Comprehensive Guide to Ryobi Parts Diagram

In the realm of equipment maintenance, having a clear overview of the various elements within a device is crucial for effective troubleshooting and repairs. This section aims to shed light on the intricacies of how different components interact and function together. By gaining insight into these layouts, users can better navigate their maintenance tasks, ensuring a smoother operational experience.

Exploring the configuration of these essential components allows users to identify specific areas that may require attention. Whether it’s for routine upkeep or addressing unforeseen issues, a comprehensive understanding of these assemblies enhances the ability to perform necessary adjustments with confidence. This knowledge not only aids in efficient repairs but also promotes longevity and reliability in device performance.

Additionally, grasping the relationships between different parts can significantly reduce the time spent on diagnostics. With a visual representation, users are empowered to recognize patterns and dependencies, streamlining their approach to maintenance. This foundation of understanding serves as an invaluable resource for both novice and seasoned individuals engaged in upkeep and repair endeavors.

Understanding Ryobi Parts Diagrams

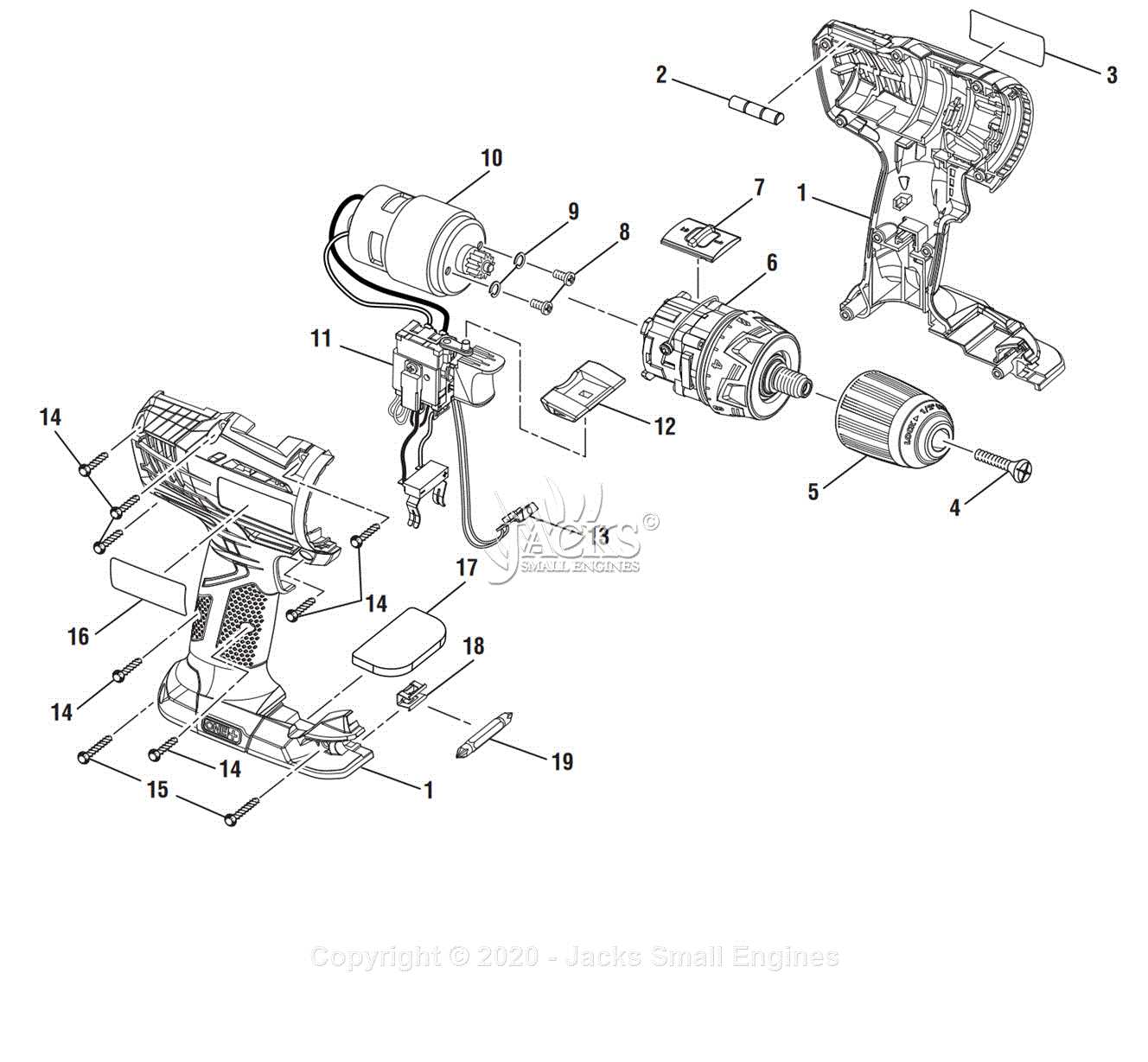

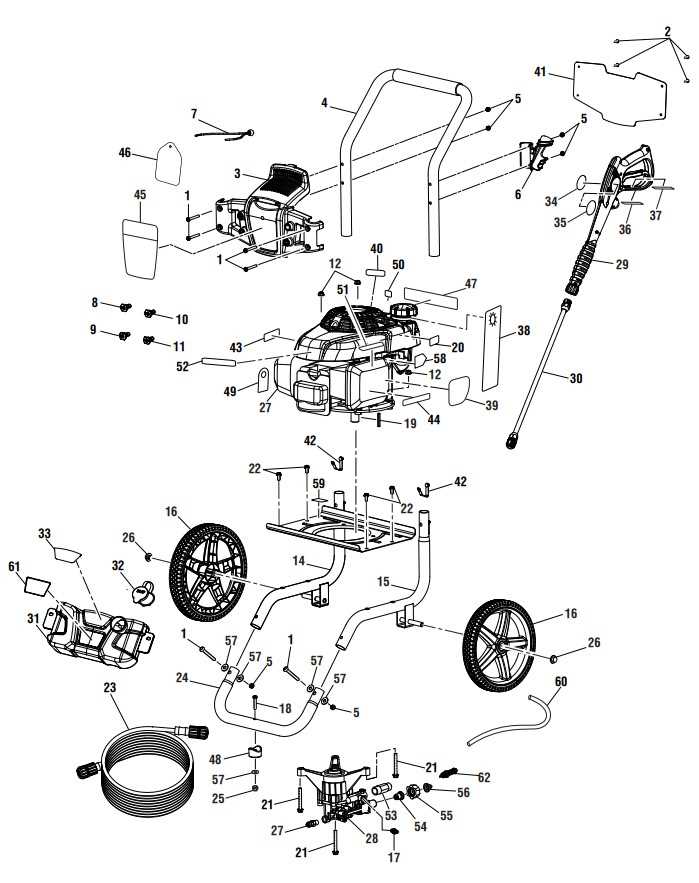

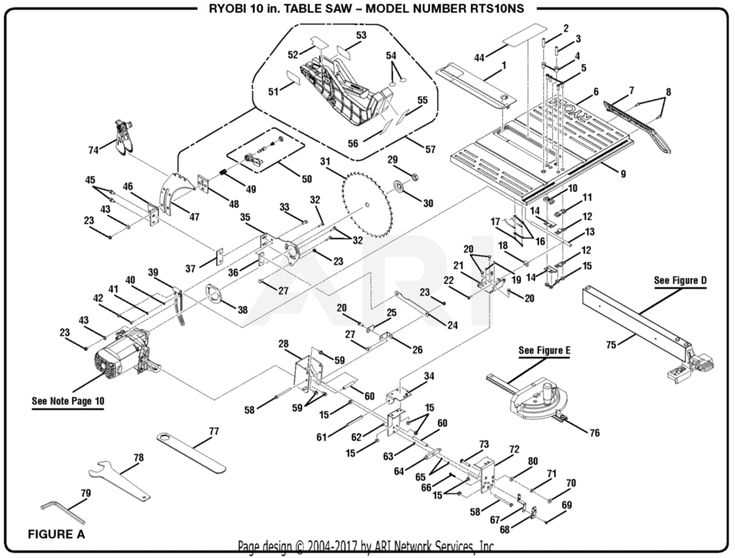

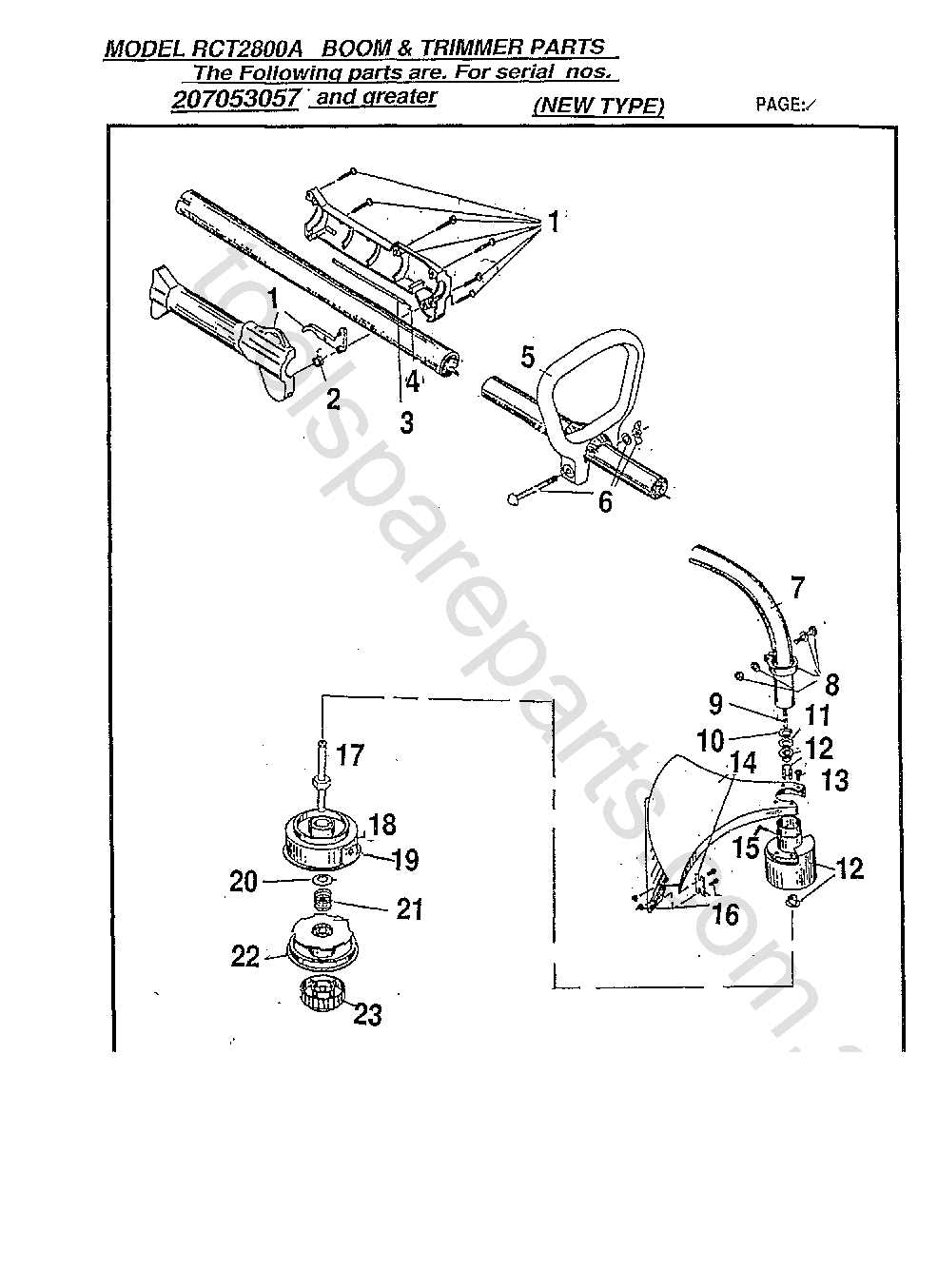

Interpreting the visual representations of components and their relationships is crucial for efficient maintenance and repair. These illustrations serve as a guide, enabling users to identify individual elements within a device and understand how they interact. By familiarizing oneself with these schematics, one can enhance their ability to troubleshoot and assemble equipment effectively.

Importance of Clarity in Visual Representation

Clear illustrations play a vital role in comprehending the structure of machinery. They break down complex assemblies into manageable parts, allowing users to grasp the overall configuration easily. A well-designed visual aid can significantly reduce the time spent on repairs and maintenance, making the process more intuitive and less frustrating.

Common Symbols and Terminology

Familiarity with standard symbols and terminology is essential for effective interpretation. Often, various shapes and lines denote different functions or connections, facilitating a better understanding of how each component operates within the system. Recognizing these elements empowers users to tackle maintenance tasks with greater confidence and efficiency.

Importance of Accurate Parts Identification

Proper recognition of components is crucial for effective maintenance and repair tasks. When individuals engage with equipment or machinery, having a clear understanding of each element ensures efficiency, safety, and longevity. This process not only streamlines repairs but also prevents unnecessary complications arising from incorrect substitutions or misidentifications.

Benefits of Correct Component Recognition

- Enhanced Efficiency: Knowing the right elements to replace or service accelerates the workflow, saving time and effort.

- Cost Savings: Accurate identification helps avoid purchasing incorrect items, reducing waste and unnecessary expenses.

- Improved Safety: Using the correct components minimizes risks associated with faulty or incompatible parts, ensuring user safety.

- Optimal Performance: Ensuring that each part is suitable for its function maintains the overall effectiveness of the equipment.

Strategies for Effective Identification

- Utilize Manuals: Refer to user guides and manuals that provide detailed information on components.

- Consult Experts: Seek assistance from professionals or knowledgeable individuals for complex machinery.

- Visual Inspection: Examine existing elements carefully to note any identifying markings or characteristics.

- Online Resources: Leverage digital platforms that offer diagrams and descriptions for reference.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear view of various elements, helping users identify and locate specific items within a larger assembly. Grasping how to interpret these visuals can enhance your ability to troubleshoot and manage equipment efficiently.

1. Familiarize Yourself with the Layout: Start by examining the overall structure of the illustration. Notice how components are arranged and labeled. Different sections may represent various functions, so understanding the layout can help in pinpointing the area of interest.

2. Identify Symbols and Labels: Pay close attention to any symbols or labels accompanying the visuals. These often indicate sizes, quantities, or specific functions of the components. Familiarizing yourself with these markers will significantly enhance your comprehension.

3. Cross-Reference with Manuals: Always refer to the accompanying documentation when available. Manuals often provide additional context and detail, ensuring you have a comprehensive understanding of the components represented.

4. Practice Regularly: Like any skill, becoming proficient in interpreting these visuals takes practice. Regularly review different illustrations to build your familiarity and confidence in identifying components and their roles.

By mastering these skills, you’ll be better equipped to manage and repair equipment efficiently.

Common Components in Ryobi Tools

Understanding the fundamental elements of power equipment can enhance user experience and facilitate maintenance. Each tool is composed of various essential parts that work together to ensure functionality and efficiency. Familiarity with these components can aid in troubleshooting and repair processes, making it easier to keep your equipment in optimal condition.

1. Motor Assembly

The motor assembly serves as the heart of any power tool, converting electrical energy into mechanical energy. This component is responsible for driving the tool’s various functions, allowing it to perform tasks effectively. In many models, the motor is designed to provide a balance of power and efficiency, ensuring reliable operation.

2. Gear Mechanism

The gear mechanism plays a crucial role in determining the speed and torque of the equipment. By adjusting the gear ratios, users can optimize performance for specific applications, whether it be drilling, cutting, or sanding. A well-engineered gear system enhances the overall durability and reliability of the tool.

Maintenance Tip: Regularly check these components for wear and tear to extend the lifespan of your equipment.

Finding Replacement Parts Easily

When it comes to maintaining tools and equipment, sourcing suitable components can often be a daunting task. Understanding where to look and how to navigate the options available can significantly simplify the process. This section provides essential insights for effortlessly acquiring the necessary items to ensure your equipment remains functional and efficient.

Start with the Manufacturer’s Website: A reliable approach is to begin your search on the official website of the equipment manufacturer. Most companies offer a user-friendly interface where you can input your model number or browse through categories to locate compatible components. This ensures that the items you find are designed specifically for your tool, enhancing compatibility and performance.

Utilize Online Retailers: Numerous online retailers specialize in selling components for a wide range of tools. Websites like Amazon and specialized hardware stores often feature extensive inventories, allowing you to compare prices and read customer reviews. This can provide valuable insights into the quality and reliability of the items you are considering.

Consult User Manuals: User manuals often contain detailed information about the specific components used in the equipment. They can guide you on what to look for when searching for replacements, ensuring that you purchase the correct specifications. Having this reference on hand can save time and reduce the likelihood of errors in your search.

Join Online Forums: Engaging with communities of other tool users can be incredibly beneficial. Online forums and social media groups dedicated to tool maintenance are excellent places to ask for advice and recommendations. Members often share their experiences and may point you towards trustworthy sources for acquiring necessary items.

Local Hardware Stores: Don’t overlook local retailers. Visiting nearby hardware or specialty stores allows you to consult with knowledgeable staff who can assist in identifying the right components. Plus, purchasing in person means you can often take the item home immediately, saving on shipping time.

Using Diagrams for Maintenance Tips

Visual representations play a crucial role in simplifying the upkeep of various tools and machinery. These illustrations not only provide clarity but also enhance understanding of the components involved. By utilizing these resources, users can effectively troubleshoot issues, identify necessary replacements, and perform routine maintenance tasks with confidence.

To maximize the benefits of these visuals, consider the following recommendations:

| Tip | Description |

|---|---|

| Familiarize Yourself | Spend time studying the illustration to recognize the different components and their functions. |

| Follow Step-by-Step Guides | Utilize the visual aid alongside written instructions for a comprehensive understanding of the maintenance process. |

| Identify Wear and Tear | Use the illustration to spot signs of damage or deterioration in specific parts that may require attention. |

| Organize Your Tools | Refer to the visual representation to ensure you have all the necessary tools before starting maintenance tasks. |

| Document Changes | Keep a record of any alterations or replacements made, referencing the visual to track what has been addressed. |

Incorporating these strategies into your maintenance routine will lead to a more efficient and effective approach, ensuring that your equipment remains in optimal condition.

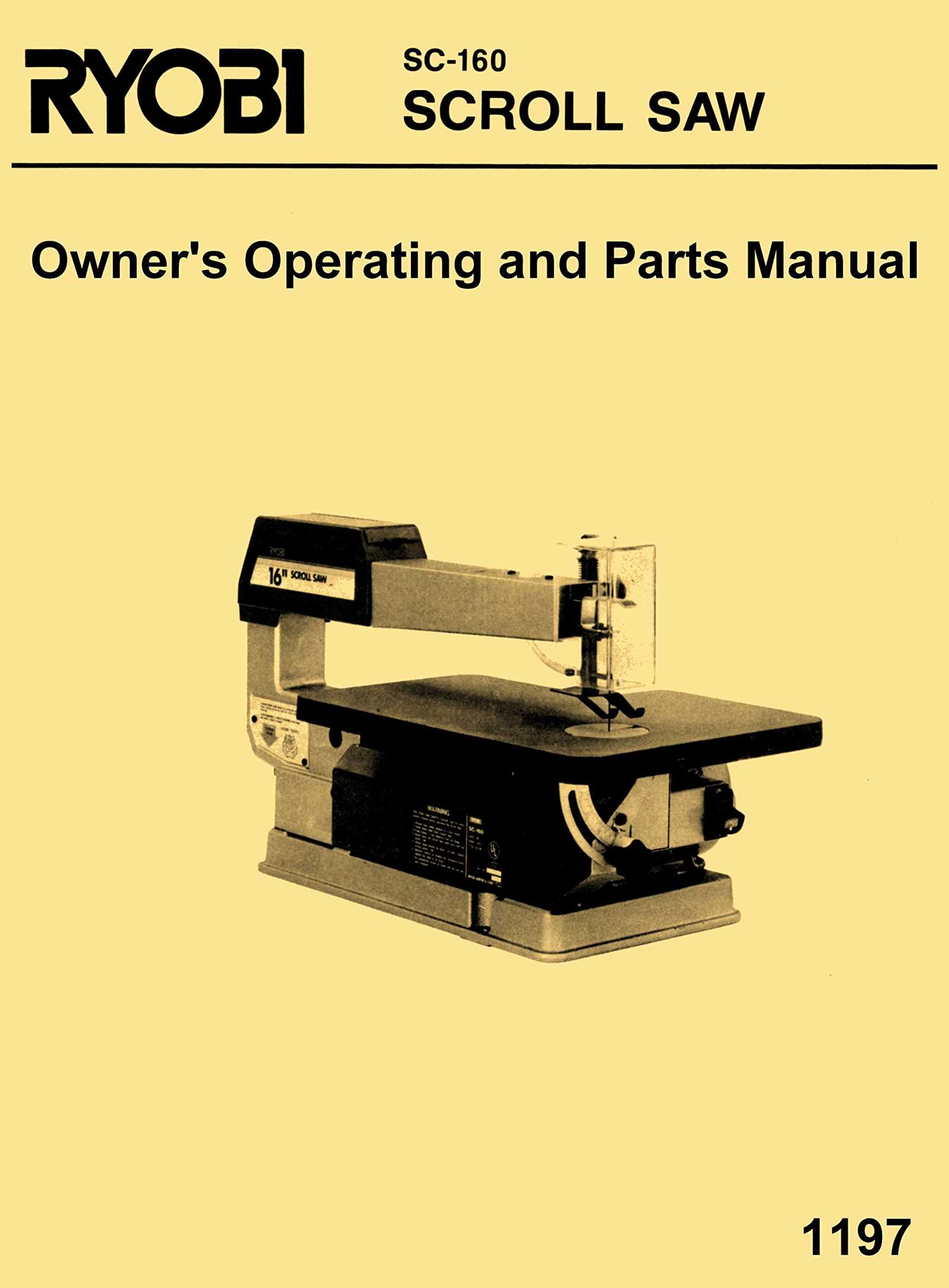

Identifying Model Numbers and Variants

Understanding how to recognize and differentiate model identifiers and their variations is essential for effective maintenance and repair. Each model may have unique features or specifications that cater to specific needs. This knowledge ensures that users can efficiently locate compatible components or accessories.

Why Model Identification Matters

Knowing the exact model number helps in various scenarios:

- Ensuring compatibility with replacements and upgrades.

- Accessing accurate instructions for maintenance and troubleshooting.

- Facilitating efficient customer support and service requests.

How to Locate Model Numbers

Model numbers are typically found in several key locations:

- On the device’s nameplate or label, usually affixed to a prominent area.

- In the user manual, which provides detailed specifications.

- On the original packaging, which often contains relevant identifiers.

By familiarizing oneself with these locations, users can quickly identify the necessary model numbers and their respective variations.

Where to Access Ryobi Diagrams

Accessing visual schematics for tools and equipment can significantly enhance repair and maintenance efforts. Various resources are available to help locate these essential illustrations, ensuring users can effectively understand their devices.

- Manufacturer’s Website: The official site often provides a comprehensive collection of visuals along with manuals.

- Authorized Dealers: Local retailers or service centers typically have access to detailed schematics, often in print or digital formats.

- Online Forums: Communities of enthusiasts frequently share links to resources, including visuals that may not be available through official channels.

- Third-Party Websites: Numerous websites specialize in tool documentation and may host extensive libraries of visuals.

- Instruction Manuals: Original guides that accompany tools often include visual references and breakdowns of components.

Utilizing these resources can provide users with the necessary information to facilitate repairs, modifications, or upgrades efficiently.

Benefits of DIY Repairs

Engaging in do-it-yourself repairs can be a rewarding experience that empowers individuals to take control of their maintenance needs. It not only fosters a sense of accomplishment but also enhances one’s skills and understanding of various tools and devices.

Cost Savings

One of the primary advantages of handling repairs personally is the significant financial savings. By bypassing professional services, individuals can avoid labor costs and often find affordable replacement components online or at local retailers. This approach enables homeowners to allocate their budget more effectively.

Increased Knowledge and Skills

Taking on repair tasks promotes learning and skill development. As individuals work through challenges, they gain practical experience and technical knowledge, which can prove invaluable in the future. This empowerment can lead to greater confidence when tackling new projects or troubleshooting issues as they arise.

Frequently Asked Questions about Parts

This section addresses common inquiries regarding components and their functionality within various tools and equipment. Understanding the intricacies of these elements can help users make informed decisions when seeking replacements or upgrades.

What should I consider when selecting a replacement component?

When choosing a substitute, it is essential to ensure compatibility with your device’s specifications. Referencing model numbers and manufacturer guidelines can prevent potential issues during installation.

How can I identify a specific component I need?

Identifying a particular element often involves examining the equipment’s manual or looking for identifying labels. Online resources and community forums can also provide valuable insights and guidance.

Are there any warranties or guarantees on components?

Many manufacturers offer warranties or guarantees for their components. Always review the terms and conditions before making a purchase to understand your rights and protections.

Where can I find reliable suppliers for replacements?

Reputable suppliers can be found both online and in physical stores. Researching customer reviews and verifying the authenticity of the supplier can ensure you receive quality items.

What are the benefits of using original components versus alternatives?

Original components are designed specifically for the equipment, often providing superior performance and longevity. Alternatives may be more cost-effective but can vary in quality and reliability.

Comparing Ryobi with Other Brands

When evaluating various tools and equipment manufacturers, it’s essential to consider the unique offerings and characteristics of each brand. This analysis aims to highlight how one specific brand stacks up against its competitors in terms of quality, performance, and user satisfaction. By examining these elements, users can make informed decisions when selecting their preferred products.

Quality and Durability

Quality is a crucial factor that influences consumer choices. Many brands claim to offer robust and long-lasting items, yet the real test lies in customer feedback and reviews. While some manufacturers focus on affordability, others prioritize premium materials and construction techniques. Understanding these differences helps consumers gauge which options align with their needs and usage scenarios.

Performance and Innovation

Performance is another significant aspect where brands differentiate themselves. Innovation in design and technology can enhance functionality, making specific products more effective for various tasks. Brands often introduce new features to improve user experience, but it’s vital to assess whether these innovations deliver tangible benefits or simply serve as marketing tools. By comparing performance metrics and unique offerings, consumers can identify the best choices for their projects.

Resources for Tool Enthusiasts

For those passionate about machinery and craftsmanship, accessing high-quality information and resources is essential. A variety of platforms can provide support, tutorials, and detailed illustrations to enhance the understanding and maintenance of various tools. This section highlights valuable sources that enthusiasts can utilize to deepen their knowledge and improve their skills.

Online Communities

Engaging with fellow enthusiasts through online forums and social media groups can be incredibly beneficial. These platforms often offer a wealth of shared experiences, troubleshooting advice, and recommendations for resources. Whether seeking guidance on specific equipment or general tips, connecting with others can provide invaluable insights.

Instructional Materials

Access to instructional manuals and user guides is vital for anyone looking to maximize the potential of their tools. Many manufacturers provide downloadable resources that offer step-by-step instructions, maintenance tips, and safety precautions. Additionally, video tutorials available on various platforms can visually guide users through complex processes.

| Resource Type | Description |

|---|---|

| Online Forums | Communities where enthusiasts share experiences and advice. |

| Video Tutorials | Visual guides for learning techniques and maintenance. |

| User Manuals | Documents offering essential information on equipment operation. |

| Workshops | Hands-on sessions for skill development and tool familiarity. |