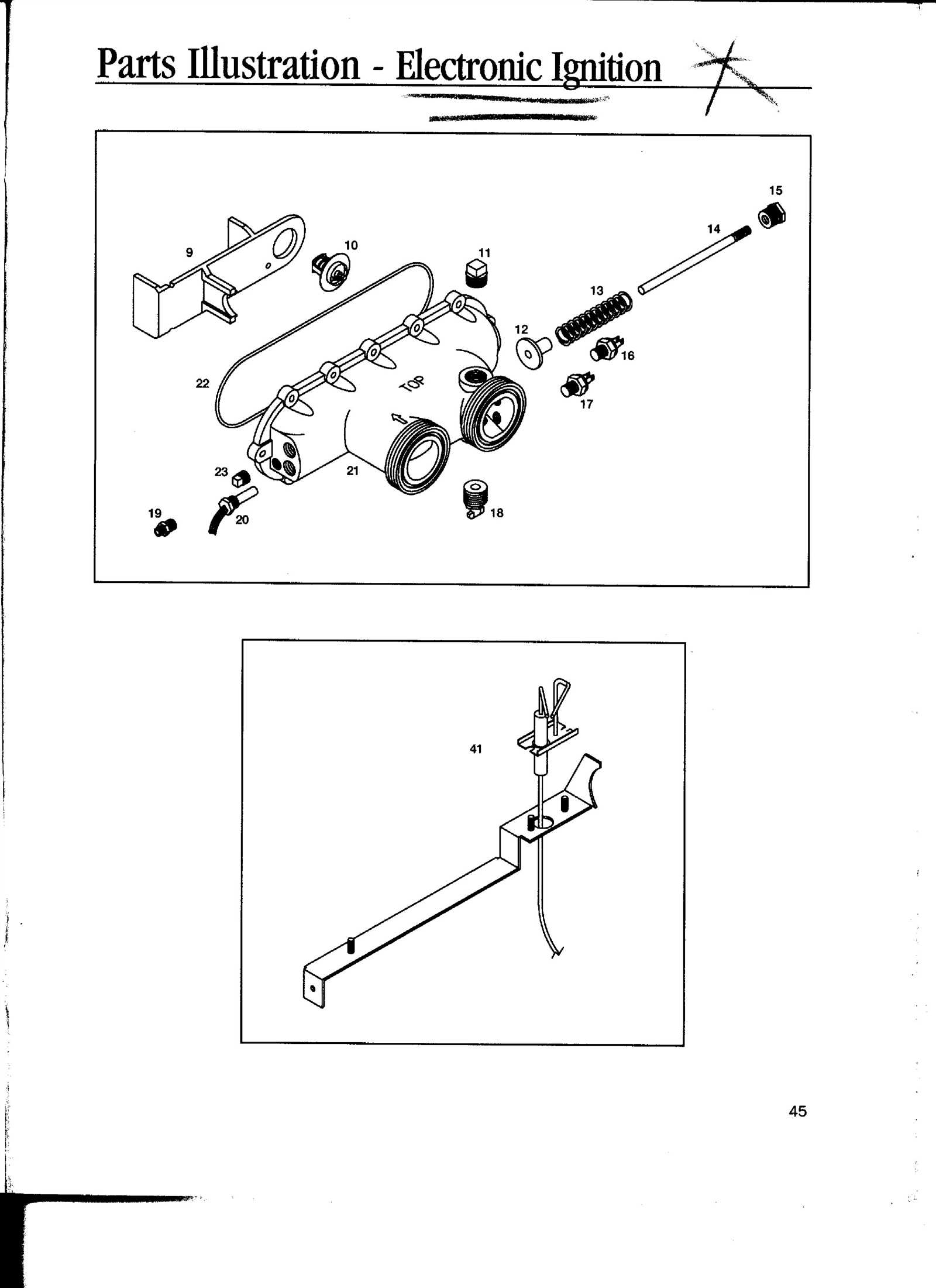

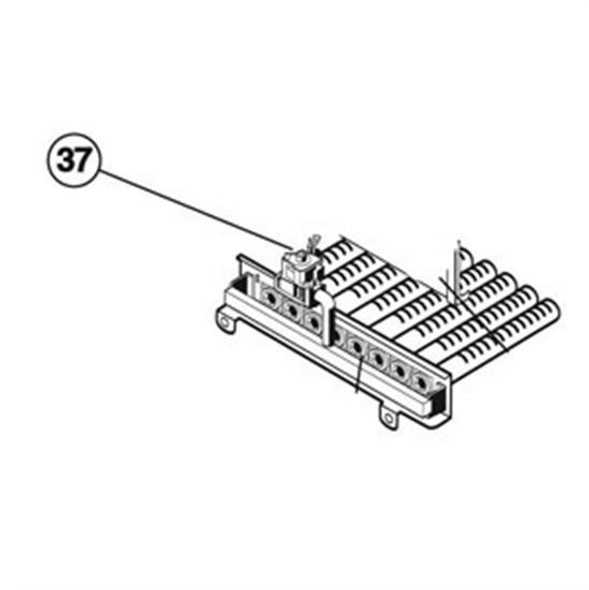

Key Components of the Heater

The functionality of a thermal device relies heavily on various integral elements, each serving a distinct purpose. Understanding these essential components is crucial for effective operation and maintenance, ensuring optimal performance throughout its lifecycle.

Essential Elements

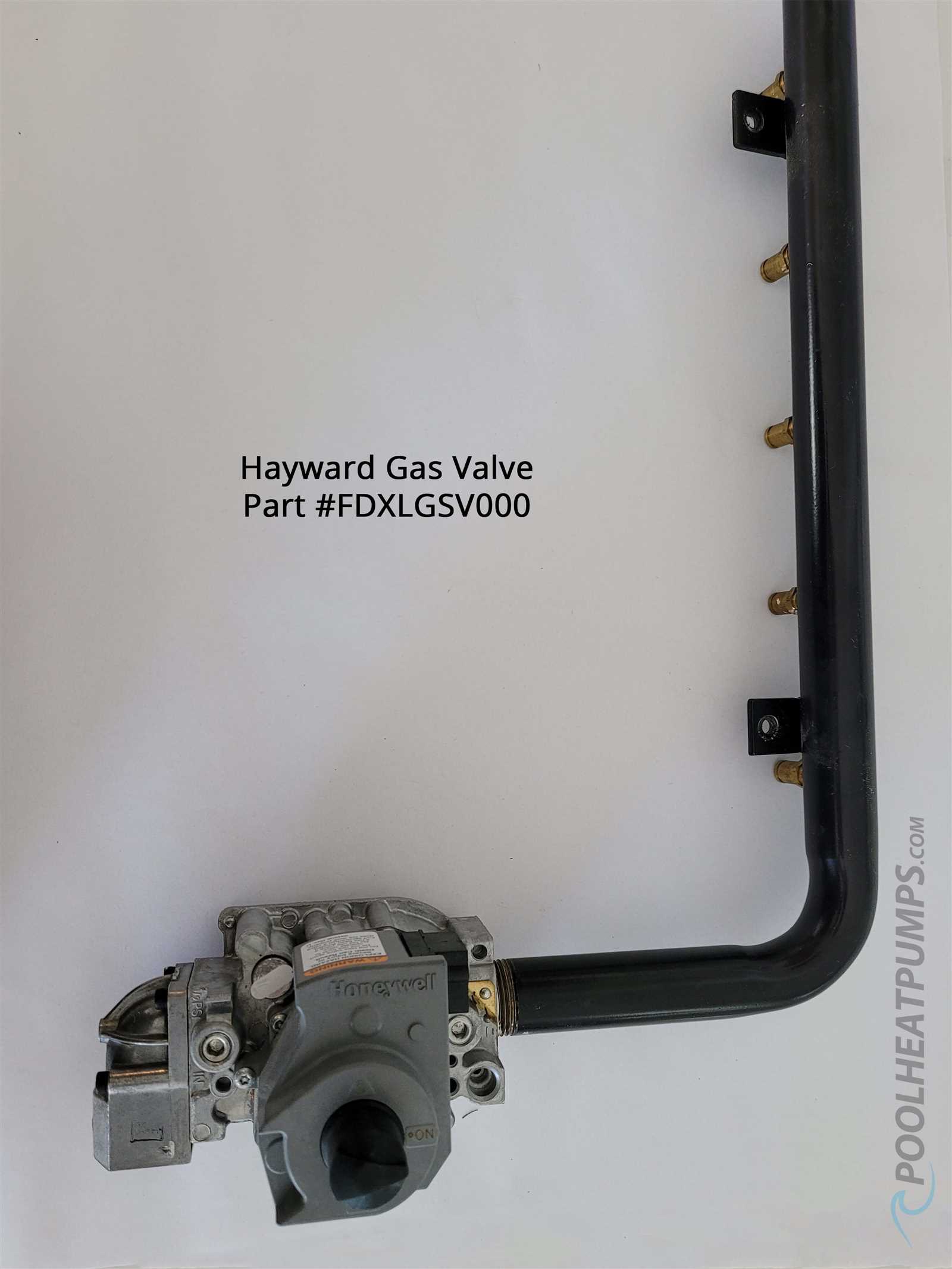

- Burner Assembly: This component is responsible for generating heat, utilizing fuel efficiently to maintain desired temperatures.

- Heat Exchanger: Vital for transferring heat from the combustion process to the circulating water, maximizing efficiency and comfort.

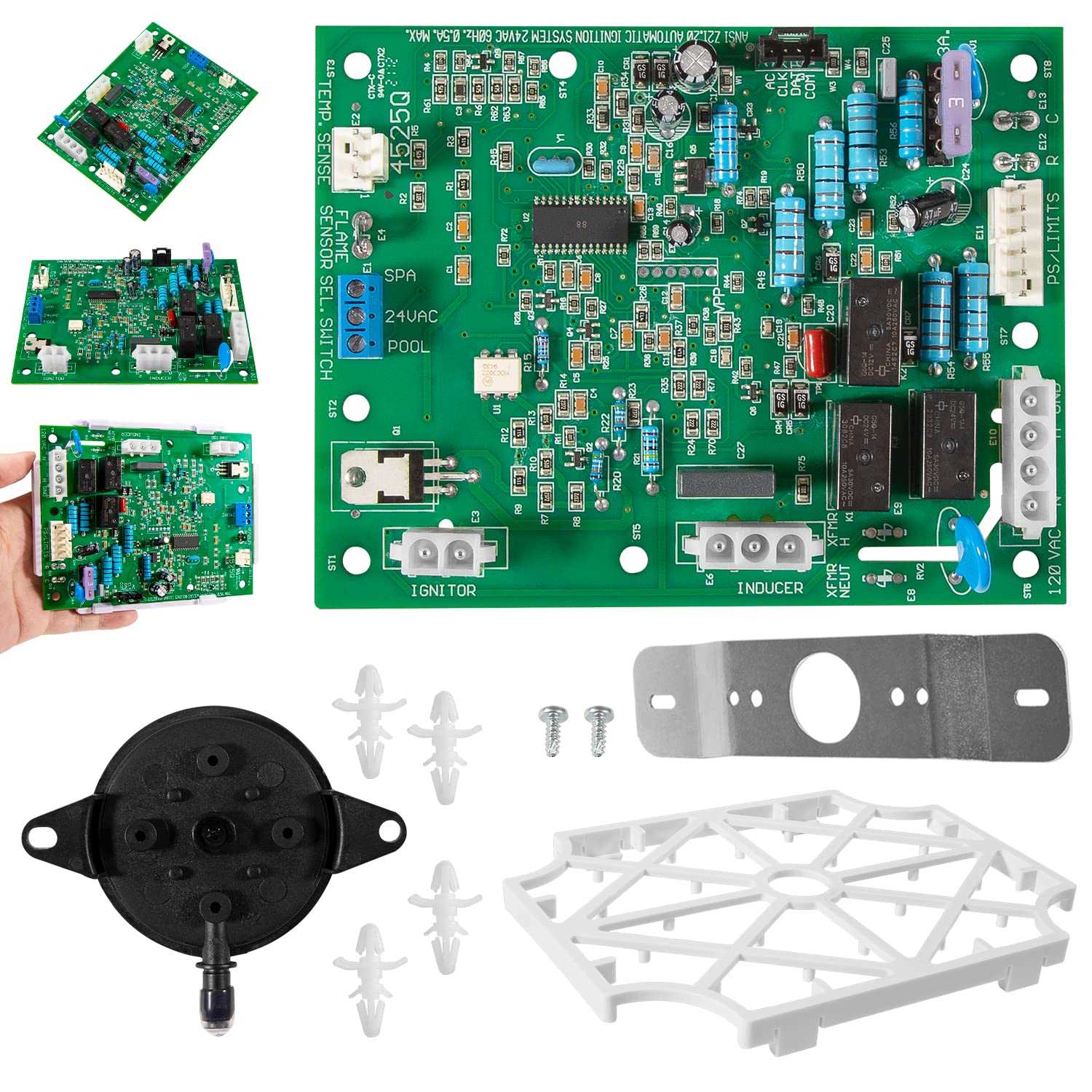

- Control System: This includes sensors and thermostats that regulate the temperature and operational settings, enhancing user convenience.

- Water Pump: Circulates water through the system, ensuring consistent flow and preventing overheating.

Supportive Features

- Safety Mechanisms: Designed to prevent malfunctions, these features help protect the unit and users.

- Electrical Components: Wiring and connections that facilitate the functioning of various systems, ensuring seamless operation.

- Enclosure: The outer shell that protects internal elements from external elements and physical damage.

Common Issues and Solutions

When operating a thermal system for water management, users may encounter several challenges that affect performance and efficiency. Understanding these common issues and their respective solutions can significantly enhance the overall experience and prolong the life of the equipment.

1. Insufficient Heating: One frequent complaint is that the water does not reach the desired temperature. This can be due to several factors, including a malfunctioning thermostat or inadequate power supply. To address this issue, check the thermostat settings and ensure the unit is receiving the correct voltage. If the problem persists, inspect the heating elements for any signs of damage.

2. Unusual Noises: Many users report hearing strange sounds during operation, which can indicate mechanical problems. To troubleshoot, listen for grinding or clanking noises that may suggest loose or damaged components. Tightening loose parts or replacing worn-out elements can often resolve these concerns.

3. Water Leaks: Leaking water can lead to significant issues, including decreased efficiency and potential damage to surrounding areas. If leaks are detected, inspect the connections and seals for wear and tear. Replacing damaged seals or tightening loose fittings can usually fix the problem.

4. Error Codes: Modern systems often display error codes to indicate malfunctions. When encountering these codes, refer to the user manual for a comprehensive list of meanings and suggested actions. Often, resetting the unit can clear temporary errors, but persistent codes may require professional attention.

By recognizing these common problems and applying the suggested solutions, users can ensure their thermal systems operate smoothly and efficiently.

Maintenance Best Practices

Regular upkeep is essential for ensuring optimal performance and longevity of your heating system. By implementing effective strategies, you can prevent potential issues and enhance efficiency, ultimately leading to cost savings and improved functionality.

Here are some best practices to consider:

- Routine Inspections: Conduct frequent examinations of the system to identify any wear or damage early on.

- Cleaning Components: Regularly clean filters, ducts, and other essential parts to maintain airflow and efficiency.

- Check for Leaks: Inspect for any signs of leakage that may indicate problems with connections or seals.

- Monitor Performance: Keep an eye on the system’s performance indicators to ensure everything operates smoothly.

In addition to these practices, consider the following maintenance activities:

- Flush the system periodically to remove sediment buildup.

- Examine electrical connections and ensure they are secure and corrosion-free.

- Replace worn or damaged components promptly to avoid further issues.

Implementing these best practices will help extend the lifespan of your system while ensuring it operates efficiently and safely.

Parts Replacement Guide

This section provides essential information for effectively replacing components in a specific type of heating device. Understanding the process can help maintain optimal functionality and extend the lifespan of the unit. Each component plays a crucial role in the overall performance, and timely replacement ensures consistent operation.

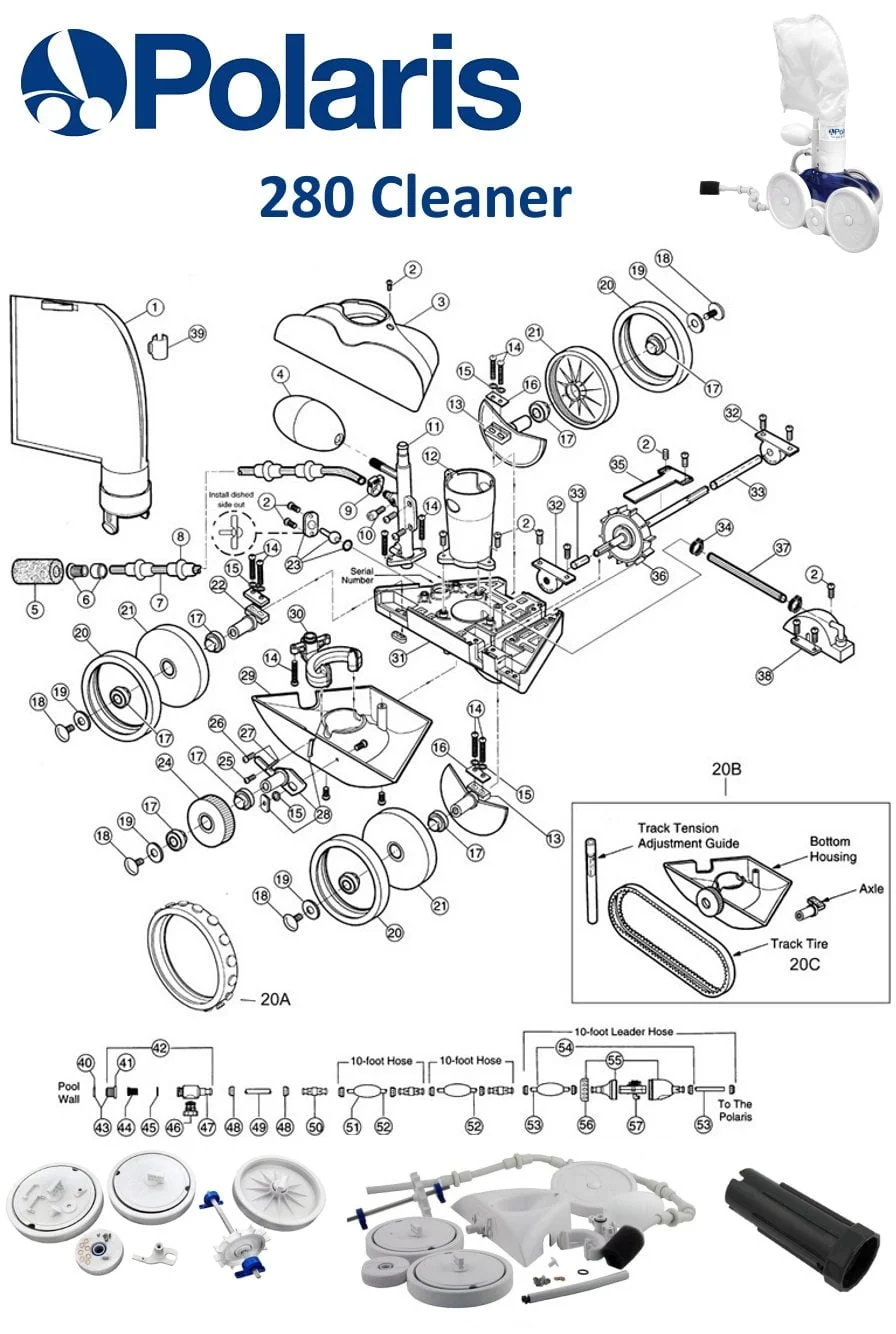

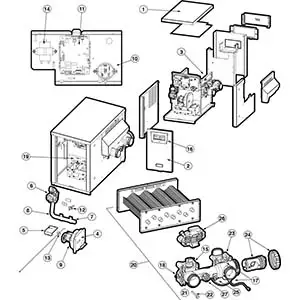

Identifying Components

Before initiating the replacement process, it is vital to identify the components that require attention. Common issues may arise from wear and tear, leading to diminished performance. Familiarize yourself with the common elements, including their locations and functions. Proper identification not only aids in troubleshooting but also assists in acquiring the correct replacements.

Replacement Process

When replacing components, follow a systematic approach. Begin by disconnecting the unit from the power supply to ensure safety. Utilize appropriate tools to carefully remove the faulty element. It’s advisable to refer to the user manual for specific instructions related to your device. Once the component is removed, install the new piece, ensuring it is securely fastened and properly aligned. Reconnect the power and test the functionality to confirm successful installation.

Note: Always consult a professional if you encounter difficulties during the replacement process or if unsure about any steps involved.

Heating Efficiency and Performance

The effectiveness and operational capability of thermal systems are crucial for maintaining desired water temperatures. Various factors contribute to how well these systems perform, including design, components, and technology used in the construction. Understanding these elements can enhance user satisfaction and overall functionality.

One key aspect influencing heating performance is energy transfer. Efficient systems maximize the heat exchange process, ensuring that a higher percentage of energy input is converted into useful heat. This can significantly reduce operational costs and increase sustainability.

Regular maintenance is essential for sustaining optimal performance. Periodic checks and servicing can prevent common issues such as blockages or inefficiencies that arise from wear and tear. Ensuring that all components are functioning correctly will also contribute to the longevity of the unit.

Another important factor is insulation. Proper insulation minimizes heat loss during operation, allowing the system to maintain temperature more effectively. Investing in high-quality insulating materials can lead to substantial energy savings and improve overall efficiency.

In summary, enhancing heating performance involves a multifaceted approach that includes optimizing energy transfer, maintaining components, and improving insulation. By focusing on these areas, users can achieve better results and a more reliable thermal experience.

Wiring and Electrical Connections

Understanding the wiring and electrical connections is crucial for ensuring efficient operation and safety in any heating appliance. Proper installation and maintenance of electrical components play a vital role in the overall performance and reliability of the unit.

Electrical schematics provide a visual representation of the connections between different components. These illustrations help in identifying the correct wiring layout, ensuring that each part is connected according to specifications. It is important to follow these guidelines closely to avoid malfunctions or potential hazards.

Power supply connections are particularly significant. They must be established securely to guarantee the unit receives the necessary voltage. Additionally, grounding connections are essential for safety, preventing electrical shocks and equipment damage.

Regular inspection of the wiring is recommended to identify any signs of wear or damage. Loose or frayed wires can lead to serious issues, including short circuits. Ensuring that all connections are tight and insulated can prolong the life of the equipment and enhance safety.

In summary, maintaining a clear understanding of the electrical connections and wiring is essential for the safe and efficient operation of heating systems. Adhering to the recommended guidelines and conducting routine checks can help in achieving optimal performance and longevity.

Pool Heater Safety Features

Ensuring a secure and dependable operation of thermal equipment for water environments is paramount. Various mechanisms and designs are integrated to safeguard users and enhance the overall efficiency of the system. These features play a crucial role in minimizing risks and ensuring the safe enjoyment of recreational activities.

Automatic Shut-Off Mechanisms

One of the essential safety components is the automatic shut-off mechanism. This feature activates when the temperature exceeds a predetermined threshold, preventing overheating and potential damage. Such systems are vital in maintaining safe operational conditions and prolonging the lifespan of the unit.

Water Flow Sensors

Water flow sensors are another critical aspect of safety in these systems. They monitor the movement of liquid and ensure adequate circulation before activation. If the flow is inadequate, the system will not operate, significantly reducing the risk of overheating and equipment failure.

Understanding Control Systems

Control systems play a vital role in the management and regulation of various processes, ensuring optimal performance and efficiency. These systems utilize a range of components and mechanisms to monitor, adjust, and maintain desired operational conditions. By effectively interpreting feedback and implementing necessary adjustments, they contribute significantly to the overall functionality of various devices and installations.

At the core of control systems lies the concept of feedback loops. These loops allow the system to continuously assess its performance by comparing actual output to the desired output. When discrepancies arise, the system can initiate corrective actions to restore balance. This dynamic process ensures that the system remains responsive to changes in its environment, promoting stability and reliability.

Moreover, control systems can be categorized into two primary types: open-loop and closed-loop systems. Open-loop systems operate without feedback, relying solely on predetermined inputs to achieve results. In contrast, closed-loop systems actively utilize feedback to refine their operations, enabling them to adapt to varying conditions and improve accuracy.

Understanding the intricacies of control systems is essential for anyone involved in the design, operation, or maintenance of complex installations. A solid grasp of these systems empowers users to make informed decisions, troubleshoot issues effectively, and enhance the overall performance of their equipment.

Recommended Tools for Repairs

When undertaking maintenance or repairs on heating appliances, having the right tools is crucial for efficiency and safety. A well-equipped toolkit not only simplifies the process but also ensures that the task is completed accurately and effectively. Below are essential instruments that every technician or DIY enthusiast should consider having on hand.

Wrenches: Various sizes of wrenches are fundamental for loosening and tightening nuts and bolts. Adjustable wrenches can accommodate different sizes, while socket sets provide flexibility for deeper access to fasteners.

Screwdrivers: A set of screwdrivers, including flathead and Phillips, is indispensable. These tools allow for easy removal and installation of screws in various components, ensuring seamless access during repairs.

Multimeter: A digital multimeter is essential for testing electrical connections and components. It helps diagnose issues by measuring voltage, current, and resistance, providing insights into the appliance’s functionality.

Pliers: Needle-nose and standard pliers are useful for gripping and manipulating wires and small parts. They can also be employed for bending and cutting tasks, making them versatile tools in the repair process.

Safety Gear: Personal protective equipment, such as gloves and safety goggles, should always be worn. These items protect against potential injuries while handling tools and working on electrical components.

Equipping yourself with these recommended tools can significantly enhance your ability to perform repairs effectively. A well-prepared technician is more likely to address issues efficiently, leading to optimal performance of heating systems.

Comparison with Other Models

This section provides an overview of how a specific model aligns with various alternatives in its category, highlighting key differences and similarities. Understanding these distinctions can help users make informed decisions based on their specific needs and preferences.

When evaluating different models, several factors come into play:

- Efficiency: Some models offer superior energy-saving features, which can lead to reduced operational costs over time.

- Size and Capacity: Variations in dimensions and output capacity are essential for ensuring compatibility with different installations.

- Durability: The materials used in construction often affect longevity and performance in varying environmental conditions.

- Control Features: Advanced control options provide more convenience and customization for users compared to basic models.

By examining these aspects, users can identify which option aligns best with their requirements. Below is a summary of notable comparisons:

- Model A: Known for its high efficiency and compact design, it is ideal for smaller spaces.

- Model B: Features a robust build, ensuring longevity even in harsh conditions, but may lack some advanced control features.

- Model C: Offers a balance of performance and price, making it a popular choice for many users.

Ultimately, the decision should be guided by specific application needs, budget constraints, and personal preferences, ensuring that the selected option meets both immediate and long-term goals.

Troubleshooting Heating Problems

Addressing issues related to inadequate warmth in your system can enhance comfort and efficiency. This section provides insights into common challenges that may arise, along with potential solutions to restore optimal performance.

Common Issues and Their Solutions

One prevalent issue is the lack of sufficient heat output. This may stem from a malfunctioning thermostat or a blockage in the flow of water. First, check the thermostat settings to ensure they are properly adjusted. If the readings are inaccurate, recalibrating or replacing the thermostat might be necessary. Additionally, inspect the water lines for any obstructions that could hinder circulation, such as debris or sediment buildup.

Electrical and Component Checks

Electrical failures can also impede heating functions. Verify that all connections are secure and that the system is receiving power. Inspect circuit breakers and fuses to rule out any electrical issues. If the unit still fails to operate, examining internal components like the ignition system or safety switches may reveal faults that require professional attention or replacement parts.

Customer Reviews and Feedback

This section aims to highlight user experiences and impressions regarding a specific product designed for temperature control in aquatic environments. By analyzing consumer opinions, potential buyers can gain valuable insights into the performance, reliability, and overall satisfaction associated with the item.

Positive Experiences

Many users express appreciation for the efficiency and effectiveness of the device. Ease of use is a recurring theme in reviews, with several customers noting that the installation process was straightforward and the operation intuitive. Users frequently mention how the system quickly reaches the desired temperature, contributing to a comfortable atmosphere.

Areas for Improvement

While feedback is generally favorable, some customers point out areas where enhancements could be made. A few reviews highlight issues with durability, suggesting that components may require more robust construction. Additionally, some users would prefer more detailed guidance in the user manual to assist with troubleshooting.