Understanding the Mercury 9.9 4 Stroke Parts Diagram

Exploring the intricacies of a compact marine engine reveals a fascinating world of mechanics and engineering. Each element plays a crucial role in ensuring optimal performance on the water. A clear comprehension of these components is essential for effective maintenance and repair.

Visual aids serve as valuable resources for both novice and experienced enthusiasts, offering insight into the assembly and functionality of various sections. These illustrations not only enhance understanding but also guide users through the complexities of the engine’s structure.

To truly appreciate the ultimate performance of a small outboard motor, one must delve into the individual parts that contribute to its efficiency and reliability. By examining these elements closely, boaters can enhance their skills and ensure the longevity of their marine investments.

Understanding Mercury 9.9 4 Stroke Engine

This section explores the intricacies of a specific outboard engine, focusing on its design, functionality, and maintenance. By grasping its components and mechanisms, users can enhance their understanding and optimize performance.

Key features include:

- Efficient fuel consumption

- Low emissions

- Quiet operation

To delve deeper, consider the following essential components:

- Powerhead: Houses the combustion system.

- Lower unit: Contains the drive system and propeller.

- Fuel system: Ensures optimal mixing and delivery of fuel.

- Cooling system: Maintains appropriate operating temperatures.

Understanding these elements is crucial for effective troubleshooting and maintenance, ultimately leading to improved longevity and reliability.

Key Features of Mercury 9.9

This section explores the remarkable characteristics of a compact, efficient outboard engine designed for versatile marine applications. Known for its reliability and user-friendly design, it caters to a wide range of boating enthusiasts, from casual users to serious adventurers.

One of the standout attributes is its lightweight construction, which enhances fuel efficiency and maneuverability. The engine is engineered with advanced technology that ensures smooth operation and minimal noise, making it a favorite for those who value a tranquil experience on the water.

Additionally, it boasts an easy-starting mechanism, allowing for hassle-free launches every time. Its robust construction ensures durability, even in challenging conditions, while the intuitive controls simplify navigation for all skill levels.

Ultimately, this engine is designed with versatility in mind, accommodating various boat sizes and styles, thus making it an excellent choice for both recreational outings and serious fishing expeditions.

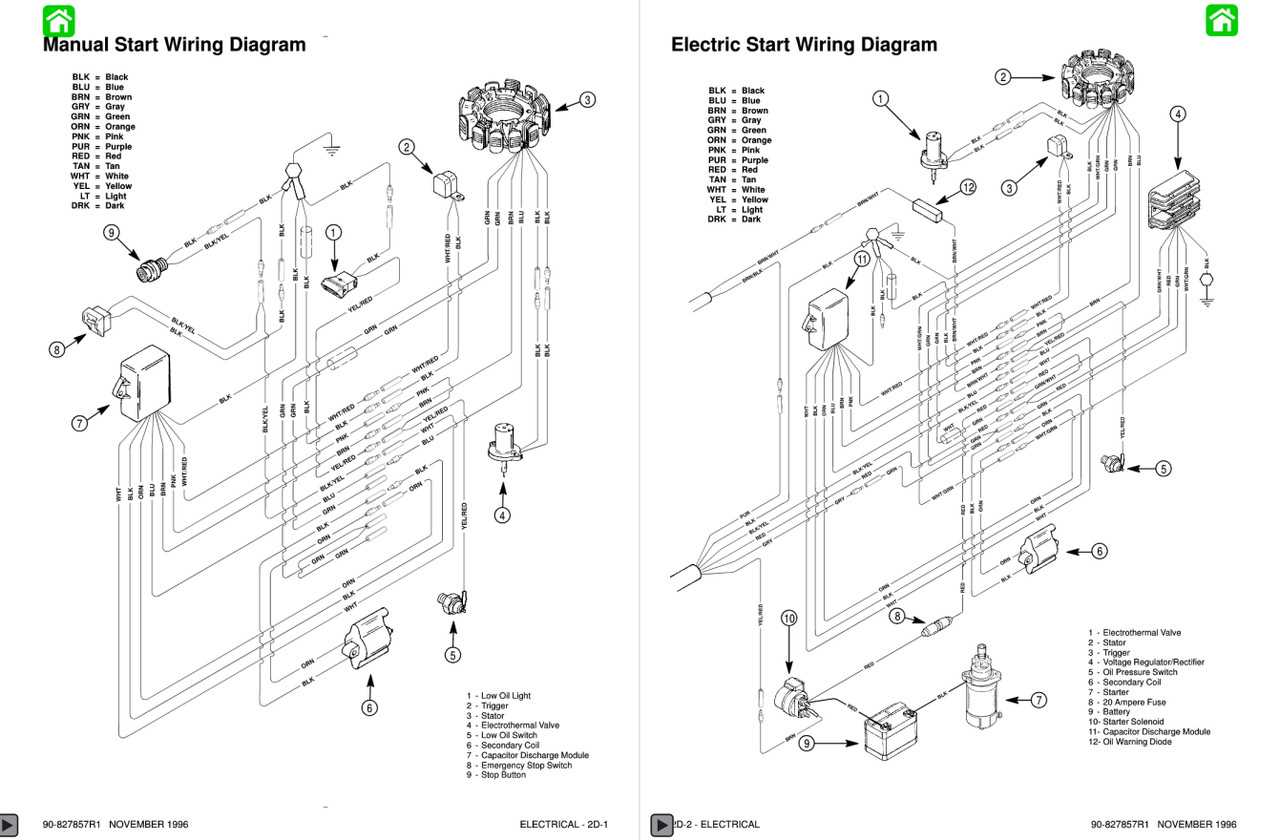

Importance of Engine Parts Diagrams

Understanding the intricate layout of an engine is crucial for maintenance and repair. Visual representations provide valuable insights into how each component interacts within the system. This knowledge is essential for both professionals and enthusiasts alike.

These illustrations serve several key purposes:

- Clarity: Diagrams simplify complex structures, making it easier to identify each element.

- Efficiency: Technicians can quickly locate specific components, speeding up repair processes.

- Safety: Knowledge of component placement helps prevent accidents during maintenance.

- Training: Visual aids are invaluable for educating new technicians on engine mechanics.

Moreover, these representations facilitate effective communication between mechanics and clients. When both parties understand the layout, discussions about repairs and costs become clearer and more straightforward.

In summary, the role of visual guides in the context of engine maintenance cannot be overstated. They enhance understanding, improve safety, and streamline the repair process, ultimately contributing to the longevity of the machinery.

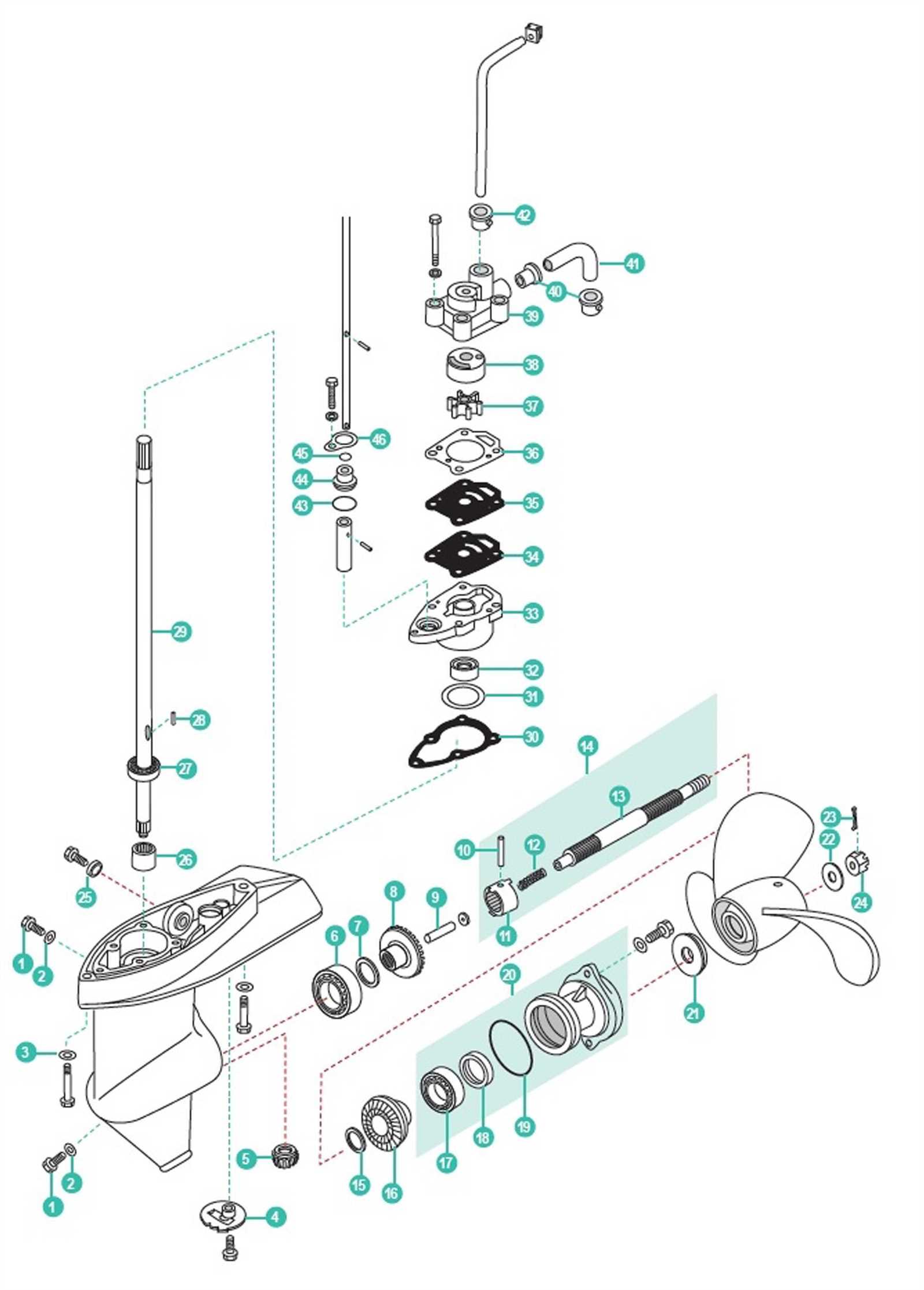

Identifying Essential Components

Understanding the critical elements of an outboard motor is vital for effective maintenance and repair. Each component plays a significant role in the overall performance and reliability of the engine. Familiarizing yourself with these parts will enhance your ability to troubleshoot issues and ensure optimal operation.

Here are some key components to recognize:

- Powerhead: The core unit that houses the combustion process.

- Lower Unit: Contains the gearing system and propeller, crucial for propulsion.

- Fuel System: Responsible for delivering the correct mixture of fuel and air.

- Ignition System: Initiates the combustion process through spark generation.

- Cooling System: Maintains an optimal operating temperature by regulating water flow.

By identifying these fundamental components, you will gain insights into how each part contributes to the functionality of the motor, aiding in both diagnostics and enhancements.

Common Maintenance Practices

Regular upkeep is essential for ensuring the longevity and optimal performance of marine engines. Implementing a structured maintenance routine can prevent unexpected failures and enhance efficiency. Understanding the key practices involved in maintaining such engines is crucial for every boat owner.

One of the primary aspects of maintenance involves routine checks of the oil and coolant levels. Keeping these fluids at appropriate levels not only supports engine function but also prevents overheating and excessive wear. Additionally, regularly replacing the oil filter contributes to the engine’s overall health.

Inspecting the fuel system is equally important. This includes cleaning or replacing fuel filters and ensuring that the fuel lines are free from obstructions or leaks. Using high-quality fuel can also enhance performance and reduce deposits that can clog the system.

Another vital practice is examining the electrical components. Checking the battery condition, connections, and charging system helps avoid electrical failures during operation. Ensuring that all wiring is intact and corrosion-free is essential for reliable performance.

Finally, regular visual inspections of the exterior components and propeller can reveal any signs of wear or damage. Addressing these issues promptly can prevent more severe problems down the line and ensure smooth operation on the water.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations help identify individual elements and their relationships, making it easier to locate specific items and comprehend how they fit together within a larger assembly. This knowledge is invaluable for both professionals and enthusiasts alike.

Key Elements to Identify

When examining such visuals, there are several critical aspects to consider:

| Element | Description |

|---|---|

| Numbering System | Most visuals feature a numbering or labeling system that corresponds to a list, aiding in quick identification of components. |

| Legend | A legend typically explains symbols or color codes used in the illustration, providing clarity on component types and functions. |

| Views | Different angles may be presented, showcasing how parts align or interact, essential for accurate assembly or disassembly. |

Practical Steps for Usage

To effectively utilize these visuals, follow these steps:

- Locate the corresponding numbers on the illustration and match them with the parts list.

- Refer to the legend for any symbols that might need clarification.

- Pay attention to the orientation and arrangement of components for correct assembly.

By mastering the interpretation of these visual guides, you will enhance your ability to carry out repairs and maintenance with confidence and precision.

Frequently Replaced Parts Overview

In the realm of small marine engines, certain components are commonly subject to wear and tear due to regular use. Understanding which elements require replacement can significantly enhance performance and longevity. This overview will highlight the most frequently changed components and their importance.

- Propeller: Essential for propulsion, damaged or worn propellers can affect efficiency and speed.

- Fuel Filter: A clean filter ensures optimal fuel flow, preventing engine stalling and performance issues.

- Oil Filter: Regularly replacing this filter helps maintain engine lubrication and prevents buildup of contaminants.

- Spark Plug: This component ignites the air-fuel mixture; a worn spark plug can lead to misfires and reduced power.

- Water Pump Impeller: Vital for cooling the engine, a damaged impeller can cause overheating and severe damage.

Regular maintenance and timely replacement of these critical elements can lead to improved operation and reduced risk of breakdowns. Keeping track of these components can save time and costs in the long run.

Troubleshooting Common Issues

Addressing frequent problems can significantly enhance the performance and longevity of your marine engine. Identifying the root cause of malfunctions is essential for effective repair and maintenance. Below are some typical issues and their potential solutions.

Starting Difficulties: If the engine fails to start, check the fuel supply, ignition system, and battery condition. Ensure there are no blockages in the fuel line and that the spark plugs are in good condition.

Overheating: Overheating can result from insufficient coolant flow or a malfunctioning thermostat. Inspect the cooling system for debris and ensure the water intake is clear.

Unusual Noises: Unexplained sounds during operation may indicate mechanical issues. Examine the engine components for wear or damage, particularly in the propeller and lower unit.

Loss of Power: A decline in power output could stem from fuel quality issues or a clogged filter. Verify that the fuel is fresh and that all filters are clean and unobstructed.

By systematically addressing these issues, you can optimize performance and enjoy a more reliable experience on the water.

Tools Needed for Repairs

When it comes to conducting maintenance or fixing machinery, having the right instruments at hand is essential for ensuring efficiency and precision. Proper tools not only facilitate smoother operations but also minimize the risk of damage during repairs.

Basic Hand Tools: Essential items such as wrenches, screwdrivers, and pliers form the foundation of any repair toolkit. These are necessary for loosening and tightening various components.

Specialized Instruments: Depending on the specific repair needs, additional tools like torque wrenches, alignment gauges, or pullers may be required. These specialized items help achieve the ultimate accuracy and safety during maintenance tasks.

Cleaning Supplies: Keeping components clean is vital for their longevity. Items such as brushes, cloths, and solvents are crucial for ensuring that everything operates smoothly.

Safety Equipment: Don’t overlook protective gear! Gloves, goggles, and masks are important to safeguard against potential hazards during the repair process.

By ensuring that all necessary tools and equipment are readily available, one can delve into repairs with confidence and proficiency, ultimately achieving successful outcomes.

Finding Genuine Replacement Parts

Locating authentic components for your marine engine is essential for maintaining performance and longevity. Using original elements ensures compatibility and reliability, which can significantly impact your vessel’s functionality.

| Tip | Description |

|---|---|

| Research Authorized Dealers | Identify certified distributors to ensure you purchase original items. |

| Check Serial Numbers | Verify serial numbers to confirm compatibility with your engine model. |

| Read Reviews | Look for customer feedback to gauge the quality of the components offered. |

| Avoid Third-Party Sources | Steer clear of non-certified vendors to prevent counterfeit purchases. |

Upgrading Your Mercury 9.9 Engine

Enhancing the performance of your small outboard motor can significantly improve your boating experience. By implementing a few strategic modifications, you can unlock more power, efficiency, and overall reliability. This section will explore various options to help you achieve the best results.

Performance Enhancements

Consider upgrading components like the carburetor and exhaust system. A high-performance carburetor can enhance fuel delivery, while a more efficient exhaust can improve airflow, ultimately boosting horsepower. These upgrades not only increase speed but also enhance fuel efficiency.

Maintenance and Reliability

Regular maintenance is crucial for long-term performance. Upgrading to higher-quality oil and filters can lead to improved engine longevity. Additionally, investing in a reliable ignition system can ensure consistent starts and smoother operation, giving you peace of mind on the water.

Resources for Further Learning

Expanding your knowledge in the realm of marine engines can significantly enhance your understanding and skills. Various resources are available to help enthusiasts and professionals alike gain insights into maintenance, troubleshooting, and optimization.

- Online Forums: Join communities where you can discuss issues, share experiences, and seek advice from fellow boaters and mechanics.

- Manufacturer Websites: Explore official sites for technical resources, including manuals and service bulletins, that provide in-depth information about specific models.

- YouTube Channels: Follow channels dedicated to engine repair and maintenance tutorials, offering visual guidance and tips from experienced technicians.

- Books and Guides: Invest in literature that covers fundamental principles, repair techniques, and performance enhancement strategies for marine engines.

By utilizing these resources, you can deepen your expertise and ensure that your aquatic adventures are both enjoyable and trouble-free.