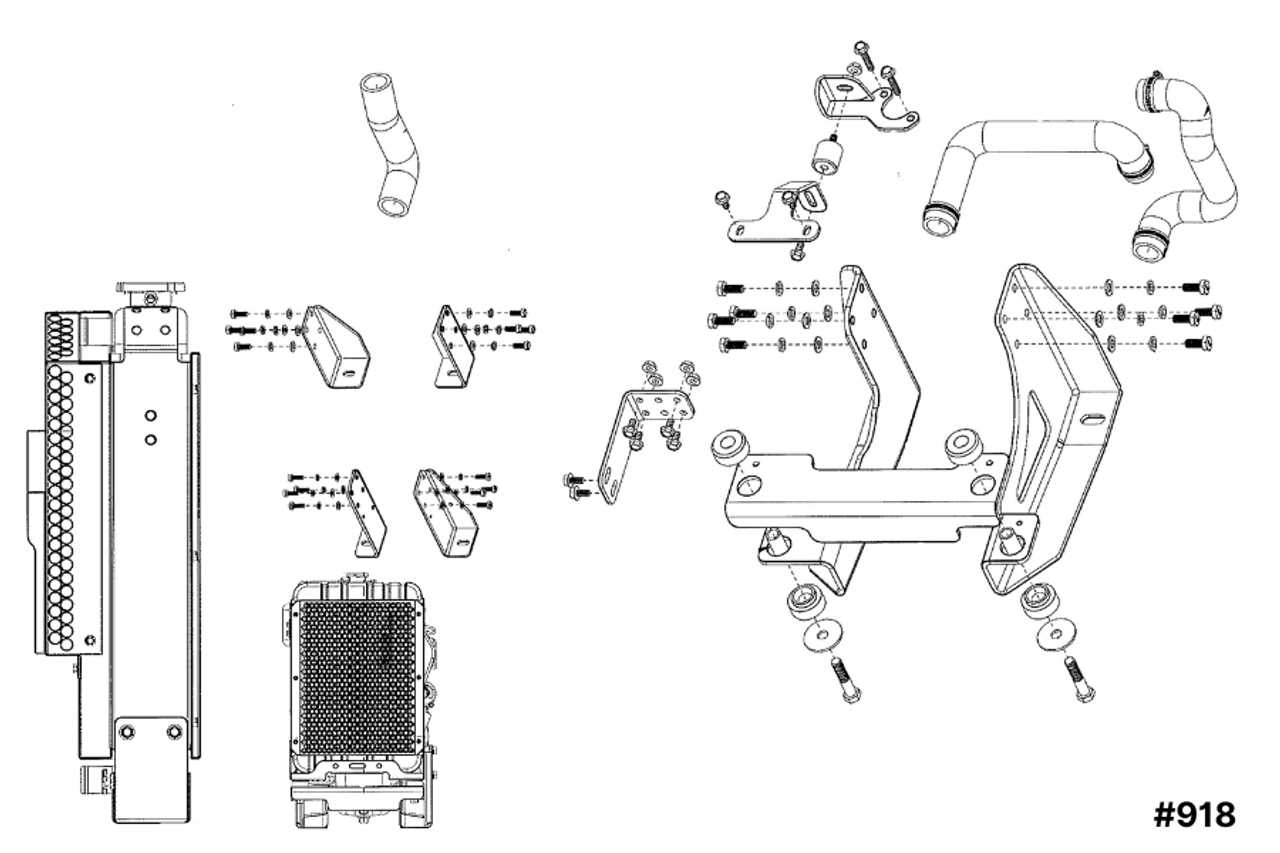

Understanding the Parts Diagram of Rinnai R53i-1

The intricate design of modern heating systems often includes various components working in harmony to ensure optimal performance. Recognizing each element’s function is crucial for efficient operation and maintenance. A comprehensive overview of these components can significantly enhance your understanding of how your system functions.

Detailed illustrations showcasing the arrangement of essential parts serve as valuable resources for both troubleshooting and upgrades. By familiarizing yourself with these visual guides, you can quickly identify specific elements, assess their condition, and determine when replacements or repairs are necessary. This knowledge empowers homeowners to make informed decisions regarding their heating systems.

In this section, we will explore the various elements that contribute to the overall efficiency and reliability of your heating solution. Whether you are a homeowner seeking to enhance your system’s performance or a professional technician aiming to refine your skills, understanding these crucial aspects will undoubtedly benefit your efforts.

Regular upkeep and timely repairs are essential for ensuring optimal performance and longevity of heating systems. Familiarity with the main components involved can significantly enhance troubleshooting and maintenance efforts. Understanding the various elements and their functions enables users to address issues effectively, ensuring a reliable heating experience.

Here is a detailed overview of the critical components typically found in these heating appliances:

| Component | Description | Function |

|---|---|---|

| Burner | The element responsible for igniting the fuel. | Produces heat for the heating system. |

| Heat Exchanger | A device that transfers heat from the combustion process to the water or air. | Ensures efficient heat transfer for optimal performance. |

| Thermostat | A control device that regulates temperature settings. | Maintains the desired temperature by adjusting the heating output. |

| Flame Sensor | A safety device that detects the presence of flame. | Prevents operation if the flame is not detected, ensuring safety. |

| Ventilation System | Components that ensure proper airflow and exhaust gases. | Facilitates safe operation by removing harmful gases. |

Essential Features of Rinnai R53i-1

This model stands out for its innovative design and advanced technology, aimed at delivering efficient performance. Its unique functionalities enhance user experience while ensuring reliability and durability. Understanding these key characteristics helps users appreciate the advantages offered by this unit.

Energy Efficiency

One of the most notable attributes is its exceptional energy efficiency. This feature not only reduces energy consumption but also contributes to lower utility bills. By optimizing performance, the system minimizes waste, making it an environmentally friendly option.

User-Friendly Interface

The intuitive interface is another essential aspect, allowing for seamless operation. Users can easily adjust settings to meet their specific needs, ensuring comfort without hassle. Additionally, clear indicators and controls enhance accessibility, making the experience straightforward for everyone.

How to Identify Component Functions

Understanding the functions of various elements within a heating system is crucial for effective maintenance and troubleshooting. By recognizing the roles that each component plays, you can ensure optimal performance and longevity of the unit. This section will guide you through the process of identifying these functions through careful observation and analysis.

Examining Key Elements

To accurately determine the functions of components, start by examining the physical characteristics and configurations. Pay attention to the shape, size, and material of each part, as these factors can provide clues about their specific roles in the system. Additionally, understanding the flow of energy and fluids within the assembly can help clarify how different parts interact.

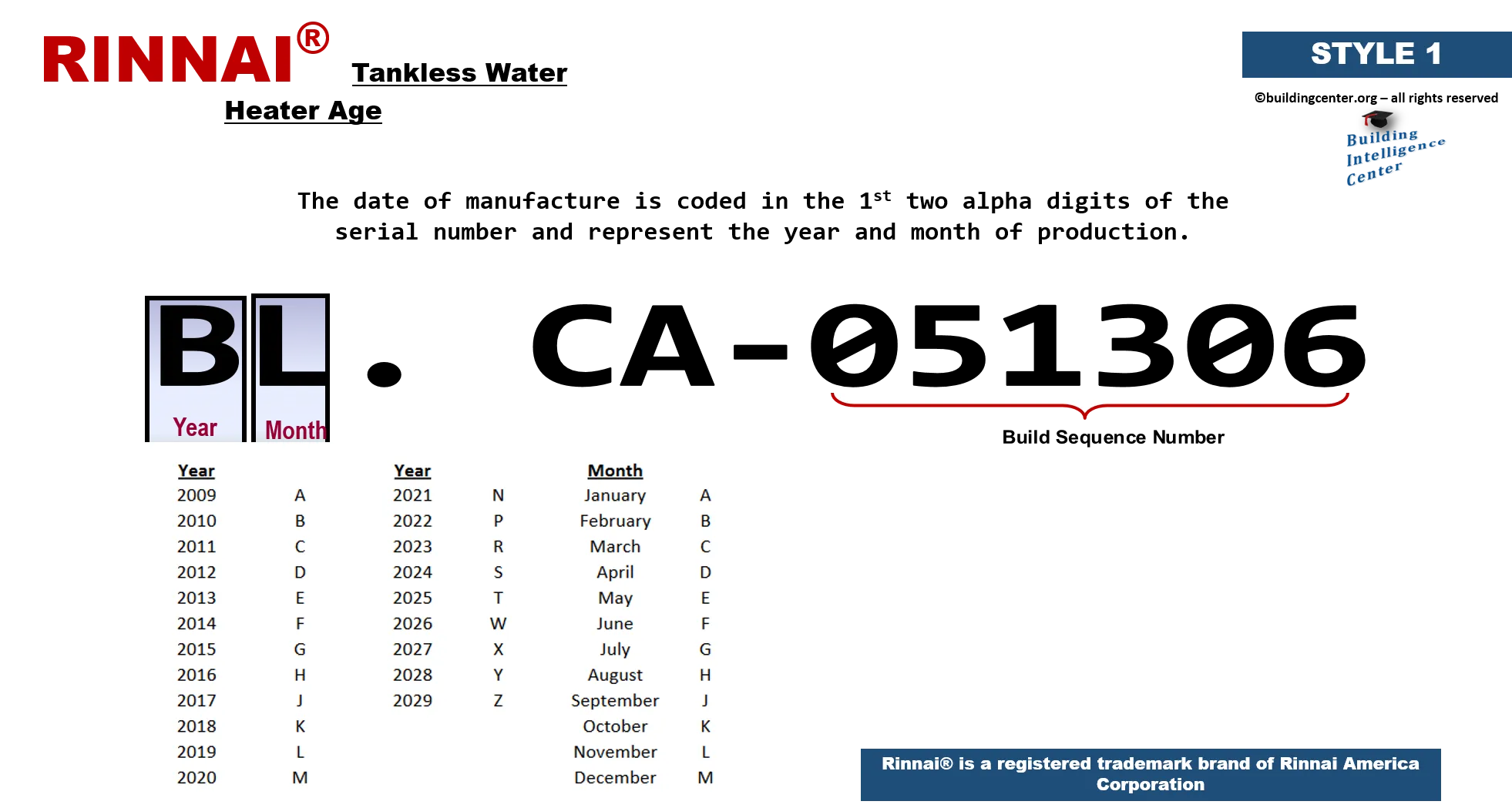

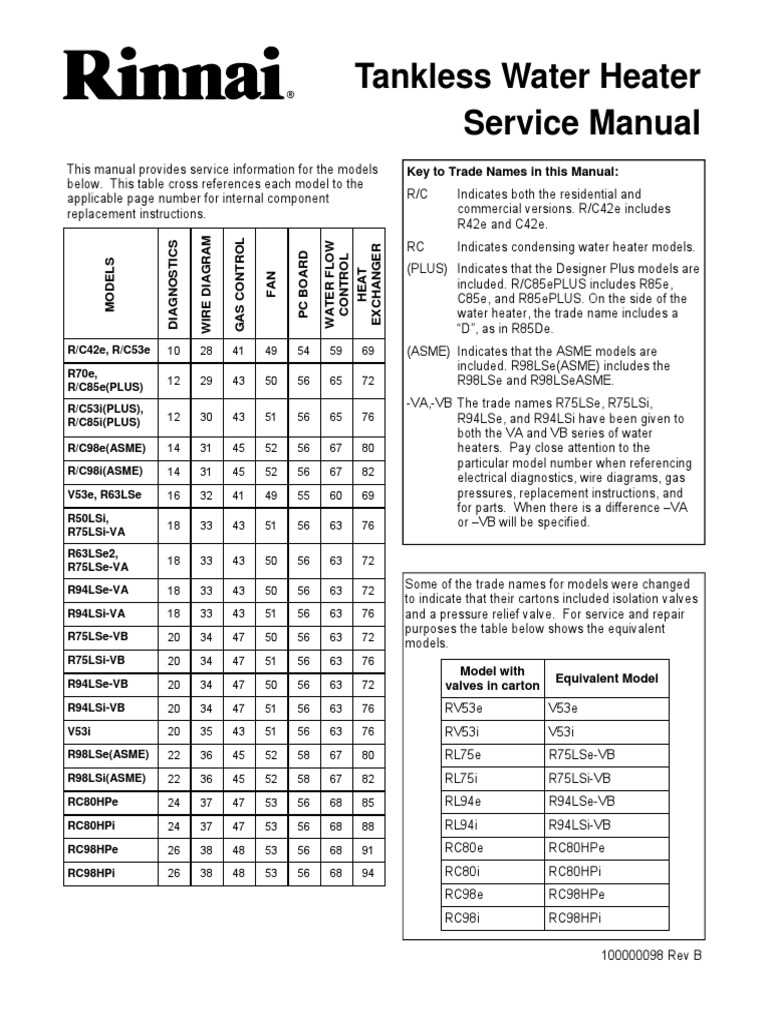

Utilizing Reference Materials

Reference materials, such as technical manuals or schematics, can be invaluable in identifying the functions of components. These documents often contain detailed descriptions and illustrations that highlight the purpose of each element. When studying these resources, focus on identifying common terminologies and visual symbols used to denote specific parts.

| Component | Function |

|---|---|

| Burner | Responsible for igniting fuel to generate heat. |

| Heat Exchanger | Transfers heat from the combustion process to the water supply. |

| Thermostat | Regulates the temperature by controlling the heating cycle. |

| Venturi | Mixes air with gas to ensure efficient combustion. |

| Ignition Module | Initiates the ignition process to start the burner. |

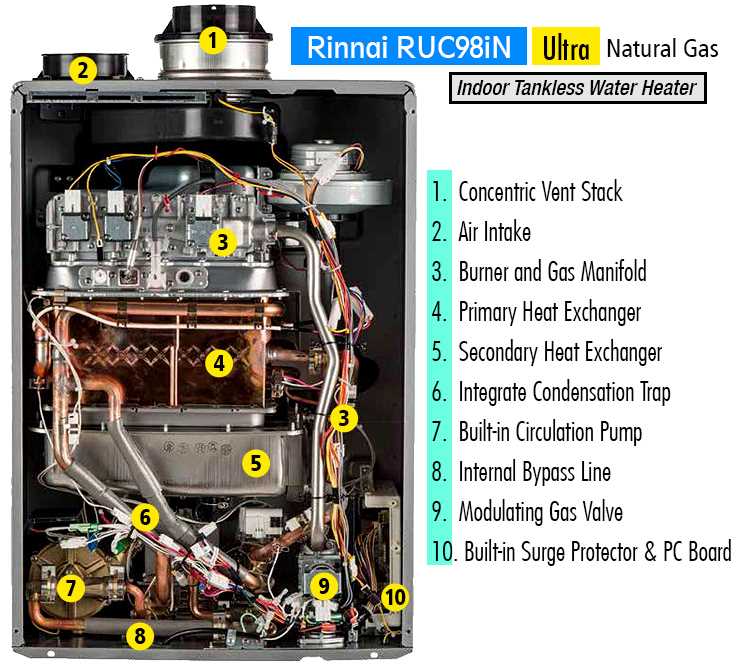

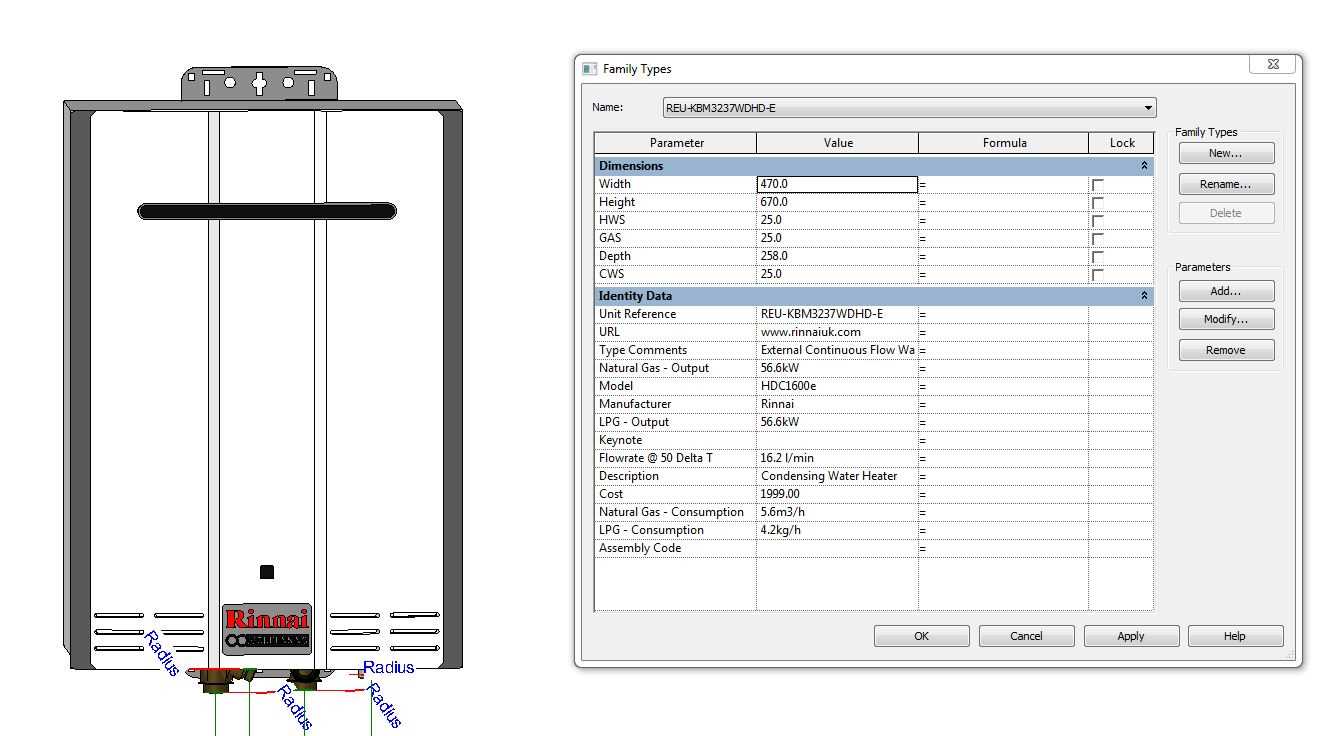

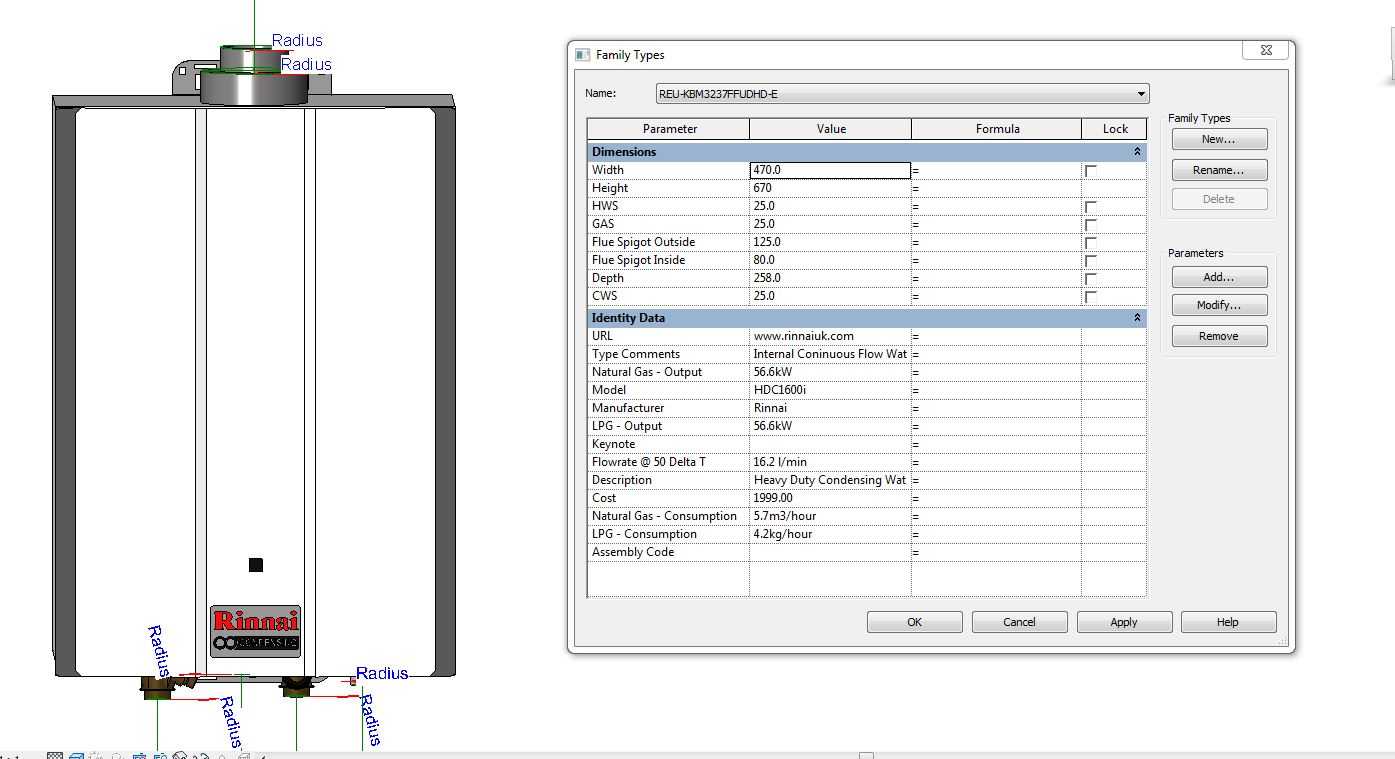

Visual Guide to Component Placement

This section provides an informative overview of how various elements are arranged within the unit. Understanding the layout is crucial for effective maintenance and troubleshooting, ensuring that each part operates harmoniously within the overall system.

In the following illustrations, you will find detailed representations of each component’s position and orientation. Recognizing these placements allows users to quickly identify parts and understand their functions. Familiarity with this arrangement not only simplifies repairs but also enhances the overall efficiency of the appliance.

For optimal performance, pay close attention to how each piece interacts with others. Proper alignment and positioning are essential for ensuring safety and functionality. By following this visual guide, users can gain confidence in navigating the assembly and performing necessary adjustments.

Common Issues with Rinnai R53i-1 Parts

Understanding the frequent challenges associated with various components of heating appliances can significantly enhance their longevity and efficiency. Many users encounter specific malfunctions that may stem from wear and tear or improper maintenance. Identifying these issues early can help prevent further damage and costly repairs.

Overheating is a prevalent problem that can arise due to malfunctioning sensors or blockages in airflow. When the system fails to regulate temperature effectively, it can lead to overheating, which not only affects performance but may also pose safety risks.

Another common issue is inconsistent performance, which may manifest as fluctuating temperatures or irregular heating cycles. This can be caused by a variety of factors, including faulty connections or degraded components that need replacement.

Leaks in the system can also occur, often due to worn seals or connections that have loosened over time. These leaks can lead to reduced efficiency and may require immediate attention to prevent further complications.

Lastly, users may experience error codes displayed on their devices, indicating specific malfunctions. Understanding these codes can help in diagnosing the underlying issues, allowing for timely repairs and maintenance actions to be taken.

Replacement Parts and Compatibility

Understanding the elements of a heating appliance and their interchangeability is crucial for maintenance and repair. When it comes to ensuring optimal performance, knowing which components can be replaced and their compatibility with existing systems plays a significant role. This knowledge not only aids in restoring functionality but also enhances the longevity of the unit.

Identifying Compatible Components is essential when looking to replace any malfunctioning or worn-out pieces. Various manufacturers produce compatible components that can serve as substitutes for original parts. It is advisable to consult technical manuals or manufacturer guidelines to ensure that replacements meet specific standards and fit correctly within the system.

Furthermore, accessibility of compatible items can vary based on location and supplier, making it important to establish reliable sources for procurement. Online retailers, local distributors, and specialty shops often stock a range of components, allowing for easier acquisition. When considering replacements, always verify compatibility with the existing setup to prevent any issues during installation.

Ultimately, making informed decisions about replacements can significantly impact the efficiency and safety of the heating appliance. Regular maintenance, combined with timely replacements of incompatible or damaged elements, ensures that the unit operates at peak performance for years to come.

Safety Considerations for Maintenance

When performing upkeep on heating units, it is essential to prioritize safety to prevent accidents and ensure efficient operation. Regular inspections and servicing can help identify potential hazards, thereby enhancing the overall performance and longevity of the equipment. Adhering to safety protocols not only protects the technician but also safeguards the environment and occupants in the vicinity.

Proper Personal Protective Equipment

Wearing appropriate personal protective gear is vital during maintenance tasks. This includes gloves, goggles, and masks to shield against harmful substances or debris. Ensuring that all safety equipment is in good condition can significantly reduce the risk of injury while performing repairs or routine checks.

Ventilation and Carbon Monoxide Monitoring

Ensuring proper ventilation in the work area is critical, especially when dealing with fuel-burning appliances. Accumulation of harmful gases, such as carbon monoxide, can pose serious health risks. Installing detectors and conducting regular checks on ventilation systems can help mitigate these dangers and create a safer working environment.

Tips for Troubleshooting Problems

When facing issues with your heating unit, it is essential to approach the situation systematically. Identifying the source of the malfunction can save time and ensure effective repairs. Start by gathering information about the symptoms and any unusual behavior, which will guide your troubleshooting efforts.

Begin with basic checks, such as verifying the power supply and ensuring all connections are secure. If the system fails to ignite or operate correctly, inspect the control settings to confirm they are adjusted appropriately. Often, simple adjustments can resolve many common problems.

Next, examine the filter and vents for blockages or debris that could hinder airflow. Regular maintenance of these components is crucial for optimal performance. Additionally, consider any recent changes in usage patterns or external conditions that might affect the unit’s functionality.

If issues persist after these preliminary steps, consult the user manual for specific error codes or indicators. This resource can provide valuable insights into more complex malfunctions that may require professional attention. Keeping detailed notes of your findings will also aid any technicians in diagnosing the problem effectively.