Comprehensive Guide to Honda HR173 Parts Diagram

When exploring the intricate design of machinery, it is essential to grasp the relationships between various elements that contribute to its overall performance. This knowledge allows for enhanced maintenance and repair, ensuring longevity and efficiency in operation.

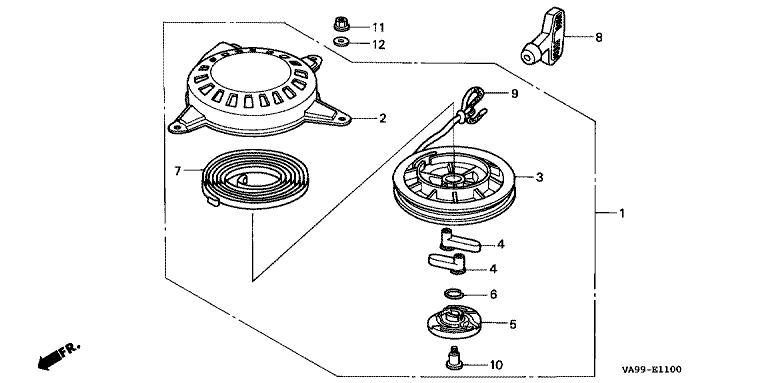

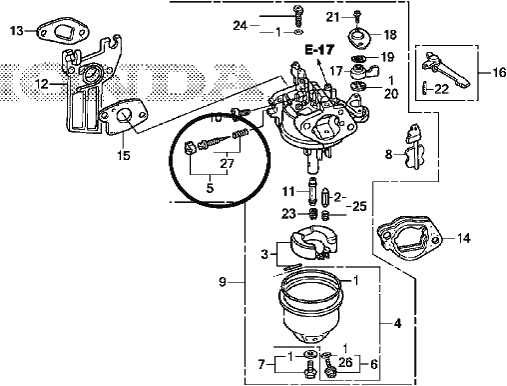

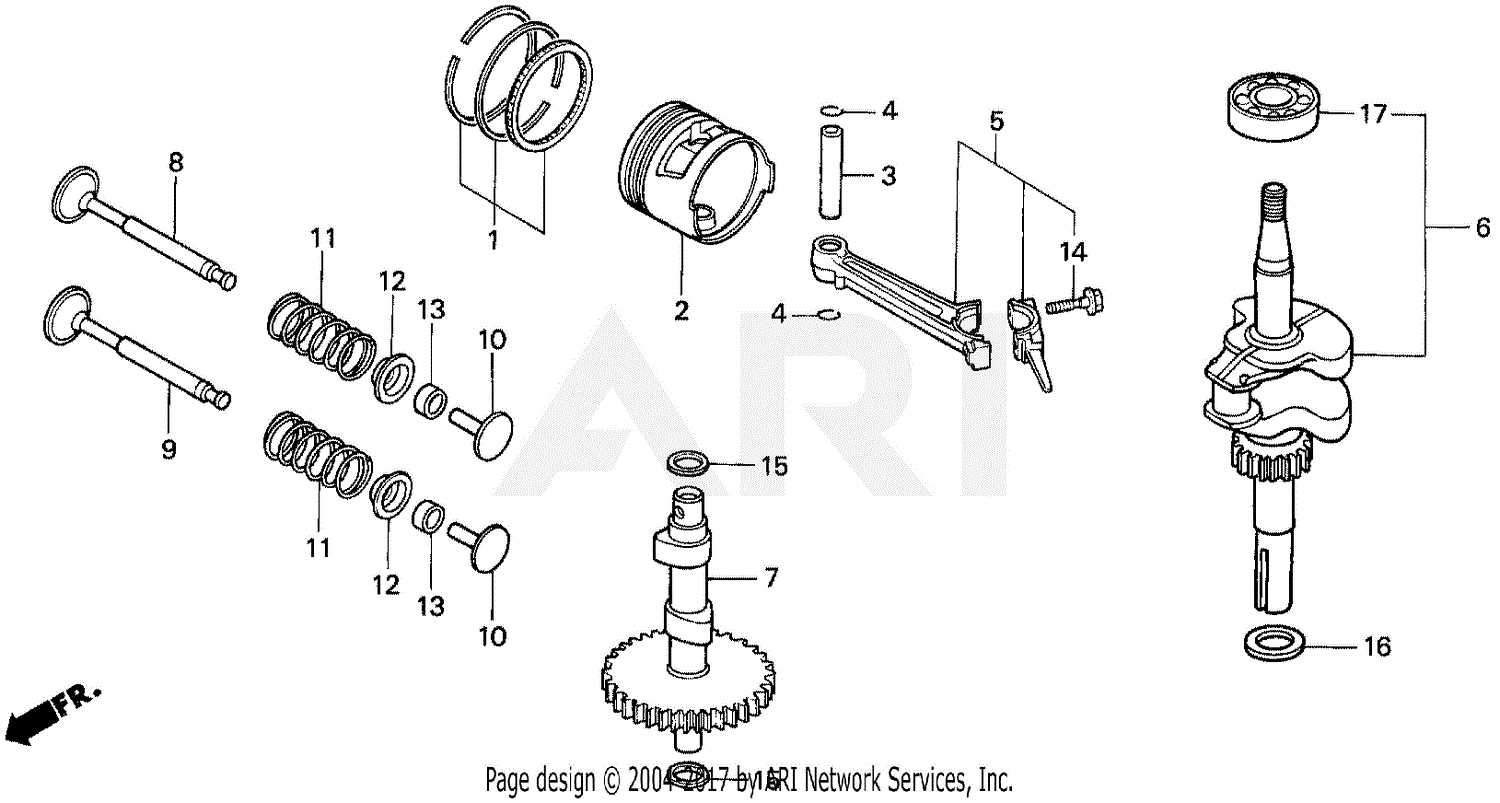

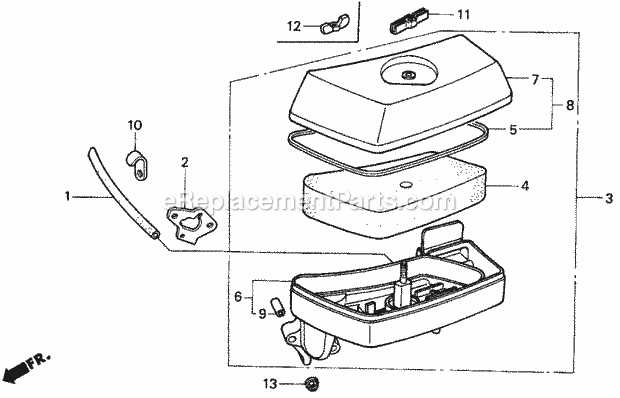

Detailed visual representations of each component can serve as invaluable tools for enthusiasts and professionals alike. By examining these schematics, one can delve into the specific roles and connections that each part plays within the larger system.

Ultimately, a comprehensive understanding of these essential features empowers users to make informed decisions regarding upgrades and replacements. This not only improves functionality but also enriches the user experience, fostering a deeper appreciation for the technology involved.

Understanding Honda HR173 Parts Diagram

Having a clear understanding of a machinery layout is crucial for effective maintenance and repairs. This visual representation aids users in identifying components and their relationships, ensuring that tasks are performed accurately. Knowledge of each section enhances efficiency and minimizes errors.

Visual guides serve as essential tools for both novices and experienced users alike. They simplify the complexities of intricate systems, allowing for easy navigation through various elements. By studying these representations, one can delve into the specifics of functionality and design.

Furthermore, grasping the structure of these layouts empowers individuals to troubleshoot issues more effectively. Familiarity with each part not only facilitates repairs but also contributes to the overall longevity and performance of the equipment. Ultimately, a comprehensive grasp of the schematic can lead to enhanced operational success.

Overview of Honda HR173 Model

This section provides insights into a specific model known for its efficiency and reliability. Designed for various applications, it has garnered attention for its robust performance and user-friendly features.

Key Features

The model boasts a compact design, making it ideal for residential spaces. Its engine delivers impressive power while maintaining fuel efficiency, ensuring optimal operation over extended periods. Additionally, maintenance is simplified, allowing users to keep it in prime condition with minimal effort.

Performance and Usability

Noteworthy for its versatility, this machine excels in different environments, from small gardens to larger landscapes. Its ease of use makes it accessible for both novice and experienced operators, enhancing overall user satisfaction.

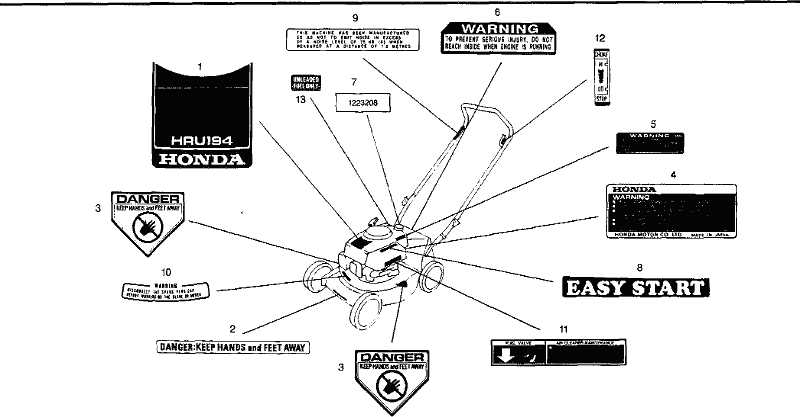

Importance of Parts Diagrams

Understanding the intricate relationships between components in machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools that clarify the layout and functionality of various elements, enabling users to easily identify and locate specific pieces within a complex assembly.

Such illustrations are invaluable not only for experienced technicians but also for novices. They provide clear guidance, reducing the likelihood of errors during assembly or disassembly. Moreover, these visual aids facilitate communication between individuals working on a project, ensuring everyone is on the same page regarding the structure and operation of the equipment.

Additionally, utilizing these visual resources can lead to improved troubleshooting processes. By pinpointing potential issues more effectively, users can address problems swiftly, minimizing downtime and enhancing overall productivity. In summary, well-crafted visuals play a pivotal role in the successful upkeep and functionality of mechanical systems, fostering a deeper understanding and more efficient workflows.

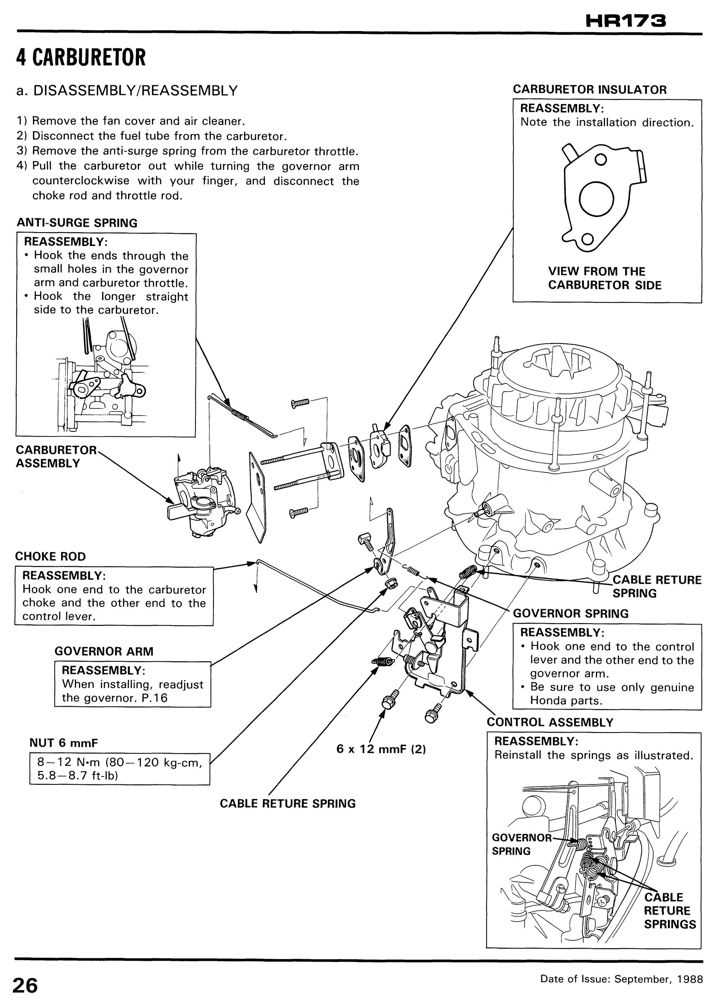

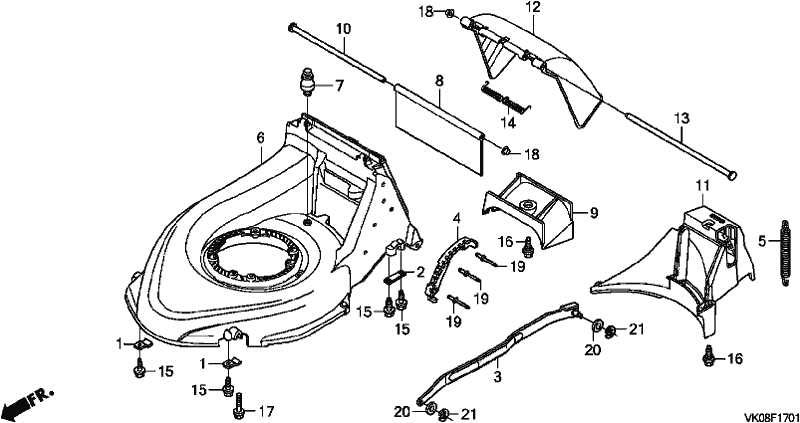

Main Components of HR173

The design of this machine incorporates several essential elements that contribute to its functionality and efficiency. Each component plays a pivotal role in ensuring optimal performance and user satisfaction.

| Component | Description |

|---|---|

| Engine | This is the heart of the machine, providing the necessary power for operation. |

| Chassis | The framework that supports all other components, ensuring stability and durability. |

| Blade Assembly | Critical for cutting efficiency, this part determines the quality of the job. |

| Fuel System | Responsible for delivering the necessary energy to the engine, enabling smooth operation. |

| Control Mechanism | Allows the operator to manage the machine’s functions easily and effectively. |

| Wheels | Facilitates movement across different terrains, enhancing maneuverability. |

Understanding these key components can help users maintain and operate the equipment more effectively, ensuring longevity and performance.

How to Read the Diagram

Understanding a schematic representation of a machine can greatly enhance your ability to identify components and their functions. This knowledge is crucial for effective maintenance and repair, allowing you to pinpoint issues swiftly and accurately.

Key Components

When examining the illustration, focus on the various sections and labels. Each part is usually marked with a code or number that corresponds to a list of descriptions. Familiarize yourself with these identifiers to streamline your troubleshooting process.

Interconnections

Pay attention to the lines connecting different elements, as these indicate how parts interact with each other. Recognizing these relationships helps in understanding the overall functionality of the system.

| Symbol | Description |

|---|---|

| A | Power Source |

| B | Drive Mechanism |

| C | Control Unit |

| D | Output Component |

Common Replacement Parts

When it comes to maintaining outdoor machinery, understanding the components that frequently require substitution is essential for optimal performance. Regular wear and tear can lead to diminished efficiency, making it vital to know which elements typically need attention.

Key Components

One of the most commonly replaced items is the engine filter, which ensures clean air intake and enhances engine longevity. Additionally, blades are crucial for effective operation, and their regular replacement can significantly impact cutting performance.

Other Essential Items

Furthermore, belts and spark plugs are integral for smooth operation and ignition. Keeping these components in good condition not only boosts functionality but also prolongs the life of the equipment.

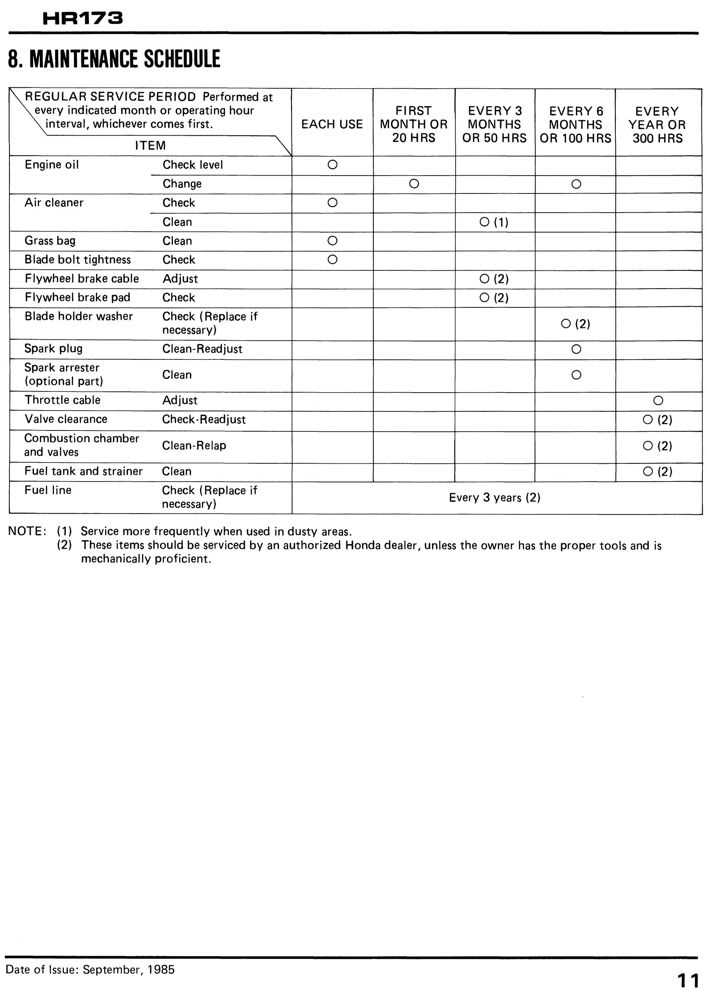

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. Regular attention to key components can prevent issues and enhance performance over time. Here are some effective strategies to keep in mind.

Routine Checks

- Inspect moving parts for wear and tear.

- Ensure lubrication is applied to prevent friction.

- Check belts and cables for any signs of damage.

Seasonal Care

- Clean the machine after each use to remove debris.

- Store it in a dry place during off-seasons.

- Replace filters and fluids according to the schedule.

By implementing these practices, you can delve into effective maintenance that ultimately leads to improved durability and reliability.

Where to Find Quality Parts

Locating high-quality components for your equipment is essential for optimal performance and longevity. Whether you are undertaking repairs or upgrades, having access to reliable sources can make all the difference. Below are some effective avenues to explore for securing quality items.

- Authorized Dealers: Start with official dealers that specialize in your brand. They typically offer genuine components and can provide expert advice.

- Online Retailers: Numerous websites specialize in aftermarket and OEM items. Look for those with positive reviews and a solid return policy.

- Local Repair Shops: Establishing a relationship with a local repair facility can be beneficial. They often have a network for sourcing quality items and may offer installation services.

- Community Forums: Engaging with online communities or forums dedicated to your specific model can yield valuable recommendations for reputable suppliers.

- Second-Hand Options: Consider visiting salvage yards or marketplaces for used components. Ensure they are in good condition before purchase.

Taking the time to research these avenues will help you find dependable items that enhance the performance of your machinery, ensuring you make the most informed decisions for your needs.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right instruments is essential for efficiency and effectiveness. A well-equipped workspace not only facilitates smooth operations but also ensures safety and precision during the process.

Essential Instruments

Here is a list of the primary tools you will need:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For removing and fastening screws. |

| Pliers | For gripping and twisting wires and small parts. |

| Socket Set | For working with various sizes of fasteners. |

| Torque Wrench | For ensuring bolts are tightened to the correct specifications. |

Additional Equipment

In addition to the basic tools, consider having the following items for more specialized tasks:

| Tool | Purpose |

|---|---|

| Jack and Stands | For lifting the vehicle safely. |

| Multimeter | For electrical diagnostics. |

| Air Compressor | For inflating tires and powering pneumatic tools. |

| Shop Vacuum | For cleaning up debris and spills. |

Common Issues and Solutions

When maintaining small machinery, users often encounter recurring problems that can hinder performance. Recognizing these challenges and implementing effective solutions is essential for ensuring longevity and efficiency. Below are some typical concerns along with their remedies.

1. Engine Starting Difficulties: A common issue faced is the engine’s reluctance to start. This may stem from a drained battery, stale fuel, or clogged filters. To resolve this, check the battery charge, replace old fuel with fresh gasoline, and clean or replace any obstructed filters.

2. Uneven Cutting: If the cutting mechanism produces uneven results, it could be due to dull blades or improper height adjustments. To fix this, sharpen the blades and ensure the cutting height is set correctly for the terrain being worked on.

3. Overheating: Overheating can significantly impact performance. This issue often arises from blocked cooling vents or low oil levels. To address this, clear any debris from the cooling system and regularly check oil levels, topping up as necessary.

4. Poor Fuel Efficiency: Reduced fuel efficiency may be linked to air filter blockages or carburetor issues. To improve efficiency, replace the air filter and consider cleaning or adjusting the carburetor to ensure optimal operation.

5. Vibration Issues: Excessive vibrations during operation can indicate loose components or imbalance. To mitigate this, inspect all bolts and screws for tightness, and check for any uneven wear on the cutting components.

DIY vs. Professional Repairs

When it comes to fixing equipment, individuals often face the choice between handling repairs themselves or seeking help from skilled technicians. Each approach has its own set of advantages and challenges that can influence the overall outcome and satisfaction of the repair process. Understanding these factors can help one make an informed decision that aligns with their capabilities and needs.

Advantages of DIY Repairs

Taking on repairs independently can be rewarding. It often leads to significant savings on labor costs and provides a sense of accomplishment. Additionally, it allows for a deeper understanding of the machinery, fostering greater confidence for future maintenance. However, this route may require a substantial investment in tools and time, as well as a commitment to learning about the specific issues at hand.

Benefits of Professional Assistance

On the other hand, enlisting the services of a professional can ensure a higher level of expertise and efficiency. Technicians typically possess specialized knowledge and experience that can expedite the repair process, reducing the risk of mistakes that could lead to further issues. This option may be more suitable for complex problems or for those who prefer a hassle-free experience. Nevertheless, it often comes at a higher financial cost.

Ultimately, the choice between DIY and professional repairs depends on individual circumstances, including skill level, the complexity of the issue, and budget considerations. Weighing these factors carefully can lead to a more satisfactory resolution.

Resources for Further Learning

Exploring additional materials can significantly enhance your understanding of machinery components and their assembly. These resources provide valuable insights, technical specifications, and practical applications that can deepen your knowledge and skills in maintenance and repair tasks.

Books and Manuals

Consider investing in specialized literature that covers machinery operation, repair techniques, and troubleshooting methods. Many manuals offer step-by-step guidance for various models, helping you grasp essential concepts.

Online Communities and Forums

Engaging with online groups can be beneficial for exchanging ideas, asking questions, and sharing experiences with fellow enthusiasts. These platforms often feature discussions, tips, and user-generated content that enhance learning.

| Resource Type | Description | Example |

|---|---|---|

| Books | Detailed guides on machinery and maintenance techniques. | “Small Engine Repair” by Paul Dempsey |

| Forums | Online platforms for discussion and advice from peers. | Reddit’s r/Mechanics |

| Video Tutorials | Visual guides for practical skills and repairs. | YouTube channels focused on equipment maintenance |