Understanding the Craftsman Leaf Blower Parts Diagram

When it comes to maintaining your outdoor tools, having a clear understanding of their components is essential for effective upkeep and troubleshooting. This section aims to provide a comprehensive overview of the various elements that make up these machines, facilitating easier repairs and enhanced performance.

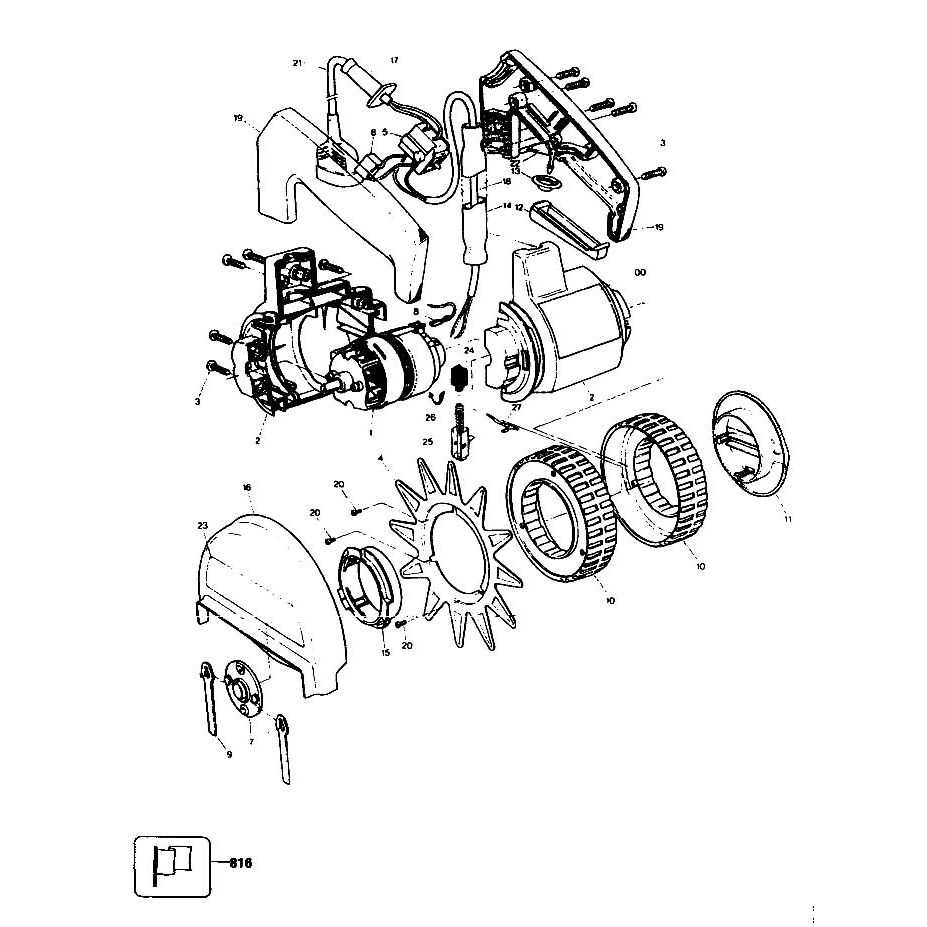

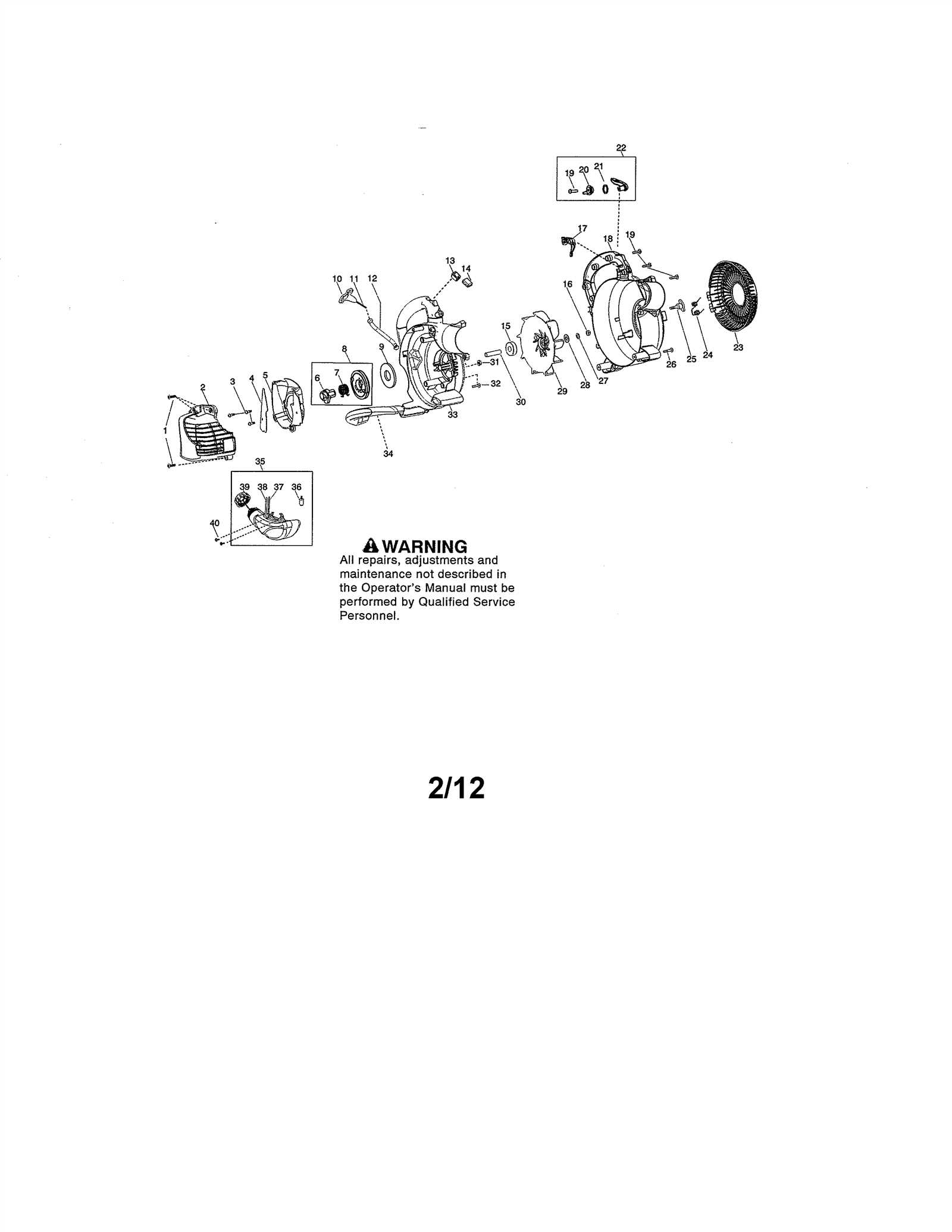

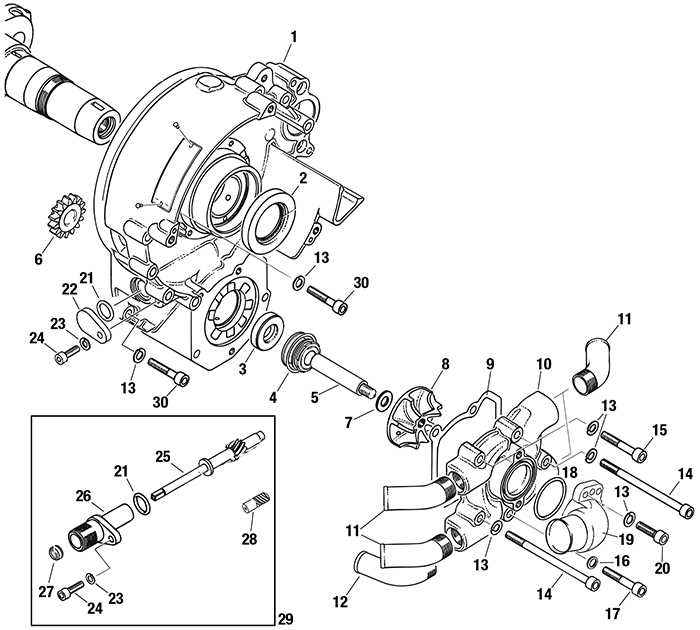

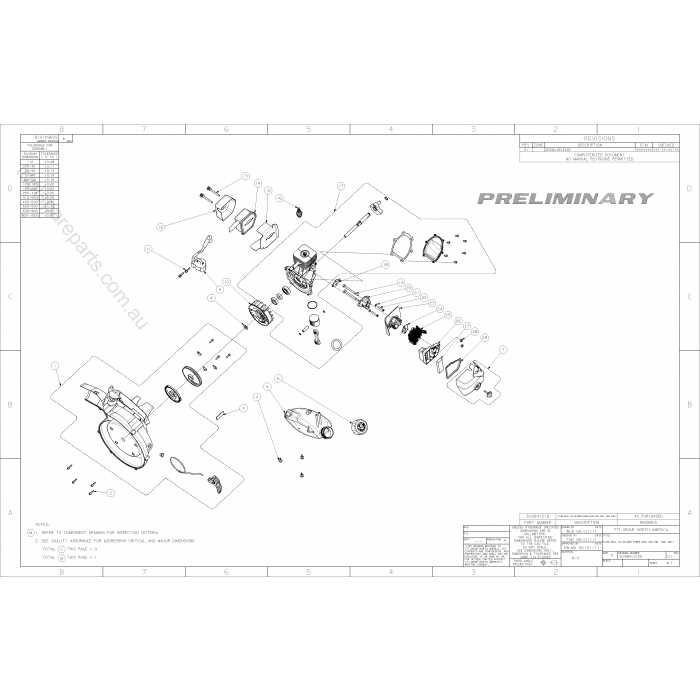

Through an illustrative representation, users will gain insights into the intricate workings of their devices. Each section will highlight specific features, allowing enthusiasts and casual users alike to delve deeper into the mechanics involved.

Ultimately, this guide serves as a valuable resource, empowering individuals to enhance their knowledge and ensure the longevity of their equipment. A clear understanding of every element can lead to more efficient usage and timely interventions when issues arise.

Understanding Your Craftsman Leaf Blower

Grasping the components and functionality of your outdoor tool is essential for optimal performance and maintenance. Familiarity with its design can enhance efficiency and prolong its lifespan. Whether tackling yard debris or fine particles, knowing the inner workings will empower you to troubleshoot and enhance usability.

Key Components

Every model features a variety of essential elements that contribute to its overall efficiency. The motor, air intake, and discharge systems play crucial roles in ensuring that your equipment operates smoothly. Understanding these parts will help you identify areas that may require attention or repair.

Maintenance Tips

Regular upkeep is vital for sustaining functionality. Ensure that you routinely check filters, clean the exterior, and inspect connections. Proper care not only boosts performance but also mitigates the risk of potential issues down the line. Investing time in maintenance ultimately pays off.

Essential Components of Leaf Blowers

Understanding the fundamental elements of outdoor air-moving tools is crucial for effective maintenance and performance. Each component plays a significant role in the overall efficiency and functionality, ensuring that users can achieve optimal results during their tasks.

Power Source

The power source serves as the heart of the equipment, providing the necessary energy for operation. Options include electric motors, gasoline engines, and battery systems, each with unique advantages and limitations that cater to different user needs.

Air Intake and Nozzle

The air intake system allows for the suction of ambient air, while the nozzle directs and amplifies airflow. A well-designed intake and nozzle enhance the tool’s effectiveness, ensuring that debris is efficiently cleared from various surfaces.

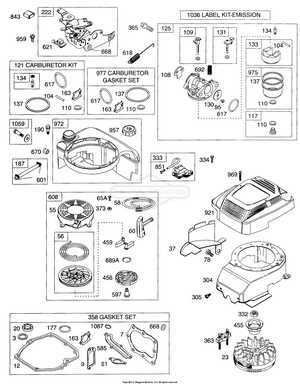

How to Read Parts Diagrams

Understanding technical illustrations is crucial for anyone looking to maintain or repair their equipment. These visual representations provide detailed insights into the components of a machine, making it easier to identify each element and its function. Familiarizing yourself with the layout and symbols used in these illustrations can significantly enhance your troubleshooting skills.

When examining a technical illustration, begin by identifying the main sections. Typically, components are grouped by function or location within the device. This organization helps streamline repairs and ensures that you can quickly locate the necessary elements.

| Symbol | Description |

|---|---|

| Circle | Often represents a connection point or a part that requires assembly. |

| Arrow | Indicates movement or the flow of materials within the machine. |

| Square | Can denote a housing or enclosure for various components. |

| Number | Refers to a specific component listed in the accompanying parts list. |

Always check for a corresponding parts list, which provides detailed descriptions and part numbers. This information is essential for ordering replacements or understanding how different components interact. By mastering the art of reading these illustrations, you empower yourself to tackle maintenance and repairs with confidence.

Common Issues with Craftsman Models

When it comes to outdoor equipment, certain challenges frequently arise that can hinder performance and efficiency. Understanding these prevalent problems can help users maintain their tools effectively and prolong their lifespan.

Engine Troubles

One of the most common setbacks involves engine malfunctions. Users often report issues such as difficulty starting or stalling during operation. Regular maintenance, including checking the fuel and spark plug, is essential for optimal functionality.

Airflow Blockages

Another frequent concern relates to airflow disruptions. Debris can accumulate in the intake or exhaust, leading to reduced performance. Regular cleaning and inspection of air passages can mitigate this issue and ensure smooth operation.

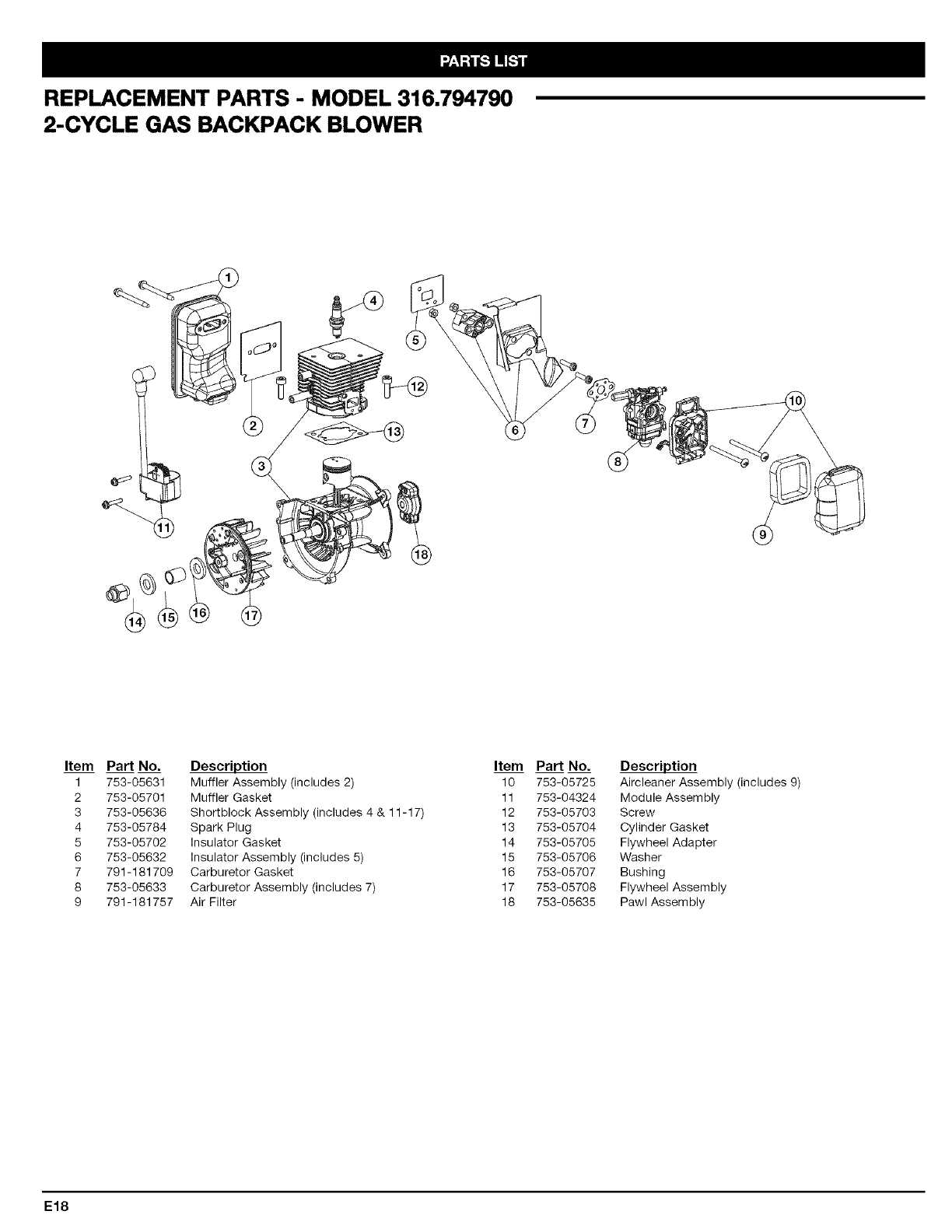

Replacement Parts for Leaf Blowers

When it comes to maintaining outdoor equipment, understanding the components that require periodic replacement is crucial. These elements ensure optimal performance and longevity of the machinery, allowing users to tackle yard work efficiently.

Common items that often need attention include motors, filters, and nozzles. Regularly checking these components can prevent malfunctions and enhance functionality. Additionally, having a reliable source for quality replacements can make repairs straightforward and hassle-free.

It’s advisable to consult manufacturer specifications to ensure compatibility with your specific model. Investing in durable and efficient components not only saves time but also enhances the overall effectiveness of your outdoor tasks.

Maintenance Tips for Longevity

Proper care is essential for extending the lifespan of your equipment and ensuring optimal performance. By following a few simple maintenance practices, you can prevent premature wear and enhance efficiency over time.

Regular Cleaning: Keep the exterior free from debris and dirt. Use a soft brush or cloth to wipe down surfaces, ensuring that air vents are unobstructed.

Check Filters: Inspect and replace filters regularly. Clean air filters can significantly improve airflow and functionality, while clogged ones can hinder performance.

Inspect Components: Periodically examine essential components for signs of wear or damage. Addressing issues early can prevent more significant problems later.

Lubrication: Apply appropriate lubricants to moving parts as specified in the user manual. This helps reduce friction and prolongs the life of mechanical elements.

Storage Practices: When not in use, store the equipment in a dry, sheltered place. Avoid exposure to harsh weather conditions to prevent rust and corrosion.

By incorporating these practices into your routine, you can ensure your equipment remains in peak condition for years to come.

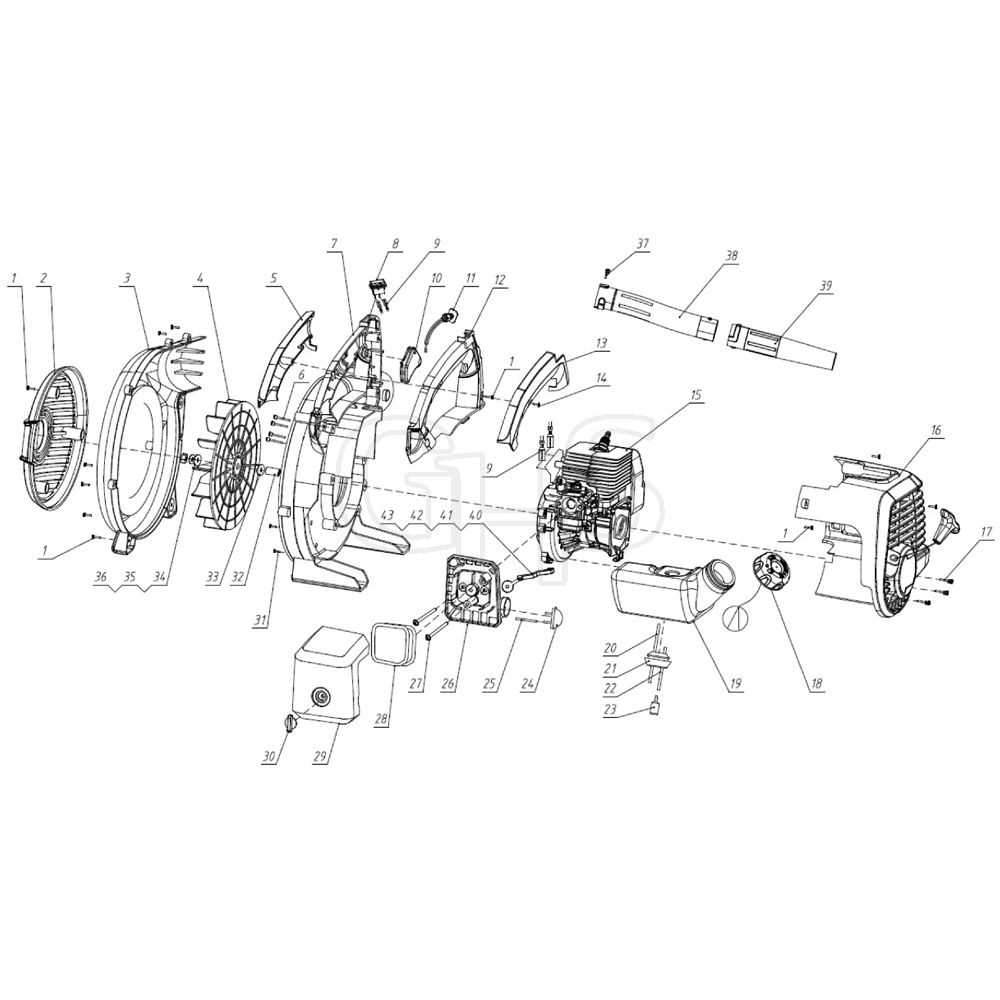

Identifying Each Part’s Function

Understanding the role of each component in a garden tool is essential for optimal performance and maintenance. By examining the various elements, users can ensure efficient operation and address any issues that may arise.

Key Components and Their Roles

- Motor: Powers the device, converting electrical energy into mechanical motion.

- Housing: Encloses internal mechanisms, providing protection and structure.

- Fan: Generates airflow, directing it for effective clearing.

- Throttle Control: Regulates speed and airflow intensity based on user needs.

Understanding Additional Features

- Filter: Keeps debris from entering the motor, ensuring longevity.

- Nozzle: Directs airflow to specific areas, enhancing precision in use.

- Power Cord: Supplies energy, allowing for continuous operation without interruption.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right tools is essential for ensuring efficiency and effectiveness. Proper equipment not only facilitates the repair process but also minimizes the risk of damage to components. Below is a comprehensive list of essential tools that will aid in your repair endeavors.

Basic Hand Tools

- Wrenches (adjustable and socket)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and regular)

- Cutting tools (utility knife and wire cutters)

Specialized Tools

- Torque wrench

- Compression gauge

- Multimeter

- Cleaning brushes

Equipping yourself with these tools will streamline your repair process and contribute to a successful outcome.

Finding Genuine Craftsman Parts

Ensuring the longevity and performance of your equipment relies heavily on sourcing authentic components. The market offers a vast array of options, but distinguishing between genuine and counterfeit items is crucial for maintaining optimal functionality. Understanding where and how to locate reliable sources can save both time and money in the long run.

Importance of Authentic Components

Using original pieces guarantees compatibility and efficiency, thereby minimizing the risk of breakdowns. Counterfeit alternatives may appear tempting due to lower prices, but they often lead to more significant issues, potentially compromising the overall integrity of your machine.

Where to Locate Reliable Sources

Start by exploring official retailers or authorized service centers. These establishments often have a comprehensive inventory of legitimate components, ensuring quality and performance. Additionally, reputable online marketplaces may offer genuine items, but it’s essential to verify seller credibility. Customer reviews and ratings can provide valuable insights into the reliability of the source.

DIY Repair vs. Professional Help

When faced with equipment issues, individuals often grapple with the choice between tackling repairs themselves or seeking external expertise. Both options come with their own set of advantages and challenges, ultimately influencing the outcome of the restoration process.

DIY repairs can be a rewarding experience, allowing individuals to delve into the mechanics and understand their tools better. This approach can save money and provide a sense of accomplishment. However, without adequate knowledge, it may lead to unintended complications, resulting in further damage.

On the other hand, enlisting professional assistance ensures a high level of expertise and efficiency. Specialists possess the necessary training and access to proper equipment, which can expedite the repair process. Yet, this option often comes with a higher price tag, and the time taken for service can vary.

Ultimately, the decision rests on one’s comfort level with technical tasks and the specific nature of the repairs needed. Weighing the pros and cons of each path can guide individuals toward the most suitable choice for their situation.

Resources for Leaf Blower Owners

For enthusiasts and users of outdoor equipment, having access to reliable information and tools is essential for maintaining performance and longevity. This section provides various resources that can help users troubleshoot issues, find replacement components, and enhance their overall experience.

- Online Forums: Engage with communities where fellow users share tips and experiences.

- Manufacturer Websites: Access official guides, manuals, and support services.

- Repair Videos: Utilize platforms like YouTube for visual tutorials on common repairs.

- Local Repair Shops: Seek professional assistance for complicated issues or part replacements.

By leveraging these resources, users can delve into maintenance strategies and ensure their equipment operates at its ultimate efficiency.