Comprehensive Parts Diagram for Maytag Commercial Dryers

In the world of household appliances, a clear understanding of individual components is essential for efficient operation and maintenance. Knowledge of how these elements work together can significantly enhance troubleshooting and repair processes. By familiarizing oneself with the intricate arrangement of each part, users can ensure optimal performance and longevity of their equipment.

Every appliance is designed with specific functionalities in mind, and each component plays a vital role in achieving these objectives. Grasping the relationship between different sections helps users identify potential issues and implement effective solutions. This comprehensive knowledge empowers individuals to take control of their appliances, leading to more informed decisions regarding repairs and replacements.

For those looking to deepen their understanding, exploring detailed layouts can serve as an invaluable resource. These layouts provide insights into the configuration of various elements, showcasing how they interact within the system. Gaining this perspective not only aids in repairs but also fosters a greater appreciation for the engineering behind everyday appliances.

This section aims to provide a comprehensive overview of the key components and their functionalities within a specific brand of fabric care appliance. By exploring the various elements involved, users can gain a clearer understanding of how each part contributes to the overall performance and efficiency of the equipment.

Below is a breakdown of significant elements commonly found in such machines:

| Component | Functionality |

|---|---|

| Drum | Responsible for holding and tumbling clothes during the drying cycle. |

| Heating Element | Generates heat necessary for drying fabrics effectively. |

| Motor | Powers the drum and other mechanical parts, ensuring smooth operation. |

| Belt | Connects the motor to the drum, facilitating movement and rotation. |

| Control Panel | Allows users to set drying cycles and monitor machine performance. |

| Lint Filter | Catches lint and debris, maintaining air quality and efficiency. |

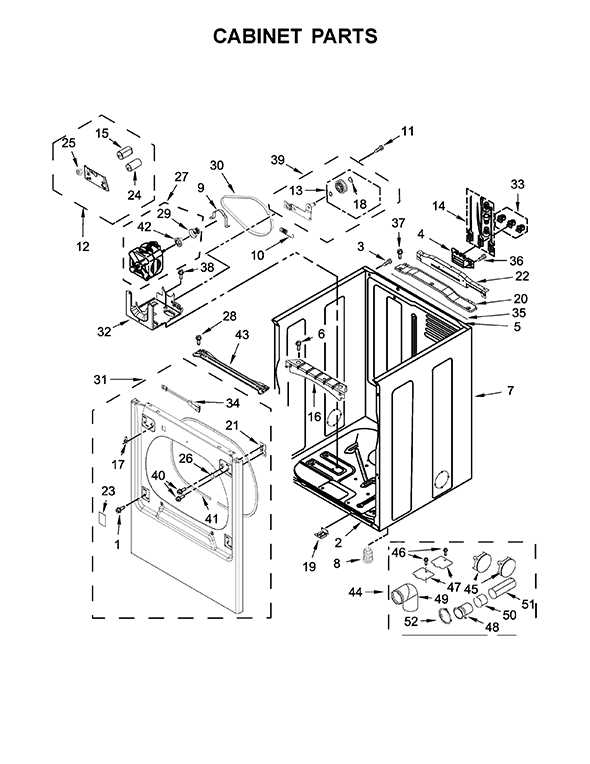

Overview of Dryer Components

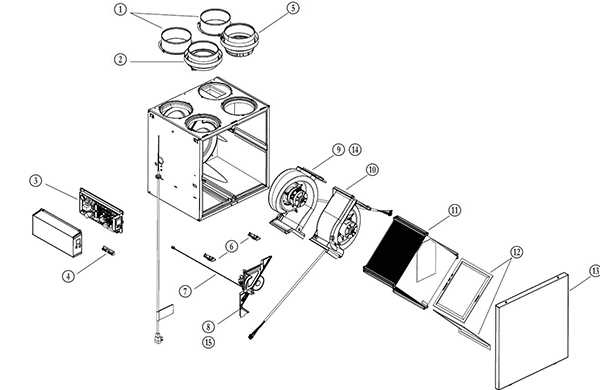

The functioning of a fabric drying appliance relies on several essential elements that work in harmony to ensure efficiency and effectiveness. Understanding these components provides insight into how they contribute to the overall operation, enhancing the performance of the appliance.

Each element plays a crucial role, from facilitating airflow to controlling temperature. Below is a list of key components and their respective functions:

- Heating Element: Generates the heat necessary for drying clothes.

- Drum: Holds and rotates the items being dried, allowing them to tumble and dry evenly.

- Belt: Connects the motor to the drum, enabling rotation during operation.

- Motor: Powers the drum and other moving parts, ensuring smooth operation.

- Thermostat: Regulates the temperature, preventing overheating and ensuring safe drying conditions.

- Blower: Circulates warm air throughout the drum, enhancing drying efficiency.

- Lint Filter: Traps lint and debris, preventing clogs and maintaining airflow.

- Control Panel: Allows users to select settings, including drying time and temperature.

These essential elements not only ensure optimal performance but also contribute to the longevity of the appliance. Familiarity with each component aids in troubleshooting and maintenance, ensuring the appliance operates efficiently for years to come.

Common Issues with Maytag Models

Understanding the frequent problems encountered with certain appliance models can greatly enhance maintenance and troubleshooting efforts. Users often report various operational challenges that can stem from different factors, including mechanical wear, electrical malfunctions, or inadequate installation. Recognizing these common issues can help in timely interventions, ensuring optimal performance and longevity.

Electrical Failures

One of the primary concerns relates to electrical components failing to function properly. Issues such as blown fuses, faulty power cords, or malfunctioning control boards can prevent the unit from starting or operating efficiently. Regular checks on these components can mitigate the risk of unexpected breakdowns.

Mechanical Problems

Another prevalent issue involves mechanical parts, including belts and motors. Wear and tear over time can lead to unusual noises, reduced efficiency, or even complete failure of the appliance. Conducting routine inspections and replacing worn components promptly can help maintain peak performance.

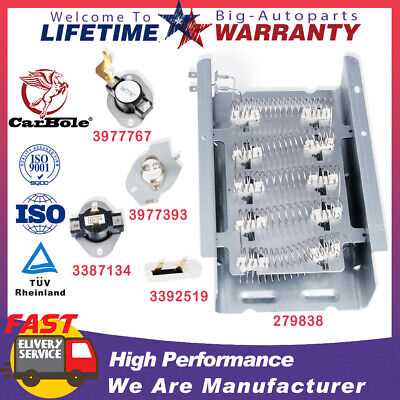

Parts Replacement Guide

Replacing components in household appliances is essential for maintaining their efficiency and longevity. This section provides guidance on how to identify and replace different elements of your machine, ensuring optimal performance and extending its service life. Proper replacement techniques not only enhance functionality but also contribute to energy savings.

Identification of Components

Before proceeding with any replacements, it is crucial to accurately identify the parts that require attention. Commonly replaced components include:

- Belt

- Motor

- Heating element

- Control board

- Drum support rollers

Replacement Steps

- Unplug the appliance to ensure safety.

- Remove the outer casing to access internal components.

- Carefully detach the worn-out component.

- Install the new part by aligning it correctly.

- Reassemble the outer casing and test the appliance.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention. Proper care not only enhances performance but also extends the lifespan of various components. By following a few essential practices, you can maintain optimal functionality and prevent premature wear and tear.

- Regular Cleaning: Keep the interior and exterior surfaces clean to prevent the buildup of lint and dust. Regular cleaning can significantly improve air circulation and efficiency.

- Check Connections: Inspect electrical connections periodically to ensure they are secure and free from corrosion. Loose or damaged connections can lead to operational issues.

- Lubricate Moving Parts: Apply appropriate lubricants to all moving components to reduce friction. This practice minimizes wear and ensures smoother operation.

- Monitor Performance: Pay attention to any changes in performance or unusual noises. Early detection of issues can prevent larger problems down the line.

- Schedule Professional Inspections: Regular professional check-ups can help identify potential issues that may not be visible during routine maintenance. Experts can provide insights and recommendations for optimal care.

By incorporating these practices into your routine, you can enhance the reliability and efficiency of your equipment, ensuring it serves you well for years to come.

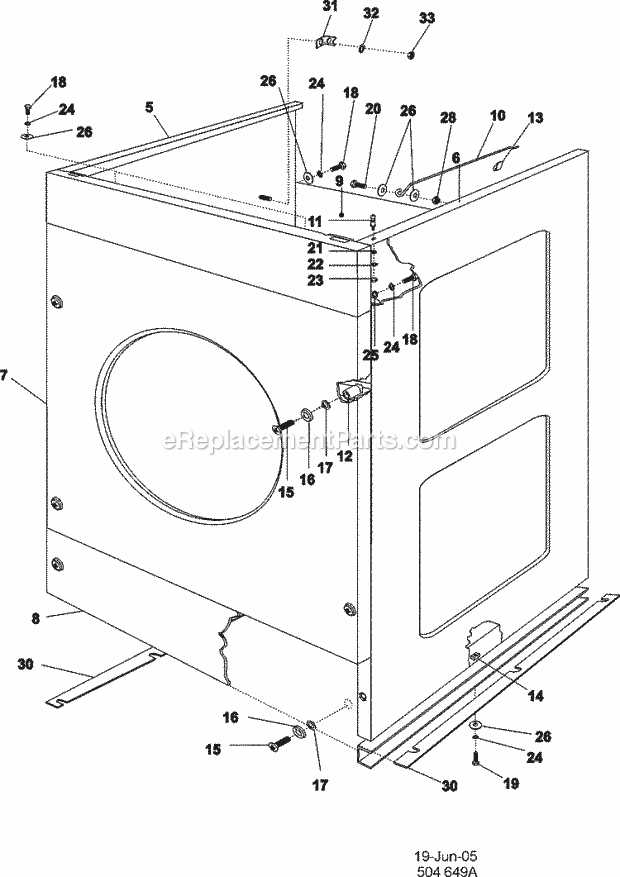

How to Identify Parts

Understanding the components of your appliance is essential for effective maintenance and repairs. Recognizing each element and its function can significantly enhance your troubleshooting skills, leading to more efficient solutions. This section outlines useful strategies to identify the various elements within your machine.

Visual Inspection

Begin with a thorough visual examination. Familiarize yourself with the overall layout and arrangement of the individual components. Look for labels or markings on the elements themselves, as many manufacturers include identification tags that provide helpful information. Taking note of the shape, size, and configuration will aid in distinguishing between similar-looking items.

Reference Manuals and Online Resources

Utilizing reference manuals can be immensely beneficial. These documents often contain detailed descriptions, illustrations, and specifications for each element. Additionally, online forums and support websites offer valuable insights from experienced users and professionals. Engaging with these communities can help clarify any uncertainties regarding the identification of specific components.

Tools Required for Repairs

Having the right tools is essential for effectively conducting maintenance and troubleshooting on any appliance. A well-equipped toolkit ensures that repairs can be carried out efficiently and safely, reducing downtime and preventing further damage. Below is a list of essential implements commonly needed for servicing and fixing issues with the unit.

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for removing and securing screws in various components. |

| Socket Wrench | Helps in loosening or tightening nuts and bolts. |

| Pliers | Assists in gripping and bending wires or small parts. |

| Multimeter | Measures voltage, current, and resistance to diagnose electrical issues. |

| Replacement Parts | Necessary components for swapping out defective items during repairs. |

| Cleaning Supplies | Used for maintaining cleanliness and removing debris from internal components. |

Wiring Diagrams Explained

Understanding the layout and connections within electrical appliances is crucial for efficient troubleshooting and maintenance. These visual representations provide a clear overview of the various components and their interconnections, making it easier to identify issues and ensure proper functionality. A well-constructed schematic can simplify the repair process and enhance safety by illustrating the correct wiring configurations.

Importance of Accurate Representations

Accurate schematics are essential for anyone working with electrical systems. They serve as a roadmap, guiding technicians through complex setups while minimizing the risk of errors. By following these illustrations, users can ensure that every connection is made correctly, reducing the likelihood of malfunctions and enhancing the overall reliability of the system.

Key Components in Wiring Illustrations

Typically, these visual aids include various symbols representing different elements such as switches, motors, and power sources. Understanding these symbols is vital for interpreting the diagrams effectively. Below is a basic table outlining common symbols and their meanings:

| Symbol | Component |

|---|---|

| Power Source | |

| Switch | |

| ⚙️ | Motor |

| Indicator Light | |

| ⚠️ | Ground Connection |

Safety Precautions During Repairs

When undertaking maintenance on any appliance, it is crucial to prioritize safety to prevent accidents and injuries. Following specific guidelines can help ensure a secure working environment while performing repairs. By adhering to these precautions, individuals can mitigate risks associated with electrical and mechanical components.

Power Disconnection

Before starting any repair work, always disconnect the power source. This step prevents electrical shocks and ensures that the appliance cannot be inadvertently activated during the process. Using a lockout/tagout system can further enhance safety by preventing the accidental re-energization of the device.

Protective Gear

Wearing appropriate personal protective equipment (PPE) is essential during repair tasks. This includes safety goggles to shield the eyes from debris, gloves to protect hands from sharp edges and hot surfaces, and sturdy footwear to minimize the risk of injury. Proper attire contributes significantly to overall safety and helps reduce the likelihood of accidents.

Where to Purchase Genuine Parts

When it comes to maintaining your appliances, sourcing authentic components is crucial for ensuring optimal performance and longevity. Genuine components are designed to meet specific standards, which can significantly enhance the reliability of your equipment. Here are some recommended avenues to explore when seeking original replacements.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides a comprehensive catalog of authentic components, along with the option to purchase directly online. |

| Authorized Retailers | Local or online retailers that are authorized by the manufacturer can offer a selection of original components with the added benefit of customer support. |

| Specialized Repair Shops | These establishments frequently stock genuine components and can provide expert advice on selection and installation. |

| Online Marketplaces | Websites dedicated to e-commerce can offer a variety of options, but ensure you verify the seller’s credibility to avoid counterfeit products. |

Choosing the right source for authentic components not only guarantees quality but also helps in maintaining the functionality of your equipment. Make informed decisions and invest in genuine components for the best results.

Customer Support Resources

Accessing reliable support can greatly enhance your experience with your appliance. Whether you are facing operational challenges or require assistance with maintenance, various resources are available to ensure you receive the help you need.

Contacting Customer Service

For immediate assistance, reaching out to the customer service team is essential. Here are some options to consider:

- Phone Support: Speak directly with a representative who can guide you through troubleshooting steps.

- Email Support: Send your inquiries via email for detailed assistance and follow-up communication.

- Live Chat: Utilize online chat services for real-time support during business hours.

Online Resources

In addition to direct communication, various online platforms offer valuable information:

- FAQs: Frequently asked questions can provide quick answers to common issues.

- User Manuals: Access detailed guides and manuals for operational insights and maintenance tips.

- Community Forums: Engage with other users to share experiences and solutions to similar problems.