Comprehensive Guide to New Holland 3 Point Hitch Parts Diagram

In the world of farming machinery, the ability to effectively connect implements to tractors is crucial for maximizing efficiency and productivity. A comprehensive overview of the components involved in these connections can greatly enhance the understanding of how various tools interact during operation. This knowledge is essential for anyone looking to optimize their agricultural practices.

Within this exploration, we will delve into the intricate assembly of connection elements, highlighting their functions and importance in the overall system. By familiarizing oneself with these components, operators can better maintain their equipment and ensure that every task is executed smoothly and effectively.

Through detailed illustrations and descriptions, this section aims to clarify the relationships between different elements of the connection system. Whether for maintenance, repair, or simply enhancing one’s operational knowledge, a thorough grasp of these components is invaluable in the agricultural sector.

Understanding New Holland Hitches

This section explores the essential components and mechanisms that facilitate the connection between agricultural machinery and various implements. A deep dive into these systems reveals how they enhance efficiency and versatility in farming operations.

Recognizing the significance of these connecting devices is crucial for optimizing performance. Each element serves a specific role, contributing to the overall functionality and adaptability of the equipment in diverse agricultural tasks.

Maintenance and correct usage of these assemblies are vital for prolonging their lifespan and ensuring safe operation. Familiarity with their design and operation allows operators to troubleshoot issues effectively, enhancing productivity in the field.

In summary, comprehending the intricacies of these systems not only aids in better equipment management but also empowers users to maximize the potential of their machinery in various farming activities.

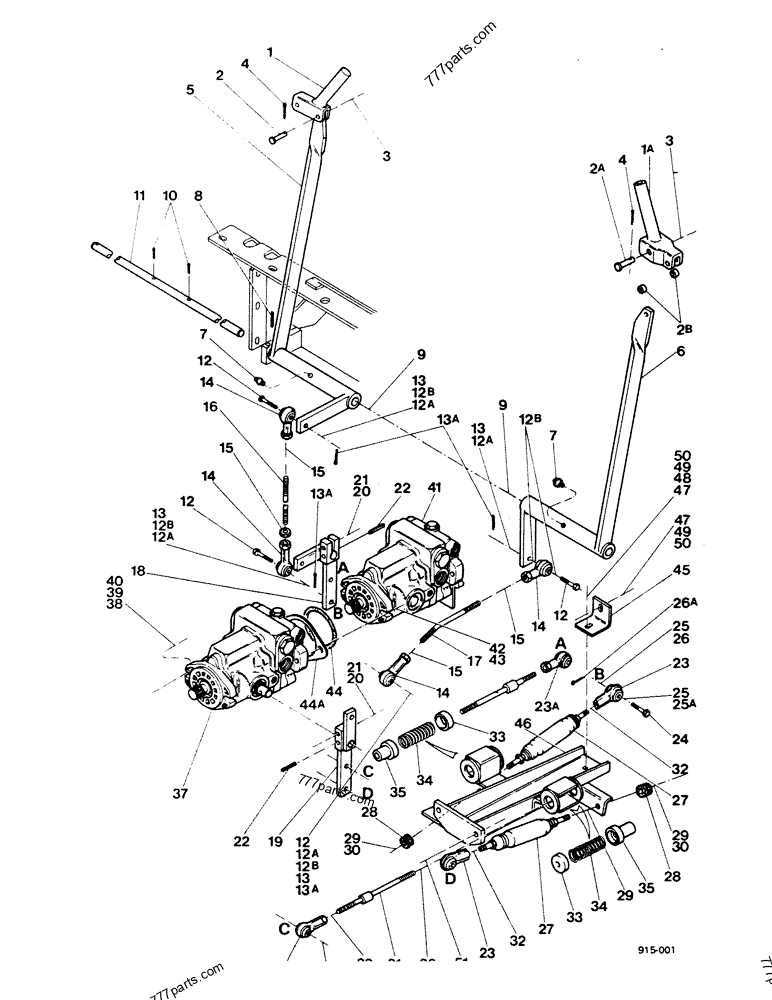

Key Components of 3 Point Hitch

The three-point attachment system is crucial for connecting various implements to agricultural machinery, providing flexibility and efficiency in farming tasks. Understanding its essential elements helps operators optimize equipment use and maintain functionality.

Upper Link

The upper link is a pivotal component that connects the implement to the tractor’s chassis. This adjustable element allows for precise alignment and angling of the tool, ensuring effective performance during operation. Its durability is vital, as it bears a significant load while facilitating smooth movement.

Lower Links

Lower links serve as the primary connections between the tractor and the implement, typically featuring a quick-attach mechanism for ease of use. These robust arms provide stability and support, allowing for the secure positioning of attachments. Proper maintenance of the lower links is essential to prevent wear and ensure reliable function.

In conclusion, understanding the essential components like the upper link and lower links aids in maximizing the effectiveness of agricultural tools, contributing to enhanced productivity on the field.

Benefits of Using 3 Point Hitches

The utilization of three-point connections in agricultural machinery offers numerous advantages that enhance productivity and efficiency. These systems provide a stable and secure method for attaching various implements, facilitating seamless operations across diverse tasks.

One of the primary benefits is improved maneuverability. Equipment with a three-point linkage can pivot around the tractor’s rear axle, allowing for tighter turns and greater control in confined spaces. This capability is particularly advantageous in fields with irregular layouts or obstacles.

Another significant advantage is the ability to quickly attach and detach implements. This feature saves valuable time, enabling operators to switch tasks with minimal downtime. Moreover, many systems are designed with user-friendly mechanisms, making it easier for operators to handle attachments safely and efficiently.

Stability is also enhanced with this type of connection. The design distributes weight evenly, reducing strain on both the tractor and the implement. This stability not only improves performance but also extends the lifespan of the equipment by minimizing wear and tear.

Lastly, the versatility offered by three-point connections cannot be overstated. They accommodate a wide range of tools, from plows to seeders, allowing farmers to adapt to various agricultural needs without investing in multiple machines. This adaptability contributes to overall operational efficiency and effectiveness in farming practices.

Common Issues with Hitch Parts

When operating agricultural machinery, various components can encounter problems that affect performance and reliability. Understanding these common challenges is essential for effective maintenance and ensuring the longevity of the equipment.

Wear and Tear

Over time, frequent use can lead to significant wear on various components. Friction and exposure to harsh conditions can degrade materials, resulting in weakened connections and reduced efficiency. Regular inspections can help identify these issues early, allowing for timely replacements and repairs.

Misalignment

Improper alignment can cause uneven stress on the machinery, leading to premature failure. Factors such as incorrect installation or accidental impacts can contribute to this problem. Ensuring that all components are properly aligned during setup can mitigate potential damage and enhance overall functionality.

Proactive maintenance and attention to common issues can greatly improve the performance and lifespan of agricultural equipment, making it crucial for operators to stay vigilant and informed.

Maintenance Tips for Hitch Systems

Proper upkeep of connection systems is essential for optimal performance and longevity. Regular attention not only enhances efficiency but also ensures safety during operations. Implementing effective maintenance practices can prevent costly repairs and downtime, allowing for seamless functionality.

Regular Inspections

Conduct routine checks to identify any signs of wear or damage. Focus on components such as pins, brackets, and linkage arms. Look for cracks, rust, or loose connections. Addressing these issues promptly can prevent more significant problems down the line.

Lubrication and Cleaning

Keep all moving parts well-lubricated to minimize friction and wear. Use appropriate grease or oil, as specified in the manufacturer’s guidelines. Additionally, maintain cleanliness by removing dirt and debris that can accumulate and hinder performance. A clean system operates more efficiently and reduces the risk of corrosion.

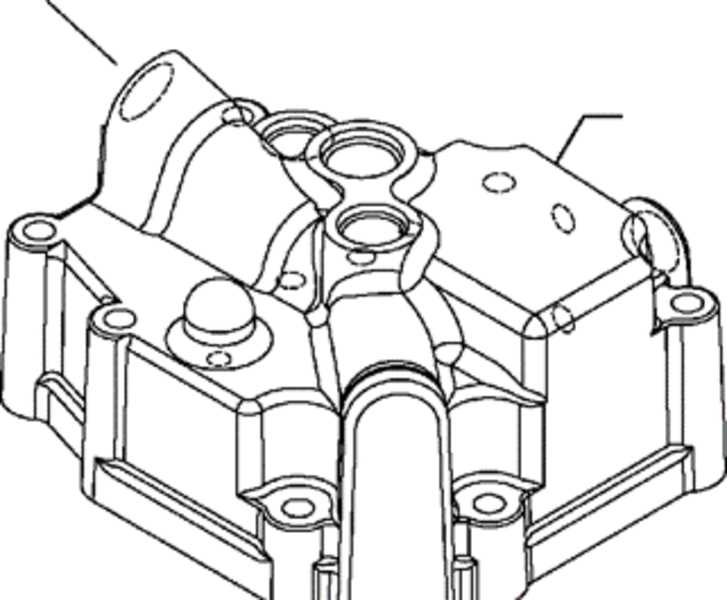

Identifying Parts in Diagrams

Understanding the various components in technical illustrations is essential for effective maintenance and repair. These visual representations serve as a guide, allowing users to recognize and locate specific elements critical to the functioning of machinery. By familiarizing oneself with the layout and symbols used, one can enhance troubleshooting and assembly processes.

Key Elements: Each component is typically labeled and often includes reference numbers. Paying attention to these labels can significantly ease the identification process. In addition, various views, such as side and top perspectives, help to illustrate how parts interact with one another.

Color Coding: Many illustrations employ color differentiation to categorize components. This visual cue not only aids in identification but also assists in distinguishing between various functions or types of parts within the assembly.

In conclusion, a thorough understanding of technical visuals is invaluable for anyone looking to effectively manage machinery. By mastering the ability to identify and interpret these illustrations, users can ensure optimal performance and longevity of their equipment.

Replacing Worn Hitch Components

Maintaining optimal functionality of attachment systems is crucial for effective operation. Over time, various elements can experience wear, leading to decreased performance and potential safety hazards. Regularly assessing and replacing these worn components can significantly enhance the longevity and efficiency of your machinery.

Identifying Worn Components

Before replacement, it’s essential to thoroughly inspect each part for signs of wear, such as cracks, rust, or excessive play. Pay particular attention to pins, bushings, and linkages, as these areas are often subjected to significant stress during operation.

Steps for Replacement

Once worn components are identified, gather the necessary tools and replacement parts. Follow a systematic approach: detach the old pieces, clean the mounting surfaces, and install the new components securely. Ensuring proper alignment and tightness will help maintain functionality and prevent further wear.

Importance of Proper Hitch Alignment

Ensuring the correct alignment of towing equipment is essential for optimal performance and safety. Misalignment can lead to increased wear and tear, affecting both the implement and the vehicle. Additionally, it can compromise handling, causing difficulties during operation and potentially leading to accidents.

Impact on Performance

Accurate alignment allows for efficient power transfer, enhancing the overall effectiveness of the machinery. When components are aligned correctly, it maximizes the efficiency of the task at hand, resulting in smoother operation and reduced fuel consumption.

Safety Considerations

Proper alignment significantly decreases the risk of accidents. When equipment is not aligned correctly, it can shift unexpectedly, leading to potential hazards for the operator and bystanders. Prioritizing alignment is crucial for maintaining a safe working environment.

Types of Attachments for Hitches

Understanding the various implements available for connecting to agricultural machinery is essential for maximizing efficiency and versatility in farming operations. Each attachment serves a unique purpose, enhancing the functionality of the equipment.

Common Attachments

- Plows – Ideal for soil preparation and turning over the earth.

- Spreaders – Useful for distributing seeds or fertilizers uniformly.

- Mowers – Designed for cutting grass or crops effectively.

Specialized Implements

- Rakes – Employed for gathering debris or hay.

- Tillers – Excellent for mixing soil and creating seed beds.

- Loaders – Facilitating the movement of materials and debris.

Tools Needed for Hitch Repair

When undertaking repairs on your equipment’s attachment system, having the right tools is essential for ensuring a smooth process and achieving the best results. A well-equipped workspace can make a significant difference in efficiency and safety.

First, a sturdy set of wrenches is vital for loosening and tightening bolts. Consider having both standard and metric sizes on hand. Additionally, a socket set can provide the necessary leverage and ease for more challenging fasteners.

Next, a high-quality screwdriver set will aid in addressing any smaller components. Both flathead and Phillips varieties should be included to cover different types of screws. Don’t forget about pliers; they are invaluable for gripping and bending parts as needed.

A torque wrench is crucial for applying the correct force to fasteners, preventing damage and ensuring stability. Furthermore, having a pry bar or crowbar can help in separating stuck components without causing harm.

Finally, a good flashlight will illuminate dark areas, allowing for thorough inspection and repair work. With these tools at your disposal, you’ll be well-prepared to tackle any challenges that arise during the maintenance process.

Comparing Different Hitch Models

Understanding the various attachment systems available for agricultural machinery is essential for optimizing functionality and performance. Each model offers unique features suited for specific tasks and equipment compatibility.

When evaluating different systems, consider the following aspects:

- Load Capacity: Assess the weight and size of implements each model can handle.

- Compatibility: Check which types of machinery and attachments can be paired with each system.

- Adjustability: Determine how easily adjustments can be made for different applications.

- Durability: Review the materials and construction quality for long-term use.

- Ease of Use: Consider how user-friendly the mechanisms are for operators.

By examining these factors, operators can make informed decisions on which attachment systems will ultimately enhance their agricultural efficiency.

Where to Find Replacement Parts

When it comes to sourcing components for agricultural machinery, it’s crucial to know where to look for reliable options. Whether you’re in need of a specific piece or a complete assembly, numerous resources are available to assist you in finding what you require.

Online Retailers: The internet is an invaluable resource for locating various components. Numerous specialized websites offer a wide range of products, often accompanied by detailed descriptions and customer reviews. This allows you to compare prices and ensure the quality of what you’re purchasing.

Local Dealers: Don’t overlook the benefits of visiting local dealers. They can provide expert advice and might have the necessary items readily available. Additionally, establishing a relationship with a local supplier can lead to better service and support in the long run.

Salvage Yards: For those on a budget, salvage yards can be a treasure trove. Many facilities stock used equipment, which can often be disassembled for reusable components. This option not only saves money but also promotes sustainability.

Online Marketplaces: Websites that facilitate peer-to-peer sales can also be a great place to find what you need. These platforms often feature listings from individuals and small businesses, providing a diverse selection of components that might not be available elsewhere.

Manufacturer Resources: Lastly, checking with the original manufacturer is always a good option. They can provide genuine components and may also have recommendations for authorized retailers, ensuring you get the correct fit and quality.